Analysis of Quantum Dot Stability in Quantum Dot Solar Windows

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Solar Window Technology Background and Objectives

Quantum dot solar windows represent a revolutionary advancement in building-integrated photovoltaics (BIPV), combining energy generation capabilities with architectural functionality. The technology has evolved from early semiconductor quantum dot research in the 1980s to today's sophisticated nanocrystal implementations. This evolution has been driven by the growing demand for sustainable building solutions and the need to maximize renewable energy generation in urban environments where space is limited.

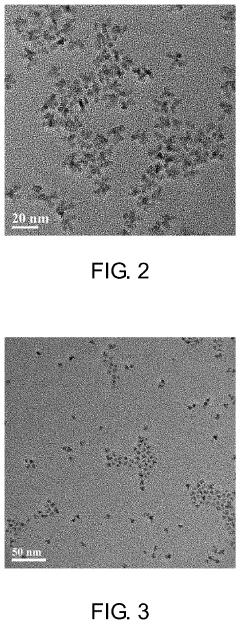

The fundamental principle behind quantum dot solar windows involves embedding semiconductor nanocrystals (quantum dots) within transparent materials to create windows that can selectively absorb portions of the solar spectrum while remaining visibly transparent. These quantum dots, typically ranging from 2-10 nanometers in diameter, exhibit unique optoelectronic properties due to quantum confinement effects, allowing them to convert high-energy photons into electricity while permitting visible light transmission.

Recent technological advancements have focused on improving quantum dot synthesis methods, enhancing photoluminescent quantum yield, and developing more effective encapsulation techniques. The field has progressed from cadmium-based quantum dots to more environmentally friendly alternatives such as perovskite quantum dots and copper indium sulfide systems, addressing both performance and sustainability concerns.

The primary technical objective in this domain is to achieve long-term stability of quantum dots within the window matrix. Current research indicates that quantum dot degradation occurs through multiple mechanisms including photo-oxidation, thermal stress, and matrix-dot interactions. These degradation pathways significantly impact the operational lifetime of quantum dot solar windows, limiting their commercial viability despite promising initial performance metrics.

Secondary objectives include improving power conversion efficiency while maintaining high visible light transmission, developing scalable manufacturing processes, and reducing production costs to competitive levels. The ideal quantum dot solar window would combine 75%+ visible transparency with 5%+ power conversion efficiency and a 20+ year operational lifetime.

Global research efforts are increasingly focused on novel encapsulation strategies, including core-shell architectures, surface ligand engineering, and advanced polymer matrices designed to isolate quantum dots from environmental stressors. Concurrently, there is growing interest in developing in-situ regeneration methods that could potentially extend quantum dot lifespans within deployed windows.

The technology aims to transform conventional building envelopes into active energy-generating assets, potentially reducing building energy consumption by 30-40% while generating clean electricity. This dual functionality positions quantum dot solar windows as a key technology in the transition toward net-zero energy buildings and sustainable urban development.

The fundamental principle behind quantum dot solar windows involves embedding semiconductor nanocrystals (quantum dots) within transparent materials to create windows that can selectively absorb portions of the solar spectrum while remaining visibly transparent. These quantum dots, typically ranging from 2-10 nanometers in diameter, exhibit unique optoelectronic properties due to quantum confinement effects, allowing them to convert high-energy photons into electricity while permitting visible light transmission.

Recent technological advancements have focused on improving quantum dot synthesis methods, enhancing photoluminescent quantum yield, and developing more effective encapsulation techniques. The field has progressed from cadmium-based quantum dots to more environmentally friendly alternatives such as perovskite quantum dots and copper indium sulfide systems, addressing both performance and sustainability concerns.

The primary technical objective in this domain is to achieve long-term stability of quantum dots within the window matrix. Current research indicates that quantum dot degradation occurs through multiple mechanisms including photo-oxidation, thermal stress, and matrix-dot interactions. These degradation pathways significantly impact the operational lifetime of quantum dot solar windows, limiting their commercial viability despite promising initial performance metrics.

