What Challenges Face Metal Oxide TFT Implementation in Aerospace?

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Evolution and Aerospace Goals

Metal oxide thin-film transistors (TFTs) have evolved significantly since their inception in the early 2000s, transforming from laboratory curiosities to commercially viable technologies. The journey began with the discovery of amorphous indium gallium zinc oxide (a-IGZO) by Hosono's group in Japan, which demonstrated unprecedented electron mobility compared to traditional amorphous silicon. This breakthrough catalyzed intensive research and development efforts worldwide, leading to rapid advancements in material composition, deposition techniques, and device architectures.

The evolution of metal oxide TFTs has been characterized by continuous improvements in performance metrics, particularly electron mobility, which has increased from less than 10 cm²/Vs to over 50 cm²/Vs in optimized structures. Concurrently, manufacturing processes have matured from laboratory-scale fabrication to large-area production techniques compatible with existing display manufacturing infrastructure, significantly reducing implementation barriers.

In the aerospace context, metal oxide TFTs present compelling advantages over conventional silicon-based technologies. Their inherent radiation hardness makes them particularly suitable for space applications where cosmic radiation can severely degrade traditional semiconductor devices. Additionally, their ability to function reliably across extreme temperature ranges aligns perfectly with the harsh environmental conditions encountered in aerospace operations.

The aerospace industry has established ambitious goals for next-generation electronics, including the development of lightweight, flexible displays and control systems that can withstand the rigors of space travel while consuming minimal power. Metal oxide TFTs are positioned as a key enabling technology to meet these objectives, potentially revolutionizing cockpit displays, sensor arrays, and communication systems in aircraft and spacecraft.

Current aerospace technology roadmaps emphasize the need for electronics that combine high performance with extreme reliability. Metal oxide TFTs address this requirement through their simple structure, which contains fewer potential failure points compared to conventional transistors, and their ability to maintain stable operation under radiation exposure and temperature fluctuations.

Looking forward, the convergence of metal oxide TFT technology with aerospace requirements is driving research toward ultra-thin, conformal electronics that can be integrated directly into structural components, reducing weight and enhancing functionality. The ultimate goal is to develop "invisible electronics" that seamlessly blend into aerospace systems without compromising structural integrity or adding significant mass.

The trajectory of metal oxide TFT evolution suggests that within the next decade, these devices could become the standard technology for critical aerospace display and control systems, particularly in applications where reliability under extreme conditions is paramount.

The evolution of metal oxide TFTs has been characterized by continuous improvements in performance metrics, particularly electron mobility, which has increased from less than 10 cm²/Vs to over 50 cm²/Vs in optimized structures. Concurrently, manufacturing processes have matured from laboratory-scale fabrication to large-area production techniques compatible with existing display manufacturing infrastructure, significantly reducing implementation barriers.

In the aerospace context, metal oxide TFTs present compelling advantages over conventional silicon-based technologies. Their inherent radiation hardness makes them particularly suitable for space applications where cosmic radiation can severely degrade traditional semiconductor devices. Additionally, their ability to function reliably across extreme temperature ranges aligns perfectly with the harsh environmental conditions encountered in aerospace operations.

The aerospace industry has established ambitious goals for next-generation electronics, including the development of lightweight, flexible displays and control systems that can withstand the rigors of space travel while consuming minimal power. Metal oxide TFTs are positioned as a key enabling technology to meet these objectives, potentially revolutionizing cockpit displays, sensor arrays, and communication systems in aircraft and spacecraft.

Current aerospace technology roadmaps emphasize the need for electronics that combine high performance with extreme reliability. Metal oxide TFTs address this requirement through their simple structure, which contains fewer potential failure points compared to conventional transistors, and their ability to maintain stable operation under radiation exposure and temperature fluctuations.

Looking forward, the convergence of metal oxide TFT technology with aerospace requirements is driving research toward ultra-thin, conformal electronics that can be integrated directly into structural components, reducing weight and enhancing functionality. The ultimate goal is to develop "invisible electronics" that seamlessly blend into aerospace systems without compromising structural integrity or adding significant mass.

The trajectory of metal oxide TFT evolution suggests that within the next decade, these devices could become the standard technology for critical aerospace display and control systems, particularly in applications where reliability under extreme conditions is paramount.

