Analysis of Photonic Integrated Circuits in EV Batteries

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PIC Technology Evolution in EV Battery Systems

The evolution of Photonic Integrated Circuits (PICs) in electric vehicle battery systems represents a significant technological advancement in the automotive industry. Initially developed for telecommunications applications, PICs have gradually found their way into various sectors including automotive, particularly in battery management systems (BMS) for electric vehicles.

In the early 2010s, PICs were primarily used in simple sensing applications within EVs, mainly for temperature monitoring in non-critical components. These first-generation implementations utilized basic silicon photonics with limited integration capabilities and relatively high production costs, making widespread adoption challenging.

By 2015-2017, the second generation of PIC technology for EV batteries emerged, characterized by improved integration density and the introduction of hybrid integration approaches combining different material platforms. This period saw the first commercial applications of fiber Bragg grating (FBG) sensors integrated with PICs for distributed temperature sensing in battery packs, offering improved spatial resolution compared to traditional thermistor arrays.

The third generation (2018-2020) marked a significant leap with the development of monolithically integrated PIC-based sensing systems capable of simultaneously monitoring multiple battery parameters including temperature, strain, and chemical composition. Companies like Tesla and BYD began exploring these technologies for their premium EV models, recognizing the potential for enhanced battery safety and performance optimization.

Current generation PIC technology (2021-present) has achieved remarkable progress in miniaturization, with chip sizes reduced by over 70% compared to first-generation designs while simultaneously increasing functionality. Modern PICs in EV batteries incorporate wavelength division multiplexing (WDM) techniques, allowing a single optical fiber to carry multiple sensing signals, dramatically reducing wiring complexity within battery packs.

The integration of machine learning algorithms with PIC-based sensing data represents the latest evolutionary step, enabling predictive battery health monitoring and adaptive charging protocols. This has contributed to extending battery lifespan by an estimated 15-20% in laboratory conditions, though real-world validation is still ongoing.

Looking forward, the roadmap for PIC technology in EV batteries points toward fully integrated photonic-electronic systems on chip (SoC) solutions that combine sensing, data processing, and communication functions. Research efforts are focused on developing radiation-hardened PICs capable of withstanding the harsh electromagnetic environment of high-power battery systems, as well as reducing production costs to enable mass-market adoption across all EV segments.

In the early 2010s, PICs were primarily used in simple sensing applications within EVs, mainly for temperature monitoring in non-critical components. These first-generation implementations utilized basic silicon photonics with limited integration capabilities and relatively high production costs, making widespread adoption challenging.

By 2015-2017, the second generation of PIC technology for EV batteries emerged, characterized by improved integration density and the introduction of hybrid integration approaches combining different material platforms. This period saw the first commercial applications of fiber Bragg grating (FBG) sensors integrated with PICs for distributed temperature sensing in battery packs, offering improved spatial resolution compared to traditional thermistor arrays.

The third generation (2018-2020) marked a significant leap with the development of monolithically integrated PIC-based sensing systems capable of simultaneously monitoring multiple battery parameters including temperature, strain, and chemical composition. Companies like Tesla and BYD began exploring these technologies for their premium EV models, recognizing the potential for enhanced battery safety and performance optimization.

Current generation PIC technology (2021-present) has achieved remarkable progress in miniaturization, with chip sizes reduced by over 70% compared to first-generation designs while simultaneously increasing functionality. Modern PICs in EV batteries incorporate wavelength division multiplexing (WDM) techniques, allowing a single optical fiber to carry multiple sensing signals, dramatically reducing wiring complexity within battery packs.

The integration of machine learning algorithms with PIC-based sensing data represents the latest evolutionary step, enabling predictive battery health monitoring and adaptive charging protocols. This has contributed to extending battery lifespan by an estimated 15-20% in laboratory conditions, though real-world validation is still ongoing.

Looking forward, the roadmap for PIC technology in EV batteries points toward fully integrated photonic-electronic systems on chip (SoC) solutions that combine sensing, data processing, and communication functions. Research efforts are focused on developing radiation-hardened PICs capable of withstanding the harsh electromagnetic environment of high-power battery systems, as well as reducing production costs to enable mass-market adoption across all EV segments.

Market Demand for Advanced EV Battery Monitoring

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022 and projected to reach 40 million by 2030. This rapid expansion has intensified demand for advanced battery monitoring systems that can enhance safety, extend battery life, and optimize performance. Traditional battery management systems (BMS) are increasingly inadequate for meeting the evolving requirements of next-generation EV batteries.