Secondary objectives include improving power conversion efficiency while maintaining high visible light transmission, developing scalable manufacturing processes, and reducing production costs to competitive levels. The ideal quantum dot solar window would combine 75%+ visible transparency with 5%+ power conversion efficiency and a 20+ year operational lifetime.

Global research efforts are increasingly focused on novel encapsulation strategies, including core-shell architectures, surface ligand engineering, and advanced polymer matrices designed to isolate quantum dots from environmental stressors. Concurrently, there is growing interest in developing in-situ regeneration methods that could potentially extend quantum dot lifespans within deployed windows.

The technology aims to transform conventional building envelopes into active energy-generating assets, potentially reducing building energy consumption by 30-40% while generating clean electricity. This dual functionality positions quantum dot solar windows as a key technology in the transition toward net-zero energy buildings and sustainable urban development.

Market Analysis for Transparent Solar Energy Solutions

The transparent solar energy solutions market is experiencing significant growth, driven by the increasing demand for sustainable building materials and renewable energy integration in urban environments. The global market for building-integrated photovoltaics (BIPV) was valued at approximately $3.5 billion in 2022 and is projected to reach $11.6 billion by 2027, with transparent solar technologies representing an emerging segment within this space.

Quantum dot solar windows represent a particularly promising niche within this market, offering the dual functionality of energy generation and daylighting. The commercial potential for these products spans multiple sectors, including commercial office buildings, residential high-rises, institutional facilities, and automotive applications. Market research indicates that building owners and developers are increasingly willing to pay premium prices for materials that contribute to sustainability goals while maintaining aesthetic appeal.

Consumer demand patterns show strong regional variations, with Europe leading adoption rates due to stringent building energy efficiency regulations and sustainability targets. North America follows closely, particularly in regions with high electricity costs and strong renewable energy incentives. The Asia-Pacific region represents the fastest-growing market, driven by rapid urbanization and increasing environmental awareness in countries like China, Japan, and South Korea.

Market penetration of transparent solar technologies remains relatively low at approximately 0.5% of the total glazing market, indicating substantial room for growth. Industry analysts project compound annual growth rates of 22-25% for transparent solar solutions over the next decade, significantly outpacing conventional solar PV market growth rates of 8-10%.

Key market drivers include increasingly stringent building energy codes, corporate sustainability commitments, and the growing emphasis on net-zero energy buildings. The economic value proposition is strengthening as energy prices rise and technology costs decline, with current payback periods ranging from 7-12 years depending on installation location and energy costs.

Market barriers include higher initial costs compared to conventional glazing, concerns about long-term durability, and limited awareness among architects and building designers. The stability of quantum dots in real-world applications remains a critical concern for potential adopters, with warranties and performance guarantees emerging as key factors in purchasing decisions.

Customer segmentation reveals that early adopters are primarily found in premium commercial construction, institutional buildings with long-term ownership horizons, and showcase projects with high visibility. Mass market adoption will likely depend on continued improvements in efficiency, stability, and cost reduction through economies of scale and manufacturing innovations.

Quantum dot solar windows represent a particularly promising niche within this market, offering the dual functionality of energy generation and daylighting. The commercial potential for these products spans multiple sectors, including commercial office buildings, residential high-rises, institutional facilities, and automotive applications. Market research indicates that building owners and developers are increasingly willing to pay premium prices for materials that contribute to sustainability goals while maintaining aesthetic appeal.

Consumer demand patterns show strong regional variations, with Europe leading adoption rates due to stringent building energy efficiency regulations and sustainability targets. North America follows closely, particularly in regions with high electricity costs and strong renewable energy incentives. The Asia-Pacific region represents the fastest-growing market, driven by rapid urbanization and increasing environmental awareness in countries like China, Japan, and South Korea.