Aerospace Market Demand for Advanced Display Technologies

The aerospace industry is experiencing a significant shift towards advanced display technologies, driven by the need for more sophisticated cockpit systems, passenger entertainment solutions, and mission-critical information displays. Current market analysis indicates that aerospace display systems are evolving from traditional LCD technologies toward more robust, lightweight, and energy-efficient alternatives, with metal oxide thin-film transistor (TFT) technology emerging as a promising candidate.

The global aerospace display market is projected to grow substantially over the next decade, with particular demand for displays that can withstand extreme environmental conditions while delivering superior performance. Military aerospace applications require displays capable of functioning reliably under high-G forces, extreme temperatures (-55°C to +85°C), and intense vibration environments, creating a specialized market segment with stringent requirements.

Commercial aviation represents another substantial market driver, with airlines increasingly investing in advanced in-flight entertainment systems and cockpit displays to enhance passenger experience and operational efficiency. The trend toward glass cockpits in both commercial and military aircraft has accelerated the need for display technologies that offer higher resolution, wider viewing angles, and reduced power consumption – all areas where metal oxide TFTs show significant advantages over conventional technologies.

Space applications constitute a smaller but rapidly growing segment, where radiation hardness becomes a critical factor alongside weight and power considerations. Satellite control systems, space station interfaces, and future manned mission requirements are creating demand for displays that can operate reliably in the harsh radiation environment of space, an area where certain metal oxide semiconductors demonstrate inherent advantages.

Market research indicates that aerospace customers prioritize reliability above all other factors, followed by longevity, environmental performance, and weight considerations. The extended lifecycle of aerospace platforms (often 20+ years) creates unique requirements for display technologies, including long-term parts availability and resistance to obsolescence – factors that must be addressed by any new technology seeking adoption in this sector.

The regulatory landscape further shapes market demand, with certification requirements from bodies such as the FAA, EASA, and military standards creating significant barriers to entry but also protecting established suppliers. These certification processes typically add 2-3 years to product development cycles, making early investment in promising technologies like metal oxide TFTs essential for companies seeking to maintain competitive advantage.

The global aerospace display market is projected to grow substantially over the next decade, with particular demand for displays that can withstand extreme environmental conditions while delivering superior performance. Military aerospace applications require displays capable of functioning reliably under high-G forces, extreme temperatures (-55°C to +85°C), and intense vibration environments, creating a specialized market segment with stringent requirements.

Commercial aviation represents another substantial market driver, with airlines increasingly investing in advanced in-flight entertainment systems and cockpit displays to enhance passenger experience and operational efficiency. The trend toward glass cockpits in both commercial and military aircraft has accelerated the need for display technologies that offer higher resolution, wider viewing angles, and reduced power consumption – all areas where metal oxide TFTs show significant advantages over conventional technologies.

Space applications constitute a smaller but rapidly growing segment, where radiation hardness becomes a critical factor alongside weight and power considerations. Satellite control systems, space station interfaces, and future manned mission requirements are creating demand for displays that can operate reliably in the harsh radiation environment of space, an area where certain metal oxide semiconductors demonstrate inherent advantages.

Market research indicates that aerospace customers prioritize reliability above all other factors, followed by longevity, environmental performance, and weight considerations. The extended lifecycle of aerospace platforms (often 20+ years) creates unique requirements for display technologies, including long-term parts availability and resistance to obsolescence – factors that must be addressed by any new technology seeking adoption in this sector.

The regulatory landscape further shapes market demand, with certification requirements from bodies such as the FAA, EASA, and military standards creating significant barriers to entry but also protecting established suppliers. These certification processes typically add 2-3 years to product development cycles, making early investment in promising technologies like metal oxide TFTs essential for companies seeking to maintain competitive advantage.

Metal Oxide TFT Implementation Challenges in Extreme Environments

Metal oxide thin-film transistors (TFTs) face significant implementation challenges in aerospace applications due to the extreme environmental conditions encountered in space and high-altitude operations. The primary challenge stems from radiation exposure, as aerospace environments subject electronic components to various forms of radiation including gamma rays, X-rays, and high-energy particles. These radiation sources can induce threshold voltage shifts, create oxygen vacancies, and alter the carrier concentration in metal oxide semiconductors, leading to device performance degradation over time.