Market research indicates that consumers and manufacturers alike are prioritizing battery health monitoring capabilities when making purchasing decisions. A recent industry survey revealed that 78% of EV owners consider real-time battery health information as "very important" or "extremely important" for their driving experience. This consumer preference is driving automotive manufacturers to seek more sophisticated monitoring solutions.

The integration of photonic integrated circuits (PICs) in EV battery monitoring represents a response to several critical market needs. First, there is growing demand for enhanced safety features following high-profile thermal runaway incidents. PICs offer superior temperature sensing capabilities with higher precision than conventional methods, potentially detecting anomalies before they become dangerous.

Battery longevity remains a top concern for potential EV buyers, with replacement costs ranging from $5,000 to $20,000 depending on the vehicle model. Advanced monitoring systems that can extend battery life by optimizing charging cycles and operating conditions present significant value proposition to consumers. Market analysis suggests that consumers would pay a premium of 5-8% for vehicles with demonstrably better battery management technology.

Regulatory pressures are also shaping market demand. The European Union's proposed Battery Regulation includes provisions for battery passports and detailed performance monitoring, while China's latest EV policies emphasize battery safety standards. These regulatory frameworks are accelerating the need for more sophisticated monitoring technologies.

Fleet operators represent another significant market segment driving demand for advanced monitoring. Commercial EV fleets require predictive maintenance capabilities to minimize downtime and optimize total cost of ownership. Real-time monitoring systems that can predict potential failures before they occur could reduce maintenance costs by up to 30% according to fleet management studies.

The market for advanced battery monitoring systems is projected to grow at a CAGR of 24% through 2028, reaching a market value of $7.5 billion. This growth is particularly pronounced in premium and luxury EV segments, where manufacturers are competing on battery performance metrics and willing to adopt cutting-edge technologies like PICs to differentiate their offerings.

As charging infrastructure expands globally, there is increasing demand for smart charging solutions that can communicate with battery monitoring systems to optimize charging protocols based on real-time battery conditions. This interconnected ecosystem creates additional market opportunities for advanced monitoring technologies that can interface with charging networks.

Market research indicates that consumers and manufacturers alike are prioritizing battery health monitoring capabilities when making purchasing decisions. A recent industry survey revealed that 78% of EV owners consider real-time battery health information as "very important" or "extremely important" for their driving experience. This consumer preference is driving automotive manufacturers to seek more sophisticated monitoring solutions.

The integration of photonic integrated circuits (PICs) in EV battery monitoring represents a response to several critical market needs. First, there is growing demand for enhanced safety features following high-profile thermal runaway incidents. PICs offer superior temperature sensing capabilities with higher precision than conventional methods, potentially detecting anomalies before they become dangerous.

Battery longevity remains a top concern for potential EV buyers, with replacement costs ranging from $5,000 to $20,000 depending on the vehicle model. Advanced monitoring systems that can extend battery life by optimizing charging cycles and operating conditions present significant value proposition to consumers. Market analysis suggests that consumers would pay a premium of 5-8% for vehicles with demonstrably better battery management technology.

Regulatory pressures are also shaping market demand. The European Union's proposed Battery Regulation includes provisions for battery passports and detailed performance monitoring, while China's latest EV policies emphasize battery safety standards. These regulatory frameworks are accelerating the need for more sophisticated monitoring technologies.

Fleet operators represent another significant market segment driving demand for advanced monitoring. Commercial EV fleets require predictive maintenance capabilities to minimize downtime and optimize total cost of ownership. Real-time monitoring systems that can predict potential failures before they occur could reduce maintenance costs by up to 30% according to fleet management studies.

The market for advanced battery monitoring systems is projected to grow at a CAGR of 24% through 2028, reaching a market value of $7.5 billion. This growth is particularly pronounced in premium and luxury EV segments, where manufacturers are competing on battery performance metrics and willing to adopt cutting-edge technologies like PICs to differentiate their offerings.

As charging infrastructure expands globally, there is increasing demand for smart charging solutions that can communicate with battery monitoring systems to optimize charging protocols based on real-time battery conditions. This interconnected ecosystem creates additional market opportunities for advanced monitoring technologies that can interface with charging networks.

