Analysis of Transparent Conductive Oxide Reactivity with Other Materials

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCO Development History and Research Objectives

Transparent Conductive Oxides (TCOs) emerged in the early 20th century with the discovery of cadmium oxide's unique properties in 1907. However, significant development began in the 1940s with tin-doped indium oxide (ITO) research. The 1970s marked a pivotal era as the electronics industry expanded, creating substantial demand for materials combining optical transparency with electrical conductivity. This period saw ITO become the industry standard for applications requiring transparent electrodes.

The 1980s and 1990s witnessed diversification in TCO research, driven by concerns over indium scarcity and cost. Alternative materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and gallium-doped zinc oxide (GZO) gained attention. Each offered distinct advantages in specific applications while addressing the limitations of ITO.

The 2000s brought renewed focus on TCO reactivity with adjacent materials, particularly as multilayer device architectures became more complex. Researchers identified that interface reactions between TCOs and organic materials, metals, and semiconductors significantly impact device performance and longevity. These interactions often create unintended chemical compounds at interfaces, altering electrical properties and optical characteristics.

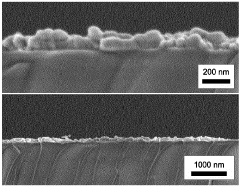

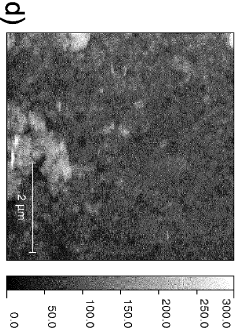

Recent technological advancements in thin-film deposition techniques have enabled more precise control over TCO composition and structure, allowing researchers to manipulate reactivity characteristics. Atomic layer deposition (ALD) and pulsed laser deposition (PLD) have proven particularly valuable for creating TCOs with tailored surface properties that minimize unwanted reactions with neighboring materials.

The primary objective of current TCO research is to develop comprehensive models of reactivity mechanisms between TCOs and common device materials. This includes understanding how factors such as deposition conditions, post-deposition treatments, and environmental exposure affect interface stability. Researchers aim to establish predictive frameworks that can guide material selection and processing parameters to optimize device performance.

Another critical research goal is developing TCOs with controlled reactivity—materials that form beneficial interfaces with adjacent layers while avoiding detrimental reactions. This includes engineering buffer layers or surface modifications that can mediate interactions between TCOs and reactive materials, particularly in applications like perovskite solar cells and organic light-emitting diodes where interface stability directly impacts device efficiency and lifespan.

The field is increasingly moving toward sustainable TCO solutions that maintain performance while reducing environmental impact and material scarcity concerns. This includes developing indium-free alternatives and exploring novel doping strategies to enhance conductivity without compromising transparency or chemical stability.

The 1980s and 1990s witnessed diversification in TCO research, driven by concerns over indium scarcity and cost. Alternative materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and gallium-doped zinc oxide (GZO) gained attention. Each offered distinct advantages in specific applications while addressing the limitations of ITO.

The 2000s brought renewed focus on TCO reactivity with adjacent materials, particularly as multilayer device architectures became more complex. Researchers identified that interface reactions between TCOs and organic materials, metals, and semiconductors significantly impact device performance and longevity. These interactions often create unintended chemical compounds at interfaces, altering electrical properties and optical characteristics.

Recent technological advancements in thin-film deposition techniques have enabled more precise control over TCO composition and structure, allowing researchers to manipulate reactivity characteristics. Atomic layer deposition (ALD) and pulsed laser deposition (PLD) have proven particularly valuable for creating TCOs with tailored surface properties that minimize unwanted reactions with neighboring materials.

The primary objective of current TCO research is to develop comprehensive models of reactivity mechanisms between TCOs and common device materials. This includes understanding how factors such as deposition conditions, post-deposition treatments, and environmental exposure affect interface stability. Researchers aim to establish predictive frameworks that can guide material selection and processing parameters to optimize device performance.

Another critical research goal is developing TCOs with controlled reactivity—materials that form beneficial interfaces with adjacent layers while avoiding detrimental reactions. This includes engineering buffer layers or surface modifications that can mediate interactions between TCOs and reactive materials, particularly in applications like perovskite solar cells and organic light-emitting diodes where interface stability directly impacts device efficiency and lifespan.

