Metal Oxide TFTs in the Context of Aerospace Industry Standards

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Evolution and Aerospace Goals

Metal oxide thin-film transistors (TFTs) have evolved significantly since their inception in the early 2000s, transforming from laboratory curiosities to commercially viable technologies. The journey began with amorphous indium gallium zinc oxide (a-IGZO) TFTs, which demonstrated superior electron mobility compared to traditional amorphous silicon alternatives. This breakthrough enabled the development of higher-performance, lower-power display technologies that could maintain state without continuous power input.

The evolution of metal oxide TFTs has been characterized by continuous improvements in material composition, deposition techniques, and device architectures. Early challenges included stability issues under bias stress and light exposure, which have been progressively addressed through materials engineering and passivation strategies. The transition from indium-heavy compositions to more sustainable alternatives represents another significant evolutionary step, driven by concerns about indium scarcity and cost.

In the aerospace context, metal oxide TFT technology presents unique opportunities and challenges. The aerospace industry demands electronic components that can withstand extreme environmental conditions, including temperature fluctuations, radiation exposure, and mechanical stress. Traditional silicon-based electronics often require extensive shielding and thermal management systems, adding weight and complexity to aerospace systems.

Metal oxide TFTs offer inherent advantages for aerospace applications, including radiation hardness, temperature stability, and mechanical flexibility. These properties align with the aerospace industry's goals of reducing weight, increasing reliability, and enhancing functionality of avionics and control systems. The potential for creating conformal displays and sensors that can be integrated into curved surfaces of aircraft or spacecraft represents a particularly compelling application.

The technical goals for metal oxide TFTs in aerospace applications include achieving operational stability across the temperature range of -55°C to +125°C (typical aerospace requirements), demonstrating resilience to cosmic radiation without performance degradation, and maintaining reliability through thousands of thermal cycles. Additionally, there are goals related to power efficiency, as aerospace systems often operate with limited power resources.

Manufacturing scalability represents another critical objective. For widespread adoption in aerospace systems, metal oxide TFT production must achieve consistency and yield rates that satisfy the stringent quality requirements of aerospace manufacturers. This includes developing deposition processes compatible with large-area substrates and complex integration schemes.

Looking forward, the convergence of metal oxide TFT technology with other emerging technologies, such as flexible substrates and printed electronics, could enable entirely new classes of aerospace components and systems. The ultimate goal is to create electronic systems that are lighter, more reliable, and more capable than current solutions, contributing to the overall advancement of aerospace capabilities.

The evolution of metal oxide TFTs has been characterized by continuous improvements in material composition, deposition techniques, and device architectures. Early challenges included stability issues under bias stress and light exposure, which have been progressively addressed through materials engineering and passivation strategies. The transition from indium-heavy compositions to more sustainable alternatives represents another significant evolutionary step, driven by concerns about indium scarcity and cost.

In the aerospace context, metal oxide TFT technology presents unique opportunities and challenges. The aerospace industry demands electronic components that can withstand extreme environmental conditions, including temperature fluctuations, radiation exposure, and mechanical stress. Traditional silicon-based electronics often require extensive shielding and thermal management systems, adding weight and complexity to aerospace systems.

Metal oxide TFTs offer inherent advantages for aerospace applications, including radiation hardness, temperature stability, and mechanical flexibility. These properties align with the aerospace industry's goals of reducing weight, increasing reliability, and enhancing functionality of avionics and control systems. The potential for creating conformal displays and sensors that can be integrated into curved surfaces of aircraft or spacecraft represents a particularly compelling application.

The technical goals for metal oxide TFTs in aerospace applications include achieving operational stability across the temperature range of -55°C to +125°C (typical aerospace requirements), demonstrating resilience to cosmic radiation without performance degradation, and maintaining reliability through thousands of thermal cycles. Additionally, there are goals related to power efficiency, as aerospace systems often operate with limited power resources.

Manufacturing scalability represents another critical objective. For widespread adoption in aerospace systems, metal oxide TFT production must achieve consistency and yield rates that satisfy the stringent quality requirements of aerospace manufacturers. This includes developing deposition processes compatible with large-area substrates and complex integration schemes.

