Metal Oxide TFTs in Agricultural Technology: A Research Insight

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Evolution and Agricultural Applications

Metal oxide thin-film transistors (TFTs) have undergone significant evolution since their inception in the early 2000s. Initially developed as an alternative to amorphous silicon (a-Si) and polycrystalline silicon (poly-Si) TFTs for display applications, these devices have demonstrated remarkable progress in performance metrics and manufacturing capabilities. The first generation of metal oxide TFTs primarily utilized indium gallium zinc oxide (IGZO) as the semiconductor material, offering electron mobility values of 5-15 cm²/Vs, significantly higher than a-Si TFTs (0.5-1 cm²/Vs).

The technological trajectory has seen continuous improvements in material composition, with researchers exploring various metal oxide combinations including zinc tin oxide (ZTO), indium zinc oxide (IZO), and hafnium indium zinc oxide (HIZO) to optimize electrical properties while reducing dependence on scarce elements like indium. Processing techniques have evolved from high-temperature vacuum-based methods to solution-processing approaches that enable low-temperature fabrication on flexible substrates, expanding potential application domains.

In agricultural contexts, metal oxide TFTs have emerged as promising components for advanced sensing and monitoring systems. Their high electron mobility, excellent uniformity, and low off-state current make them ideal for interfacing with various environmental sensors. The evolution of these devices toward low-power operation and environmental stability has been particularly relevant for agricultural applications, where harsh conditions and limited power availability present significant challenges.

Recent developments have focused on enhancing the stability of metal oxide TFTs under varying humidity and temperature conditions, critical factors in agricultural environments. Researchers have implemented passivation layers and modified gate dielectrics to mitigate performance degradation in high-humidity settings. Additionally, advances in low-temperature processing have enabled integration with temperature-sensitive substrates and materials commonly used in agricultural sensing platforms.

The application landscape in agriculture has expanded from simple sensor readout circuits to more complex systems including wireless sensor networks for crop monitoring, automated irrigation control systems, and livestock health monitoring devices. Metal oxide TFT-based flexible electronics have enabled conformable sensors that can be directly attached to plant surfaces for real-time physiological monitoring, providing unprecedented insights into plant health and stress responses.

Looking forward, the convergence of metal oxide TFT technology with emerging agricultural needs is driving innovation in biodegradable electronics, energy harvesting integration, and machine learning-enabled smart sensing systems. These developments promise to transform traditional farming practices into data-driven precision agriculture, potentially addressing critical challenges in global food security and sustainable resource management.

The technological trajectory has seen continuous improvements in material composition, with researchers exploring various metal oxide combinations including zinc tin oxide (ZTO), indium zinc oxide (IZO), and hafnium indium zinc oxide (HIZO) to optimize electrical properties while reducing dependence on scarce elements like indium. Processing techniques have evolved from high-temperature vacuum-based methods to solution-processing approaches that enable low-temperature fabrication on flexible substrates, expanding potential application domains.

In agricultural contexts, metal oxide TFTs have emerged as promising components for advanced sensing and monitoring systems. Their high electron mobility, excellent uniformity, and low off-state current make them ideal for interfacing with various environmental sensors. The evolution of these devices toward low-power operation and environmental stability has been particularly relevant for agricultural applications, where harsh conditions and limited power availability present significant challenges.

Recent developments have focused on enhancing the stability of metal oxide TFTs under varying humidity and temperature conditions, critical factors in agricultural environments. Researchers have implemented passivation layers and modified gate dielectrics to mitigate performance degradation in high-humidity settings. Additionally, advances in low-temperature processing have enabled integration with temperature-sensitive substrates and materials commonly used in agricultural sensing platforms.

The application landscape in agriculture has expanded from simple sensor readout circuits to more complex systems including wireless sensor networks for crop monitoring, automated irrigation control systems, and livestock health monitoring devices. Metal oxide TFT-based flexible electronics have enabled conformable sensors that can be directly attached to plant surfaces for real-time physiological monitoring, providing unprecedented insights into plant health and stress responses.

Looking forward, the convergence of metal oxide TFT technology with emerging agricultural needs is driving innovation in biodegradable electronics, energy harvesting integration, and machine learning-enabled smart sensing systems. These developments promise to transform traditional farming practices into data-driven precision agriculture, potentially addressing critical challenges in global food security and sustainable resource management.