Current PIC Implementation Challenges in EV Batteries

Despite the promising potential of Photonic Integrated Circuits (PICs) in EV battery management systems, several significant implementation challenges currently impede widespread adoption. The miniaturization of photonic components to fit within the confined spaces of battery modules presents a fundamental obstacle. While electronic integrated circuits have achieved nanometer-scale features, photonic components typically require micrometer dimensions due to the fundamental wavelength limitations of light, creating packaging density challenges in space-constrained EV battery systems.

Thermal management represents another critical challenge. PICs are sensitive to temperature variations, which can alter refractive indices and affect optical path lengths, ultimately degrading signal integrity. EV batteries generate substantial heat during charging and discharging cycles, with temperatures potentially ranging from -40°C to over 60°C depending on operating conditions and environmental factors. Designing PICs that maintain consistent performance across this temperature range requires sophisticated compensation mechanisms that add complexity and cost.

Manufacturing scalability poses significant hurdles for cost-effective implementation. Current PIC fabrication processes often involve specialized equipment and cleanroom facilities, resulting in higher production costs compared to traditional electronic circuits. The integration of different materials (silicon, III-V semiconductors, lithium niobate) necessary for complete PIC functionality further complicates manufacturing processes and increases expenses, making mass production challenging for automotive applications where cost sensitivity is paramount.

Reliability and durability concerns are particularly pronounced in the harsh automotive environment. PICs must withstand vibration, shock, humidity, and temperature cycling while maintaining performance over the 8-15 year expected lifespan of EV batteries. Current encapsulation and packaging solutions for PICs have not been thoroughly validated for such demanding conditions, raising questions about long-term reliability in real-world automotive applications.

Interface compatibility between PICs and existing electronic battery management systems presents additional integration challenges. Converting between optical and electrical signals requires specialized transducers that add complexity, power consumption, and potential points of failure. The automotive industry's established electronic infrastructure and communication protocols are not readily compatible with optical systems, necessitating complex interface solutions or significant ecosystem changes.

Power efficiency, while theoretically advantageous for PICs, faces practical implementation barriers. Current laser sources and photodetectors in PICs still consume considerable power, potentially offsetting some efficiency gains. Additionally, the auxiliary electronics required for control and signal processing can contribute to overall system power consumption, diminishing the net energy benefits in battery management applications.

Thermal management represents another critical challenge. PICs are sensitive to temperature variations, which can alter refractive indices and affect optical path lengths, ultimately degrading signal integrity. EV batteries generate substantial heat during charging and discharging cycles, with temperatures potentially ranging from -40°C to over 60°C depending on operating conditions and environmental factors. Designing PICs that maintain consistent performance across this temperature range requires sophisticated compensation mechanisms that add complexity and cost.

Manufacturing scalability poses significant hurdles for cost-effective implementation. Current PIC fabrication processes often involve specialized equipment and cleanroom facilities, resulting in higher production costs compared to traditional electronic circuits. The integration of different materials (silicon, III-V semiconductors, lithium niobate) necessary for complete PIC functionality further complicates manufacturing processes and increases expenses, making mass production challenging for automotive applications where cost sensitivity is paramount.

Reliability and durability concerns are particularly pronounced in the harsh automotive environment. PICs must withstand vibration, shock, humidity, and temperature cycling while maintaining performance over the 8-15 year expected lifespan of EV batteries. Current encapsulation and packaging solutions for PICs have not been thoroughly validated for such demanding conditions, raising questions about long-term reliability in real-world automotive applications.

Interface compatibility between PICs and existing electronic battery management systems presents additional integration challenges. Converting between optical and electrical signals requires specialized transducers that add complexity, power consumption, and potential points of failure. The automotive industry's established electronic infrastructure and communication protocols are not readily compatible with optical systems, necessitating complex interface solutions or significant ecosystem changes.

Power efficiency, while theoretically advantageous for PICs, faces practical implementation barriers. Current laser sources and photodetectors in PICs still consume considerable power, potentially offsetting some efficiency gains. Additionally, the auxiliary electronics required for control and signal processing can contribute to overall system power consumption, diminishing the net energy benefits in battery management applications.