The field is increasingly moving toward sustainable TCO solutions that maintain performance while reducing environmental impact and material scarcity concerns. This includes developing indium-free alternatives and exploring novel doping strategies to enhance conductivity without compromising transparency or chemical stability.

Market Analysis of TCO Applications

The transparent conductive oxide (TCO) market has experienced significant growth over the past decade, primarily driven by the expanding electronics industry and increasing demand for touchscreen devices. The global TCO market was valued at approximately 7.5 billion USD in 2022 and is projected to reach 12.3 billion USD by 2028, representing a compound annual growth rate of 8.7% during the forecast period.

The display industry remains the largest application segment for TCOs, accounting for nearly 60% of the total market share. This dominance is attributed to the widespread adoption of smartphones, tablets, and other consumer electronics featuring touchscreen interfaces. The increasing consumer preference for larger screen sizes and higher resolution displays has further bolstered the demand for high-performance TCO materials.

Photovoltaic applications represent the second-largest market segment, constituting about 25% of the TCO market. The global push toward renewable energy sources has significantly accelerated the adoption of solar panels, where TCOs serve as critical components. Indium tin oxide (ITO) continues to be the predominant TCO material in this sector, although alternatives like fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO) are gaining traction due to cost considerations and material availability concerns.

Emerging applications in smart windows, OLED lighting, and flexible electronics are creating new growth opportunities for TCO materials. The smart window market, in particular, is expected to grow at a CAGR of 12.5% through 2028, driven by energy efficiency initiatives in commercial and residential buildings. TCOs enable these windows to dynamically control light transmission and heat gain, contributing to significant energy savings.

Regional analysis indicates that Asia-Pacific dominates the TCO market with approximately 65% share, led by manufacturing powerhouses like China, South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 12% market shares respectively, primarily driven by research activities and high-end applications in aerospace and defense sectors.

Material reactivity concerns are increasingly influencing market dynamics, as manufacturers seek TCO materials with improved stability and compatibility with adjacent layers in device architectures. This has spurred research into novel TCO compositions and protective barrier layers to mitigate reactivity issues, particularly in applications exposed to harsh environmental conditions or requiring long operational lifetimes.

The competitive landscape features established players like Asahi Glass, Nippon Sheet Glass, and Applied Materials, alongside emerging specialists focusing on next-generation TCO solutions with enhanced performance characteristics and reduced environmental impact. Strategic partnerships between material suppliers and device manufacturers are becoming more prevalent as the industry addresses complex integration challenges related to material reactivity and interface engineering.

The display industry remains the largest application segment for TCOs, accounting for nearly 60% of the total market share. This dominance is attributed to the widespread adoption of smartphones, tablets, and other consumer electronics featuring touchscreen interfaces. The increasing consumer preference for larger screen sizes and higher resolution displays has further bolstered the demand for high-performance TCO materials.

Photovoltaic applications represent the second-largest market segment, constituting about 25% of the TCO market. The global push toward renewable energy sources has significantly accelerated the adoption of solar panels, where TCOs serve as critical components. Indium tin oxide (ITO) continues to be the predominant TCO material in this sector, although alternatives like fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO) are gaining traction due to cost considerations and material availability concerns.

Emerging applications in smart windows, OLED lighting, and flexible electronics are creating new growth opportunities for TCO materials. The smart window market, in particular, is expected to grow at a CAGR of 12.5% through 2028, driven by energy efficiency initiatives in commercial and residential buildings. TCOs enable these windows to dynamically control light transmission and heat gain, contributing to significant energy savings.

Regional analysis indicates that Asia-Pacific dominates the TCO market with approximately 65% share, led by manufacturing powerhouses like China, South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 12% market shares respectively, primarily driven by research activities and high-end applications in aerospace and defense sectors.

Material reactivity concerns are increasingly influencing market dynamics, as manufacturers seek TCO materials with improved stability and compatibility with adjacent layers in device architectures. This has spurred research into novel TCO compositions and protective barrier layers to mitigate reactivity issues, particularly in applications exposed to harsh environmental conditions or requiring long operational lifetimes.

