What Are the Endurance Tests for Photonic Integrated Circuits

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PIC Endurance Testing Background and Objectives

Photonic Integrated Circuits (PICs) have emerged as a transformative technology in the field of optoelectronics over the past two decades. These miniaturized optical systems integrate multiple photonic functions on a single chip, similar to how electronic integrated circuits revolutionized electronics. The evolution of PICs has been driven by increasing demands for higher bandwidth, lower power consumption, and more compact solutions in telecommunications, data centers, sensing, and biomedical applications.

Endurance testing for PICs represents a critical aspect of their development and commercialization process. Historically, reliability testing methodologies for PICs have evolved from those used in electronic integrated circuits and discrete optical components, gradually adapting to address the unique challenges posed by integrated photonics. The convergence of optical and electronic functionalities on a single platform necessitates comprehensive testing protocols that evaluate both optical and electrical performance over extended periods.

The primary objective of PIC endurance testing is to verify the long-term reliability and stability of these devices under various operational conditions. This includes assessing performance degradation mechanisms, identifying failure modes, and establishing the mean time between failures (MTBF) for different PIC architectures and materials. Such testing aims to ensure that PICs can maintain their optical and electrical specifications throughout their intended service life, which may span decades in telecommunications infrastructure applications.

Current technological trends in PIC development, including the integration of new materials like silicon nitride, lithium niobate on insulator (LNOI), and III-V semiconductors, have introduced additional complexities to endurance testing requirements. Each material system presents unique degradation mechanisms that must be thoroughly characterized to ensure reliable operation in field deployments.

The industry is witnessing a shift toward standardized testing protocols for PICs, driven by collaborative efforts between academic institutions, industry consortia, and standards organizations. These emerging standards aim to establish uniform methodologies for evaluating PIC reliability across different manufacturing platforms and application domains, facilitating technology adoption and market growth.

Technical goals for PIC endurance testing include developing accelerated aging methodologies that can accurately predict device lifetimes in a fraction of the actual service period, creating non-destructive testing techniques that preserve device functionality, and implementing in-situ monitoring capabilities that enable real-time assessment of performance parameters during stress testing.

As PICs continue to penetrate critical applications in quantum computing, autonomous vehicles, and medical diagnostics, the importance of robust endurance testing frameworks becomes increasingly paramount. The evolution of these testing methodologies will play a decisive role in determining the pace of PIC adoption across emerging application domains and their ultimate commercial success.

Endurance testing for PICs represents a critical aspect of their development and commercialization process. Historically, reliability testing methodologies for PICs have evolved from those used in electronic integrated circuits and discrete optical components, gradually adapting to address the unique challenges posed by integrated photonics. The convergence of optical and electronic functionalities on a single platform necessitates comprehensive testing protocols that evaluate both optical and electrical performance over extended periods.

The primary objective of PIC endurance testing is to verify the long-term reliability and stability of these devices under various operational conditions. This includes assessing performance degradation mechanisms, identifying failure modes, and establishing the mean time between failures (MTBF) for different PIC architectures and materials. Such testing aims to ensure that PICs can maintain their optical and electrical specifications throughout their intended service life, which may span decades in telecommunications infrastructure applications.

Current technological trends in PIC development, including the integration of new materials like silicon nitride, lithium niobate on insulator (LNOI), and III-V semiconductors, have introduced additional complexities to endurance testing requirements. Each material system presents unique degradation mechanisms that must be thoroughly characterized to ensure reliable operation in field deployments.

The industry is witnessing a shift toward standardized testing protocols for PICs, driven by collaborative efforts between academic institutions, industry consortia, and standards organizations. These emerging standards aim to establish uniform methodologies for evaluating PIC reliability across different manufacturing platforms and application domains, facilitating technology adoption and market growth.