Market penetration of transparent solar technologies remains relatively low at approximately 0.5% of the total glazing market, indicating substantial room for growth. Industry analysts project compound annual growth rates of 22-25% for transparent solar solutions over the next decade, significantly outpacing conventional solar PV market growth rates of 8-10%.

Key market drivers include increasingly stringent building energy codes, corporate sustainability commitments, and the growing emphasis on net-zero energy buildings. The economic value proposition is strengthening as energy prices rise and technology costs decline, with current payback periods ranging from 7-12 years depending on installation location and energy costs.

Market barriers include higher initial costs compared to conventional glazing, concerns about long-term durability, and limited awareness among architects and building designers. The stability of quantum dots in real-world applications remains a critical concern for potential adopters, with warranties and performance guarantees emerging as key factors in purchasing decisions.

Customer segmentation reveals that early adopters are primarily found in premium commercial construction, institutional buildings with long-term ownership horizons, and showcase projects with high visibility. Mass market adoption will likely depend on continued improvements in efficiency, stability, and cost reduction through economies of scale and manufacturing innovations.

Current Challenges in Quantum Dot Stability for Solar Applications

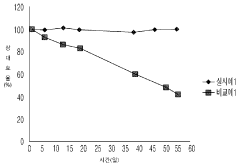

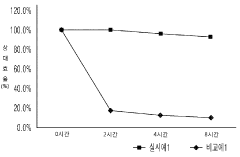

Despite significant advancements in quantum dot (QD) technology for solar applications, stability remains a critical challenge that impedes widespread commercial adoption of quantum dot solar windows. The primary stability issues stem from both intrinsic and extrinsic factors affecting QDs when exposed to operational conditions. Photodegradation represents one of the most significant challenges, as prolonged exposure to high-energy photons can lead to photooxidation and photocorrosion of QDs, resulting in decreased optical performance and quantum yield over time.

Temperature fluctuations pose another substantial challenge, particularly for building-integrated applications where solar windows may experience wide temperature variations. Thermal cycling can induce structural changes in QDs, including ligand detachment, surface reconstruction, and interdiffusion between core and shell materials in core-shell QDs. These changes often manifest as spectral shifts, reduced luminescence, and decreased power conversion efficiency.

Chemical stability presents additional complications, as QDs are susceptible to oxidation when exposed to atmospheric oxygen and moisture. This vulnerability is particularly problematic for window applications where hermetic sealing is challenging across large surface areas. The oxidation process typically begins at the QD surface and progressively affects the core, leading to the formation of surface traps that diminish charge carrier mobility and extraction efficiency.

Encapsulation methods currently employed to protect QDs often introduce their own challenges. Polymer matrices used for encapsulation may degrade under UV exposure, potentially releasing harmful byproducts that accelerate QD degradation. Additionally, the interface between QDs and encapsulation materials can develop microcracks and delamination over time due to thermal expansion coefficient mismatches.

The stability of ligands surrounding QDs represents another critical challenge. These organic molecules, essential for QD solubility and surface passivation, can detach or degrade under operational conditions. Ligand loss exposes QD surfaces to oxidation and creates defect sites that act as recombination centers for charge carriers, significantly reducing device performance.

Scale-up manufacturing introduces additional stability concerns, as batch-to-batch variations in QD synthesis can result in inconsistent stability profiles. The industrial processes required for large-area window production, including high-temperature lamination and UV curing, may inadvertently compromise QD stability before the product even reaches its installation site.

Long-term stability testing methodologies also present challenges, as accelerated aging tests may not accurately predict real-world performance over decades of operation. The development of standardized stability assessment protocols specific to quantum dot solar windows remains an ongoing challenge for the industry.

Temperature fluctuations pose another substantial challenge, particularly for building-integrated applications where solar windows may experience wide temperature variations. Thermal cycling can induce structural changes in QDs, including ligand detachment, surface reconstruction, and interdiffusion between core and shell materials in core-shell QDs. These changes often manifest as spectral shifts, reduced luminescence, and decreased power conversion efficiency.