The competitive landscape features established players like Asahi Glass, Nippon Sheet Glass, and Applied Materials, alongside emerging specialists focusing on next-generation TCO solutions with enhanced performance characteristics and reduced environmental impact. Strategic partnerships between material suppliers and device manufacturers are becoming more prevalent as the industry addresses complex integration challenges related to material reactivity and interface engineering.

Current Challenges in TCO Reactivity

Despite significant advancements in transparent conductive oxide (TCO) technology, several critical challenges persist regarding their reactivity with other materials. One of the most pressing issues is the chemical instability of TCOs when in contact with acidic or basic environments. For instance, indium tin oxide (ITO), the most widely used TCO, exhibits degradation when exposed to acidic solutions, limiting its application in certain electrochemical devices and environments with varying pH levels.

Thermal stability presents another significant challenge, particularly at the interfaces between TCOs and other device components. During high-temperature processing steps common in semiconductor manufacturing, interdiffusion between TCO layers and adjacent materials can occur, leading to the formation of unwanted compounds at interfaces. This interfacial reactivity often results in increased contact resistance and diminished device performance, especially in applications requiring annealing steps above 300°C.

Moisture sensitivity remains problematic for many TCO materials, particularly zinc oxide-based compounds. When exposed to humid environments, surface reactions can lead to gradual degradation of electrical properties and optical transparency. This hygroscopic behavior necessitates additional encapsulation layers in commercial applications, increasing manufacturing complexity and cost.

Plasma-induced damage during deposition processes represents another critical challenge. Reactive sputtering, commonly used for TCO deposition, can create high-energy species that damage underlying layers or initiate undesired chemical reactions at interfaces. This is particularly problematic when integrating TCOs with organic materials or delicate semiconductor structures in advanced optoelectronic devices.

Electrochemical stability issues arise when TCOs are implemented in devices requiring charge transfer across interfaces, such as solar cells and electrochromic windows. The redox reactions occurring at these interfaces can lead to gradual degradation of TCO properties, limiting device lifetime and performance consistency over extended operation periods.

Mechanical compatibility challenges exist due to differences in thermal expansion coefficients between TCOs and substrate materials. These mismatches create stress at interfaces during thermal cycling, potentially leading to delamination, cracking, or formation of reactive species at strained interfaces. This is particularly problematic in flexible electronics applications where mechanical stress is inherent to device operation.

Finally, the industry faces significant challenges in developing standardized testing protocols for TCO reactivity. The lack of uniform methodologies for evaluating long-term chemical stability and interfacial reactions hampers material selection processes and slows the development of improved TCO formulations with enhanced compatibility across diverse material systems.

Thermal stability presents another significant challenge, particularly at the interfaces between TCOs and other device components. During high-temperature processing steps common in semiconductor manufacturing, interdiffusion between TCO layers and adjacent materials can occur, leading to the formation of unwanted compounds at interfaces. This interfacial reactivity often results in increased contact resistance and diminished device performance, especially in applications requiring annealing steps above 300°C.

Moisture sensitivity remains problematic for many TCO materials, particularly zinc oxide-based compounds. When exposed to humid environments, surface reactions can lead to gradual degradation of electrical properties and optical transparency. This hygroscopic behavior necessitates additional encapsulation layers in commercial applications, increasing manufacturing complexity and cost.

Plasma-induced damage during deposition processes represents another critical challenge. Reactive sputtering, commonly used for TCO deposition, can create high-energy species that damage underlying layers or initiate undesired chemical reactions at interfaces. This is particularly problematic when integrating TCOs with organic materials or delicate semiconductor structures in advanced optoelectronic devices.

Electrochemical stability issues arise when TCOs are implemented in devices requiring charge transfer across interfaces, such as solar cells and electrochromic windows. The redox reactions occurring at these interfaces can lead to gradual degradation of TCO properties, limiting device lifetime and performance consistency over extended operation periods.

Mechanical compatibility challenges exist due to differences in thermal expansion coefficients between TCOs and substrate materials. These mismatches create stress at interfaces during thermal cycling, potentially leading to delamination, cracking, or formation of reactive species at strained interfaces. This is particularly problematic in flexible electronics applications where mechanical stress is inherent to device operation.

