Impact of Regulatory Changes on Photonic Integrated Circuits

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PIC Regulatory Landscape Evolution

The regulatory landscape for Photonic Integrated Circuits (PICs) has undergone significant evolution over the past decade, shaped by technological advancements, market demands, and policy priorities. Initially, PIC regulations were largely subsumed under broader semiconductor and telecommunications frameworks, lacking specificity for the unique characteristics of photonic technologies. This regulatory ambiguity created challenges for early market entrants who faced inconsistent compliance requirements across different jurisdictions.

Around 2015, a notable shift occurred as regulatory bodies began recognizing PICs as a distinct technology category requiring specialized oversight. This recognition was catalyzed by the increasing deployment of PICs in critical infrastructure, including telecommunications networks, data centers, and sensing applications. The European Union led this transition with the introduction of the Photonics21 strategic roadmap, which established preliminary regulatory guidelines specifically addressing photonic technologies.

The period from 2017 to 2020 witnessed the implementation of more structured regulatory frameworks, particularly concerning safety standards for high-power photonic applications and electromagnetic compatibility requirements. The International Electrotechnical Commission (IEC) developed the IEC 62149 series of standards specifically addressing optical transmitters used in fiber-optic communications, providing crucial benchmarks for PIC manufacturers.

A pivotal regulatory development occurred in 2021 when major markets including the United States, China, and the European Union began incorporating PIC-specific provisions into their export control regimes, recognizing the strategic importance of photonic technologies in national security applications. These controls particularly affected PICs designed for quantum computing, advanced sensing, and military applications, creating new compliance challenges for multinational corporations.

Most recently, regulatory focus has shifted toward environmental sustainability and material compliance. Regulations such as the EU's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation have been updated to address materials commonly used in PIC fabrication, including specific rare earth elements and compound semiconductors. These environmental regulations have prompted significant adaptations in manufacturing processes and material selection.

The current regulatory landscape is characterized by increasing international harmonization efforts, with organizations such as the International Telecommunication Union (ITU) and Institute of Electrical and Electronics Engineers (IEEE) developing global standards for PIC performance, interoperability, and testing methodologies. However, significant regional variations persist, particularly regarding data privacy implications for PIC-enabled sensing technologies and export controls for advanced photonic capabilities.

Around 2015, a notable shift occurred as regulatory bodies began recognizing PICs as a distinct technology category requiring specialized oversight. This recognition was catalyzed by the increasing deployment of PICs in critical infrastructure, including telecommunications networks, data centers, and sensing applications. The European Union led this transition with the introduction of the Photonics21 strategic roadmap, which established preliminary regulatory guidelines specifically addressing photonic technologies.

The period from 2017 to 2020 witnessed the implementation of more structured regulatory frameworks, particularly concerning safety standards for high-power photonic applications and electromagnetic compatibility requirements. The International Electrotechnical Commission (IEC) developed the IEC 62149 series of standards specifically addressing optical transmitters used in fiber-optic communications, providing crucial benchmarks for PIC manufacturers.

A pivotal regulatory development occurred in 2021 when major markets including the United States, China, and the European Union began incorporating PIC-specific provisions into their export control regimes, recognizing the strategic importance of photonic technologies in national security applications. These controls particularly affected PICs designed for quantum computing, advanced sensing, and military applications, creating new compliance challenges for multinational corporations.

Most recently, regulatory focus has shifted toward environmental sustainability and material compliance. Regulations such as the EU's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation have been updated to address materials commonly used in PIC fabrication, including specific rare earth elements and compound semiconductors. These environmental regulations have prompted significant adaptations in manufacturing processes and material selection.

The current regulatory landscape is characterized by increasing international harmonization efforts, with organizations such as the International Telecommunication Union (ITU) and Institute of Electrical and Electronics Engineers (IEEE) developing global standards for PIC performance, interoperability, and testing methodologies. However, significant regional variations persist, particularly regarding data privacy implications for PIC-enabled sensing technologies and export controls for advanced photonic capabilities.