Looking forward, the convergence of metal oxide TFT technology with other emerging technologies, such as flexible substrates and printed electronics, could enable entirely new classes of aerospace components and systems. The ultimate goal is to create electronic systems that are lighter, more reliable, and more capable than current solutions, contributing to the overall advancement of aerospace capabilities.

Aerospace Industry Demand for Advanced Display Technologies

The aerospace industry has witnessed a significant shift towards advanced display technologies in recent years, driven by the need for more reliable, efficient, and durable systems capable of withstanding extreme environmental conditions. Cockpit displays, navigation systems, and passenger entertainment units all require cutting-edge display solutions that can maintain performance integrity under high altitude, extreme temperature variations, and intense vibration conditions.

Market research indicates that the aerospace display technology sector is experiencing robust growth, with an estimated market value expected to reach several billion dollars by 2030. This growth is primarily fueled by increasing aircraft production, retrofitting of existing fleets with modern avionics, and the rising demand for enhanced in-flight entertainment systems in commercial aviation.

Military aerospace applications present particularly stringent requirements for display technologies, necessitating solutions that offer superior readability in varying light conditions, from direct sunlight to night operations. These displays must also maintain functionality under electromagnetic interference and radiation exposure, common challenges in military aircraft environments.

The commercial aviation segment demonstrates growing demand for larger, higher resolution displays with improved power efficiency. Airlines are increasingly investing in advanced cockpit display systems that integrate multiple functions into consolidated screens, reducing pilot workload and enhancing situational awareness. Simultaneously, passenger experience has become a competitive differentiator, driving demand for high-quality, interactive entertainment displays throughout the cabin.

Metal oxide TFT technology, particularly IGZO (Indium Gallium Zinc Oxide) based displays, has emerged as a promising solution for aerospace applications due to their exceptional electron mobility, low power consumption, and stability under varying environmental conditions. These characteristics directly address the aerospace industry's requirements for displays that can operate reliably in extreme conditions while maintaining low power consumption – a critical factor in aircraft design where energy efficiency directly impacts operational costs and environmental footprint.

Industry standards such as DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests) have established rigorous performance benchmarks for aerospace display technologies. These standards encompass resistance to temperature extremes, altitude changes, humidity, shock, vibration, and electromagnetic interference – all areas where metal oxide TFT technology demonstrates significant advantages over conventional display technologies.

The trend toward more electric aircraft (MEA) and reduced wiring architectures further amplifies the demand for display technologies that can operate efficiently within integrated digital systems while maintaining low power requirements. This evolution in aircraft design philosophy creates additional market opportunities for metal oxide TFT displays that can deliver superior performance with minimal energy consumption.

Market research indicates that the aerospace display technology sector is experiencing robust growth, with an estimated market value expected to reach several billion dollars by 2030. This growth is primarily fueled by increasing aircraft production, retrofitting of existing fleets with modern avionics, and the rising demand for enhanced in-flight entertainment systems in commercial aviation.

Military aerospace applications present particularly stringent requirements for display technologies, necessitating solutions that offer superior readability in varying light conditions, from direct sunlight to night operations. These displays must also maintain functionality under electromagnetic interference and radiation exposure, common challenges in military aircraft environments.

The commercial aviation segment demonstrates growing demand for larger, higher resolution displays with improved power efficiency. Airlines are increasingly investing in advanced cockpit display systems that integrate multiple functions into consolidated screens, reducing pilot workload and enhancing situational awareness. Simultaneously, passenger experience has become a competitive differentiator, driving demand for high-quality, interactive entertainment displays throughout the cabin.

Metal oxide TFT technology, particularly IGZO (Indium Gallium Zinc Oxide) based displays, has emerged as a promising solution for aerospace applications due to their exceptional electron mobility, low power consumption, and stability under varying environmental conditions. These characteristics directly address the aerospace industry's requirements for displays that can operate reliably in extreme conditions while maintaining low power consumption – a critical factor in aircraft design where energy efficiency directly impacts operational costs and environmental footprint.