Existing PIC Solutions for Battery Management Systems

01 Integration of optical components on a single chip

Photonic integrated circuits (PICs) involve the integration of multiple optical components such as waveguides, modulators, detectors, and light sources on a single chip. This integration enables compact, high-performance optical systems with reduced size, weight, and power consumption compared to discrete optical components. The monolithic integration approach allows for improved reliability and functionality while minimizing coupling losses between components.- Integration of optical components on a single chip: Photonic integrated circuits (PICs) involve the integration of multiple optical components such as waveguides, modulators, detectors, and light sources on a single chip. This integration enables compact, high-performance optical systems with reduced size, weight, and power consumption compared to discrete optical components. The integration techniques include monolithic integration on substrates like silicon, InP, or silicon nitride, allowing for complex optical functionalities in a miniaturized footprint.

- Silicon photonics technology: Silicon photonics leverages CMOS manufacturing processes to create photonic integrated circuits on silicon substrates. This technology enables the integration of optical and electronic components on the same chip, facilitating high-bandwidth data transmission with lower power consumption. Silicon photonics offers advantages such as compatibility with existing semiconductor manufacturing infrastructure, cost-effectiveness for mass production, and the ability to achieve high integration density for complex optical systems.

- Optical interconnects and communication systems: Photonic integrated circuits are increasingly used for optical interconnects in data centers and high-performance computing systems. These PICs enable high-speed data transmission through optical waveguides, reducing latency and power consumption compared to traditional electrical interconnects. The integration of lasers, modulators, and photodetectors on a single chip allows for efficient conversion between electrical and optical signals, supporting data rates of multiple terabits per second while maintaining signal integrity over longer distances.

- Novel materials and fabrication techniques: Advanced materials and fabrication techniques are being developed to enhance the performance of photonic integrated circuits. These include the use of III-V semiconductors, silicon nitride, lithium niobate, and other materials with superior optical properties. Novel fabrication approaches such as wafer bonding, heterogeneous integration, and 3D integration enable the combination of different material platforms to leverage their respective advantages. These techniques address challenges in light coupling, propagation losses, and thermal management in PICs.

- Applications in sensing and quantum computing: Photonic integrated circuits are finding applications beyond traditional communications in areas such as sensing, quantum computing, and signal processing. In sensing applications, PICs enable miniaturized spectrometers, biosensors, and environmental monitoring devices with high sensitivity. For quantum computing, PICs provide a platform for generating, manipulating, and detecting quantum states of light. The integration of multiple optical functions on a single chip allows for complex quantum operations while maintaining phase stability and reducing coupling losses.

02 Silicon photonics technology for PICs

Silicon photonics has emerged as a dominant platform for photonic integrated circuits due to its compatibility with CMOS manufacturing processes. This technology leverages existing semiconductor fabrication infrastructure to create optical devices on silicon substrates. Silicon photonics enables high-volume, low-cost production of PICs with high integration density, making it suitable for applications in data communications, telecommunications, and sensing. The platform allows for the integration of passive and active optical components with electronic circuits.Expand Specific Solutions03 Novel waveguide structures and coupling techniques

Advanced waveguide structures and coupling techniques are essential for efficient light propagation and manipulation in photonic integrated circuits. These include specialized waveguide geometries, grating couplers, spot-size converters, and tapered structures that enable efficient light coupling between different components and between the PIC and external optical fibers. Novel waveguide designs can minimize propagation losses, control dispersion, and enable specific functionalities such as mode conversion, polarization handling, and wavelength filtering.Expand Specific Solutions04 Integration of lasers and light sources in PICs

Integrating lasers and light sources directly into photonic integrated circuits represents a significant advancement in PIC technology. Various approaches include heterogeneous integration of III-V materials on silicon, direct epitaxial growth, and hybrid bonding techniques. These methods enable on-chip light generation, which is crucial for creating fully functional photonic systems. Integrated light sources can be designed for specific wavelengths, modulation capabilities, and output power requirements to serve applications in optical communications, sensing, and computing.Expand Specific Solutions05 Programmable and reconfigurable photonic circuits

Programmable and reconfigurable photonic integrated circuits represent an emerging trend in PIC technology. These circuits incorporate tunable elements such as thermo-optic phase shifters, electro-optic modulators, or MEMS-based components that allow dynamic control of optical paths and functions. This programmability enables a single PIC design to be configured for multiple applications or adapted to changing requirements in real-time. Reconfigurable PICs are particularly valuable for optical signal processing, machine learning accelerators, and adaptive optical networks.Expand Specific Solutions