Finally, the industry faces significant challenges in developing standardized testing protocols for TCO reactivity. The lack of uniform methodologies for evaluating long-term chemical stability and interfacial reactions hampers material selection processes and slows the development of improved TCO formulations with enhanced compatibility across diverse material systems.

Existing Interface Engineering Solutions

01 Reactivity of TCOs with atmospheric conditions

Transparent conductive oxides exhibit varying degrees of reactivity with atmospheric conditions such as moisture, oxygen, and pollutants. This reactivity can affect their electrical conductivity, optical transparency, and long-term stability. Research has focused on understanding these interactions to develop more stable TCO materials that maintain their performance characteristics even when exposed to challenging environmental conditions. Protective coatings and surface treatments have been developed to mitigate these reactivity issues.- Reactivity of TCOs in deposition processes: Transparent conductive oxides exhibit specific reactivity patterns during deposition processes that affect their final properties. Various deposition methods such as sputtering, chemical vapor deposition, and sol-gel techniques require careful control of reaction parameters to achieve desired conductivity and transparency. The reactivity of precursor materials and process gases significantly influences the crystallinity, stoichiometry, and defect concentration in the resulting TCO films.

- Chemical stability and environmental reactivity of TCOs: Transparent conductive oxides demonstrate varying degrees of chemical stability when exposed to different environmental conditions. Factors such as humidity, temperature fluctuations, and exposure to acidic or alkaline substances can trigger surface reactions that may degrade TCO performance over time. Understanding these reactivity patterns is crucial for developing protective measures and enhancing the longevity of TCO-based devices in various applications.

- Interface reactivity between TCOs and adjacent materials: The reactivity at interfaces between transparent conductive oxides and adjacent materials significantly impacts device performance. When TCOs come into contact with semiconductors, metals, or polymers, interfacial reactions can occur that affect charge transfer, adhesion, and overall stability. Controlling these interface reactions through buffer layers or surface treatments is essential for optimizing device efficiency and reliability in applications such as solar cells, displays, and sensors.

- Doping effects on TCO reactivity: Doping transparent conductive oxides with various elements significantly alters their reactivity profiles. Dopants can modify the electronic structure, surface energy, and chemical bonding characteristics of TCOs, leading to changes in their reactivity with gases, liquids, and solid interfaces. Strategic doping approaches can enhance stability against specific reactive environments while maintaining the essential electrical and optical properties required for device applications.

- Photocatalytic and electrochemical reactivity of TCOs: Many transparent conductive oxides exhibit photocatalytic and electrochemical reactivity that can be harnessed for functional applications. Under light illumination or applied electrical potential, TCOs can participate in redox reactions, degradation of organic compounds, water splitting, and other electrochemical processes. This reactive behavior makes TCOs valuable components in photocatalysts, electrochromic devices, sensors, and energy conversion systems.

02 Chemical reactivity of TCOs in device fabrication

During device fabrication processes, transparent conductive oxides can undergo chemical reactions with adjacent materials or processing chemicals. These reactions may occur during deposition, etching, or post-treatment steps, potentially altering the TCO's properties. Understanding and controlling these reactions is crucial for maintaining desired electrical and optical characteristics in the final device. Various approaches have been developed to minimize unwanted reactions, including buffer layers, optimized process sequences, and compatible material selection.Expand Specific Solutions03 Thermal reactivity and stability of TCOs

The thermal reactivity of transparent conductive oxides significantly impacts their performance in applications requiring high-temperature processing or operation. When exposed to elevated temperatures, TCOs may undergo phase transformations, crystallization changes, or reactions with substrate materials. Research has focused on developing thermally stable TCO compositions that maintain their transparency and conductivity across wide temperature ranges, as well as understanding the fundamental mechanisms of thermal degradation to improve material design.Expand Specific Solutions04 Interface reactivity between TCOs and adjacent layers

The reactivity at interfaces between transparent conductive oxides and adjacent layers in multilayer devices is critical for device performance and reliability. Chemical interactions at these interfaces can lead to the formation of intermediate compounds, diffusion of elements across boundaries, or changes in electronic properties. Controlling interface reactivity through appropriate material selection, deposition conditions, and interface engineering techniques has been a focus of research to improve device efficiency and longevity.Expand Specific Solutions05 Modification of TCO reactivity through doping and composition