Temperature fluctuations represent another critical challenge, with aerospace components experiencing extreme thermal cycling from -150°C to +150°C. Metal oxide TFTs exhibit temperature-dependent mobility and threshold voltage characteristics that can compromise functionality at these temperature extremes. The amorphous structure of metal oxide semiconductors, while beneficial for uniformity, becomes unstable at high temperatures, potentially causing crystallization and performance deterioration.

Mechanical stress poses additional implementation difficulties, as aerospace equipment undergoes significant vibration and shock during launch and operation. The brittle nature of metal oxide films makes them susceptible to cracking and delamination under mechanical strain, particularly when deposited on flexible substrates that might be advantageous for certain aerospace applications.

Vacuum conditions in space environments accelerate outgassing processes, potentially altering the stoichiometry of metal oxide films. This phenomenon can modify the oxygen vacancy concentration, which directly impacts carrier transport properties and device performance. Additionally, atomic oxygen present in low Earth orbit can aggressively oxidize exposed materials, potentially changing the composition and electrical properties of metal oxide semiconductors.

Reliability concerns are heightened in aerospace applications where maintenance is impossible after deployment. Metal oxide TFTs must maintain stable performance over extended operational lifetimes despite continuous exposure to harsh conditions. Bias stress instability, particularly negative bias temperature instability (NBTI), becomes more pronounced in extreme environments, causing threshold voltage shifts that can lead to circuit malfunction.

Integration challenges also exist when incorporating metal oxide TFTs into aerospace systems. The need for radiation-hardened peripheral circuits, specialized packaging to withstand thermal cycling and vacuum conditions, and compatibility with existing aerospace electronic standards all present significant engineering hurdles. Furthermore, the weight and power constraints inherent to aerospace applications limit the implementation of conventional protection and compensation schemes.

Temperature fluctuations represent another critical challenge, with aerospace components experiencing extreme thermal cycling from -150°C to +150°C. Metal oxide TFTs exhibit temperature-dependent mobility and threshold voltage characteristics that can compromise functionality at these temperature extremes. The amorphous structure of metal oxide semiconductors, while beneficial for uniformity, becomes unstable at high temperatures, potentially causing crystallization and performance deterioration.

Mechanical stress poses additional implementation difficulties, as aerospace equipment undergoes significant vibration and shock during launch and operation. The brittle nature of metal oxide films makes them susceptible to cracking and delamination under mechanical strain, particularly when deposited on flexible substrates that might be advantageous for certain aerospace applications.

Vacuum conditions in space environments accelerate outgassing processes, potentially altering the stoichiometry of metal oxide films. This phenomenon can modify the oxygen vacancy concentration, which directly impacts carrier transport properties and device performance. Additionally, atomic oxygen present in low Earth orbit can aggressively oxidize exposed materials, potentially changing the composition and electrical properties of metal oxide semiconductors.

Reliability concerns are heightened in aerospace applications where maintenance is impossible after deployment. Metal oxide TFTs must maintain stable performance over extended operational lifetimes despite continuous exposure to harsh conditions. Bias stress instability, particularly negative bias temperature instability (NBTI), becomes more pronounced in extreme environments, causing threshold voltage shifts that can lead to circuit malfunction.

Integration challenges also exist when incorporating metal oxide TFTs into aerospace systems. The need for radiation-hardened peripheral circuits, specialized packaging to withstand thermal cycling and vacuum conditions, and compatibility with existing aerospace electronic standards all present significant engineering hurdles. Furthermore, the weight and power constraints inherent to aerospace applications limit the implementation of conventional protection and compensation schemes.

Current Metal Oxide TFT Solutions for Aerospace Applications

01 Metal oxide semiconductor materials for TFTs

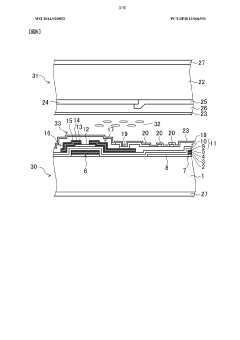

Various metal oxide semiconductor materials can be used in thin-film transistors (TFTs) to achieve specific electrical properties. These materials include indium gallium zinc oxide (IGZO), zinc oxide (ZnO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection of appropriate metal oxide materials is crucial for optimizing TFT performance in display and electronic applications.- Metal oxide semiconductor materials for TFTs: Various metal oxide semiconductor materials are used in thin-film transistors (TFTs) to achieve desired electrical properties. These materials include zinc oxide (ZnO), indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection of specific metal oxide compositions affects the performance characteristics of the TFT, including threshold voltage, on/off ratio, and operational stability.