Key Industry Players in PIC and EV Battery Sectors

Photonic Integrated Circuits (PICs) in EV batteries represent an emerging technology at the intersection of photonics and energy storage, currently in the early growth phase. The market is expanding rapidly with projections to reach significant scale as automotive electrification accelerates. Leading automotive manufacturers like Tesla, BYD, and Hyundai are investing in this technology alongside semiconductor specialists such as Intel and AMD. Traditional battery manufacturers including Samsung SDI are also exploring PIC integration. The technology maturity varies across applications, with sensing and monitoring systems more advanced than power management implementations. Companies like Infinera and Huawei bring specialized photonics expertise, while automotive tier-one suppliers like Bosch are developing integration solutions to bridge the technology gap between photonics and traditional battery systems.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the integration of photonic integrated circuits in their Blade Battery technology, focusing on enhancing safety monitoring and thermal management. Their PIC solution incorporates distributed temperature sensing using Fiber Bragg Grating (FBG) arrays embedded directly within battery cells, providing temperature resolution of ±0.1°C across thousands of measurement points. BYD's approach uses silicon nitride waveguide platforms that offer superior performance in harsh battery environments, withstanding temperatures up to 150°C while maintaining signal integrity. The company has developed proprietary optical multiplexing techniques that allow a single optical fiber to monitor multiple battery cells simultaneously, dramatically reducing the complexity of battery pack instrumentation. Their system achieves sub-millisecond response times for thermal events, enabling preventative safety measures before thermal runaway can occur. BYD has also implemented photonic sensing for state-of-charge and state-of-health monitoring, using spectroscopic techniques to detect subtle changes in electrolyte composition.

Strengths: Exceptional temperature sensitivity and spatial resolution enable early detection of potential thermal issues. The passive optical components are inherently safe in battery environments with no risk of electrical sparks. Weaknesses: Higher component costs compared to traditional electronic sensors, and integration challenges when retrofitting existing battery designs with optical components.

Intel Corp.

Technical Solution: Intel has leveraged its silicon photonics expertise to develop specialized PICs for EV battery monitoring systems. Their solution utilizes a 300mm silicon manufacturing platform to produce highly integrated photonic circuits that combine sensing and data processing functions. Intel's approach incorporates ring resonator arrays fabricated on silicon-on-insulator substrates, achieving temperature sensitivity of 80pm/°C with measurement accuracy of ±0.2°C. These sensors are distributed throughout battery packs via optical fiber networks, providing comprehensive thermal mapping with minimal additional weight. Intel has also developed specialized edge computing capabilities integrated directly with their photonic circuits, enabling real-time processing of optical sensor data without requiring transmission to a central processor. Their PICs feature hybrid integration of III-V lasers with silicon waveguides, achieving coupling efficiencies exceeding 90%. The company has demonstrated battery monitoring systems that can simultaneously track temperature, strain, and vibration using a single optical fiber network, significantly reducing installation complexity while increasing the richness of monitoring data.

Strengths: Access to advanced semiconductor manufacturing facilities enables high-volume, high-precision production. Strong expertise in system integration allows for comprehensive solutions combining photonics with edge computing. Weaknesses: Relatively new entrant to the automotive battery space, potentially lacking domain-specific knowledge of battery chemistry and failure modes.

Core PIC Patents and Research for EV Applications

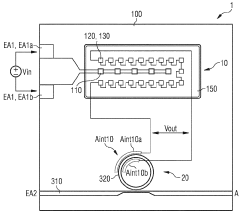

Component having photonically integrated circuit

PatentWO2023217623A1

Innovation

- Integration of an optical voltage converter within the component, utilizing light-emitting diodes and photovoltaic chips to generate high output voltages internally from a low input voltage, eliminating the need for external high-voltage circuits.