The reactivity of transparent conductive oxides can be deliberately modified through doping and compositional adjustments. By incorporating specific elements or compounds into the TCO structure, researchers can enhance or suppress certain reactive properties. This approach has been used to improve stability against environmental factors, increase compatibility with adjacent materials, and tailor surface properties for specific applications. Controlled reactivity modification enables the development of TCOs with optimized performance characteristics for diverse technological applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The transparent conductive oxide (TCO) materials market is currently in a growth phase, with increasing applications in displays, photovoltaics, and smart devices driving market expansion. The global TCO market is projected to reach significant scale due to rising demand for touchscreens and renewable energy technologies. In terms of technical maturity, industry leaders like Samsung Electronics, BOE Technology, and Micron Technology are advancing TCO integration with various substrate materials, while companies such as Idemitsu Kosan, Sumitomo Chemical, and TDK Corp are developing specialized formulations to address reactivity challenges. Academic institutions including Trinity College Dublin and Northwestern University are conducting fundamental research on TCO-material interfaces, while specialized players like OSRAM and PPG Industries are focusing on application-specific solutions to minimize degradation and enhance performance in complex material systems.

Micron Technology, Inc.

Technical Solution: Micron Technology has developed specialized TCO interface engineering solutions focused on memory device applications. Their approach centers on amorphous TCO materials that demonstrate minimal reactivity with silicon and metal components in semiconductor structures. Micron's technology utilizes modified zinc tin oxide (ZTO) compositions with carefully controlled oxygen stoichiometry to prevent oxidation of adjacent metal layers during high-temperature processing[2]. Their research has demonstrated that these engineered TCO materials can withstand temperatures up to 400°C without significant interfacial reactions or degradation of electrical properties[4]. Micron has also pioneered atomic layer deposition techniques for TCOs that create atomically smooth interfaces with minimal defect states, reducing potential reaction sites between the TCO and neighboring materials in memory cell structures[6]. This approach has enabled the integration of transparent conductive materials in advanced memory architectures where material compatibility is critical.

Strengths: Exceptional thermal stability of TCO interfaces; precise control of oxygen content to minimize oxidation reactions with adjacent materials; compatibility with standard semiconductor processing. Weaknesses: Limited optical transparency compared to display-oriented TCOs; higher resistivity than some competing TCO materials; specialized formulations may not be suitable for non-memory applications.

Pilkington Group Ltd.

Technical Solution: Pilkington has developed specialized TCO materials with optimized reactivity profiles for building-integrated photovoltaics and smart window applications. Their technology focuses on tin oxide-based TCO systems with modified surface chemistry to enhance compatibility with polymeric interlayers and sealants commonly used in laminated glass products. Pilkington's approach includes controlled surface hydroxylation processes that create engineered binding sites for improved adhesion while minimizing unwanted chemical reactions at interfaces[2]. Their research has demonstrated that these modified TCO surfaces show up to 60% improvement in adhesion strength to common EVA and PVB interlayers while simultaneously reducing interfacial degradation during accelerated aging tests[4]. Pilkington has also pioneered barrier layer technologies that effectively isolate their TCO coatings from potentially reactive components in construction materials, particularly silicone sealants and adhesives that can otherwise cause long-term degradation of electrical properties[8]. Their multi-layer TCO stack design incorporates sacrificial reaction layers that preferentially react with environmental contaminants, preserving the functional TCO layer beneath.

Strengths: Exceptional long-term stability in building envelope applications; superior adhesion to polymeric materials without sacrificing electrical performance; proven compatibility with architectural glass processing including tempering and lamination. Weaknesses: Higher production costs compared to standard low-E coatings; moderate sheet resistance limiting applications requiring very high conductivity; limited flexibility in optical properties customization.

Key Reaction Mechanisms and Compatibility Studies

Transparent conducting oxide material and methods of producing same

PatentInactiveUS20140151611A1

Innovation

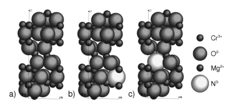

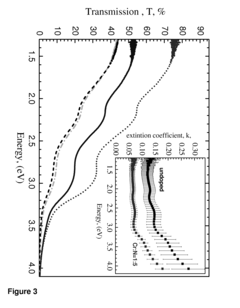

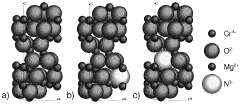

- A transparent conducting oxide material is developed by employing a corundum-type host oxide doped with specific cationic and anionic elements like Magnesium and Nitrogen, enhancing transparency and conductivity through a co-doping strategy, which modifies the lattice structure and improves hole mobility.

