Analysis of Resistive RAM Technology in Current Market Scopes

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ReRAM Technology Background and Objectives

Resistive Random Access Memory (ReRAM) represents a significant advancement in non-volatile memory technology, emerging as a promising alternative to conventional memory solutions. The evolution of ReRAM technology can be traced back to the early 2000s when researchers began exploring the potential of resistance switching phenomena in various material systems. This technology leverages the ability of certain materials to change their resistance state when subjected to electrical stimuli, enabling data storage through resistance variations rather than charge storage.

The development trajectory of ReRAM has been characterized by continuous improvements in material science, device architecture, and fabrication techniques. Initially focused on binary metal oxide systems such as HfO2, TiO2, and Ta2O5, the field has expanded to include complex oxides, chalcogenides, and organic materials, each offering unique advantages in terms of switching characteristics, endurance, and retention properties.

Current technological trends in ReRAM development are primarily directed toward addressing key performance metrics including switching speed, power consumption, endurance cycles, and data retention capabilities. The industry is witnessing a shift from proof-of-concept demonstrations to practical implementations that can compete with established memory technologies in specific application domains.

The primary technical objectives for ReRAM technology encompass several dimensions. First, achieving higher density integration to enable terabit-scale memory arrays while maintaining reliable operation. Second, reducing operational power requirements to facilitate integration into energy-constrained systems such as IoT devices and edge computing platforms. Third, enhancing endurance capabilities to support applications requiring frequent write operations.

Additionally, the industry aims to develop robust manufacturing processes that ensure consistent device performance across large-scale production. This includes standardizing fabrication methods, implementing effective quality control measures, and establishing reliable testing protocols to validate device functionality and longevity.

From a system integration perspective, objectives include developing efficient peripheral circuitry for ReRAM arrays, creating optimized programming algorithms that maximize device lifetime, and designing architecture-level solutions that leverage ReRAM's unique characteristics such as multi-level cell capability and potential for in-memory computing applications.

The ultimate goal of ReRAM technology development is to position it as a versatile memory solution capable of addressing the growing demands of data-intensive applications while overcoming the scaling limitations of conventional memory technologies. This includes potential deployment in storage-class memory applications, neuromorphic computing systems, and as embedded non-volatile memory in advanced semiconductor nodes.

The development trajectory of ReRAM has been characterized by continuous improvements in material science, device architecture, and fabrication techniques. Initially focused on binary metal oxide systems such as HfO2, TiO2, and Ta2O5, the field has expanded to include complex oxides, chalcogenides, and organic materials, each offering unique advantages in terms of switching characteristics, endurance, and retention properties.

Current technological trends in ReRAM development are primarily directed toward addressing key performance metrics including switching speed, power consumption, endurance cycles, and data retention capabilities. The industry is witnessing a shift from proof-of-concept demonstrations to practical implementations that can compete with established memory technologies in specific application domains.

The primary technical objectives for ReRAM technology encompass several dimensions. First, achieving higher density integration to enable terabit-scale memory arrays while maintaining reliable operation. Second, reducing operational power requirements to facilitate integration into energy-constrained systems such as IoT devices and edge computing platforms. Third, enhancing endurance capabilities to support applications requiring frequent write operations.

Additionally, the industry aims to develop robust manufacturing processes that ensure consistent device performance across large-scale production. This includes standardizing fabrication methods, implementing effective quality control measures, and establishing reliable testing protocols to validate device functionality and longevity.

From a system integration perspective, objectives include developing efficient peripheral circuitry for ReRAM arrays, creating optimized programming algorithms that maximize device lifetime, and designing architecture-level solutions that leverage ReRAM's unique characteristics such as multi-level cell capability and potential for in-memory computing applications.

The ultimate goal of ReRAM technology development is to position it as a versatile memory solution capable of addressing the growing demands of data-intensive applications while overcoming the scaling limitations of conventional memory technologies. This includes potential deployment in storage-class memory applications, neuromorphic computing systems, and as embedded non-volatile memory in advanced semiconductor nodes.