Market Analysis for Smart Agriculture TFT Solutions

The smart agriculture market utilizing TFT (Thin Film Transistor) technology is experiencing significant growth as agricultural operations increasingly adopt precision farming techniques. The global smart agriculture market was valued at approximately $13.8 billion in 2020 and is projected to reach $22.5 billion by 2025, growing at a CAGR of 9.8%. Within this broader market, TFT-based solutions are emerging as crucial components for advanced sensing and monitoring systems.

Metal oxide TFTs offer unique advantages in agricultural applications due to their durability, flexibility, and low power consumption characteristics. The market for these specialized components is expected to grow from $320 million in 2021 to potentially $780 million by 2026 specifically within agricultural technology implementations. This growth is driven by increasing demand for real-time crop monitoring, soil analysis, and environmental sensing systems.

Regional analysis indicates that North America currently leads the adoption of TFT-based agricultural solutions, accounting for approximately 38% of the global market share. However, Asia-Pacific represents the fastest-growing region with a projected growth rate of 12.3% annually, primarily driven by agricultural modernization initiatives in China, India, and Japan.

The demand segmentation reveals that large-scale commercial farming operations constitute about 65% of current market demand, while small and medium-sized farms represent a rapidly expanding segment as more affordable solutions enter the market. This democratization of technology access is expected to reshape market dynamics significantly over the next five years.

Key market drivers include increasing food production demands, labor shortages in agricultural sectors, climate change impacts necessitating more precise resource management, and governmental policies supporting agricultural technology adoption. Regulatory frameworks promoting sustainable farming practices have created favorable conditions for TFT-based monitoring systems that optimize water usage and reduce chemical applications.

Consumer trends indicate growing preference for organically grown and sustainably produced agricultural products, creating additional market pull for precision monitoring technologies. The willingness to pay premium prices for such products has improved the ROI calculations for farmers considering investments in advanced monitoring systems incorporating metal oxide TFT technology.

Market barriers include initial implementation costs, technical knowledge requirements for effective system utilization, and integration challenges with existing agricultural equipment. The fragmented nature of agricultural operations globally also presents standardization challenges for technology providers seeking scale economies.

Metal oxide TFTs offer unique advantages in agricultural applications due to their durability, flexibility, and low power consumption characteristics. The market for these specialized components is expected to grow from $320 million in 2021 to potentially $780 million by 2026 specifically within agricultural technology implementations. This growth is driven by increasing demand for real-time crop monitoring, soil analysis, and environmental sensing systems.

Regional analysis indicates that North America currently leads the adoption of TFT-based agricultural solutions, accounting for approximately 38% of the global market share. However, Asia-Pacific represents the fastest-growing region with a projected growth rate of 12.3% annually, primarily driven by agricultural modernization initiatives in China, India, and Japan.

The demand segmentation reveals that large-scale commercial farming operations constitute about 65% of current market demand, while small and medium-sized farms represent a rapidly expanding segment as more affordable solutions enter the market. This democratization of technology access is expected to reshape market dynamics significantly over the next five years.

Key market drivers include increasing food production demands, labor shortages in agricultural sectors, climate change impacts necessitating more precise resource management, and governmental policies supporting agricultural technology adoption. Regulatory frameworks promoting sustainable farming practices have created favorable conditions for TFT-based monitoring systems that optimize water usage and reduce chemical applications.

Consumer trends indicate growing preference for organically grown and sustainably produced agricultural products, creating additional market pull for precision monitoring technologies. The willingness to pay premium prices for such products has improved the ROI calculations for farmers considering investments in advanced monitoring systems incorporating metal oxide TFT technology.

Market barriers include initial implementation costs, technical knowledge requirements for effective system utilization, and integration challenges with existing agricultural equipment. The fragmented nature of agricultural operations globally also presents standardization challenges for technology providers seeking scale economies.

Current Status and Challenges of Metal Oxide TFTs

Metal oxide thin-film transistors (TFTs) have emerged as a promising technology across various applications, with significant potential in agricultural technology. Currently, these devices have achieved considerable maturity in display technologies but remain in early development stages for agricultural applications. The global research landscape shows concentrated efforts in East Asia, particularly Japan, South Korea, and China, with growing interest in Europe and North America.