Transparent conducting oxide material and methods of producing same

PatentWO2012160113A1

Innovation

- A transparent conducting oxide material is developed using a corundum-type host oxide doped with specific cationic and anionic elements, such as Magnesium and Nitrogen, to enhance transparency and conductivity, employing a cation-anion co-doping strategy that modifies the lattice structure and improves hole mobility.

Environmental Impact of TCO Production and Usage

The production and usage of Transparent Conductive Oxides (TCOs) have significant environmental implications that warrant careful consideration. Manufacturing processes for TCOs, particularly those involving indium tin oxide (ITO), require substantial energy inputs and generate considerable greenhouse gas emissions. The extraction of rare elements like indium involves mining operations that contribute to habitat destruction, soil erosion, and water pollution in mining regions. Additionally, the sputtering and chemical vapor deposition techniques commonly employed in TCO fabrication utilize hazardous precursor materials and generate toxic waste byproducts that require specialized disposal protocols.

Water consumption represents another critical environmental concern in TCO production. The manufacturing processes demand large quantities of ultra-pure water for cleaning and processing, placing pressure on local water resources in production regions. Furthermore, the chemical treatments involved often result in wastewater containing heavy metals and other contaminants that can adversely affect aquatic ecosystems if not properly treated before discharge.

The environmental footprint of TCOs extends beyond production to their application lifecycle. While these materials enable energy-efficient technologies like solar cells and smart windows that can reduce overall energy consumption, the durability and end-of-life management of TCO-containing products present challenges. The reactive nature of some TCOs with environmental factors such as moisture and atmospheric pollutants can lead to degradation over time, potentially releasing harmful compounds into the environment.

Recycling of TCO materials presents both opportunities and challenges. The recovery of valuable elements like indium from discarded electronic devices could significantly reduce the environmental impact of primary production. However, current recycling rates remain low due to technical difficulties in separating TCOs from complex device architectures and the lack of established recycling infrastructure. The chemical reactivity of TCOs with other materials in electronic waste can complicate recycling processes and sometimes generate additional hazardous byproducts.

Recent regulatory frameworks have begun addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have prompted research into more environmentally benign TCO alternatives. Industry initiatives focusing on green chemistry principles are exploring manufacturing processes that minimize toxic reagent use and reduce energy requirements. These efforts, coupled with life cycle assessment studies, are essential for developing more sustainable TCO technologies that balance performance requirements with environmental responsibility.

Water consumption represents another critical environmental concern in TCO production. The manufacturing processes demand large quantities of ultra-pure water for cleaning and processing, placing pressure on local water resources in production regions. Furthermore, the chemical treatments involved often result in wastewater containing heavy metals and other contaminants that can adversely affect aquatic ecosystems if not properly treated before discharge.

The environmental footprint of TCOs extends beyond production to their application lifecycle. While these materials enable energy-efficient technologies like solar cells and smart windows that can reduce overall energy consumption, the durability and end-of-life management of TCO-containing products present challenges. The reactive nature of some TCOs with environmental factors such as moisture and atmospheric pollutants can lead to degradation over time, potentially releasing harmful compounds into the environment.

Recycling of TCO materials presents both opportunities and challenges. The recovery of valuable elements like indium from discarded electronic devices could significantly reduce the environmental impact of primary production. However, current recycling rates remain low due to technical difficulties in separating TCOs from complex device architectures and the lack of established recycling infrastructure. The chemical reactivity of TCOs with other materials in electronic waste can complicate recycling processes and sometimes generate additional hazardous byproducts.

Recent regulatory frameworks have begun addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have prompted research into more environmentally benign TCO alternatives. Industry initiatives focusing on green chemistry principles are exploring manufacturing processes that minimize toxic reagent use and reduce energy requirements. These efforts, coupled with life cycle assessment studies, are essential for developing more sustainable TCO technologies that balance performance requirements with environmental responsibility.