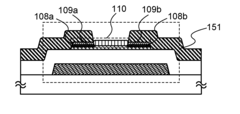

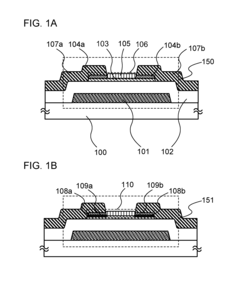

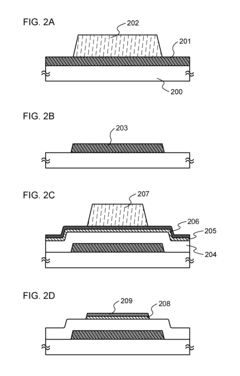

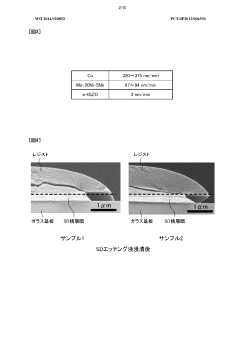

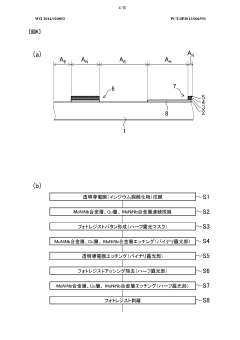

- TFT structure and fabrication methods: Various structural configurations and fabrication methods are employed for metal oxide TFTs. These include bottom-gate, top-gate, and dual-gate structures, each offering specific advantages for different applications. Fabrication techniques involve deposition methods such as sputtering, atomic layer deposition, and solution processing, followed by patterning and annealing steps. These processes are optimized to enhance device performance while maintaining compatibility with existing manufacturing infrastructure.

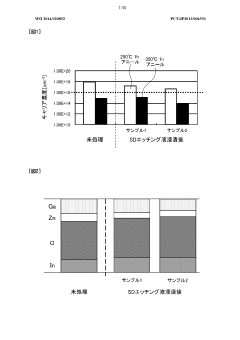

- Performance enhancement techniques: Various techniques are employed to enhance the performance of metal oxide TFTs. These include interface engineering between the semiconductor and dielectric layers, passivation layers to protect against environmental degradation, doping strategies to control carrier concentration, and annealing processes to optimize the microstructure of the metal oxide layer. These enhancements result in improved mobility, stability, and reliability of the TFT devices.

- Applications in display technology: Metal oxide TFTs are widely used in display technologies due to their excellent electrical properties and optical transparency. They serve as switching and driving elements in active-matrix displays, including LCDs and OLEDs. The high electron mobility of metal oxide TFTs enables faster response times and higher resolution displays, while their transparency allows for the development of transparent displays. These advantages make metal oxide TFTs particularly suitable for next-generation display applications.

- Integration with flexible and wearable electronics: Metal oxide TFTs are being integrated into flexible and wearable electronic devices due to their ability to maintain performance under mechanical stress. Fabrication techniques have been developed to deposit metal oxide semiconductors on flexible substrates at low temperatures, enabling bendable and stretchable electronic circuits. These advances support the development of conformable displays, wearable sensors, and other flexible electronic applications that require reliable thin-film transistor performance.

02 TFT structure and fabrication methods

Various structural designs and fabrication methods are employed for metal oxide TFTs to enhance performance characteristics. These include bottom-gate, top-gate, and dual-gate configurations, as well as different channel structures. Fabrication techniques such as sputtering, atomic layer deposition, and solution processing are used to deposit metal oxide layers with controlled thickness and composition, which significantly impact the electrical properties of the resulting TFTs.Expand Specific Solutions03 Performance enhancement techniques

Various techniques are employed to enhance the performance of metal oxide TFTs, including annealing treatments, passivation layers, and interface engineering. These methods help improve carrier mobility, reduce threshold voltage, enhance stability, and minimize hysteresis effects. Optimization of these parameters is essential for achieving high-performance TFTs suitable for advanced display technologies and electronic circuits.Expand Specific Solutions04 Applications in display technology