Industry standards such as DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests) have established rigorous performance benchmarks for aerospace display technologies. These standards encompass resistance to temperature extremes, altitude changes, humidity, shock, vibration, and electromagnetic interference – all areas where metal oxide TFT technology demonstrates significant advantages over conventional display technologies.

The trend toward more electric aircraft (MEA) and reduced wiring architectures further amplifies the demand for display technologies that can operate efficiently within integrated digital systems while maintaining low power requirements. This evolution in aircraft design philosophy creates additional market opportunities for metal oxide TFT displays that can deliver superior performance with minimal energy consumption.

Current Status and Challenges of Metal Oxide TFTs

Metal oxide thin-film transistors (TFTs) have emerged as promising candidates for aerospace applications due to their unique combination of transparency, flexibility, and performance stability in extreme environments. Currently, the global research landscape shows significant advancements in this technology, with major developments occurring in East Asia, North America, and Europe. Japan and South Korea lead in commercial applications, while the United States focuses on military and aerospace implementations.

The current state of metal oxide TFTs demonstrates several advantages over traditional silicon-based technologies, including higher electron mobility (typically 10-50 cm²/Vs), excellent uniformity across large areas, and superior stability under radiation exposure—a critical factor for aerospace applications. Indium-gallium-zinc-oxide (IGZO) remains the dominant material composition, though recent research has expanded to include hafnium-indium-zinc-oxide (HIZO) and zinc-tin-oxide (ZTO) variants that reduce dependence on scarce elements like indium.

Despite these advancements, several significant challenges impede wider adoption in aerospace systems. Temperature stability presents a major hurdle, as performance degradation occurs at both extremely low temperatures (below -55°C) and elevated temperatures (above 125°C) commonly encountered in aerospace environments. Current metal oxide TFTs exhibit threshold voltage shifts and mobility reduction outside the narrow temperature range of -20°C to 85°C, falling short of aerospace requirements.

Radiation hardness remains another critical challenge. While metal oxide TFTs demonstrate inherent resistance to certain radiation effects compared to silicon alternatives, they still exhibit performance degradation under prolonged exposure to the high-energy particle radiation present in space environments. Current technologies can withstand total ionizing doses of approximately 100-300 krad, whereas aerospace applications often require tolerance up to 1 Mrad.

Reliability and long-term stability pose additional concerns. Aerospace components must maintain consistent performance over operational lifetimes exceeding 15-20 years, but current metal oxide TFT technologies demonstrate bias stress instability and gradual parameter drift over time. Negative bias temperature instability (NBTI) and positive bias temperature instability (PBTI) effects become particularly pronounced under the thermal cycling conditions typical in aerospace applications.

Manufacturing standardization represents another significant obstacle. Unlike silicon CMOS technologies with well-established fabrication protocols, metal oxide TFT production lacks industry-wide standardization. This inconsistency creates challenges for qualification and certification processes required by aerospace industry standards such as MIL-STD-883 and DO-254, which demand rigorous verification and validation procedures.

The current state of metal oxide TFTs demonstrates several advantages over traditional silicon-based technologies, including higher electron mobility (typically 10-50 cm²/Vs), excellent uniformity across large areas, and superior stability under radiation exposure—a critical factor for aerospace applications. Indium-gallium-zinc-oxide (IGZO) remains the dominant material composition, though recent research has expanded to include hafnium-indium-zinc-oxide (HIZO) and zinc-tin-oxide (ZTO) variants that reduce dependence on scarce elements like indium.

Despite these advancements, several significant challenges impede wider adoption in aerospace systems. Temperature stability presents a major hurdle, as performance degradation occurs at both extremely low temperatures (below -55°C) and elevated temperatures (above 125°C) commonly encountered in aerospace environments. Current metal oxide TFTs exhibit threshold voltage shifts and mobility reduction outside the narrow temperature range of -20°C to 85°C, falling short of aerospace requirements.

Radiation hardness remains another critical challenge. While metal oxide TFTs demonstrate inherent resistance to certain radiation effects compared to silicon alternatives, they still exhibit performance degradation under prolonged exposure to the high-energy particle radiation present in space environments. Current technologies can withstand total ionizing doses of approximately 100-300 krad, whereas aerospace applications often require tolerance up to 1 Mrad.