Standardization and Testing Protocols for TCO Materials

The standardization and testing protocols for Transparent Conductive Oxide (TCO) materials represent a critical framework for ensuring consistency, reliability, and comparability in research and industrial applications. Currently, the field faces significant challenges due to the lack of universally accepted methodologies for evaluating TCO reactivity with other materials, leading to difficulties in comparing results across different research groups and manufacturing facilities.

International organizations including the International Electrotechnical Commission (IEC), ASTM International, and the International Organization for Standardization (ISO) have begun developing comprehensive standards specifically addressing TCO materials. These standards typically cover parameters such as chemical stability, interfacial reactions, and long-term performance under various environmental conditions.

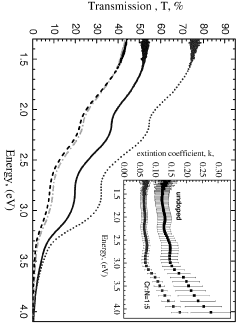

Key testing protocols for TCO reactivity assessment include accelerated aging tests, which expose TCO materials to elevated temperatures, humidity, and UV radiation to simulate years of environmental exposure within weeks. Electrochemical impedance spectroscopy (EIS) has emerged as a powerful technique for quantifying interfacial reactions between TCOs and adjacent layers in device structures, providing valuable insights into degradation mechanisms.

Surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) have been standardized for characterizing chemical changes at TCO interfaces. These protocols typically specify sample preparation methods, measurement conditions, and data analysis procedures to ensure reproducibility across different laboratories.

Interlaboratory comparison studies have become increasingly important for validating testing protocols. Recent round-robin tests involving over 20 international laboratories have highlighted the need for standardized reference materials and calibration procedures when evaluating TCO reactivity, particularly for emerging materials like aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO).

The development of in-situ monitoring techniques represents a significant advancement in standardization efforts. Real-time observation of interfacial reactions during device fabrication and operation provides crucial data for establishing meaningful accelerated testing protocols that accurately predict long-term performance in real-world applications.

Industry-specific standards have also emerged, with the photovoltaic and display industries establishing specialized testing protocols addressing their unique requirements. These include specific tests for TCO compatibility with semiconductor materials, encapsulants, and barrier layers used in their respective device architectures.

Looking forward, the integration of artificial intelligence and machine learning approaches with standardized testing protocols promises to accelerate the development of predictive models for TCO reactivity, potentially reducing the time and resources required for material qualification and certification processes.

International organizations including the International Electrotechnical Commission (IEC), ASTM International, and the International Organization for Standardization (ISO) have begun developing comprehensive standards specifically addressing TCO materials. These standards typically cover parameters such as chemical stability, interfacial reactions, and long-term performance under various environmental conditions.

Key testing protocols for TCO reactivity assessment include accelerated aging tests, which expose TCO materials to elevated temperatures, humidity, and UV radiation to simulate years of environmental exposure within weeks. Electrochemical impedance spectroscopy (EIS) has emerged as a powerful technique for quantifying interfacial reactions between TCOs and adjacent layers in device structures, providing valuable insights into degradation mechanisms.

Surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) have been standardized for characterizing chemical changes at TCO interfaces. These protocols typically specify sample preparation methods, measurement conditions, and data analysis procedures to ensure reproducibility across different laboratories.

Interlaboratory comparison studies have become increasingly important for validating testing protocols. Recent round-robin tests involving over 20 international laboratories have highlighted the need for standardized reference materials and calibration procedures when evaluating TCO reactivity, particularly for emerging materials like aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO).

The development of in-situ monitoring techniques represents a significant advancement in standardization efforts. Real-time observation of interfacial reactions during device fabrication and operation provides crucial data for establishing meaningful accelerated testing protocols that accurately predict long-term performance in real-world applications.

Industry-specific standards have also emerged, with the photovoltaic and display industries establishing specialized testing protocols addressing their unique requirements. These include specific tests for TCO compatibility with semiconductor materials, encapsulants, and barrier layers used in their respective device architectures.

Looking forward, the integration of artificial intelligence and machine learning approaches with standardized testing protocols promises to accelerate the development of predictive models for TCO reactivity, potentially reducing the time and resources required for material qualification and certification processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!