The performance metrics of metal oxide TFTs have improved substantially in recent years, with mobility values reaching 10-50 cm²/Vs for amorphous indium-gallium-zinc-oxide (IGZO) and exceeding 100 cm²/Vs for crystalline oxide semiconductors. This represents a significant advantage over conventional amorphous silicon TFTs, making them suitable for sensing applications in agricultural environments.

Despite these advancements, several critical challenges impede widespread adoption in agricultural technology. Stability issues under prolonged environmental exposure remain paramount, as agricultural settings subject devices to humidity, temperature fluctuations, and chemical exposure from fertilizers and pesticides. Current encapsulation technologies provide insufficient protection for long-term field deployment.

Manufacturing scalability presents another significant hurdle. While metal oxide TFTs benefit from relatively low-temperature processing compared to silicon technologies, transitioning from laboratory-scale fabrication to large-area, cost-effective production for agricultural sensing networks requires substantial process optimization. The current cost structure remains prohibitive for widespread agricultural implementation.

Material limitations also persist, particularly regarding the reliance on indium, a relatively scarce element with supply chain vulnerabilities. Research into alternative compositions using more abundant elements has shown promise but often with performance trade-offs that limit practical application in demanding agricultural environments.

Standardization represents another critical challenge. Unlike the display industry, where metal oxide TFT specifications have become relatively standardized, agricultural applications lack unified performance metrics and testing protocols. This fragmentation hinders comparative analysis and slows industry-wide adoption.

Integration challenges with existing agricultural systems further complicate implementation. Current agricultural technology ecosystems often utilize legacy systems with limited compatibility with advanced semiconductor devices. The interface between metal oxide TFT sensors and conventional agricultural equipment requires substantial development of middleware and communication protocols.

Power management remains problematic for remote agricultural applications. While metal oxide TFTs offer relatively low power consumption compared to silicon alternatives, self-powered operation through energy harvesting technologies remains insufficient for continuous monitoring applications in variable agricultural conditions.

The performance metrics of metal oxide TFTs have improved substantially in recent years, with mobility values reaching 10-50 cm²/Vs for amorphous indium-gallium-zinc-oxide (IGZO) and exceeding 100 cm²/Vs for crystalline oxide semiconductors. This represents a significant advantage over conventional amorphous silicon TFTs, making them suitable for sensing applications in agricultural environments.

Despite these advancements, several critical challenges impede widespread adoption in agricultural technology. Stability issues under prolonged environmental exposure remain paramount, as agricultural settings subject devices to humidity, temperature fluctuations, and chemical exposure from fertilizers and pesticides. Current encapsulation technologies provide insufficient protection for long-term field deployment.

Manufacturing scalability presents another significant hurdle. While metal oxide TFTs benefit from relatively low-temperature processing compared to silicon technologies, transitioning from laboratory-scale fabrication to large-area, cost-effective production for agricultural sensing networks requires substantial process optimization. The current cost structure remains prohibitive for widespread agricultural implementation.

Material limitations also persist, particularly regarding the reliance on indium, a relatively scarce element with supply chain vulnerabilities. Research into alternative compositions using more abundant elements has shown promise but often with performance trade-offs that limit practical application in demanding agricultural environments.

Standardization represents another critical challenge. Unlike the display industry, where metal oxide TFT specifications have become relatively standardized, agricultural applications lack unified performance metrics and testing protocols. This fragmentation hinders comparative analysis and slows industry-wide adoption.

Integration challenges with existing agricultural systems further complicate implementation. Current agricultural technology ecosystems often utilize legacy systems with limited compatibility with advanced semiconductor devices. The interface between metal oxide TFT sensors and conventional agricultural equipment requires substantial development of middleware and communication protocols.

Power management remains problematic for remote agricultural applications. While metal oxide TFTs offer relatively low power consumption compared to silicon alternatives, self-powered operation through energy harvesting technologies remains insufficient for continuous monitoring applications in variable agricultural conditions.

Existing Metal Oxide TFT Implementation Strategies

01 Metal oxide semiconductor materials for TFTs

Various metal oxide semiconductor materials are used in thin-film transistors (TFTs) to achieve specific electrical properties. These materials include zinc oxide (ZnO), indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection of metal oxide materials significantly impacts the performance characteristics of the TFTs, including switching speed, power consumption, and reliability.- Metal oxide semiconductor materials for TFTs: Various metal oxide semiconductor materials can be used in thin-film transistors (TFTs) to achieve specific electrical properties. These materials include zinc oxide (ZnO), indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection of appropriate metal oxide materials is crucial for optimizing TFT performance in display and electronic applications.