Reliability and long-term stability pose additional concerns. Aerospace components must maintain consistent performance over operational lifetimes exceeding 15-20 years, but current metal oxide TFT technologies demonstrate bias stress instability and gradual parameter drift over time. Negative bias temperature instability (NBTI) and positive bias temperature instability (PBTI) effects become particularly pronounced under the thermal cycling conditions typical in aerospace applications.

Manufacturing standardization represents another significant obstacle. Unlike silicon CMOS technologies with well-established fabrication protocols, metal oxide TFT production lacks industry-wide standardization. This inconsistency creates challenges for qualification and certification processes required by aerospace industry standards such as MIL-STD-883 and DO-254, which demand rigorous verification and validation procedures.

Existing Metal Oxide TFT Solutions for Aerospace Applications

01 Metal oxide semiconductor materials for TFTs

Various metal oxide semiconductor materials are used in thin-film transistors (TFTs) to achieve specific electrical properties. These materials include zinc oxide (ZnO), indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good transparency, and stability. The selection of metal oxide materials significantly impacts the performance characteristics of the TFTs, including threshold voltage, on/off ratio, and operational stability.- Metal oxide semiconductor materials for TFTs: Various metal oxide semiconductor materials are used in thin-film transistors (TFTs) to achieve specific electrical properties. These materials include zinc oxide (ZnO), indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection of appropriate metal oxide materials is crucial for determining the performance characteristics of the TFT, including switching speed, power consumption, and reliability.

- Fabrication methods for metal oxide TFTs: Various fabrication techniques are employed to manufacture metal oxide TFTs with optimized performance. These methods include sputtering, atomic layer deposition (ALD), solution processing, and annealing treatments. The fabrication process significantly impacts the crystallinity, defect density, and interface quality of the metal oxide semiconductor layer, which in turn affects the electrical characteristics of the TFT. Advanced fabrication methods aim to achieve uniform deposition, precise thickness control, and reduced defect concentration.