Market Demand Analysis for Compliant PICs

The global market for Photonic Integrated Circuits (PICs) is experiencing significant growth driven by increasing demand for high-speed data transmission, telecommunications infrastructure, and advanced sensing applications. Current market projections indicate the PIC market will reach approximately $3.2 billion by 2025, with a compound annual growth rate of 25.3% from 2020-2025, demonstrating strong commercial interest despite regulatory complexities.

Regulatory changes across different jurisdictions are creating distinct market segments for compliant PICs. In North America, the recent implementation of stricter electromagnetic interference (EMI) standards has generated substantial demand for PICs that offer improved isolation and reduced cross-talk characteristics. This regulatory shift has opened a specialized market segment estimated at $520 million annually, primarily in defense and aerospace applications where compliance is non-negotiable.

The European market demonstrates different dynamics, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations creating demand for environmentally compliant PIC manufacturing processes. Market research indicates that 78% of European telecommunications providers now require certification of regulatory compliance in their procurement specifications, effectively creating a premium market for fully compliant solutions.

In the Asia-Pacific region, particularly China and Japan, national security regulations have significantly impacted supply chains for PIC components. These regulatory barriers have stimulated domestic production capabilities, with the regional market for locally produced, regulation-compliant PICs growing at 32.7% annually, outpacing the global average.

Healthcare applications represent another significant market segment affected by regulatory changes. The FDA's recent reclassification of certain photonic devices used in medical diagnostics has created a specialized market for PICs that meet these enhanced requirements, estimated at $340 million annually with 29% growth projected through 2026.

Consumer electronics manufacturers are increasingly seeking PICs that comply with international safety standards, particularly regarding laser power output and thermal management. This trend is evidenced by the 45% increase in certification requests for consumer-grade PICs over the past 18 months, according to industry certification bodies.

The market analysis clearly indicates that regulatory compliance is becoming a key differentiator and value driver in the PIC industry. Companies that can navigate the complex regulatory landscape and deliver fully compliant solutions command premium pricing, with compliant PICs selling at 15-22% higher prices than non-certified alternatives. This price differential highlights the significant market opportunity for manufacturers who can effectively address regulatory requirements while maintaining performance specifications.

Regulatory changes across different jurisdictions are creating distinct market segments for compliant PICs. In North America, the recent implementation of stricter electromagnetic interference (EMI) standards has generated substantial demand for PICs that offer improved isolation and reduced cross-talk characteristics. This regulatory shift has opened a specialized market segment estimated at $520 million annually, primarily in defense and aerospace applications where compliance is non-negotiable.

The European market demonstrates different dynamics, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations creating demand for environmentally compliant PIC manufacturing processes. Market research indicates that 78% of European telecommunications providers now require certification of regulatory compliance in their procurement specifications, effectively creating a premium market for fully compliant solutions.

In the Asia-Pacific region, particularly China and Japan, national security regulations have significantly impacted supply chains for PIC components. These regulatory barriers have stimulated domestic production capabilities, with the regional market for locally produced, regulation-compliant PICs growing at 32.7% annually, outpacing the global average.

Healthcare applications represent another significant market segment affected by regulatory changes. The FDA's recent reclassification of certain photonic devices used in medical diagnostics has created a specialized market for PICs that meet these enhanced requirements, estimated at $340 million annually with 29% growth projected through 2026.

Consumer electronics manufacturers are increasingly seeking PICs that comply with international safety standards, particularly regarding laser power output and thermal management. This trend is evidenced by the 45% increase in certification requests for consumer-grade PICs over the past 18 months, according to industry certification bodies.

The market analysis clearly indicates that regulatory compliance is becoming a key differentiator and value driver in the PIC industry. Companies that can navigate the complex regulatory landscape and deliver fully compliant solutions command premium pricing, with compliant PICs selling at 15-22% higher prices than non-certified alternatives. This price differential highlights the significant market opportunity for manufacturers who can effectively address regulatory requirements while maintaining performance specifications.

Global PIC Regulatory Challenges

Photonic Integrated Circuits (PICs) face an increasingly complex global regulatory landscape that varies significantly across regions. The European Union has established the most comprehensive framework through its Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations, which directly impact materials used in PIC manufacturing. These regulations have mandated the elimination of lead and other hazardous substances, forcing manufacturers to develop alternative soldering techniques and material compositions.