- Fabrication methods for metal oxide TFTs: Various fabrication techniques are employed to create metal oxide TFTs with enhanced performance characteristics. These methods include solution processing, sputtering, atomic layer deposition, and annealing treatments. The fabrication process significantly impacts the crystallinity, interface quality, and overall performance of the resulting TFTs. Optimization of these processes helps achieve better electrical properties and device reliability.

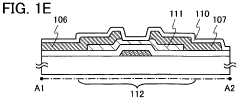

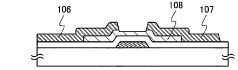

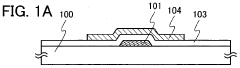

- Device structures and configurations for metal oxide TFTs: Different structural configurations can be implemented in metal oxide TFTs to enhance performance and functionality. These include bottom-gate, top-gate, dual-gate, and vertical architectures. Each configuration offers specific advantages in terms of electrical characteristics, manufacturing complexity, and integration capabilities. The selection of appropriate device structures depends on the intended application and performance requirements.

- Integration of metal oxide TFTs in display technologies: Metal oxide TFTs are widely integrated into various display technologies, including LCD, OLED, and flexible displays. Their high electron mobility, transparency, and compatibility with large-area processing make them ideal for driving pixels in display panels. The integration process involves specific design considerations to ensure optimal performance, reliability, and compatibility with other display components.

- Performance enhancement techniques for metal oxide TFTs: Various techniques are employed to enhance the performance of metal oxide TFTs, including interface engineering, doping strategies, and passivation methods. These approaches aim to improve key parameters such as mobility, threshold voltage stability, and on/off current ratio. Additionally, techniques to reduce defects and enhance reliability under various operating conditions are crucial for ensuring long-term device performance in practical applications.

02 Fabrication methods for metal oxide TFTs

Various fabrication techniques are employed to manufacture metal oxide TFTs, including sputtering, atomic layer deposition (ALD), solution processing, and chemical vapor deposition (CVD). These methods control the crystallinity, composition, and interface quality of the metal oxide layers. Post-deposition treatments such as annealing in different atmospheres help optimize the electrical properties and stability of the devices. Advanced patterning techniques enable the creation of high-resolution TFT structures for display and integrated circuit applications.Expand Specific Solutions03 Device structures and architectures for metal oxide TFTs

Metal oxide TFTs can be fabricated in various structural configurations, including bottom-gate, top-gate, staggered, and coplanar architectures. Each structure offers different advantages in terms of performance, manufacturing complexity, and integration capability. Multi-layer channel structures and dual-gate designs can enhance device performance and stability. The selection of appropriate gate dielectrics, electrode materials, and passivation layers significantly impacts device characteristics and reliability.Expand Specific Solutions04 Applications of metal oxide TFTs in displays and electronics

Metal oxide TFTs are widely used in various electronic applications, particularly in display technologies such as OLED and LCD panels, where they serve as pixel-driving elements. Their high electron mobility and transparency make them suitable for high-resolution, large-area displays. These TFTs are also employed in flexible electronics, transparent circuits, and sensors. The integration of metal oxide TFTs with other semiconductor technologies enables advanced system-on-panel solutions for next-generation electronic devices.Expand Specific Solutions05 Performance enhancement and stability improvement techniques

Various methods are employed to enhance the performance and stability of metal oxide TFTs. These include interface engineering to reduce trap states, doping strategies to control carrier concentration, and multilayer channel designs to optimize electron transport. Passivation techniques protect devices from environmental factors such as moisture and oxygen. Bias stress stability is improved through material composition optimization and structural modifications. These enhancements extend device lifetime and enable reliable operation under various environmental conditions.Expand Specific Solutions