Market Demand Analysis for ReRAM Solutions

The global memory market is witnessing a significant shift towards non-volatile memory technologies, with Resistive Random Access Memory (ReRAM) emerging as a promising contender. Current market analysis indicates that the ReRAM market is projected to grow at a compound annual growth rate of 16% between 2023 and 2030, driven primarily by increasing demand for high-performance, low-power computing solutions across various sectors.

Data centers represent one of the largest potential markets for ReRAM technology. With the exponential growth in cloud computing and big data applications, data centers face mounting challenges related to power consumption, heat generation, and storage density. ReRAM offers substantial advantages in these areas, potentially reducing power consumption by up to 90% compared to conventional DRAM while providing comparable or superior performance characteristics.

The consumer electronics sector presents another substantial market opportunity for ReRAM solutions. Smartphones, tablets, and wearable devices continue to demand memory technologies that balance performance with energy efficiency. Market research indicates that approximately 30% of next-generation mobile devices could incorporate some form of ReRAM technology by 2028, particularly as manufacturers seek to extend battery life while supporting increasingly complex applications.

Automotive applications represent a rapidly expanding market segment for ReRAM technology. The transition towards autonomous vehicles and advanced driver assistance systems (ADAS) requires robust, high-performance memory solutions capable of operating reliably in extreme conditions. ReRAM's radiation hardness, temperature stability, and fast write speeds make it particularly suitable for these demanding environments, with the automotive memory market expected to reach substantial growth in the coming years.

Industrial IoT applications constitute another significant market opportunity. The proliferation of edge computing devices in industrial settings necessitates memory solutions that combine durability, low power consumption, and rapid data access. Market forecasts suggest that industrial IoT deployments will increase dramatically over the next five years, creating substantial demand for ReRAM and similar non-volatile memory technologies.

Healthcare and medical devices represent an emerging but potentially lucrative market for ReRAM solutions. Applications ranging from implantable medical devices to portable diagnostic equipment benefit from ReRAM's combination of low power consumption, radiation resistance, and reliability. The medical device memory market is expected to grow steadily as healthcare becomes increasingly digitized and personalized.

Despite these promising market opportunities, several factors currently limit widespread ReRAM adoption. Cost remains a significant barrier, with ReRAM solutions generally commanding premium prices compared to established technologies like NAND flash. Additionally, concerns regarding long-term reliability, endurance, and standardization continue to influence purchasing decisions, particularly in risk-averse sectors such as healthcare and automotive applications.

Data centers represent one of the largest potential markets for ReRAM technology. With the exponential growth in cloud computing and big data applications, data centers face mounting challenges related to power consumption, heat generation, and storage density. ReRAM offers substantial advantages in these areas, potentially reducing power consumption by up to 90% compared to conventional DRAM while providing comparable or superior performance characteristics.

The consumer electronics sector presents another substantial market opportunity for ReRAM solutions. Smartphones, tablets, and wearable devices continue to demand memory technologies that balance performance with energy efficiency. Market research indicates that approximately 30% of next-generation mobile devices could incorporate some form of ReRAM technology by 2028, particularly as manufacturers seek to extend battery life while supporting increasingly complex applications.

Automotive applications represent a rapidly expanding market segment for ReRAM technology. The transition towards autonomous vehicles and advanced driver assistance systems (ADAS) requires robust, high-performance memory solutions capable of operating reliably in extreme conditions. ReRAM's radiation hardness, temperature stability, and fast write speeds make it particularly suitable for these demanding environments, with the automotive memory market expected to reach substantial growth in the coming years.

Industrial IoT applications constitute another significant market opportunity. The proliferation of edge computing devices in industrial settings necessitates memory solutions that combine durability, low power consumption, and rapid data access. Market forecasts suggest that industrial IoT deployments will increase dramatically over the next five years, creating substantial demand for ReRAM and similar non-volatile memory technologies.

Healthcare and medical devices represent an emerging but potentially lucrative market for ReRAM solutions. Applications ranging from implantable medical devices to portable diagnostic equipment benefit from ReRAM's combination of low power consumption, radiation resistance, and reliability. The medical device memory market is expected to grow steadily as healthcare becomes increasingly digitized and personalized.