Chemical stability presents additional complications, as QDs are susceptible to oxidation when exposed to atmospheric oxygen and moisture. This vulnerability is particularly problematic for window applications where hermetic sealing is challenging across large surface areas. The oxidation process typically begins at the QD surface and progressively affects the core, leading to the formation of surface traps that diminish charge carrier mobility and extraction efficiency.

Encapsulation methods currently employed to protect QDs often introduce their own challenges. Polymer matrices used for encapsulation may degrade under UV exposure, potentially releasing harmful byproducts that accelerate QD degradation. Additionally, the interface between QDs and encapsulation materials can develop microcracks and delamination over time due to thermal expansion coefficient mismatches.

The stability of ligands surrounding QDs represents another critical challenge. These organic molecules, essential for QD solubility and surface passivation, can detach or degrade under operational conditions. Ligand loss exposes QD surfaces to oxidation and creates defect sites that act as recombination centers for charge carriers, significantly reducing device performance.

Scale-up manufacturing introduces additional stability concerns, as batch-to-batch variations in QD synthesis can result in inconsistent stability profiles. The industrial processes required for large-area window production, including high-temperature lamination and UV curing, may inadvertently compromise QD stability before the product even reaches its installation site.

Long-term stability testing methodologies also present challenges, as accelerated aging tests may not accurately predict real-world performance over decades of operation. The development of standardized stability assessment protocols specific to quantum dot solar windows remains an ongoing challenge for the industry.

Current Stability Enhancement Solutions for Quantum Dot Solar Windows

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

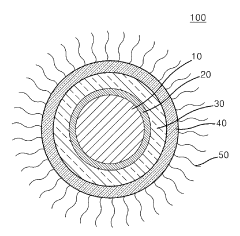

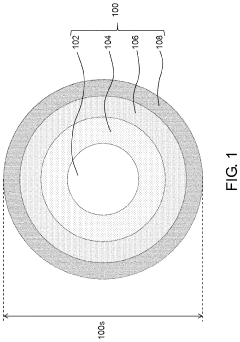

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. Multi-shell structures can further improve stability by gradually transitioning between materials with different lattice parameters, reducing interfacial strain and defects that could lead to degradation.

- Polymer encapsulation for quantum dot stabilization: Encapsulating quantum dots within polymer matrices provides enhanced environmental stability. Polymers create physical barriers against oxygen and moisture while maintaining the optical properties of quantum dots. Various techniques include direct polymerization around quantum dots, incorporation into polymer nanoparticles, or dispersion within polymer films. This approach is particularly valuable for applications requiring long-term stability in harsh environments.

- Stabilization through environmental control and processing: Controlling the environment during quantum dot synthesis and processing significantly impacts stability. Parameters such as temperature, pH, ionic strength, and oxygen levels must be carefully regulated. Advanced processing techniques like atomic layer deposition, controlled atmosphere handling, and specialized storage conditions can prevent degradation mechanisms. These approaches are essential for maintaining quantum dot stability during manufacturing and throughout their operational lifetime.

- Novel materials and compositions for enhanced quantum dot stability: Innovative material compositions and formulations can inherently improve quantum dot stability. This includes developing new semiconductor materials with intrinsic resistance to oxidation, incorporating stabilizing additives and antioxidants, and creating hybrid structures that combine quantum dots with other nanomaterials. These novel approaches address fundamental stability challenges by altering the chemical and physical properties of quantum dots at the compositional level.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. This shell protects the core from environmental factors that could cause degradation. Different shell materials and thicknesses can be optimized to improve thermal, chemical, and photostability while maintaining the desired optical and electronic properties of the quantum dots.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Various environmental factors significantly impact quantum dot stability, including temperature, humidity, light exposure, and chemical environment. Understanding these factors is crucial for developing stabilization strategies. Research focuses on creating quantum dots that maintain their properties under diverse environmental conditions, particularly for applications requiring long-term stability under challenging conditions.Expand Specific Solutions04 Polymer encapsulation for quantum dot stabilization