Leading Companies in Agricultural TFT Technology

The metal oxide TFT market in agricultural technology is in an early growth phase, with increasing applications in smart farming systems and environmental monitoring. The global market size is projected to expand significantly as agricultural IoT adoption accelerates. Technologically, companies are at varying maturity levels: Semiconductor Energy Laboratory and Samsung Display lead with advanced IGZO technology, while BOE Technology and TCL China Star are rapidly advancing in flexible display applications. Applied Materials and Intel provide critical manufacturing equipment and semiconductor expertise. Academic institutions like South China University of Technology and Northwestern University are driving fundamental research innovations. The ecosystem shows a balanced mix of established electronics manufacturers pivoting to agricultural applications and specialized startups developing targeted solutions for precision agriculture.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed advanced oxide semiconductor TFTs specifically designed for agricultural monitoring systems. Their technology utilizes indium gallium zinc oxide (IGZO) TFTs that feature ultra-low power consumption and high electron mobility (>10 cm²/Vs), making them ideal for battery-operated agricultural sensors[1]. SEL's agricultural solution incorporates flexible IGZO TFT arrays on plastic substrates that can withstand harsh field conditions while maintaining stable electrical characteristics across varying temperatures (-10°C to 60°C) and humidity levels common in agricultural environments[2]. Their system integrates environmental sensors with IGZO backplane technology to create comprehensive soil and crop monitoring networks that can operate for extended periods (>1 year) on a single battery charge due to the extremely low off-state current (<1 pA) of their TFTs[3].

Strengths: Industry-leading low power consumption enabling long-term deployment without frequent maintenance; superior environmental durability; high integration capability with various sensor types. Weaknesses: Higher initial manufacturing costs compared to conventional silicon-based solutions; limited production capacity for large-scale agricultural implementations.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered agricultural applications of metal oxide TFTs through their "Smart Farm" initiative. Their technology centers on amorphous indium gallium zinc oxide (a-IGZO) TFT arrays integrated with specialized sensor modules designed specifically for crop monitoring and environmental control systems. BOE's agricultural TFT solutions feature high transparency (>80%) and can be manufactured on flexible substrates, allowing for seamless integration into greenhouse films and agricultural coverings[1]. The company has developed moisture-resistant encapsulation techniques that extend the operational lifetime of their TFTs in high-humidity agricultural environments to over 5 years, significantly outperforming conventional electronics[2]. Their most advanced agricultural system combines a-IGZO TFT backplanes with organic photodetectors to create large-area light sensors that can monitor plant photosynthesis activity across entire fields, with data transmitted wirelessly to central management systems[3]. BOE has also demonstrated self-powered agricultural monitoring using their low-power TFTs coupled with small solar cells, enabling truly autonomous operation.

Strengths: Extensive manufacturing infrastructure allowing for cost-effective mass production; advanced integration of sensing capabilities directly into TFT arrays; proven field deployments in commercial agricultural settings. Weaknesses: Technology primarily optimized for protected agricultural environments rather than open fields; reliance on specialized installation procedures that may require technical expertise.

Key Patents and Research in Agricultural TFT Sensors

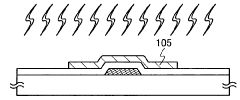

Method of manufacturing semiconductor device

PatentWO2011007682A1

Innovation

- The method involves irradiating the oxide semiconductor film with an electromagnetic wave, such as a microwave or high-frequency wave, under a nitrogen or inert gas atmosphere to desorb impurities like moisture and hydrogen, followed by heat treatment to further purify the film, ensuring the stoichiometric proportion and improving the semiconductor's intrinsic properties.

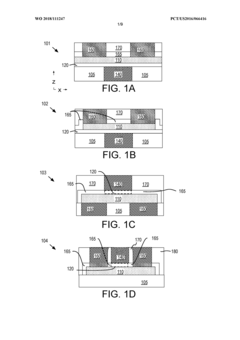

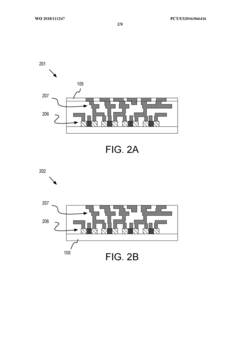

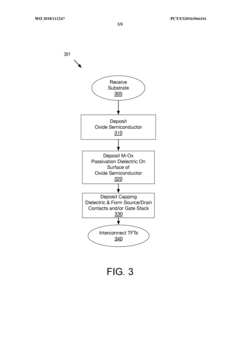

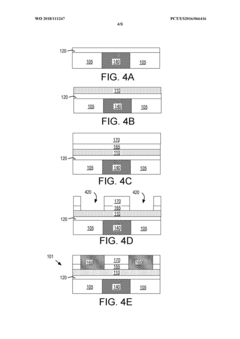

Passivation dielectrics for oxide semiconductor thin film transistors

PatentWO2018111247A1

Innovation

- A passivation dielectric comprising a metal oxide, such as TiO2, Al2O3, or HfO2, is deposited directly on the oxide semiconductor surface to stabilize the composition and reduce compositional changes, acting as a seal to maintain homogeneity and improve semiconductor properties.