Despite these promising market opportunities, several factors currently limit widespread ReRAM adoption. Cost remains a significant barrier, with ReRAM solutions generally commanding premium prices compared to established technologies like NAND flash. Additionally, concerns regarding long-term reliability, endurance, and standardization continue to influence purchasing decisions, particularly in risk-averse sectors such as healthcare and automotive applications.

ReRAM Technical Status and Challenges

Resistive RAM (ReRAM) technology has reached a critical juncture in its development cycle, with significant advancements achieved globally while still facing substantial technical barriers to widespread commercial adoption. Current global development status shows that ReRAM has progressed from laboratory research to early commercialization phases, with several companies producing limited-scale products for specific applications.

In the United States, companies like Crossbar, Weebit Nano, and Intel have made substantial progress in ReRAM development, focusing on high-density storage solutions and embedded applications. Asian markets, particularly Japan, South Korea, and Taiwan, have seen aggressive development from companies such as Panasonic, Samsung, and TSMC, who have integrated ReRAM into their semiconductor roadmaps. European research institutions continue to contribute significantly to fundamental ReRAM materials science and device physics.

The primary technical challenges currently limiting ReRAM adoption include reliability issues, particularly related to endurance and retention. Most commercial ReRAM solutions still struggle to achieve endurance cycles comparable to NAND flash (>10^5 cycles) while maintaining data retention periods necessary for long-term storage applications (>10 years). This reliability-performance trade-off represents a significant hurdle for mass market adoption.

Device variability remains another critical challenge, with cell-to-cell and cycle-to-cycle variations affecting yield rates and complicating large-array implementations. This variability stems from the stochastic nature of filament formation in oxide-based ReRAM, requiring sophisticated error correction and compensation circuits that increase overall system complexity and power consumption.

Scaling limitations present additional obstacles, as reducing cell dimensions below 20nm introduces quantum effects that can destabilize the conductive filaments. While theoretical models suggest ReRAM could scale to sub-10nm nodes, practical implementations have encountered significant yield and reliability issues at these dimensions.

Manufacturing integration challenges persist, particularly regarding compatibility with standard CMOS processes. The high-temperature processing required for certain ReRAM materials can damage underlying CMOS layers, necessitating either material innovations or process modifications that increase manufacturing complexity and cost.

Power consumption during write operations remains higher than initially projected, with SET/RESET operations typically requiring current densities that limit the technology's applicability in ultra-low-power applications. This challenge is particularly relevant for IoT and edge computing implementations where energy efficiency is paramount.

The geographical distribution of ReRAM technology development shows concentration in technology hubs across North America, East Asia, and Western Europe, with limited activity in emerging markets despite the potential benefits ReRAM could offer for local electronics industries in these regions.

In the United States, companies like Crossbar, Weebit Nano, and Intel have made substantial progress in ReRAM development, focusing on high-density storage solutions and embedded applications. Asian markets, particularly Japan, South Korea, and Taiwan, have seen aggressive development from companies such as Panasonic, Samsung, and TSMC, who have integrated ReRAM into their semiconductor roadmaps. European research institutions continue to contribute significantly to fundamental ReRAM materials science and device physics.

The primary technical challenges currently limiting ReRAM adoption include reliability issues, particularly related to endurance and retention. Most commercial ReRAM solutions still struggle to achieve endurance cycles comparable to NAND flash (>10^5 cycles) while maintaining data retention periods necessary for long-term storage applications (>10 years). This reliability-performance trade-off represents a significant hurdle for mass market adoption.

Device variability remains another critical challenge, with cell-to-cell and cycle-to-cycle variations affecting yield rates and complicating large-array implementations. This variability stems from the stochastic nature of filament formation in oxide-based ReRAM, requiring sophisticated error correction and compensation circuits that increase overall system complexity and power consumption.

Scaling limitations present additional obstacles, as reducing cell dimensions below 20nm introduces quantum effects that can destabilize the conductive filaments. While theoretical models suggest ReRAM could scale to sub-10nm nodes, practical implementations have encountered significant yield and reliability issues at these dimensions.