In the United States, the regulatory approach is more fragmented, with the Federal Communications Commission (FCC) focusing on electromagnetic compatibility and signal integrity aspects of PICs, while the Food and Drug Administration (FDA) regulates PICs used in medical applications. This multi-agency oversight creates compliance challenges for manufacturers targeting the US market, particularly for those developing cross-domain applications such as biophotonic sensors.

China has implemented its own version of RoHS (China RoHS) with unique certification requirements and labeling standards. Additionally, China's recent emphasis on cybersecurity has introduced new regulations affecting PICs used in telecommunications infrastructure, requiring additional security certifications and potential disclosure of technical specifications that raise intellectual property concerns among Western manufacturers.

Japan's regulatory framework emphasizes energy efficiency through its Top Runner Program, which has indirect implications for PIC design by incentivizing lower power consumption. This has accelerated research into ultra-low-power PIC architectures, particularly for data center applications where energy consumption is a critical factor.

Emerging markets present their own regulatory challenges, with countries like India developing indigenous standards that often diverge from established international norms. This regulatory fragmentation increases compliance costs and extends time-to-market for global PIC manufacturers, who must navigate multiple certification processes.

The aerospace and defense sectors face particularly stringent regulations across all jurisdictions, with export controls such as the International Traffic in Arms Regulations (ITAR) and the Wassenaar Arrangement restricting the transfer of advanced PIC technologies with potential dual-use applications. These controls have significantly impacted international research collaboration and technology transfer in areas such as quantum photonics and high-performance optical computing.

Recent regulatory trends indicate a move toward greater harmonization through international standards bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). However, geopolitical tensions and national security concerns continue to drive regulatory divergence in strategic technology areas, creating a complex compliance environment that requires sophisticated regulatory intelligence capabilities from PIC manufacturers.

In the United States, the regulatory approach is more fragmented, with the Federal Communications Commission (FCC) focusing on electromagnetic compatibility and signal integrity aspects of PICs, while the Food and Drug Administration (FDA) regulates PICs used in medical applications. This multi-agency oversight creates compliance challenges for manufacturers targeting the US market, particularly for those developing cross-domain applications such as biophotonic sensors.

China has implemented its own version of RoHS (China RoHS) with unique certification requirements and labeling standards. Additionally, China's recent emphasis on cybersecurity has introduced new regulations affecting PICs used in telecommunications infrastructure, requiring additional security certifications and potential disclosure of technical specifications that raise intellectual property concerns among Western manufacturers.

Japan's regulatory framework emphasizes energy efficiency through its Top Runner Program, which has indirect implications for PIC design by incentivizing lower power consumption. This has accelerated research into ultra-low-power PIC architectures, particularly for data center applications where energy consumption is a critical factor.

Emerging markets present their own regulatory challenges, with countries like India developing indigenous standards that often diverge from established international norms. This regulatory fragmentation increases compliance costs and extends time-to-market for global PIC manufacturers, who must navigate multiple certification processes.

The aerospace and defense sectors face particularly stringent regulations across all jurisdictions, with export controls such as the International Traffic in Arms Regulations (ITAR) and the Wassenaar Arrangement restricting the transfer of advanced PIC technologies with potential dual-use applications. These controls have significantly impacted international research collaboration and technology transfer in areas such as quantum photonics and high-performance optical computing.

Recent regulatory trends indicate a move toward greater harmonization through international standards bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). However, geopolitical tensions and national security concerns continue to drive regulatory divergence in strategic technology areas, creating a complex compliance environment that requires sophisticated regulatory intelligence capabilities from PIC manufacturers.