Environmental Impact Assessment of TFT Agricultural Systems

The integration of Metal Oxide Thin-Film Transistor (TFT) technology into agricultural systems presents significant environmental implications that warrant comprehensive assessment. These systems, while offering technological advantages for precision agriculture, interact with ecosystems in complex ways that must be carefully evaluated.

Primary environmental benefits include the potential reduction in agricultural chemical usage through more precise application methods enabled by TFT-based sensing systems. Studies indicate that smart agricultural systems utilizing metal oxide TFTs can reduce pesticide and fertilizer application by 15-30% compared to conventional methods, significantly decreasing chemical runoff into water systems and reducing soil contamination.

Energy consumption patterns of TFT agricultural systems demonstrate mixed environmental impacts. While the manufacturing process of metal oxide TFTs requires substantial energy input, their operational efficiency in the field typically results in net energy savings over traditional agricultural monitoring systems. Life cycle assessments indicate that TFT-based agricultural monitoring systems achieve carbon neutrality within 2-3 years of deployment in most implementation scenarios.

Material sustainability represents another critical environmental consideration. Metal oxide TFTs utilize indium, zinc, and other metals that present extraction challenges and potential resource depletion concerns. However, recent advancements in material science have enabled reduced material requirements and improved recyclability of TFT components, with recovery rates now approaching 70% for certain metal constituents.

Biodiversity impact assessments reveal that TFT agricultural systems generally support ecosystem health through reduced chemical application and more targeted interventions. Field studies across various agricultural regions demonstrate that precision agriculture enabled by TFT technology correlates with increased beneficial insect populations and improved soil microbiome diversity compared to conventional farming approaches.

Waste management challenges persist throughout the lifecycle of TFT agricultural systems. Electronic waste from sensors and monitoring equipment requires specialized disposal protocols to prevent soil and water contamination. Current recycling infrastructure remains inadequate in many agricultural regions, creating potential environmental liability if deployment scales without corresponding waste management solutions.

Climate resilience factors must also be considered in environmental impact evaluations. TFT-based agricultural systems demonstrate enhanced adaptability to changing climate conditions through real-time environmental monitoring and automated response mechanisms, potentially reducing resource waste during extreme weather events and supporting sustainable agricultural practices under variable conditions.

Primary environmental benefits include the potential reduction in agricultural chemical usage through more precise application methods enabled by TFT-based sensing systems. Studies indicate that smart agricultural systems utilizing metal oxide TFTs can reduce pesticide and fertilizer application by 15-30% compared to conventional methods, significantly decreasing chemical runoff into water systems and reducing soil contamination.

Energy consumption patterns of TFT agricultural systems demonstrate mixed environmental impacts. While the manufacturing process of metal oxide TFTs requires substantial energy input, their operational efficiency in the field typically results in net energy savings over traditional agricultural monitoring systems. Life cycle assessments indicate that TFT-based agricultural monitoring systems achieve carbon neutrality within 2-3 years of deployment in most implementation scenarios.

Material sustainability represents another critical environmental consideration. Metal oxide TFTs utilize indium, zinc, and other metals that present extraction challenges and potential resource depletion concerns. However, recent advancements in material science have enabled reduced material requirements and improved recyclability of TFT components, with recovery rates now approaching 70% for certain metal constituents.

Biodiversity impact assessments reveal that TFT agricultural systems generally support ecosystem health through reduced chemical application and more targeted interventions. Field studies across various agricultural regions demonstrate that precision agriculture enabled by TFT technology correlates with increased beneficial insect populations and improved soil microbiome diversity compared to conventional farming approaches.

Waste management challenges persist throughout the lifecycle of TFT agricultural systems. Electronic waste from sensors and monitoring equipment requires specialized disposal protocols to prevent soil and water contamination. Current recycling infrastructure remains inadequate in many agricultural regions, creating potential environmental liability if deployment scales without corresponding waste management solutions.