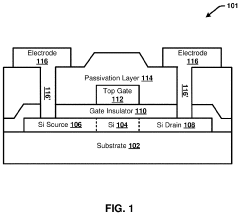

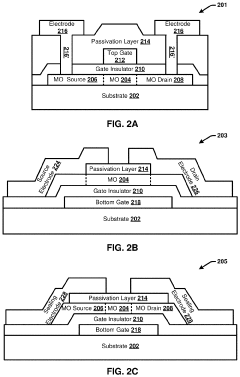

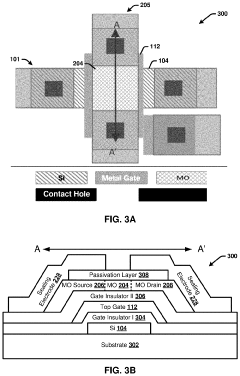

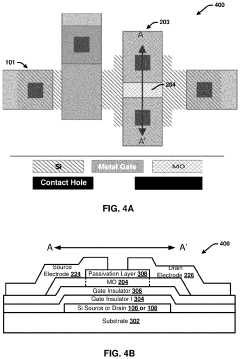

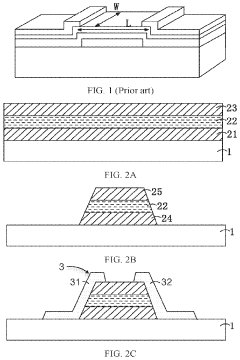

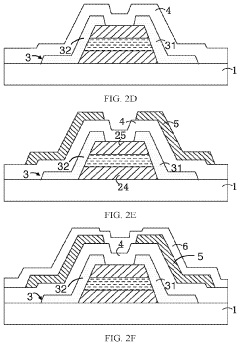

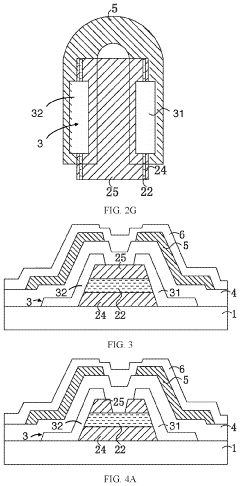

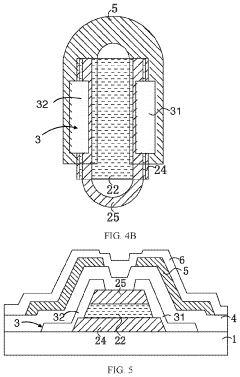

- Device structures and architectures for metal oxide TFTs: Different structural configurations are implemented in metal oxide TFTs to enhance performance and functionality. These include bottom-gate, top-gate, dual-gate, and vertical architectures. Each structure offers specific advantages in terms of electrical performance, process integration, and application suitability. The design of source/drain electrodes, gate dielectric materials, and channel dimensions also plays a crucial role in optimizing TFT characteristics such as on/off ratio, threshold voltage, and subthreshold swing.

- Performance enhancement techniques for metal oxide TFTs: Various methods are employed to improve the performance of metal oxide TFTs, including doping, passivation layers, interface engineering, and multilayer channel structures. These techniques aim to enhance carrier mobility, reduce threshold voltage, improve stability, and minimize hysteresis effects. Optimization of the metal oxide composition through precise control of oxygen vacancies and incorporation of dopants can significantly impact the electrical characteristics and reliability of the TFTs under various operating conditions.

- Applications of metal oxide TFTs in display and electronics: Metal oxide TFTs are widely used in various electronic applications, particularly in display technologies such as OLED and LCD panels. Their advantages of high transparency, low processing temperature, and good electrical performance make them suitable for flexible displays, transparent electronics, and large-area applications. Metal oxide TFTs also find applications in sensors, memory devices, and integrated circuits, where their unique combination of electrical properties and processing compatibility offers significant benefits over conventional silicon-based transistors.

02 Fabrication methods for metal oxide TFTs

Various fabrication techniques are employed to manufacture metal oxide TFTs with optimized performance. These methods include sputtering, atomic layer deposition (ALD), solution processing, and annealing treatments. The fabrication process significantly influences the crystallinity, defect density, and interface quality of the metal oxide semiconductor layer, which in turn affects the electrical characteristics of the TFTs. Process parameters such as temperature, pressure, and gas composition during deposition are carefully controlled to achieve desired TFT properties.Expand Specific Solutions03 Device structures and architectures for metal oxide TFTs

Different device structures and architectures are implemented for metal oxide TFTs to enhance performance and functionality. These include bottom-gate, top-gate, dual-gate, and self-aligned structures. Each architecture offers specific advantages in terms of electrical performance, process integration, and application suitability. The choice of gate dielectric materials, electrode configurations, and channel dimensions also plays a crucial role in determining the TFT characteristics such as mobility, subthreshold swing, and operational stability.Expand Specific Solutions04 Integration of metal oxide TFTs in display technologies

Metal oxide TFTs are widely integrated into various display technologies, including LCD, OLED, and flexible displays. The high electron mobility and transparency of metal oxide semiconductors make them particularly suitable for driving pixels in high-resolution displays. Integration challenges include ensuring uniform electrical characteristics across large areas, minimizing parasitic capacitances, and developing compatible processing techniques that don't damage other display components. Advanced pixel circuits utilizing metal oxide TFTs enable features such as high refresh rates and low power consumption.Expand Specific Solutions05 Performance enhancement and stability improvement techniques