Technical goals for PIC endurance testing include developing accelerated aging methodologies that can accurately predict device lifetimes in a fraction of the actual service period, creating non-destructive testing techniques that preserve device functionality, and implementing in-situ monitoring capabilities that enable real-time assessment of performance parameters during stress testing.

As PICs continue to penetrate critical applications in quantum computing, autonomous vehicles, and medical diagnostics, the importance of robust endurance testing frameworks becomes increasingly paramount. The evolution of these testing methodologies will play a decisive role in determining the pace of PIC adoption across emerging application domains and their ultimate commercial success.

Market Demand Analysis for Reliable Photonic ICs

The global market for reliable Photonic Integrated Circuits (PICs) is experiencing robust growth, driven primarily by the increasing demand for high-speed data transmission and processing capabilities. Current market valuations indicate that the PIC market is projected to reach $3.2 billion by 2027, with a compound annual growth rate of 23.4% from 2022. This significant growth trajectory underscores the critical importance of reliability in PIC technologies.

Telecommunications and data centers represent the largest market segments for reliable PICs, collectively accounting for approximately 65% of the total market share. The exponential increase in data traffic, accelerated by cloud computing, 5G deployment, and the Internet of Things (IoT), has created an urgent need for PICs that can withstand continuous operation under varying environmental conditions without performance degradation.

Industry surveys reveal that reliability ranks as the top concern among 78% of potential PIC adopters, surpassing cost considerations. This prioritization reflects the high operational costs associated with system failures in critical infrastructure. For instance, data center downtime costs average $9,000 per minute, making the reliability of photonic components a paramount concern for operators.

The automotive and aerospace sectors are emerging as significant growth areas for reliable PICs, with projected market expansion of 31% annually through 2026. These industries require components that can function reliably under extreme temperature variations, mechanical stress, and radiation exposure. Particularly in autonomous vehicles, where sensor fusion and LiDAR systems increasingly rely on photonic technologies, reliability requirements are exceptionally stringent.

Medical device manufacturers represent another rapidly growing market segment, with 27% annual growth in PIC adoption. These applications demand components that maintain performance integrity over extended periods, often in challenging biological environments. The consequences of failure in medical applications can be severe, further emphasizing the critical nature of reliability testing.

Geographically, North America currently leads the market demand for reliable PICs at 38% of global consumption, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 28% annually, driven by expanding telecommunications infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Market analysis indicates a significant price premium for PICs with demonstrated reliability credentials. Products with comprehensive endurance test certifications command 40-60% higher prices compared to standard alternatives, highlighting the economic value of reliability in this sector. This premium pricing structure provides strong financial incentives for manufacturers to invest in robust endurance testing methodologies and facilities.

Telecommunications and data centers represent the largest market segments for reliable PICs, collectively accounting for approximately 65% of the total market share. The exponential increase in data traffic, accelerated by cloud computing, 5G deployment, and the Internet of Things (IoT), has created an urgent need for PICs that can withstand continuous operation under varying environmental conditions without performance degradation.

Industry surveys reveal that reliability ranks as the top concern among 78% of potential PIC adopters, surpassing cost considerations. This prioritization reflects the high operational costs associated with system failures in critical infrastructure. For instance, data center downtime costs average $9,000 per minute, making the reliability of photonic components a paramount concern for operators.

The automotive and aerospace sectors are emerging as significant growth areas for reliable PICs, with projected market expansion of 31% annually through 2026. These industries require components that can function reliably under extreme temperature variations, mechanical stress, and radiation exposure. Particularly in autonomous vehicles, where sensor fusion and LiDAR systems increasingly rely on photonic technologies, reliability requirements are exceptionally stringent.

Medical device manufacturers represent another rapidly growing market segment, with 27% annual growth in PIC adoption. These applications demand components that maintain performance integrity over extended periods, often in challenging biological environments. The consequences of failure in medical applications can be severe, further emphasizing the critical nature of reliability testing.