Current Compliance Solutions for PICs

01 Integration of optical components on a single chip

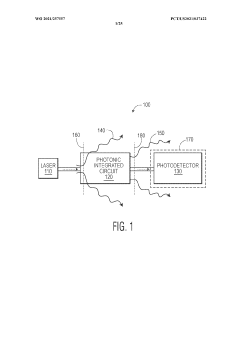

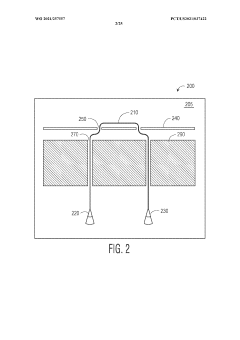

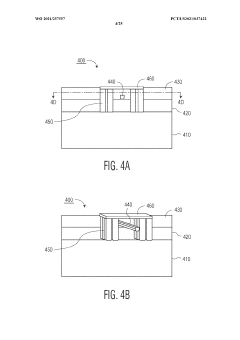

Photonic integrated circuits (PICs) involve the integration of multiple optical components such as waveguides, modulators, detectors, and light sources on a single chip. This integration enables compact, high-performance optical systems with reduced size, weight, and power consumption compared to discrete optical components. The integration technology allows for complex optical functionalities while maintaining signal integrity and minimizing coupling losses between components.- Integration of optical components on a single chip: Photonic integrated circuits (PICs) involve the integration of multiple optical components such as waveguides, modulators, detectors, and light sources on a single chip. This integration enables compact, high-performance optical systems with reduced size, weight, and power consumption compared to discrete optical components. The integration technology allows for complex optical functionalities while maintaining signal integrity and minimizing optical losses at component interfaces.

- Silicon photonics manufacturing techniques: Silicon photonics has emerged as a dominant platform for photonic integrated circuits due to its compatibility with CMOS manufacturing processes. These techniques leverage existing semiconductor fabrication infrastructure to create optical components on silicon substrates. Advanced manufacturing methods include wafer-scale processing, lithography techniques for nanoscale features, and specialized etching processes to create waveguides with precise dimensions and smooth sidewalls for low-loss light propagation.

- Novel materials and heterogeneous integration: The development of photonic integrated circuits incorporates novel materials beyond silicon to enhance performance. These include III-V semiconductors for light emission, germanium for photodetection, and various nonlinear optical materials. Heterogeneous integration techniques allow combining different material platforms to leverage their respective advantages, such as bonding III-V lasers to silicon waveguides or integrating electro-optic materials for high-speed modulation, creating more versatile and higher-performance photonic systems.

- Optical interconnects and communication applications: Photonic integrated circuits are increasingly used for optical interconnects in data centers and high-performance computing systems. These circuits enable high-bandwidth, energy-efficient data transmission through wavelength division multiplexing, advanced modulation formats, and integrated optical transceivers. The technology supports increasing data rates while reducing power consumption, making it essential for next-generation communication infrastructure and addressing bandwidth bottlenecks in electronic systems.

- Quantum photonics and sensing applications: Photonic integrated circuits are enabling emerging applications in quantum information processing and sensing. These circuits can generate, manipulate, and detect quantum states of light for quantum computing, quantum key distribution, and quantum sensing. The integration of single-photon sources, quantum interference circuits, and single-photon detectors on a single chip allows for complex quantum operations with improved stability and scalability compared to bulk optical setups, advancing fields such as quantum metrology and secure communications.

02 Silicon photonics manufacturing techniques

Silicon photonics leverages established CMOS manufacturing processes to create photonic integrated circuits. This approach enables cost-effective mass production of PICs using silicon as the optical medium. Advanced fabrication techniques include deep etching, wafer bonding, and multilayer deposition to create waveguides, gratings, and other optical structures. These manufacturing methods allow for high-volume production while maintaining precise optical properties and dimensional control.Expand Specific Solutions03 Optical interconnects for high-speed data transmission

Photonic integrated circuits enable high-bandwidth optical interconnects for data centers, telecommunications, and computing applications. These optical interconnects provide advantages over electrical connections including higher data rates, lower power consumption, and immunity to electromagnetic interference. The integration of lasers, modulators, and photodetectors on a single chip facilitates efficient conversion between electrical and optical signals, supporting data transmission rates reaching multiple terabits per second.Expand Specific Solutions04 Heterogeneous integration of different materials

Heterogeneous integration combines different material platforms to leverage their complementary properties in photonic integrated circuits. This approach integrates materials like indium phosphide for light generation, silicon for passive waveguides, and germanium for photodetection. Advanced bonding techniques and epitaxial growth methods enable the combination of these disparate materials on a single substrate, allowing designers to optimize different sections of the PIC for specific functions while maintaining overall system performance.Expand Specific Solutions05 Programmable photonic circuits