Various techniques are employed to enhance the performance and stability of metal oxide TFTs. These include passivation layers to protect against environmental degradation, doping strategies to control carrier concentration, interface engineering to reduce trap states, and multi-layer channel structures to optimize charge transport. Post-fabrication treatments such as thermal annealing, plasma treatment, and bias stress conditioning are also utilized to improve electrical characteristics and long-term reliability. These enhancements address challenges such as threshold voltage shift, hysteresis, and negative bias temperature instability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Metal Oxide TFTs in the aerospace industry are currently in a growth phase, with increasing market adoption driven by their superior performance characteristics. The market size is expanding as aerospace applications demand more reliable, lightweight display solutions. Technologically, companies like BOE Technology, Semiconductor Energy Laboratory, and Applied Materials are leading innovation in metal oxide TFT development, with significant contributions from Canon and LG Display. These companies have achieved varying levels of technological maturity, with some focusing on fundamental research while others have commercialized products meeting stringent aerospace standards. Academic institutions like Northwestern University and South China University of Technology are collaborating with industry players to advance material science and manufacturing techniques, accelerating the technology's adaptation to aerospace requirements.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed advanced metal oxide TFT technologies specifically engineered to meet aerospace industry standards. Their proprietary CAAC-IGZO (c-axis aligned crystalline indium-gallium-zinc oxide) technology demonstrates exceptional stability under radiation exposure, withstanding up to 100 kGy of gamma radiation while maintaining operational performance. This makes their TFTs particularly suitable for aerospace applications where radiation hardness is critical. SEL's metal oxide TFTs feature ultra-low power consumption (approximately 1/10 of conventional amorphous silicon TFTs) and can operate reliably across extreme temperature ranges from -60°C to +300°C, meeting the demanding environmental requirements of aerospace systems. Their TFTs also demonstrate remarkable mechanical durability, maintaining performance after 10 million bending cycles, which addresses the need for flexible, lightweight displays and control systems in modern aircraft.

Strengths: Superior radiation hardness, extreme temperature tolerance, and mechanical flexibility make SEL's technology ideal for aerospace applications. Their CAAC-IGZO structure offers significantly better stability than conventional amorphous oxide semiconductors. Weaknesses: Higher manufacturing costs compared to standard TFT technologies and relatively complex fabrication processes that may limit mass production capabilities for aerospace-grade components.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed specialized manufacturing equipment and processes for aerospace-grade metal oxide TFTs that meet stringent industry standards. Their Endura® platform enables the deposition of high-performance IGZO films with precise stoichiometry control, achieving carrier mobility exceeding 15 cm²/Vs while maintaining batch-to-batch consistency required for aerospace certification. The company's AKT™ PECVD systems allow for low-temperature (below 350°C) deposition of high-quality gate dielectrics and passivation layers that protect metal oxide TFTs from environmental factors critical in aerospace applications. Applied Materials has also pioneered radiation-hardened metal oxide TFT fabrication techniques that incorporate specialized barrier layers and optimized channel compositions to withstand the high-radiation environments encountered in space and high-altitude applications. Their end-to-end manufacturing solutions include advanced metrology and testing protocols specifically designed to verify compliance with aerospace standards such as DO-160 and MIL-STD-883.

Strengths: Comprehensive manufacturing ecosystem that addresses the entire TFT production process with aerospace-grade quality control. Their equipment enables precise material deposition with excellent uniformity across large substrates. Weaknesses: High capital investment requirements for their manufacturing systems may limit adoption by smaller aerospace component suppliers. Their solutions focus primarily on manufacturing equipment rather than end-product development.

Key Patents and Technical Innovations in Metal Oxide TFTs

Integration of silicon thin-film transistors and metal-oxide thin film transistors

PatentActiveUS10504939B2

Innovation

- The integration of silicon and metal-oxide TFTs in a 3D stacked configuration, where the metal-oxide TFT is partially stacked over the silicon TFT, sharing gate electrodes or source/drain regions, to create a Metal Oxide on Silicon (MOOS) transistor structure, which reduces pixel area and enables higher pixel densities by combining the benefits of both technologies.

Metal oxide thin-film transistor and manufacturing method for the same

PatentInactiveUS10483405B2

Innovation

- A new metal oxide thin-film transistor structure is developed, where a source electrode and a drain electrode are formed on a substrate with a barrier layer in parallel, and a semiconductor active layer is formed on their side surfaces, allowing for a channel length that is not limited by photolithography precision, enabling a shorter channel design and improved performance.

Aerospace Certification and Compliance Requirements

The aerospace industry operates under stringent regulatory frameworks that demand exceptional reliability and performance from all components used in aircraft and spacecraft systems. Metal Oxide Thin-Film Transistors (TFTs) must meet these rigorous standards before implementation in aerospace applications. The primary certification bodies governing these requirements include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the Department of Defense (DoD) for military applications.