Geographically, North America currently leads the market demand for reliable PICs at 38% of global consumption, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 28% annually, driven by expanding telecommunications infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Market analysis indicates a significant price premium for PICs with demonstrated reliability credentials. Products with comprehensive endurance test certifications command 40-60% higher prices compared to standard alternatives, highlighting the economic value of reliability in this sector. This premium pricing structure provides strong financial incentives for manufacturers to invest in robust endurance testing methodologies and facilities.

Current PIC Reliability Testing Challenges

Despite significant advancements in Photonic Integrated Circuit (PIC) technology, reliability testing remains one of the most challenging aspects of PIC development and commercialization. Current testing methodologies face several critical limitations that impede the industry's ability to ensure consistent performance and longevity of these complex devices.

The heterogeneous nature of PICs presents a fundamental challenge for standardized testing protocols. Unlike electronic integrated circuits, PICs incorporate multiple material systems and component types—including waveguides, modulators, photodetectors, and lasers—each requiring different testing parameters and conditions. This diversity makes it difficult to establish unified testing frameworks that can comprehensively evaluate all aspects of PIC reliability.

Temperature sensitivity poses another significant challenge in PIC reliability testing. Photonic components often exhibit performance variations across temperature ranges, necessitating complex environmental control during testing. Current temperature cycling tests struggle to accurately simulate real-world conditions while maintaining precise optical alignment and measurement accuracy, particularly for extended durations required for endurance evaluation.

Optical coupling stability during long-term testing represents a persistent technical hurdle. Maintaining consistent optical input/output conditions throughout extended reliability tests is problematic, as even minor alignment shifts can significantly impact measurement results. This creates uncertainty in distinguishing between actual device degradation and testing system instability.

The industry also faces challenges with accelerated aging methodologies for PICs. While electronic components have well-established acceleration factors for lifetime prediction, photonic components often exhibit complex degradation mechanisms that don't follow simple Arrhenius models. This makes it difficult to correlate accelerated test results with actual field reliability.

Data interpretation presents another substantial challenge. The multi-parameter nature of PIC performance (including optical power, wavelength stability, modulation efficiency, and crosstalk) creates complex failure modes that are difficult to characterize and predict. Current analytical frameworks struggle to process this multi-dimensional data effectively.

Test equipment limitations further complicate reliability assessment. Most commercially available photonic test systems are designed for functional verification rather than long-term reliability monitoring. They often lack the stability, automation capabilities, and environmental control required for comprehensive endurance testing.

Finally, the absence of industry-wide standardization creates significant barriers to progress. Unlike the electronic semiconductor industry with its established JEDEC standards, the photonic industry lacks consensus on reliability testing methodologies, failure criteria, and qualification procedures. This fragmentation leads to inconsistent approaches across manufacturers and hampers the establishment of reliable supply chains for PIC technologies.

The heterogeneous nature of PICs presents a fundamental challenge for standardized testing protocols. Unlike electronic integrated circuits, PICs incorporate multiple material systems and component types—including waveguides, modulators, photodetectors, and lasers—each requiring different testing parameters and conditions. This diversity makes it difficult to establish unified testing frameworks that can comprehensively evaluate all aspects of PIC reliability.

Temperature sensitivity poses another significant challenge in PIC reliability testing. Photonic components often exhibit performance variations across temperature ranges, necessitating complex environmental control during testing. Current temperature cycling tests struggle to accurately simulate real-world conditions while maintaining precise optical alignment and measurement accuracy, particularly for extended durations required for endurance evaluation.

Optical coupling stability during long-term testing represents a persistent technical hurdle. Maintaining consistent optical input/output conditions throughout extended reliability tests is problematic, as even minor alignment shifts can significantly impact measurement results. This creates uncertainty in distinguishing between actual device degradation and testing system instability.

The industry also faces challenges with accelerated aging methodologies for PICs. While electronic components have well-established acceleration factors for lifetime prediction, photonic components often exhibit complex degradation mechanisms that don't follow simple Arrhenius models. This makes it difficult to correlate accelerated test results with actual field reliability.