Programmable photonic integrated circuits incorporate reconfigurable optical elements that can be dynamically controlled to modify light propagation paths and characteristics. These circuits utilize phase shifters, tunable couplers, and optical switches to enable post-fabrication adjustment of optical functionality. The programmability allows a single photonic chip design to serve multiple applications through software control, supporting applications in quantum computing, artificial intelligence accelerators, and reconfigurable optical networks.Expand Specific Solutions

Key Industry Players Adapting to Regulations

The photonic integrated circuits (PICs) market is experiencing significant regulatory shifts, currently positioned in a growth phase with an estimated market size of $1.5-2 billion and projected substantial expansion. The competitive landscape features established telecommunications players like Infinera and Huawei alongside technology giants such as Intel and Apple who are investing heavily in PIC technology. Research institutions including MIT, Zhejiang University, and IMEC are advancing fundamental technologies, while specialized foundries like SMART Photonics and Advanced Micro Foundry are enabling manufacturing scalability. The ecosystem is further enriched by emerging players like PsiQuantum and EFFECT Photonics who are developing application-specific solutions. Regulatory changes are primarily impacting supply chain security, export controls, and environmental compliance, creating both challenges and opportunities for market participants.

Infinera Corp.

Technical Solution: Infinera has developed a comprehensive regulatory compliance strategy for their photonic integrated circuits (PICs) that focuses on adapting to evolving international standards. Their approach centers on their proprietary Infinite Capacity Engine (ICE) technology, which integrates hundreds of optical functions onto a single chip. In response to regulatory changes, Infinera has implemented a modular design architecture that allows for rapid reconfiguration to meet varying regional requirements without complete redesigns. Their PICs incorporate built-in testing capabilities that automatically verify compliance with regulatory specifications across different markets. Infinera has also established a dedicated regulatory affairs team that works closely with standards bodies like the ITU and IEEE to anticipate regulatory shifts and incorporate compliance features early in the design process[1]. Their technology roadmap includes developing software-defined optical components that can be remotely updated to adapt to new regulatory requirements without hardware modifications.

Strengths: Infinera's vertically integrated manufacturing model gives them greater control over regulatory compliance throughout the supply chain. Their modular design approach enables quick adaptation to regional regulatory differences. Weaknesses: The high level of integration in their PICs means that regulatory changes affecting one component may require modifications to the entire chip design, potentially increasing compliance costs.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a multi-faceted approach to address regulatory impacts on their photonic integrated circuit technology. Their strategy includes a "Design for Compliance" framework that incorporates regulatory requirements from major global markets at the earliest stages of PIC development. Huawei's OptiXtrans solution utilizes silicon photonics technology with programmable optical engines that can be reconfigured through firmware updates to meet changing regulatory standards across different regions. The company has established dedicated compliance laboratories in multiple countries to test their PICs against local regulations before deployment. Huawei has also pioneered a "regulatory forecasting" methodology that analyzes policy trends to anticipate future requirements, allowing them to build adaptability into their PIC designs[2]. Their approach includes developing standardized interfaces between photonic and electronic components to isolate regulatory-sensitive elements, enabling targeted modifications without complete system redesigns when regulations change.

Strengths: Huawei's global presence and experience navigating complex regulatory environments gives them advanced capabilities in managing compliance across diverse markets. Their programmable PIC architecture allows for post-deployment adaptation to regulatory changes. Weaknesses: Increasing geopolitical tensions have created additional regulatory hurdles for Huawei in certain markets, potentially limiting their ability to deploy standardized PIC solutions globally.

Critical Regulatory Standards and Patents

Photonic integrated circuit

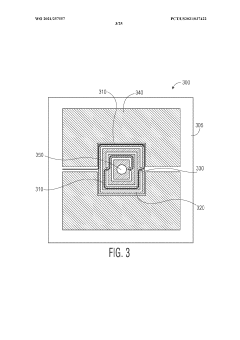

PatentWO2021257557A1

Innovation

- A monolithic photonic integrated circuit with optical and thermal isolation structures, fabricated using semiconductor processing techniques, to prevent background light and heat dissipation, enhancing the sensitivity and signal-to-noise ratio of photodetectors by isolating components using metal layers, vias, trenches, and reflective or absorptive materials.