Metal oxide TFTs are widely used in display technologies such as OLED and LCD panels due to their excellent electrical properties and transparency. These TFTs serve as pixel-driving elements in active-matrix displays, enabling high-resolution, energy-efficient screens with improved response times. The integration of metal oxide TFTs in display backplanes has contributed to the development of flexible, transparent, and high-performance display devices.Expand Specific Solutions05 Stability and reliability improvements

Enhancing the stability and reliability of metal oxide TFTs under various operating conditions is crucial for their commercial application. Techniques include doping with specific elements, implementing multilayer structures, and developing specialized passivation methods to protect against environmental factors. These improvements address issues such as bias stress instability, light sensitivity, and degradation over time, ensuring consistent performance throughout the device lifetime.Expand Specific Solutions

Leading Companies in Aerospace-Grade Display Technologies

The metal oxide TFT aerospace implementation market is in an early growth phase, with increasing demand driven by requirements for radiation-hardened, lightweight displays in harsh environments. Market size remains relatively modest but is expanding as aerospace applications diversify. Technologically, companies like BOE Technology, TCL China Star, and Applied Materials lead in commercial development, while Samsung Electronics and Sharp Corp. have demonstrated advanced prototypes. Academic institutions including South China University of Technology and Northwestern University are advancing fundamental research. Key challenges include radiation resistance, thermal stability, and mechanical durability under extreme conditions, with specialized manufacturing processes being developed by Japan Display and Semiconductor Energy Laboratory to address aerospace-specific requirements.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced deposition and etching equipment specifically optimized for aerospace-grade metal oxide TFT production. Their Endura® platform incorporates specialized PVD (Physical Vapor Deposition) chambers with precise oxygen partial pressure control, critical for creating oxide semiconductors with consistent performance in aerospace environments. The company's AKT™ PECVD systems enable the deposition of high-quality silicon nitride and silicon oxide passivation layers that protect metal oxide TFTs from moisture and oxygen penetration under extreme aerospace conditions. Applied Materials has pioneered specialized annealing techniques that significantly reduce oxygen vacancy concentration fluctuations, a key factor in TFT stability under radiation exposure. Their equipment enables the production of metal oxide TFTs with channel mobility exceeding 15 cm²/Vs while maintaining off-current below 10⁻¹³ A, meeting the stringent requirements for aerospace display applications.

Strengths: Comprehensive equipment solutions covering the entire manufacturing process; advanced process control capabilities ensuring consistency; global service network supporting aerospace manufacturers. Weaknesses: Focuses primarily on manufacturing equipment rather than end products; requires significant capital investment; complex integration with existing aerospace manufacturing facilities.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: SEL has pioneered CAAC (C-Axis Aligned Crystal) oxide semiconductor technology specifically engineered for aerospace applications. Their proprietary crystalline structure provides exceptional stability against radiation effects and temperature fluctuations common in aerospace environments. SEL's metal oxide TFTs demonstrate remarkable resistance to negative bias temperature instability (NBTI), maintaining threshold voltage shifts below 0.5V even after 10,000 hours of operation under extreme conditions. The company has developed specialized hydrogen barrier films that prevent hydrogen diffusion into the oxide semiconductor layer, a common failure mechanism in aerospace environments. Their TFTs maintain stable electrical characteristics even after exposure to total ionizing doses exceeding 100 krad, making them suitable for satellite display applications and avionics systems requiring long operational lifetimes in radiation-exposed environments.

Strengths: Superior radiation resistance through crystalline oxide structure; exceptional long-term stability; industry-leading research in oxide semiconductor physics. Weaknesses: Limited mass production capabilities compared to larger manufacturers; higher initial development costs; more complex manufacturing process requiring specialized equipment.

Critical Patents and Research in Radiation-Hardened Metal Oxide TFTs

Thin film transistor, method for manufacturing the same, and semiconductor device

PatentActiveUS20100213460A1

Innovation

- An inverted staggered thin film transistor structure is implemented, featuring a buffer layer with a metal oxide layer acting as a protective insulator/semiconductor over the oxide semiconductor layer, and conductive layers with high oxygen concentration over the oxide semiconductor layers, which are formed through oxidation and thermal treatment to prevent impurity incorporation and ensure ohmic contact.