Data interpretation presents another substantial challenge. The multi-parameter nature of PIC performance (including optical power, wavelength stability, modulation efficiency, and crosstalk) creates complex failure modes that are difficult to characterize and predict. Current analytical frameworks struggle to process this multi-dimensional data effectively.

Test equipment limitations further complicate reliability assessment. Most commercially available photonic test systems are designed for functional verification rather than long-term reliability monitoring. They often lack the stability, automation capabilities, and environmental control required for comprehensive endurance testing.

Finally, the absence of industry-wide standardization creates significant barriers to progress. Unlike the electronic semiconductor industry with its established JEDEC standards, the photonic industry lacks consensus on reliability testing methodologies, failure criteria, and qualification procedures. This fragmentation leads to inconsistent approaches across manufacturers and hampers the establishment of reliable supply chains for PIC technologies.

Established PIC Endurance Testing Protocols

01 Thermal management for PIC endurance

Effective thermal management is crucial for ensuring the long-term endurance of Photonic Integrated Circuits (PICs). Heat dissipation techniques, including specialized heat sinks, thermal vias, and advanced cooling systems, help maintain optimal operating temperatures and prevent thermal degradation of photonic components. These thermal management solutions extend the operational lifetime of PICs by reducing thermal stress and preventing performance deterioration under high-power conditions.- Thermal management for PIC endurance: Effective thermal management is crucial for ensuring the long-term endurance of Photonic Integrated Circuits (PICs). Various cooling techniques and heat dissipation methods are employed to maintain optimal operating temperatures and prevent thermal degradation of photonic components. These include specialized heat sinks, thermal interface materials, and active cooling systems that help extend the operational lifetime of PICs by reducing thermal stress and preventing performance degradation under high-power conditions.

- Packaging solutions for environmental protection: Advanced packaging technologies play a vital role in protecting PICs from environmental factors that could compromise their endurance. Hermetic sealing, moisture-resistant encapsulation, and specialized packaging materials shield sensitive photonic components from humidity, dust, and other contaminants. These packaging solutions incorporate robust interfaces between optical and electrical domains while maintaining mechanical stability, thereby significantly enhancing the reliability and operational lifetime of photonic integrated circuits in various deployment environments.

- Material selection for enhanced durability: The choice of materials significantly impacts the endurance characteristics of photonic integrated circuits. Silicon, silicon nitride, indium phosphide, and other specialized materials are selected based on their resistance to degradation mechanisms such as photo-oxidation, mechanical stress, and thermal cycling. Novel material compositions and structures are developed to withstand harsh operating conditions while maintaining optical performance over extended periods, resulting in PICs with superior reliability and longer service life.

- Redundancy and fault-tolerance architectures: Implementing redundancy and fault-tolerance in photonic integrated circuit design significantly enhances their operational endurance. These architectures incorporate backup optical pathways, self-healing mechanisms, and error correction capabilities that allow PICs to continue functioning even when individual components fail. Advanced monitoring systems detect performance degradation and automatically reroute optical signals through alternative paths, ensuring continuous operation and extending the effective lifetime of the integrated photonic system.

- Testing and qualification methodologies: Comprehensive testing and qualification methodologies are essential for predicting and improving the endurance of photonic integrated circuits. Accelerated aging tests, environmental stress screening, and reliability modeling help identify potential failure modes and design weaknesses. These methodologies include thermal cycling, humidity testing, mechanical shock testing, and long-term optical performance monitoring to ensure that PICs can withstand expected operational conditions throughout their intended service life, providing valuable data for continuous improvement of endurance characteristics.