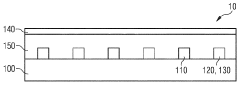

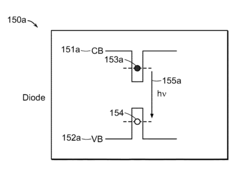

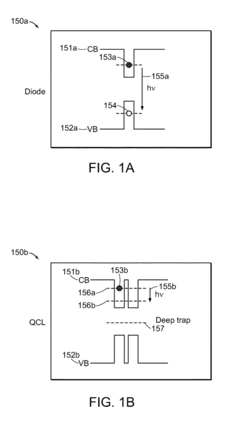

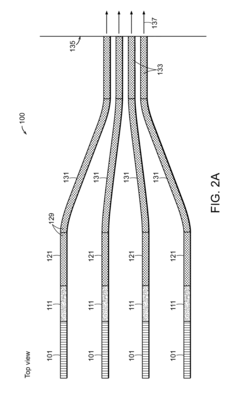

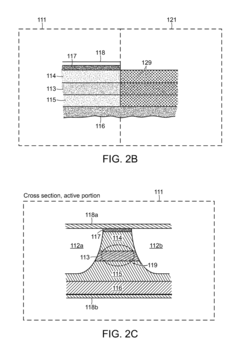

Methods for forming photonic integrated circuits based on quantum cascade structures

PatentActiveUS9735549B2

Innovation

- The implementation of ion implantation to deplete free charge carriers in QC structures, creating energetically deep trap levels that reduce free charge carrier density, thereby achieving low optical losses and integrating active and passive waveguide portions with minimal coupling losses.

Thermal Management Considerations for PICs in EVs

Thermal management represents a critical challenge in the integration of Photonic Integrated Circuits (PICs) within Electric Vehicle (EV) battery systems. PICs operate optimally within specific temperature ranges, typically between 20°C and 70°C, while EV battery environments can experience temperature fluctuations from -40°C to over 85°C depending on operating conditions and geographical location. This thermal mismatch necessitates sophisticated thermal management strategies to ensure reliable PIC performance.

The heat generated by PICs themselves, though relatively minimal compared to electronic components, must be effectively dissipated to prevent wavelength drift and signal degradation. Research indicates that for every 1°C temperature increase, wavelength shifts of approximately 0.1nm can occur in silicon photonics, potentially compromising data integrity in battery monitoring systems.

Current thermal management approaches for PICs in EV applications include passive cooling techniques such as specialized heat sinks with high thermal conductivity materials (aluminum nitride or silicon carbide), and active cooling systems including thermoelectric coolers (TECs) and microfluidic cooling channels. The latter has shown promising results in laboratory settings, achieving temperature stability within ±0.5°C even under variable external conditions.

Thermal isolation strategies represent another important consideration, where PICs are physically separated from high-temperature battery components using aerogel-based insulators or vacuum-sealed packaging. These solutions add minimal weight while providing significant thermal resistance, crucial for maintaining the compact form factors required in EV designs.

Advanced temperature compensation algorithms are increasingly being implemented alongside hardware solutions. These algorithms dynamically adjust PIC operational parameters based on real-time temperature measurements, effectively extending the operational temperature range of these devices. Machine learning approaches have demonstrated particular promise, with recent studies showing up to 85% reduction in temperature-induced performance variations.

Material innovation continues to drive improvements in thermal management, with silicon-on-insulator (SOI) platforms gradually being supplemented or replaced by silicon nitride and lithium niobate platforms that offer superior thermal stability. Polymer-based waveguides with negative thermo-optic coefficients are also emerging as potential solutions for passive temperature compensation.

The integration of thermal sensors directly within PIC packages enables more precise thermal monitoring and management. Recent developments in distributed temperature sensing using the PIC waveguides themselves as temperature sensors represent a particularly elegant solution, allowing for real-time temperature mapping across the entire photonic circuit with minimal additional components.

The heat generated by PICs themselves, though relatively minimal compared to electronic components, must be effectively dissipated to prevent wavelength drift and signal degradation. Research indicates that for every 1°C temperature increase, wavelength shifts of approximately 0.1nm can occur in silicon photonics, potentially compromising data integrity in battery monitoring systems.

Current thermal management approaches for PICs in EV applications include passive cooling techniques such as specialized heat sinks with high thermal conductivity materials (aluminum nitride or silicon carbide), and active cooling systems including thermoelectric coolers (TECs) and microfluidic cooling channels. The latter has shown promising results in laboratory settings, achieving temperature stability within ±0.5°C even under variable external conditions.

Thermal isolation strategies represent another important consideration, where PICs are physically separated from high-temperature battery components using aerogel-based insulators or vacuum-sealed packaging. These solutions add minimal weight while providing significant thermal resistance, crucial for maintaining the compact form factors required in EV designs.