Manufacturing integration challenges persist, particularly regarding compatibility with standard CMOS processes. The high-temperature processing required for certain ReRAM materials can damage underlying CMOS layers, necessitating either material innovations or process modifications that increase manufacturing complexity and cost.

Power consumption during write operations remains higher than initially projected, with SET/RESET operations typically requiring current densities that limit the technology's applicability in ultra-low-power applications. This challenge is particularly relevant for IoT and edge computing implementations where energy efficiency is paramount.

The geographical distribution of ReRAM technology development shows concentration in technology hubs across North America, East Asia, and Western Europe, with limited activity in emerging markets despite the potential benefits ReRAM could offer for local electronics industries in these regions.

Current ReRAM Implementation Approaches

01 ReRAM device structures and fabrication methods

Resistive RAM devices can be fabricated using various structures and methods to enhance performance and reliability. These include multi-layer structures with specific electrode materials, integration of selector devices, and specialized deposition techniques for the resistive switching layer. The fabrication processes often involve precise control of material interfaces and optimization of switching layer thickness to achieve desired resistance states and switching characteristics.- ReRAM device structures and fabrication methods: Resistive RAM devices can be fabricated using various structures and methods to enhance performance and reliability. These include multi-layer structures with specific electrode materials, dielectric layers, and resistive switching materials. Advanced fabrication techniques such as atomic layer deposition, physical vapor deposition, and lithography processes are employed to create these structures with precise control over dimensions and interfaces, which are critical for reliable resistive switching behavior.

- Resistive switching materials and mechanisms: The core functionality of ReRAM depends on resistive switching materials that can change their resistance states under applied voltage. Various materials including metal oxides, chalcogenides, and perovskites exhibit this behavior through different mechanisms such as filament formation/rupture, interface-type switching, or phase change. Understanding and controlling these mechanisms is essential for designing ReRAM devices with optimal performance characteristics including switching speed, endurance, and retention.

- ReRAM array architecture and integration: ReRAM cells can be organized into memory arrays using various architectures such as crossbar arrays, 3D stacking, or hybrid configurations. These architectures address challenges related to sneak path currents, access device integration, and density optimization. Integration with CMOS technology and other memory types enables the creation of efficient memory subsystems that can leverage the advantages of ReRAM while mitigating its limitations.

- Programming and read schemes for ReRAM: Specialized programming and read schemes are essential for reliable operation of ReRAM devices. These include voltage/current pulse shaping, verify-after-write operations, and adaptive programming algorithms that can compensate for device variability. Advanced read techniques such as multi-level sensing and reference cell designs help distinguish between resistance states accurately while minimizing read disturbance effects.

- ReRAM applications and emerging technologies: Beyond conventional memory applications, ReRAM is being explored for neuromorphic computing, in-memory computing, and edge AI applications due to its analog switching characteristics and low power operation. Emerging technologies combining ReRAM with other novel materials or device concepts are being developed to address specific application requirements such as ultra-low power operation, radiation hardness, or extreme temperature operation.

02 Resistive switching materials for ReRAM

Various materials can be used as the resistive switching layer in ReRAM devices. These include metal oxides (such as HfOx, TaOx, TiOx), chalcogenides, and perovskites. The selection of appropriate materials affects key performance parameters such as switching speed, endurance, retention time, and power consumption. Material engineering approaches like doping, defect control, and interface modification are employed to optimize the resistive switching behavior.Expand Specific Solutions03 ReRAM array architecture and integration

ReRAM can be integrated into various memory array architectures including crossbar arrays, 3D stacked structures, and hybrid memory systems. These architectures address challenges related to sneak path currents, cell density, and integration with CMOS technology. Advanced interconnect schemes and peripheral circuitry designs are implemented to support high-density memory arrays while maintaining reliable operation and addressing signal integrity issues.Expand Specific Solutions04 Programming and operation methods for ReRAM

Specific programming methods and operation schemes are crucial for reliable ReRAM performance. These include pulse shaping techniques, multi-level cell programming algorithms, and read/write schemes that mitigate variability issues. Advanced sensing circuits and reference schemes are employed to accurately distinguish between resistance states. Adaptive programming approaches can be used to compensate for device-to-device variations and extend device lifetime by managing stress on the switching material.Expand Specific Solutions05 ReRAM applications and system integration