Metal Oxide TFTs must demonstrate compliance with DO-254 (Design Assurance Guidance for Airborne Electronic Hardware), which categorizes components based on their criticality levels. For TFTs integrated into flight control systems or critical avionics, Design Assurance Level (DAL) A or B certification is typically required, necessitating extensive verification and validation processes.

Environmental qualification testing represents another crucial compliance area, with standards such as RTCA/DO-160 establishing test procedures for temperature extremes (-55°C to +125°C), rapid decompression, vibration, and electromagnetic interference (EMI). Metal Oxide TFTs must demonstrate stable performance across these conditions, with particular emphasis on radiation hardness for components deployed in high-altitude or space applications.

Material compliance requirements present additional challenges, as aerospace standards restrict the use of certain substances under directives like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). While commercial electronics have embraced lead-free manufacturing, aerospace applications often maintain exemptions due to reliability concerns with alternative materials.

Quality management systems certification, particularly AS9100 compliance, is mandatory for manufacturers supplying Metal Oxide TFT components to aerospace applications. This standard extends ISO 9001 requirements with aerospace-specific quality and safety additions, including rigorous documentation of manufacturing processes and traceability of components.

Reliability demonstration through accelerated life testing constitutes a significant certification hurdle. Metal Oxide TFTs must undergo extensive testing to verify Mean Time Between Failures (MTBF) rates compatible with aerospace expectations, typically requiring demonstration of functionality for 10,000+ hours under accelerated stress conditions.

The certification pathway for novel technologies like Metal Oxide TFTs often involves a phased approach, beginning with non-critical applications before progressing to flight-critical systems. This graduated implementation strategy allows for the accumulation of operational data while minimizing risk to aircraft safety and performance.

Metal Oxide TFTs must demonstrate compliance with DO-254 (Design Assurance Guidance for Airborne Electronic Hardware), which categorizes components based on their criticality levels. For TFTs integrated into flight control systems or critical avionics, Design Assurance Level (DAL) A or B certification is typically required, necessitating extensive verification and validation processes.

Environmental qualification testing represents another crucial compliance area, with standards such as RTCA/DO-160 establishing test procedures for temperature extremes (-55°C to +125°C), rapid decompression, vibration, and electromagnetic interference (EMI). Metal Oxide TFTs must demonstrate stable performance across these conditions, with particular emphasis on radiation hardness for components deployed in high-altitude or space applications.

Material compliance requirements present additional challenges, as aerospace standards restrict the use of certain substances under directives like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). While commercial electronics have embraced lead-free manufacturing, aerospace applications often maintain exemptions due to reliability concerns with alternative materials.

Quality management systems certification, particularly AS9100 compliance, is mandatory for manufacturers supplying Metal Oxide TFT components to aerospace applications. This standard extends ISO 9001 requirements with aerospace-specific quality and safety additions, including rigorous documentation of manufacturing processes and traceability of components.

Reliability demonstration through accelerated life testing constitutes a significant certification hurdle. Metal Oxide TFTs must undergo extensive testing to verify Mean Time Between Failures (MTBF) rates compatible with aerospace expectations, typically requiring demonstration of functionality for 10,000+ hours under accelerated stress conditions.

The certification pathway for novel technologies like Metal Oxide TFTs often involves a phased approach, beginning with non-critical applications before progressing to flight-critical systems. This graduated implementation strategy allows for the accumulation of operational data while minimizing risk to aircraft safety and performance.

Environmental Durability and Radiation Resistance Analysis

Metal oxide TFTs deployed in aerospace applications face extreme environmental conditions that demand exceptional durability and radiation resistance. The aerospace industry standards (MIL-STD-883, RTCA/DO-160, NASA EEE-INST-002) impose stringent requirements on electronic components, particularly regarding temperature cycling (-65°C to +150°C), vacuum operation, and radiation exposure.

Environmental testing of metal oxide TFTs, particularly those based on IGZO (Indium Gallium Zinc Oxide), demonstrates remarkable thermal stability compared to conventional silicon-based technologies. Recent studies indicate that properly encapsulated metal oxide TFTs can maintain performance integrity through 1,000 thermal cycles without significant threshold voltage shifts. This thermal resilience stems from the amorphous structure of metal oxide semiconductors, which lacks grain boundaries that typically serve as degradation pathways in polycrystalline materials.