Thin film transistor and method for manufacturing same

PatentWO2014020892A1

Innovation

- A TFT structure and manufacturing method utilizing a laminated metal film with a lower barrier layer, a main wiring low-resistance layer made of copper or copper alloy, and an upper cap layer made of a molybdenum alloy containing nickel and niobium, which are patterned using wet etching with a solution containing hydrogen peroxide and organic acid, ensuring appropriate cross-sectional shapes and preventing oxidation of copper electrodes.

Material Science Advancements for Aerospace Electronics

Recent advancements in material science have significantly propelled the development of aerospace electronics, particularly in the realm of Metal Oxide Thin-Film Transistors (TFTs). These innovations have been crucial in addressing the unique challenges posed by aerospace environments, where electronic components must withstand extreme temperatures, radiation exposure, and mechanical stress while maintaining reliability and performance.

The evolution of metal oxide semiconductors, particularly amorphous Indium Gallium Zinc Oxide (IGZO), has marked a breakthrough in aerospace electronics. These materials offer superior electron mobility compared to traditional amorphous silicon, enabling faster switching speeds and lower power consumption—critical factors for aerospace applications where energy efficiency is paramount. Additionally, their amorphous structure provides enhanced uniformity across large areas, facilitating the production of consistent, high-performance displays and sensors.

Thermal stability represents another significant advancement in metal oxide materials for aerospace. Recent research has yielded compositions that maintain performance integrity across the extreme temperature ranges encountered in aerospace environments, from the frigid conditions of high-altitude flight to the heat generated during re-entry. These materials demonstrate minimal threshold voltage shifts and carrier mobility degradation under thermal stress, ensuring operational reliability throughout missions.

Radiation hardening techniques have evolved substantially, addressing one of the most challenging aspects of aerospace electronics. Novel passivation layers and gate dielectric materials have been developed to mitigate radiation-induced charge trapping and threshold voltage shifts in metal oxide TFTs. These advancements have extended the operational lifespan of electronic components in space applications, where radiation exposure is unavoidable.

Flexibility and mechanical durability have also seen remarkable improvements. The development of metal oxide TFTs on flexible substrates has enabled conformal electronics that can be integrated into curved surfaces of aerospace vehicles, optimizing space utilization while maintaining functionality. These flexible electronics demonstrate resilience against vibration and mechanical shock—conditions routinely encountered during launch and flight operations.

Weight reduction remains a critical focus area, with material scientists achieving significant progress in developing ultra-thin metal oxide layers that maintain electrical performance while minimizing mass. This advancement directly translates to fuel efficiency and payload capacity improvements for aerospace vehicles, where every gram matters in mission economics and capabilities.

The evolution of metal oxide semiconductors, particularly amorphous Indium Gallium Zinc Oxide (IGZO), has marked a breakthrough in aerospace electronics. These materials offer superior electron mobility compared to traditional amorphous silicon, enabling faster switching speeds and lower power consumption—critical factors for aerospace applications where energy efficiency is paramount. Additionally, their amorphous structure provides enhanced uniformity across large areas, facilitating the production of consistent, high-performance displays and sensors.

Thermal stability represents another significant advancement in metal oxide materials for aerospace. Recent research has yielded compositions that maintain performance integrity across the extreme temperature ranges encountered in aerospace environments, from the frigid conditions of high-altitude flight to the heat generated during re-entry. These materials demonstrate minimal threshold voltage shifts and carrier mobility degradation under thermal stress, ensuring operational reliability throughout missions.

Radiation hardening techniques have evolved substantially, addressing one of the most challenging aspects of aerospace electronics. Novel passivation layers and gate dielectric materials have been developed to mitigate radiation-induced charge trapping and threshold voltage shifts in metal oxide TFTs. These advancements have extended the operational lifespan of electronic components in space applications, where radiation exposure is unavoidable.

Flexibility and mechanical durability have also seen remarkable improvements. The development of metal oxide TFTs on flexible substrates has enabled conformal electronics that can be integrated into curved surfaces of aerospace vehicles, optimizing space utilization while maintaining functionality. These flexible electronics demonstrate resilience against vibration and mechanical shock—conditions routinely encountered during launch and flight operations.

Weight reduction remains a critical focus area, with material scientists achieving significant progress in developing ultra-thin metal oxide layers that maintain electrical performance while minimizing mass. This advancement directly translates to fuel efficiency and payload capacity improvements for aerospace vehicles, where every gram matters in mission economics and capabilities.