ReRAM technology can be applied in various applications beyond conventional memory storage, including neuromorphic computing, in-memory computing, and edge AI systems. The non-volatile nature and analog switching characteristics make ReRAM suitable for implementing artificial neural networks and other brain-inspired computing paradigms. System-level integration approaches address challenges related to interfacing with conventional computing architectures, power management, and reliability in specific application environments.Expand Specific Solutions

Key ReRAM Industry Players and Competition

Resistive RAM (RRAM) technology is currently in the early growth phase of its industry lifecycle, transitioning from research to commercialization. The global RRAM market is projected to reach approximately $4-5 billion by 2025, with significant growth potential in embedded memory, storage-class memory, and neuromorphic computing applications. Major players including Samsung, Micron, Crossbar, and KIOXIA are advancing the technology's maturity, while research institutions like Peking University, IMEC, and Industrial Technology Research Institute provide foundational innovations. Chinese entities such as SMIC and Huali Microelectronics are increasing investments to reduce the technology gap with established semiconductor leaders like TSMC and UMC, who are integrating RRAM into their advanced process nodes for IoT and AI applications.

CrossBar, Inc.

Technical Solution: CrossBar has developed a proprietary ReRAM technology based on a silver-doped silicon-based switching material that creates a non-conductive amorphous silicon layer between electrodes. When voltage is applied, a filament forms through the amorphous silicon to create a low-resistance path. Their 3D ReRAM architecture allows for multiple terabytes of storage capacity by stacking memory arrays vertically. CrossBar's technology achieves write speeds 1,000 times faster than NAND flash with 20 times lower power consumption[1]. Their cells can be manufactured using standard CMOS processes at temperatures below 400°C, enabling back-end-of-line integration. The company has demonstrated excellent retention capabilities with data preservation for over 10 years at 85°C and endurance of up to 10^9 cycles[2], making it suitable for both storage and embedded applications.

Strengths: Superior write speed and power efficiency compared to flash memory; excellent data retention and endurance characteristics; CMOS-compatible manufacturing process enabling easy integration with logic circuits. Weaknesses: Relatively new technology with limited commercial deployment; requires specialized materials handling; faces competition from established memory technologies with mature ecosystems.

Micron Technology, Inc.

Technical Solution: Micron has developed 3D XPoint technology (jointly with Intel) which, while technically not pure ReRAM, shares many characteristics with resistive memory technologies. Their approach uses chalcogenide materials in a cross-point architecture where memory cells are located at the intersection of word lines and bit lines. Micron's implementation allows for non-destructive reads and bit-alterable writes without the need to first erase blocks of data. The technology achieves 1000x faster write speeds and 10x higher density compared to conventional NAND flash[3]. Micron has also been researching true ReRAM solutions based on metal-oxide switching materials, particularly using hafnium oxide and tantalum oxide stacks that demonstrate improved switching uniformity. Their ReRAM research has shown devices capable of sub-10ns switching speeds with endurance exceeding 10^6 cycles[4], positioning the technology for both storage class memory and embedded applications.

Strengths: Established manufacturing infrastructure and expertise in memory production; significant R&D resources; ability to integrate ReRAM technology with existing product lines. Weaknesses: Primary commercial focus has shifted toward 3D XPoint rather than pure ReRAM solutions; faces challenges in scaling production to compete with established memory technologies on cost.

Critical ReRAM Patents and Technical Innovations

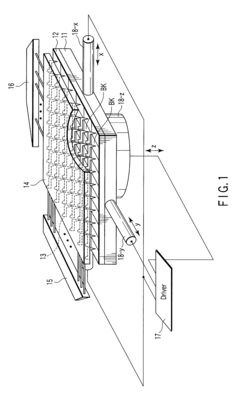

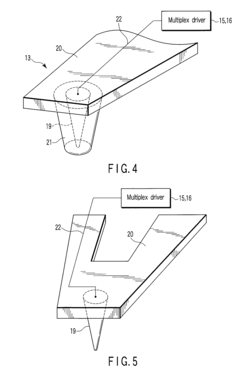

Information recording/reproducing device having head covering by resistance element

PatentInactiveUS8050171B2

Innovation

- Incorporating a resistance element on the conductive region of the probe head for reading servo burst signals, allowing for smooth intensity changes based on position deviation, enabling precise position control and high sensitivity data reproduction.