02 Protective packaging and encapsulation methods

Specialized packaging and encapsulation techniques significantly enhance the endurance of Photonic Integrated Circuits by protecting sensitive optical components from environmental factors. Hermetic sealing, moisture-resistant materials, and specialized encapsulants shield PICs from humidity, dust, and chemical contaminants. Advanced packaging designs also incorporate stress-relief mechanisms to prevent mechanical damage during thermal cycling and physical stress, thereby extending the operational lifetime and reliability of the circuits in various deployment environments.Expand Specific Solutions03 Radiation-hardened PIC designs

Radiation-hardened designs for Photonic Integrated Circuits incorporate specialized materials and circuit architectures that withstand exposure to ionizing radiation. These designs include radiation-resistant waveguides, shielding layers, and redundant optical pathways that maintain signal integrity even when exposed to harsh radiation environments. Such radiation-hardened PICs are particularly important for space applications, nuclear facilities, and other high-radiation environments where conventional circuits would rapidly degrade.Expand Specific Solutions04 Self-healing and redundancy mechanisms

Self-healing and redundancy mechanisms in Photonic Integrated Circuits significantly enhance their endurance by enabling continued operation despite component failures. These designs incorporate backup optical pathways, reconfigurable optical elements, and fault detection systems that can automatically reroute signals around damaged areas. Some advanced PICs also feature self-calibration capabilities that compensate for performance drift over time, maintaining optimal operation throughout the circuit's extended lifetime.Expand Specific Solutions05 Material selection for enhanced durability

The selection of highly durable materials is fundamental to extending the endurance of Photonic Integrated Circuits. Advanced semiconductor compounds, specialized glass formulations, and novel polymer materials with superior resistance to environmental degradation significantly enhance PIC longevity. These materials maintain their optical and mechanical properties over extended periods, even when subjected to thermal cycling, humidity, and mechanical stress. The integration of these materials with conventional silicon platforms creates hybrid PICs with exceptional durability while maintaining compatibility with existing manufacturing processes.Expand Specific Solutions

Key Industry Players in PIC Testing Equipment

The photonic integrated circuits (PICs) endurance testing market is in a growth phase, characterized by increasing demand for reliable testing solutions as PICs gain adoption in telecommunications, data centers, and sensing applications. The market is projected to expand significantly with the rising deployment of optical communication networks globally. Technologically, endurance testing capabilities vary across industry players, with established companies like EXFO, Cisco, and Nokia Solutions & Networks offering comprehensive test solutions for commercial applications. Research institutions including University of Rochester, CEA, and University of Southampton are advancing fundamental testing methodologies. Emerging specialists such as POET Technologies, PsiQuantum, and Photonic Inc. are developing innovative testing approaches specific to quantum and silicon photonics applications, while semiconductor manufacturers like GlobalFoundries and SMIC-Beijing are integrating PIC testing into their broader semiconductor validation frameworks.

EXFO, Inc.

Technical Solution: EXFO has pioneered advanced endurance testing solutions specifically designed for photonic integrated circuits, focusing on automated characterization and reliability assessment. Their CTP10 Component Testing Platform provides comprehensive endurance testing capabilities including thermal cycling (-40°C to +85°C), damp heat exposure (85°C/85% RH), and mechanical shock/vibration analysis. EXFO's testing methodology incorporates real-time monitoring of critical PIC parameters such as insertion loss, polarization-dependent loss, and wavelength stability throughout extended test periods (typically 2000+ hours). Their proprietary LTB-8 platform enables simultaneous testing of multiple PICs under varying environmental conditions, with automated data collection and analysis to identify performance degradation patterns. EXFO's testing protocols comply with Telcordia GR-468 and MIL-STD-883 standards, ensuring industry-accepted reliability metrics. The company has developed specialized fiber-to-chip coupling fixtures that maintain alignment stability during extended endurance tests, addressing a critical challenge in PIC testing.

Strengths: Industry-leading test equipment specifically designed for photonic components with high precision measurement capabilities; extensive experience in standardized testing protocols. Weakness: Their solutions may require significant capital investment, potentially limiting accessibility for smaller PIC developers.

Cisco Technology, Inc.