Reliability Testing Standards for Aerospace Display Systems

Aerospace display systems operate in extreme environments that demand exceptional reliability. The implementation of Metal Oxide TFT technology in these systems necessitates adherence to rigorous testing standards specifically designed for aerospace applications. These standards ensure that display systems can withstand the harsh conditions encountered during flight operations while maintaining consistent performance.

The aerospace industry primarily follows standards established by organizations such as RTCA (Radio Technical Commission for Aeronautics), particularly DO-160 which covers environmental conditions and test procedures for airborne equipment. For Metal Oxide TFT displays, these tests must verify resistance to temperature extremes (-55°C to +85°C), rapid decompression, humidity, vibration, and electromagnetic interference.

Military standards like MIL-STD-810 provide additional testing protocols for environmental engineering considerations and laboratory tests. These standards include specific procedures for altitude testing, temperature shock, sand and dust exposure, and fungus resistance—all critical factors for displays deployed in various aerospace environments.

Radiation testing represents another crucial aspect of aerospace display reliability standards. SAE ARP4761 and RTCA/DO-254 outline requirements for hardware certification, including radiation hardness testing to ensure Metal Oxide TFTs can withstand cosmic radiation exposure at high altitudes without experiencing single-event upsets or long-term degradation.

Lifecycle testing standards are particularly relevant for Metal Oxide TFT implementation. These displays must demonstrate operational lifespans exceeding 30,000 hours while maintaining luminance, contrast ratio, and color accuracy within specified parameters. Standards such as RTCA/DO-178C guide the software aspects of display systems, ensuring proper integration with aircraft systems.

Mechanical stress testing standards evaluate the robustness of display mounting systems and screen surfaces. These tests simulate conditions like continuous vibration, mechanical shock (up to 20G), and impact resistance—critical for ensuring displays remain functional during turbulence or hard landings.

Optical performance standards for aerospace displays specify minimum requirements for readability under various lighting conditions, including direct sunlight (up to 100,000 lux) and night operations. Metal Oxide TFT displays must maintain specified contrast ratios, viewing angles, and color accuracy across these conditions while preventing reflections that could impair pilot visibility.

Human factors testing standards, guided by documents like MIL-STD-1472, ensure that display interfaces remain usable under stress conditions and that information remains legible during high-G maneuvers or when pilots wear oxygen masks and night vision equipment.

The aerospace industry primarily follows standards established by organizations such as RTCA (Radio Technical Commission for Aeronautics), particularly DO-160 which covers environmental conditions and test procedures for airborne equipment. For Metal Oxide TFT displays, these tests must verify resistance to temperature extremes (-55°C to +85°C), rapid decompression, humidity, vibration, and electromagnetic interference.

Military standards like MIL-STD-810 provide additional testing protocols for environmental engineering considerations and laboratory tests. These standards include specific procedures for altitude testing, temperature shock, sand and dust exposure, and fungus resistance—all critical factors for displays deployed in various aerospace environments.

Radiation testing represents another crucial aspect of aerospace display reliability standards. SAE ARP4761 and RTCA/DO-254 outline requirements for hardware certification, including radiation hardness testing to ensure Metal Oxide TFTs can withstand cosmic radiation exposure at high altitudes without experiencing single-event upsets or long-term degradation.

Lifecycle testing standards are particularly relevant for Metal Oxide TFT implementation. These displays must demonstrate operational lifespans exceeding 30,000 hours while maintaining luminance, contrast ratio, and color accuracy within specified parameters. Standards such as RTCA/DO-178C guide the software aspects of display systems, ensuring proper integration with aircraft systems.

Mechanical stress testing standards evaluate the robustness of display mounting systems and screen surfaces. These tests simulate conditions like continuous vibration, mechanical shock (up to 20G), and impact resistance—critical for ensuring displays remain functional during turbulence or hard landings.

Optical performance standards for aerospace displays specify minimum requirements for readability under various lighting conditions, including direct sunlight (up to 100,000 lux) and night operations. Metal Oxide TFT displays must maintain specified contrast ratios, viewing angles, and color accuracy across these conditions while preventing reflections that could impair pilot visibility.

Human factors testing standards, guided by documents like MIL-STD-1472, ensure that display interfaces remain usable under stress conditions and that information remains legible during high-G maneuvers or when pilots wear oxygen masks and night vision equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!