ReRAM Manufacturing Process Analysis

The manufacturing process of Resistive Random Access Memory (ReRAM) represents a critical factor in its market adoption and technological advancement. Current ReRAM fabrication typically employs a CMOS-compatible process, allowing integration with existing semiconductor manufacturing infrastructure. The standard process flow involves substrate preparation, bottom electrode deposition, resistive switching layer formation, top electrode deposition, and final encapsulation.

The resistive switching layer, typically composed of metal oxides such as HfOx, TaOx, or TiOx, constitutes the most crucial component. These materials are deposited using various techniques including atomic layer deposition (ALD), physical vapor deposition (PVD), or reactive sputtering. ALD has gained prominence due to its precise thickness control and excellent conformality, enabling the formation of ultra-thin films with minimal defects.

Process temperature represents a significant manufacturing consideration. While some ReRAM variants require high-temperature annealing (400-800°C) to optimize the switching layer properties, others employ room-temperature processes that facilitate back-end-of-line (BEOL) integration. This temperature flexibility allows ReRAM to be integrated either as embedded memory in logic chips or as standalone memory devices.

Scaling challenges persist in ReRAM manufacturing, particularly in achieving consistent switching behavior across billions of cells. Current manufacturing processes have demonstrated capabilities down to 22nm node, with research prototypes reaching 10nm. However, uniformity issues increase at smaller nodes, requiring innovations in deposition techniques and materials engineering.

Yield management represents another critical aspect of ReRAM manufacturing. The formation of conductive filaments within the switching layer must occur consistently across the entire wafer. Process variations can lead to device-to-device variability, necessitating tight process control and advanced metrology techniques. Leading manufacturers have implemented in-line testing and statistical process control to identify and mitigate yield-limiting factors.

Cost considerations significantly impact ReRAM's market viability. While the basic structure appears simple, achieving reliable switching behavior requires precise material engineering and process control. Current manufacturing costs exceed those of established memory technologies, though economies of scale and process optimization are gradually reducing this gap. The potential for 3D stacking further enhances cost-effectiveness by increasing bit density without proportional cost increases.

The resistive switching layer, typically composed of metal oxides such as HfOx, TaOx, or TiOx, constitutes the most crucial component. These materials are deposited using various techniques including atomic layer deposition (ALD), physical vapor deposition (PVD), or reactive sputtering. ALD has gained prominence due to its precise thickness control and excellent conformality, enabling the formation of ultra-thin films with minimal defects.

Process temperature represents a significant manufacturing consideration. While some ReRAM variants require high-temperature annealing (400-800°C) to optimize the switching layer properties, others employ room-temperature processes that facilitate back-end-of-line (BEOL) integration. This temperature flexibility allows ReRAM to be integrated either as embedded memory in logic chips or as standalone memory devices.

Scaling challenges persist in ReRAM manufacturing, particularly in achieving consistent switching behavior across billions of cells. Current manufacturing processes have demonstrated capabilities down to 22nm node, with research prototypes reaching 10nm. However, uniformity issues increase at smaller nodes, requiring innovations in deposition techniques and materials engineering.

Yield management represents another critical aspect of ReRAM manufacturing. The formation of conductive filaments within the switching layer must occur consistently across the entire wafer. Process variations can lead to device-to-device variability, necessitating tight process control and advanced metrology techniques. Leading manufacturers have implemented in-line testing and statistical process control to identify and mitigate yield-limiting factors.

Cost considerations significantly impact ReRAM's market viability. While the basic structure appears simple, achieving reliable switching behavior requires precise material engineering and process control. Current manufacturing costs exceed those of established memory technologies, though economies of scale and process optimization are gradually reducing this gap. The potential for 3D stacking further enhances cost-effectiveness by increasing bit density without proportional cost increases.