Technical Solution: Cisco has developed a comprehensive endurance testing framework for photonic integrated circuits used in their high-speed networking equipment. Their approach includes extended high-temperature operating life (HTOL) testing at 85°C for 5000+ hours to verify long-term reliability of silicon photonics transceivers. Cisco employs automated test systems that continuously monitor key parameters including optical output power stability, wavelength drift, bit error rate (BER), and receiver sensitivity throughout the endurance testing period. Their methodology incorporates temperature cycling tests (-5°C to +70°C) with 15-minute dwell times and 1000+ cycles to evaluate thermal stress resistance. Cisco has implemented accelerated stress testing protocols that combine elevated temperature, humidity (85°C/85% RH), and bias current to identify potential failure mechanisms. Their testing includes mechanical shock and vibration testing according to GR-63-CORE standards to ensure robustness in data center environments. Cisco's endurance testing has demonstrated silicon photonic devices maintaining <0.5dB power variation and <0.1nm wavelength stability over thousands of hours of operation.

Strengths: Extensive real-world deployment experience informing practical endurance requirements; comprehensive testing infrastructure capable of evaluating complete transceiver systems rather than just individual components. Weakness: Testing methodologies may be optimized specifically for data center applications and might not fully address requirements for other PIC deployment scenarios.

Critical Test Parameters and Failure Mechanisms

Photonic integrated circuit and characterization method

PatentPendingUS20230324311A1

Innovation

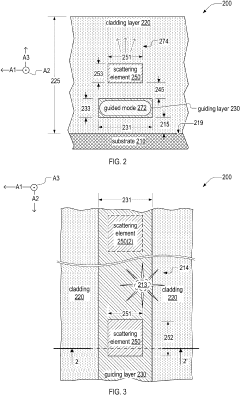

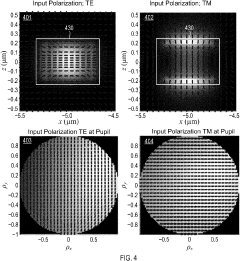

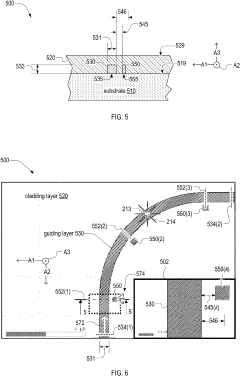

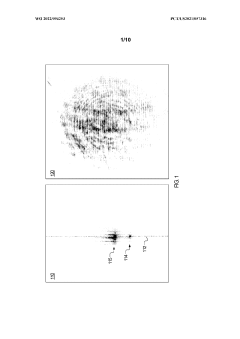

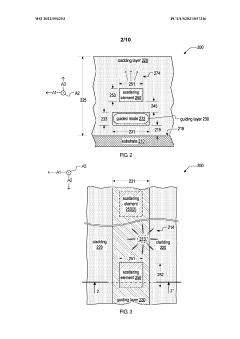

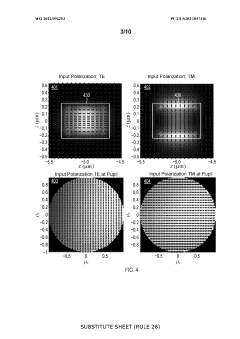

- The implementation of subwavelength photonic test points that scatter light with a known polarization state, allowing for remote polarization testing using a microscope and polarimetric optics, which are designed into the circuit during the foundry process and scatter light in a manner similar to a dipole antenna, enabling precise measurement of polarization and power within the waveguide.

Photonic integrated circuit and characterization method

PatentWO2022094253A1

Innovation

- The use of subwavelength photonic test points, such as small scatterers designed into the circuit, which scatter light with a known polarization state, allowing for remote polarization testing using a microscope and polarimetric optics, enabling precise and quantitative measurement of polarization states without depleting the available light or requiring extensive chip area.