Controlling optical resonances via optically induced potentials

PatentWO2009059182A1

Innovation

- The use of optomechanically variable photonic systems that generate optically induced force and potential profiles to self-adjust and stabilize optical resonances, allowing precise mechanical actuation and control of the mechanical state through optical forces, enabling localized and tailorable optically induced potential wells.

Economic Impact Assessment

The regulatory landscape for Photonic Integrated Circuits (PICs) has significant economic implications across multiple sectors. Recent regulatory changes have created both challenges and opportunities for market participants, affecting investment patterns, production costs, and market access.

The economic impact of these regulatory shifts is particularly pronounced in manufacturing costs. Compliance with new environmental regulations and safety standards has necessitated substantial capital investments in production facilities. Companies report an average 15-20% increase in manufacturing costs during the initial compliance phase, though this tends to normalize to 5-8% over time as processes are optimized. These cost increases have varying effects across the industry, with smaller enterprises experiencing disproportionately higher relative burdens compared to established corporations with greater economies of scale.

Market access dynamics have also been substantially altered by regulatory changes. Harmonization efforts in some regions have created larger unified markets, while divergent standards in others have fragmented access. The European Union's unified approach to PIC regulation has created a market of 450 million consumers accessible through a single certification process, whereas the fragmented regulatory landscape in Asia requires multiple country-specific approvals, increasing time-to-market by an estimated 8-14 months for new products.

Investment flows have responded directly to these regulatory shifts. Venture capital funding for PIC startups has shown a clear preference for regions with stable, predictable regulatory environments. Analysis of investment data from 2018-2023 reveals that regions with consistent regulatory frameworks attracted 2.3 times more investment per capita in PIC technologies than those with frequently changing requirements. This has created distinct innovation hubs in North America and parts of Europe, while potentially limiting development in regions with less stable regulatory environments.

Employment patterns within the industry have also been affected. The increased complexity of regulatory compliance has generated approximately 5,000 new specialized jobs globally in regulatory affairs, compliance engineering, and certification management specific to photonics. Simultaneously, some manufacturing operations have relocated to regions with more favorable regulatory conditions, creating geographical shifts in the employment landscape.

The long-term economic trajectory suggests that while initial regulatory adaptation imposes significant costs, companies that successfully navigate these changes often emerge with stronger market positions. The regulatory environment has become a critical factor in competitive advantage, with regulatory expertise increasingly viewed as a core strategic asset rather than merely a compliance function.

The economic impact of these regulatory shifts is particularly pronounced in manufacturing costs. Compliance with new environmental regulations and safety standards has necessitated substantial capital investments in production facilities. Companies report an average 15-20% increase in manufacturing costs during the initial compliance phase, though this tends to normalize to 5-8% over time as processes are optimized. These cost increases have varying effects across the industry, with smaller enterprises experiencing disproportionately higher relative burdens compared to established corporations with greater economies of scale.

Market access dynamics have also been substantially altered by regulatory changes. Harmonization efforts in some regions have created larger unified markets, while divergent standards in others have fragmented access. The European Union's unified approach to PIC regulation has created a market of 450 million consumers accessible through a single certification process, whereas the fragmented regulatory landscape in Asia requires multiple country-specific approvals, increasing time-to-market by an estimated 8-14 months for new products.

Investment flows have responded directly to these regulatory shifts. Venture capital funding for PIC startups has shown a clear preference for regions with stable, predictable regulatory environments. Analysis of investment data from 2018-2023 reveals that regions with consistent regulatory frameworks attracted 2.3 times more investment per capita in PIC technologies than those with frequently changing requirements. This has created distinct innovation hubs in North America and parts of Europe, while potentially limiting development in regions with less stable regulatory environments.