Energy Efficiency and Sustainability Aspects

Resistive RAM (ReRAM) technology stands out in the semiconductor landscape for its remarkable energy efficiency characteristics. When compared to conventional memory technologies such as DRAM and NAND Flash, ReRAM demonstrates significantly lower power consumption during both active operations and standby modes. This efficiency stems from its fundamental operating principle, which requires minimal energy to switch between resistance states, typically in the range of picojoules per bit operation.

The sustainability profile of ReRAM extends beyond mere power consumption metrics. The manufacturing processes for ReRAM involve fewer toxic materials and chemicals compared to traditional memory fabrication. Additionally, the simpler structure of ReRAM cells translates to reduced material requirements and potentially lower environmental impact during production phases. These attributes position ReRAM as an environmentally preferable alternative in the evolving memory technology landscape.

From a lifecycle perspective, ReRAM offers compelling advantages. The technology's non-volatile nature eliminates the need for constant power to maintain stored data, resulting in substantial energy savings in large-scale data storage applications. Furthermore, the projected longevity of ReRAM devices—with endurance ratings potentially reaching 10^12 cycles in advanced implementations—contributes to reduced electronic waste generation through extended product lifespans.

In data center environments, where energy consumption represents both a significant operational cost and environmental concern, ReRAM's efficiency characteristics present particularly valuable benefits. Preliminary studies suggest that widespread ReRAM adoption could reduce memory subsystem power requirements by 30-40% compared to current technologies, with corresponding reductions in cooling infrastructure demands and overall carbon footprint.

The sustainability advantages of ReRAM align with global initiatives toward greener computing and carbon neutrality goals. As regulatory frameworks increasingly emphasize energy efficiency metrics and environmental impact considerations, ReRAM's favorable profile may accelerate its market adoption beyond purely technical performance considerations. Several major semiconductor manufacturers have already highlighted the technology's sustainability aspects in their strategic roadmaps and environmental commitment statements.

Looking forward, ongoing research focuses on further enhancing ReRAM's energy efficiency through materials innovation and architectural optimizations. Emerging approaches include exploration of novel switching materials with lower energy barriers, integration with energy harvesting technologies for ultra-low-power applications, and development of specialized power management techniques tailored to ReRAM's unique operational characteristics.

The sustainability profile of ReRAM extends beyond mere power consumption metrics. The manufacturing processes for ReRAM involve fewer toxic materials and chemicals compared to traditional memory fabrication. Additionally, the simpler structure of ReRAM cells translates to reduced material requirements and potentially lower environmental impact during production phases. These attributes position ReRAM as an environmentally preferable alternative in the evolving memory technology landscape.

From a lifecycle perspective, ReRAM offers compelling advantages. The technology's non-volatile nature eliminates the need for constant power to maintain stored data, resulting in substantial energy savings in large-scale data storage applications. Furthermore, the projected longevity of ReRAM devices—with endurance ratings potentially reaching 10^12 cycles in advanced implementations—contributes to reduced electronic waste generation through extended product lifespans.

In data center environments, where energy consumption represents both a significant operational cost and environmental concern, ReRAM's efficiency characteristics present particularly valuable benefits. Preliminary studies suggest that widespread ReRAM adoption could reduce memory subsystem power requirements by 30-40% compared to current technologies, with corresponding reductions in cooling infrastructure demands and overall carbon footprint.

The sustainability advantages of ReRAM align with global initiatives toward greener computing and carbon neutrality goals. As regulatory frameworks increasingly emphasize energy efficiency metrics and environmental impact considerations, ReRAM's favorable profile may accelerate its market adoption beyond purely technical performance considerations. Several major semiconductor manufacturers have already highlighted the technology's sustainability aspects in their strategic roadmaps and environmental commitment statements.

Looking forward, ongoing research focuses on further enhancing ReRAM's energy efficiency through materials innovation and architectural optimizations. Emerging approaches include exploration of novel switching materials with lower energy barriers, integration with energy harvesting technologies for ultra-low-power applications, and development of specialized power management techniques tailored to ReRAM's unique operational characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!