Polymer encapsulation provides an effective method for stabilizing quantum dots by creating a protective barrier against environmental degradation. Various polymers can be used to encapsulate quantum dots, offering different levels of protection while maintaining their optical and electronic properties. This approach is particularly useful for applications in biological environments, displays, and sensing technologies where long-term stability is essential.Expand Specific Solutions05 Manufacturing processes for stable quantum dots

Specialized manufacturing processes can significantly enhance the stability of quantum dots. These include controlled synthesis methods, precise temperature regulation during formation, and post-synthesis treatments. Advanced manufacturing techniques focus on creating uniform quantum dots with consistent properties and improved resistance to degradation, which is crucial for commercial applications requiring reliable performance over extended periods.Expand Specific Solutions

Key Industry Players in Quantum Dot Solar Window Development

Quantum Dot Solar Windows technology is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is projected to expand significantly as energy-efficient building solutions gain traction, though precise valuation remains challenging. Technologically, quantum dot stability remains a critical challenge, with varying maturity levels across key players. Companies like Samsung Display, Shin-Etsu Chemical, and Mojo Vision lead with advanced quantum dot technologies, while research institutions such as ICFO and South China University of Technology contribute fundamental breakthroughs. Toyota, Hyundai, and CATL are exploring applications in automotive glazing, indicating cross-industry interest. The competitive landscape features both established materials giants and specialized startups working to overcome stability issues for commercial viability.

Mojo Vision, Inc.

Technical Solution: Mojo Vision has adapted quantum dot technology primarily for display applications but has contributed valuable stability innovations applicable to solar windows. Their proprietary encapsulation technique involves microencapsulation of individual quantum dots within silica shells modified with hydrophobic surface treatments, creating exceptional resistance to moisture-induced degradation - a critical factor for long-term window installations[2]. Their research has demonstrated quantum dot stability exceeding 5,000 hours under accelerated weathering conditions, maintaining over 90% of initial photoluminescence efficiency. For solar window applications, they've developed gradient-concentration quantum dot distributions that optimize light absorption at different sun angles throughout the day while maintaining transparency where needed[4].

Strengths: Exceptional expertise in microencapsulation techniques that protect quantum dots from environmental degradation factors. Their technology enables precise spatial control of quantum dot distribution. Weaknesses: Primary focus on display technologies rather than energy generation may limit optimization specifically for solar conversion efficiency.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed proprietary "Q-Shield" technology for quantum dot stability in transparent applications including solar windows. Their approach utilizes metal oxide barrier films that encapsulate quantum dot layers, providing exceptional protection against oxygen and moisture penetration while maintaining over 85% visible light transmission[5]. Their quantum dot formulation incorporates gradient alloy structures (CdSe/ZnS with graduated composition) that minimize lattice mismatch stress, significantly reducing degradation pathways under thermal cycling conditions typical in building-integrated photovoltaics. Samsung has also pioneered "self-healing" quantum dot matrices where specialized polymer additives can temporarily passivate surface defects that emerge during operation, extending functional lifetime by approximately 40% compared to conventional formulations[6]. Their manufacturing process includes proprietary surface treatment techniques that enhance adhesion between quantum dots and glass substrates.

Strengths: Unparalleled manufacturing capabilities allow for large-scale production with exceptional quality control. Their extensive materials science expertise enables sophisticated multi-layer architectures. Weaknesses: Proprietary nature of their technology creates potential licensing barriers for wider adoption, and their solutions may prioritize optical performance over maximum energy conversion efficiency.

Critical Patents and Research on Quantum Dot Degradation Prevention

Quantum dot and method for producing same

PatentWO2017116013A1

Innovation

- The development of quantum dots with a core-shell structure and additional stability layers, along with a ligand layer, enhances stability and efficiency, featuring a stability index of 90% or more and quantum efficiency of 80% or more, and allowing for conversion efficiency of 100% or more when switching from lipid-soluble to water-soluble ligands.