Standards and Certification Requirements

The standardization landscape for Photonic Integrated Circuits (PICs) endurance testing is still evolving, with several key organizations leading the development of comprehensive certification frameworks. The International Electrotechnical Commission (IEC) has established the IEC 62149 series specifically addressing optical amplifiers and transceivers, which includes relevant testing methodologies applicable to PICs. Similarly, Telcordia GR-468 provides reliability assurance criteria that have been adapted for photonic components.

The IEEE P2432 working group is currently developing standards specifically for silicon photonics, including endurance test protocols that address the unique challenges of integrated photonic platforms. These standards aim to establish uniform qualification procedures that ensure consistent performance evaluation across different manufacturers and applications.

For automotive applications, the AEC-Q100 qualification requirements have been extended to cover photonic components, with specific temperature cycling and operational lifetime requirements that exceed those of standard telecommunications applications. Medical device implementations of PICs must comply with ISO 13485 quality management systems, which mandate rigorous reliability testing and traceability documentation.

The Photonics Industry Consortium has published recommended test procedures that are gaining industry acceptance, particularly for emerging applications in quantum computing and sensing. These procedures include accelerated aging tests under various environmental conditions, with standardized reporting formats to facilitate comparison between different PIC technologies.

Certification requirements typically include demonstration of compliance with Telcordia GR-468 or equivalent standards, with documentation of test conditions, sample sizes, and statistical analysis of results. For space applications, NASA and ESA have developed specialized certification protocols that include radiation hardness testing and extended temperature range operation verification.

The lack of fully harmonized global standards remains a challenge for PIC manufacturers, often requiring multiple certifications to address different market requirements. Industry leaders are advocating for the development of unified testing frameworks through organizations like the International Organization for Standardization (ISO) and the Photonics Industry Association.

Emerging certification requirements are beginning to address not only reliability but also interoperability between different PIC platforms, with standardized optical interfaces and performance metrics. This trend reflects the industry's movement toward more modular and interchangeable photonic components, requiring standardized endurance testing methodologies that can verify long-term compatibility between interconnected systems.

The IEEE P2432 working group is currently developing standards specifically for silicon photonics, including endurance test protocols that address the unique challenges of integrated photonic platforms. These standards aim to establish uniform qualification procedures that ensure consistent performance evaluation across different manufacturers and applications.

For automotive applications, the AEC-Q100 qualification requirements have been extended to cover photonic components, with specific temperature cycling and operational lifetime requirements that exceed those of standard telecommunications applications. Medical device implementations of PICs must comply with ISO 13485 quality management systems, which mandate rigorous reliability testing and traceability documentation.

The Photonics Industry Consortium has published recommended test procedures that are gaining industry acceptance, particularly for emerging applications in quantum computing and sensing. These procedures include accelerated aging tests under various environmental conditions, with standardized reporting formats to facilitate comparison between different PIC technologies.

Certification requirements typically include demonstration of compliance with Telcordia GR-468 or equivalent standards, with documentation of test conditions, sample sizes, and statistical analysis of results. For space applications, NASA and ESA have developed specialized certification protocols that include radiation hardness testing and extended temperature range operation verification.

The lack of fully harmonized global standards remains a challenge for PIC manufacturers, often requiring multiple certifications to address different market requirements. Industry leaders are advocating for the development of unified testing frameworks through organizations like the International Organization for Standardization (ISO) and the Photonics Industry Association.

Emerging certification requirements are beginning to address not only reliability but also interoperability between different PIC platforms, with standardized optical interfaces and performance metrics. This trend reflects the industry's movement toward more modular and interchangeable photonic components, requiring standardized endurance testing methodologies that can verify long-term compatibility between interconnected systems.

Environmental Factors in PIC Lifetime Testing

Environmental factors play a crucial role in determining the reliability and longevity of Photonic Integrated Circuits (PICs). These sophisticated components must withstand various environmental stressors throughout their operational lifetime, necessitating comprehensive testing protocols that simulate real-world conditions.