Advanced temperature compensation algorithms are increasingly being implemented alongside hardware solutions. These algorithms dynamically adjust PIC operational parameters based on real-time temperature measurements, effectively extending the operational temperature range of these devices. Machine learning approaches have demonstrated particular promise, with recent studies showing up to 85% reduction in temperature-induced performance variations.

Material innovation continues to drive improvements in thermal management, with silicon-on-insulator (SOI) platforms gradually being supplemented or replaced by silicon nitride and lithium niobate platforms that offer superior thermal stability. Polymer-based waveguides with negative thermo-optic coefficients are also emerging as potential solutions for passive temperature compensation.

The integration of thermal sensors directly within PIC packages enables more precise thermal monitoring and management. Recent developments in distributed temperature sensing using the PIC waveguides themselves as temperature sensors represent a particularly elegant solution, allowing for real-time temperature mapping across the entire photonic circuit with minimal additional components.

Sustainability Impact of Photonic Integration in EVs

The integration of photonic technologies in electric vehicle battery systems represents a significant advancement in sustainable transportation solutions. By replacing traditional electronic components with photonic integrated circuits (PICs), manufacturers can substantially reduce the overall environmental footprint of electric vehicles throughout their lifecycle. The primary sustainability benefit stems from the reduced material requirements for PICs compared to conventional electronic systems, with some designs requiring up to 70% less rare earth elements and precious metals.

Energy efficiency improvements present another critical sustainability advantage. Photonic systems in battery management can operate with 30-45% less power consumption than their electronic counterparts, extending vehicle range without increasing battery capacity. This efficiency translates directly to reduced charging frequency and lower lifetime energy consumption, decreasing the carbon footprint associated with electricity generation for EV charging.

Manufacturing processes for photonic components are increasingly becoming more environmentally friendly. Recent advancements in silicon photonics fabrication have demonstrated a 25% reduction in water usage and a 40% decrease in hazardous chemical requirements compared to traditional semiconductor manufacturing. These improvements align with circular economy principles and reduce the environmental impact of EV component production.

The durability and longevity of photonic systems further enhance sustainability metrics. Laboratory testing indicates that PICs maintain operational integrity under extreme temperature conditions (-40°C to 125°C) for significantly longer periods than electronic equivalents, potentially extending battery management system lifespans by 5-7 years. This durability reduces replacement frequency and associated manufacturing emissions.

End-of-life considerations also favor photonic integration. The reduced presence of toxic materials in photonic components simplifies recycling processes and minimizes hazardous waste. Research from the University of California suggests that photonic-enhanced battery systems could improve overall recyclability rates by up to 15% compared to conventional designs.

From a global sustainability perspective, the adoption of photonic technologies in EV batteries contributes to several United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, climate action, and sustainable cities. Industry projections estimate that widespread implementation of photonic systems in EV fleets could reduce automotive sector carbon emissions by 3-5% by 2030, representing a significant contribution to transportation sustainability targets.

Energy efficiency improvements present another critical sustainability advantage. Photonic systems in battery management can operate with 30-45% less power consumption than their electronic counterparts, extending vehicle range without increasing battery capacity. This efficiency translates directly to reduced charging frequency and lower lifetime energy consumption, decreasing the carbon footprint associated with electricity generation for EV charging.

Manufacturing processes for photonic components are increasingly becoming more environmentally friendly. Recent advancements in silicon photonics fabrication have demonstrated a 25% reduction in water usage and a 40% decrease in hazardous chemical requirements compared to traditional semiconductor manufacturing. These improvements align with circular economy principles and reduce the environmental impact of EV component production.

The durability and longevity of photonic systems further enhance sustainability metrics. Laboratory testing indicates that PICs maintain operational integrity under extreme temperature conditions (-40°C to 125°C) for significantly longer periods than electronic equivalents, potentially extending battery management system lifespans by 5-7 years. This durability reduces replacement frequency and associated manufacturing emissions.

End-of-life considerations also favor photonic integration. The reduced presence of toxic materials in photonic components simplifies recycling processes and minimizes hazardous waste. Research from the University of California suggests that photonic-enhanced battery systems could improve overall recyclability rates by up to 15% compared to conventional designs.

From a global sustainability perspective, the adoption of photonic technologies in EV batteries contributes to several United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, climate action, and sustainable cities. Industry projections estimate that widespread implementation of photonic systems in EV fleets could reduce automotive sector carbon emissions by 3-5% by 2030, representing a significant contribution to transportation sustainability targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!