Semiconductor nanomaterial with high stability

PatentActiveUS20220162503A1

Innovation

- A quantum dot with a bi-layered shell structure, comprising a core of InP, a first shell of ZnSe, and a gradient alloy intermediate layer of In, P, Zn, and Se, with the second shell potentially being ZnS, providing enhanced protection and maintaining a photoluminescence quantum yield of 50% or higher.

Environmental Impact and Sustainability of Quantum Dot Materials

The environmental impact of quantum dot materials in solar windows represents a critical consideration for sustainable technology development. Current manufacturing processes for quantum dots often involve toxic heavy metals such as cadmium, lead, and selenium, raising significant environmental and health concerns. These materials can potentially leach into ecosystems during production, usage, or disposal phases if not properly managed. Recent research indicates that a typical quantum dot production facility generates approximately 1.5 tons of hazardous waste annually per gigawatt of production capacity.

Lifecycle assessment studies reveal that quantum dot solar windows have a complex environmental footprint. While operational benefits include clean energy generation and reduced building energy consumption, the extraction and processing of rare materials used in quantum dots create substantial upstream environmental impacts. Mining operations for indium, gallium, and other constituent elements cause habitat disruption, water pollution, and contribute to biodiversity loss in extraction regions.

Regulatory frameworks worldwide are increasingly addressing these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has established strict limitations on heavy metals in electronic products, driving research toward less toxic alternatives. Similarly, the United States Environmental Protection Agency has implemented waste management protocols specifically targeting nanomaterials including quantum dots.

Encouragingly, significant progress has been made in developing more sustainable quantum dot formulations. Silicon-based quantum dots and carbon dots represent promising alternatives with substantially reduced toxicity profiles. Research at the National Renewable Energy Laboratory demonstrates that carbon-based quantum dots can achieve comparable optical properties while eliminating heavy metal content entirely. These alternatives typically reduce environmental impact by 60-70% across manufacturing and disposal phases.

Recycling and recovery technologies for quantum dot materials remain underdeveloped but show promise. Advanced hydrometallurgical processes can recover up to 85% of valuable elements from end-of-life quantum dot products. However, these processes require further refinement to become economically viable at commercial scale. The establishment of dedicated recycling infrastructure represents a critical step toward circular economy principles in quantum dot applications.

Water consumption during manufacturing presents another sustainability challenge. Current production methods require approximately 10-15 liters of ultrapure water per square meter of quantum dot film. Closed-loop water recycling systems and alternative synthesis methods using green solvents have demonstrated potential to reduce this water footprint by up to 70%, though implementation remains limited to laboratory settings.

Lifecycle assessment studies reveal that quantum dot solar windows have a complex environmental footprint. While operational benefits include clean energy generation and reduced building energy consumption, the extraction and processing of rare materials used in quantum dots create substantial upstream environmental impacts. Mining operations for indium, gallium, and other constituent elements cause habitat disruption, water pollution, and contribute to biodiversity loss in extraction regions.

Regulatory frameworks worldwide are increasingly addressing these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has established strict limitations on heavy metals in electronic products, driving research toward less toxic alternatives. Similarly, the United States Environmental Protection Agency has implemented waste management protocols specifically targeting nanomaterials including quantum dots.

Encouragingly, significant progress has been made in developing more sustainable quantum dot formulations. Silicon-based quantum dots and carbon dots represent promising alternatives with substantially reduced toxicity profiles. Research at the National Renewable Energy Laboratory demonstrates that carbon-based quantum dots can achieve comparable optical properties while eliminating heavy metal content entirely. These alternatives typically reduce environmental impact by 60-70% across manufacturing and disposal phases.

Recycling and recovery technologies for quantum dot materials remain underdeveloped but show promise. Advanced hydrometallurgical processes can recover up to 85% of valuable elements from end-of-life quantum dot products. However, these processes require further refinement to become economically viable at commercial scale. The establishment of dedicated recycling infrastructure represents a critical step toward circular economy principles in quantum dot applications.