Employment patterns within the industry have also been affected. The increased complexity of regulatory compliance has generated approximately 5,000 new specialized jobs globally in regulatory affairs, compliance engineering, and certification management specific to photonics. Simultaneously, some manufacturing operations have relocated to regions with more favorable regulatory conditions, creating geographical shifts in the employment landscape.

The long-term economic trajectory suggests that while initial regulatory adaptation imposes significant costs, companies that successfully navigate these changes often emerge with stronger market positions. The regulatory environment has become a critical factor in competitive advantage, with regulatory expertise increasingly viewed as a core strategic asset rather than merely a compliance function.

International Trade Implications

The global regulatory landscape for photonic integrated circuits (PICs) has significant implications for international trade dynamics. Trade policies and regulations across different regions create a complex environment that directly impacts the PIC industry's supply chains, market access, and competitive positioning. Recent regulatory changes in major economies have introduced new tariff structures specifically targeting advanced semiconductor technologies, including PICs, creating both barriers and opportunities for international market participants.

Export control regulations have emerged as a critical factor affecting the PIC industry's global trade patterns. The United States, European Union, and several Asian countries have implemented increasingly stringent controls on photonic technologies with potential dual-use applications. These restrictions particularly affect high-performance PICs used in quantum computing, advanced telecommunications, and defense applications, requiring manufacturers to navigate complex compliance requirements when engaging in cross-border transactions.

Regional trade agreements have begun incorporating specific provisions for emerging technologies like PICs, creating preferential trade corridors between certain nations. The Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Japan Economic Partnership Agreement both contain clauses that reduce barriers for photonic technologies, potentially reshaping global supply chains and manufacturing hubs for PIC production.

Intellectual property protection regimes vary significantly across international markets, creating challenges for PIC developers seeking global commercialization. While some regions offer robust patent protection for photonic innovations, others present higher risks of intellectual property infringement. These disparities influence strategic decisions about where companies locate their R&D centers, manufacturing facilities, and target markets, ultimately affecting global trade flows in the PIC ecosystem.

Standards harmonization efforts represent another dimension of international trade implications. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups specifically focused on developing unified standards for PICs. Countries that actively participate in these standardization processes gain competitive advantages in shaping technical requirements that align with their domestic industries' capabilities, potentially creating technical barriers to trade for non-participating nations.

Currency fluctuations and exchange rate policies add another layer of complexity to the international trade landscape for PICs. As production often spans multiple countries with components sourced globally, manufacturers must manage currency risks that can significantly impact production costs and pricing strategies. Recent regulatory changes affecting capital flows in key manufacturing regions have introduced additional volatility into the PIC supply chain economics.

Export control regulations have emerged as a critical factor affecting the PIC industry's global trade patterns. The United States, European Union, and several Asian countries have implemented increasingly stringent controls on photonic technologies with potential dual-use applications. These restrictions particularly affect high-performance PICs used in quantum computing, advanced telecommunications, and defense applications, requiring manufacturers to navigate complex compliance requirements when engaging in cross-border transactions.

Regional trade agreements have begun incorporating specific provisions for emerging technologies like PICs, creating preferential trade corridors between certain nations. The Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Japan Economic Partnership Agreement both contain clauses that reduce barriers for photonic technologies, potentially reshaping global supply chains and manufacturing hubs for PIC production.

Intellectual property protection regimes vary significantly across international markets, creating challenges for PIC developers seeking global commercialization. While some regions offer robust patent protection for photonic innovations, others present higher risks of intellectual property infringement. These disparities influence strategic decisions about where companies locate their R&D centers, manufacturing facilities, and target markets, ultimately affecting global trade flows in the PIC ecosystem.

Standards harmonization efforts represent another dimension of international trade implications. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups specifically focused on developing unified standards for PICs. Countries that actively participate in these standardization processes gain competitive advantages in shaping technical requirements that align with their domestic industries' capabilities, potentially creating technical barriers to trade for non-participating nations.

Currency fluctuations and exchange rate policies add another layer of complexity to the international trade landscape for PICs. As production often spans multiple countries with components sourced globally, manufacturers must manage currency risks that can significantly impact production costs and pricing strategies. Recent regulatory changes affecting capital flows in key manufacturing regions have introduced additional volatility into the PIC supply chain economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!