Vacuum stability represents another critical parameter for aerospace applications. Metal oxide TFTs exhibit minimal outgassing characteristics when manufactured using appropriate processes. Tests conducted at pressures below 10^-6 Torr show that IGZO-based devices maintain consistent electrical performance, with carrier mobility variations under 5% after 1,000 hours of vacuum exposure. This stability surpasses that of organic semiconductor alternatives being considered for flexible electronics applications.

Radiation hardness presents perhaps the most significant advantage of metal oxide TFTs for aerospace deployment. Total Ionizing Dose (TID) testing reveals that unshielded IGZO TFTs can withstand radiation doses up to 1 Mrad with threshold voltage shifts below 1V, substantially outperforming conventional silicon technologies. This inherent radiation tolerance derives from the predominant ionic bonding in metal oxides, which creates fewer radiation-induced trap states compared to the covalent bonds in silicon.

Single Event Effects (SEE) testing further demonstrates the robustness of metal oxide TFTs. When exposed to heavy ion bombardment simulating cosmic rays, these devices exhibit significantly lower cross-sections for destructive events compared to silicon MOSFETs. The wide bandgap nature of metal oxide semiconductors (typically 3-4 eV) contributes to this enhanced radiation immunity by requiring higher energy particles to generate electron-hole pairs.

Recent innovations in protective coatings and device architectures have further enhanced the environmental durability of metal oxide TFTs. Atomic Layer Deposition (ALD) of Al2O3 and HfO2 barrier layers has proven effective in preventing moisture ingress and ion migration, addressing historical reliability concerns. Additionally, dual-gate structures have demonstrated improved stability under both radiation exposure and temperature cycling by providing redundant control over channel conductivity.

Environmental testing of metal oxide TFTs, particularly those based on IGZO (Indium Gallium Zinc Oxide), demonstrates remarkable thermal stability compared to conventional silicon-based technologies. Recent studies indicate that properly encapsulated metal oxide TFTs can maintain performance integrity through 1,000 thermal cycles without significant threshold voltage shifts. This thermal resilience stems from the amorphous structure of metal oxide semiconductors, which lacks grain boundaries that typically serve as degradation pathways in polycrystalline materials.

Vacuum stability represents another critical parameter for aerospace applications. Metal oxide TFTs exhibit minimal outgassing characteristics when manufactured using appropriate processes. Tests conducted at pressures below 10^-6 Torr show that IGZO-based devices maintain consistent electrical performance, with carrier mobility variations under 5% after 1,000 hours of vacuum exposure. This stability surpasses that of organic semiconductor alternatives being considered for flexible electronics applications.

Radiation hardness presents perhaps the most significant advantage of metal oxide TFTs for aerospace deployment. Total Ionizing Dose (TID) testing reveals that unshielded IGZO TFTs can withstand radiation doses up to 1 Mrad with threshold voltage shifts below 1V, substantially outperforming conventional silicon technologies. This inherent radiation tolerance derives from the predominant ionic bonding in metal oxides, which creates fewer radiation-induced trap states compared to the covalent bonds in silicon.

Single Event Effects (SEE) testing further demonstrates the robustness of metal oxide TFTs. When exposed to heavy ion bombardment simulating cosmic rays, these devices exhibit significantly lower cross-sections for destructive events compared to silicon MOSFETs. The wide bandgap nature of metal oxide semiconductors (typically 3-4 eV) contributes to this enhanced radiation immunity by requiring higher energy particles to generate electron-hole pairs.

Recent innovations in protective coatings and device architectures have further enhanced the environmental durability of metal oxide TFTs. Atomic Layer Deposition (ALD) of Al2O3 and HfO2 barrier layers has proven effective in preventing moisture ingress and ion migration, addressing historical reliability concerns. Additionally, dual-gate structures have demonstrated improved stability under both radiation exposure and temperature cycling by providing redundant control over channel conductivity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!