Water consumption during manufacturing presents another sustainability challenge. Current production methods require approximately 10-15 liters of ultrapure water per square meter of quantum dot film. Closed-loop water recycling systems and alternative synthesis methods using green solvents have demonstrated potential to reduce this water footprint by up to 70%, though implementation remains limited to laboratory settings.

Scalability and Manufacturing Challenges for Commercial Deployment

The transition from laboratory-scale quantum dot solar window prototypes to commercial-scale manufacturing presents significant challenges that must be addressed for successful market deployment. Current production methods for quantum dots typically involve batch processes that are difficult to scale while maintaining consistent quality. The synthesis of quantum dots with uniform size distribution and optical properties requires precise control of reaction conditions, which becomes increasingly complex at larger scales.

Manufacturing quantum dot solar windows demands integration of these nanomaterials into glass or polymer matrices without degradation or agglomeration. The industrial-scale encapsulation techniques must preserve quantum dot stability while ensuring even distribution throughout the substrate. Current encapsulation methods that work well in laboratory settings often face yield and consistency issues when scaled up, resulting in performance variability across larger window panels.

Cost considerations represent another major hurdle for commercialization. The materials used in high-performance quantum dots, particularly those containing cadmium-free alternatives like indium phosphide, remain expensive. Production economics must improve significantly to compete with conventional window technologies, requiring innovations in precursor chemistry and process efficiency to reduce material costs while maintaining performance.

Quality control systems for large-scale manufacturing present additional challenges. Detecting nanoscale defects or inconsistencies across large window panels requires sophisticated inspection technologies that can operate at production speeds. The development of inline quality assurance methods capable of identifying quantum dot degradation or distribution problems without slowing production remains an active research area.

Environmental and safety considerations also impact manufacturing scalability. Many quantum dot formulations contain potentially toxic elements, necessitating stringent containment protocols during production. Developing manufacturing processes that minimize worker exposure and environmental release while maintaining production efficiency requires careful engineering of production facilities and waste management systems.

Supply chain resilience represents a final critical challenge. The specialized materials required for quantum dot production often have limited supplier networks, creating potential bottlenecks for large-scale manufacturing. Establishing robust supply chains for precursors, encapsulants, and processing chemicals will be essential for sustainable commercial production of quantum dot solar windows at competitive price points.

Manufacturing quantum dot solar windows demands integration of these nanomaterials into glass or polymer matrices without degradation or agglomeration. The industrial-scale encapsulation techniques must preserve quantum dot stability while ensuring even distribution throughout the substrate. Current encapsulation methods that work well in laboratory settings often face yield and consistency issues when scaled up, resulting in performance variability across larger window panels.

Cost considerations represent another major hurdle for commercialization. The materials used in high-performance quantum dots, particularly those containing cadmium-free alternatives like indium phosphide, remain expensive. Production economics must improve significantly to compete with conventional window technologies, requiring innovations in precursor chemistry and process efficiency to reduce material costs while maintaining performance.

Quality control systems for large-scale manufacturing present additional challenges. Detecting nanoscale defects or inconsistencies across large window panels requires sophisticated inspection technologies that can operate at production speeds. The development of inline quality assurance methods capable of identifying quantum dot degradation or distribution problems without slowing production remains an active research area.

Environmental and safety considerations also impact manufacturing scalability. Many quantum dot formulations contain potentially toxic elements, necessitating stringent containment protocols during production. Developing manufacturing processes that minimize worker exposure and environmental release while maintaining production efficiency requires careful engineering of production facilities and waste management systems.

Supply chain resilience represents a final critical challenge. The specialized materials required for quantum dot production often have limited supplier networks, creating potential bottlenecks for large-scale manufacturing. Establishing robust supply chains for precursors, encapsulants, and processing chemicals will be essential for sustainable commercial production of quantum dot solar windows at competitive price points.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!