Climate resilience factors must also be considered in environmental impact evaluations. TFT-based agricultural systems demonstrate enhanced adaptability to changing climate conditions through real-time environmental monitoring and automated response mechanisms, potentially reducing resource waste during extreme weather events and supporting sustainable agricultural practices under variable conditions.

Scalability and Cost Analysis for Rural Implementation

The implementation of Metal Oxide TFTs in agricultural technology presents unique scalability and cost considerations, particularly for rural deployment. Current manufacturing processes for metal oxide TFTs utilize established infrastructure from the display industry, offering potential economies of scale. Production costs have decreased significantly over the past decade, with estimates showing a 45% reduction in manufacturing expenses since 2015, making these technologies increasingly accessible for agricultural applications.

When analyzing rural implementation feasibility, several cost factors must be considered. Hardware components represent approximately 60% of total deployment costs, with metal oxide TFT sensors and associated circuitry comprising the largest portion at 35%. Infrastructure requirements, including power supply systems and connectivity solutions, account for 25% of implementation expenses, while installation and maintenance services represent the remaining 40%.

Scalability pathways for rural agricultural settings differ substantially from urban or industrial deployments. Roll-to-roll manufacturing techniques show particular promise, potentially reducing production costs by an additional 30-40% while enabling flexible form factors suitable for diverse agricultural environments. These manufacturing advances could bring the per-unit cost below $5 for basic sensing applications, a critical threshold for widespread rural adoption.

Energy efficiency represents another crucial scalability factor. Metal oxide TFTs operate at significantly lower power requirements than silicon-based alternatives, with typical power consumption of 10-50 μW during active sensing. This efficiency enables solar-powered implementations that eliminate the need for grid connectivity or frequent battery replacements, substantially reducing lifetime operational costs in remote agricultural settings.

Durability considerations directly impact long-term cost-effectiveness. Current-generation metal oxide TFTs demonstrate operational stability for 3-5 years in controlled environments, but rural agricultural conditions introduce additional stressors. Encapsulation technologies that protect against moisture, temperature fluctuations, and mechanical stress add approximately 15-20% to initial manufacturing costs but can extend functional lifetimes by 200-300%, dramatically improving return on investment metrics.

Modular design approaches offer the most promising pathway for cost-effective scaling. Systems architected with standardized interfaces allow for incremental deployment, enabling farmers to begin with essential soil monitoring capabilities and expand to more comprehensive environmental sensing networks as resources permit. This approach reduces initial capital requirements by 50-70% compared to comprehensive system deployments, creating viable adoption pathways even for small-scale agricultural operations.

When analyzing rural implementation feasibility, several cost factors must be considered. Hardware components represent approximately 60% of total deployment costs, with metal oxide TFT sensors and associated circuitry comprising the largest portion at 35%. Infrastructure requirements, including power supply systems and connectivity solutions, account for 25% of implementation expenses, while installation and maintenance services represent the remaining 40%.

Scalability pathways for rural agricultural settings differ substantially from urban or industrial deployments. Roll-to-roll manufacturing techniques show particular promise, potentially reducing production costs by an additional 30-40% while enabling flexible form factors suitable for diverse agricultural environments. These manufacturing advances could bring the per-unit cost below $5 for basic sensing applications, a critical threshold for widespread rural adoption.

Energy efficiency represents another crucial scalability factor. Metal oxide TFTs operate at significantly lower power requirements than silicon-based alternatives, with typical power consumption of 10-50 μW during active sensing. This efficiency enables solar-powered implementations that eliminate the need for grid connectivity or frequent battery replacements, substantially reducing lifetime operational costs in remote agricultural settings.

Durability considerations directly impact long-term cost-effectiveness. Current-generation metal oxide TFTs demonstrate operational stability for 3-5 years in controlled environments, but rural agricultural conditions introduce additional stressors. Encapsulation technologies that protect against moisture, temperature fluctuations, and mechanical stress add approximately 15-20% to initial manufacturing costs but can extend functional lifetimes by 200-300%, dramatically improving return on investment metrics.

Modular design approaches offer the most promising pathway for cost-effective scaling. Systems architected with standardized interfaces allow for incremental deployment, enabling farmers to begin with essential soil monitoring capabilities and expand to more comprehensive environmental sensing networks as resources permit. This approach reduces initial capital requirements by 50-70% compared to comprehensive system deployments, creating viable adoption pathways even for small-scale agricultural operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!