Temperature cycling represents one of the most significant environmental challenges for PICs. Testing typically involves subjecting devices to temperature extremes ranging from -40°C to +125°C, with controlled ramp rates and dwell times at each temperature point. These tests evaluate thermal expansion coefficient mismatches between different materials within the PIC, which can lead to mechanical stress, delamination, or fractures in optical waveguides.

Humidity testing is equally critical, as moisture ingress can severely impact optical performance. Standard humidity tests expose PICs to relative humidity levels of 85-95% at elevated temperatures (typically 85°C) for extended periods, often 1,000 hours or more. This high-temperature/high-humidity (HTHH) testing reveals potential issues with hermetic sealing, material degradation, and corrosion of metallic components.

Mechanical shock and vibration testing simulates transportation and handling conditions that PICs may encounter. Devices are subjected to controlled mechanical shocks (up to 1,500G) and vibration profiles across various frequency ranges (typically 20-2000 Hz) to evaluate structural integrity and optical alignment stability under stress.

Atmospheric pressure variation testing is particularly important for PICs deployed in aerospace applications. These tests evaluate performance across pressure ranges from sea level to high altitude conditions, identifying potential issues with hermetic packaging and internal gas pressures that might affect optical pathways.

Radiation hardness testing has become increasingly important for PICs used in space, nuclear, and high-energy physics applications. Exposure to gamma radiation, protons, and heavy ions at controlled dosage rates evaluates potential degradation mechanisms in both passive and active photonic components.

Chemical resistance testing assesses PIC resilience against environmental contaminants including salt spray, industrial pollutants, and cleaning agents. These tests are particularly relevant for PICs deployed in harsh industrial environments or marine applications where corrosive elements are present.

Standardized testing protocols such as Telcordia GR-468, MIL-STD-883, and various IEC standards provide frameworks for environmental testing of PICs, though industry-specific adaptations are often necessary to address the unique challenges of integrated photonics technology.

Temperature cycling represents one of the most significant environmental challenges for PICs. Testing typically involves subjecting devices to temperature extremes ranging from -40°C to +125°C, with controlled ramp rates and dwell times at each temperature point. These tests evaluate thermal expansion coefficient mismatches between different materials within the PIC, which can lead to mechanical stress, delamination, or fractures in optical waveguides.

Humidity testing is equally critical, as moisture ingress can severely impact optical performance. Standard humidity tests expose PICs to relative humidity levels of 85-95% at elevated temperatures (typically 85°C) for extended periods, often 1,000 hours or more. This high-temperature/high-humidity (HTHH) testing reveals potential issues with hermetic sealing, material degradation, and corrosion of metallic components.

Mechanical shock and vibration testing simulates transportation and handling conditions that PICs may encounter. Devices are subjected to controlled mechanical shocks (up to 1,500G) and vibration profiles across various frequency ranges (typically 20-2000 Hz) to evaluate structural integrity and optical alignment stability under stress.

Atmospheric pressure variation testing is particularly important for PICs deployed in aerospace applications. These tests evaluate performance across pressure ranges from sea level to high altitude conditions, identifying potential issues with hermetic packaging and internal gas pressures that might affect optical pathways.

Radiation hardness testing has become increasingly important for PICs used in space, nuclear, and high-energy physics applications. Exposure to gamma radiation, protons, and heavy ions at controlled dosage rates evaluates potential degradation mechanisms in both passive and active photonic components.

Chemical resistance testing assesses PIC resilience against environmental contaminants including salt spray, industrial pollutants, and cleaning agents. These tests are particularly relevant for PICs deployed in harsh industrial environments or marine applications where corrosive elements are present.

Standardized testing protocols such as Telcordia GR-468, MIL-STD-883, and various IEC standards provide frameworks for environmental testing of PICs, though industry-specific adaptations are often necessary to address the unique challenges of integrated photonics technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!