Investigating Transparent Conductive Oxides for Wearable Technology

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCO Development History and Objectives

Transparent Conductive Oxides (TCOs) have evolved significantly since their initial discovery in the early 20th century. The journey began with the development of tin-doped indium oxide (ITO) in the 1940s, which marked a pivotal moment in the field of transparent conductors. By the 1970s, ITO had become commercially viable and was increasingly adopted in display technologies. This period established the fundamental understanding of the trade-off between optical transparency and electrical conductivity that continues to guide TCO research today.

The evolution of TCOs accelerated in the 1990s with the emergence of alternative materials such as fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO), driven by concerns over indium scarcity and cost. The early 2000s witnessed a paradigm shift as researchers began exploring nanostructured TCOs, which offered enhanced flexibility and novel optical properties crucial for emerging applications in flexible electronics.

The wearable technology revolution of the 2010s created unprecedented demands for TCOs that could maintain performance under mechanical stress, leading to intensive research into materials that combine transparency, conductivity, and flexibility. This period saw significant advancements in solution-processed TCOs and composite structures that could be integrated into textiles and conformable substrates.

Current technical objectives for TCOs in wearable applications focus on several critical parameters. Achieving sheet resistance below 100 Ω/sq while maintaining >85% transparency in the visible spectrum remains a primary goal. Additionally, researchers aim to develop TCOs that can withstand repeated mechanical deformation (>10,000 bending cycles at radii <5mm) without significant performance degradation.

Biocompatibility has emerged as another crucial objective, particularly for TCOs intended for direct skin contact in health monitoring devices. This includes developing materials with minimal ion leaching and reduced skin irritation potential. Energy efficiency is equally important, with efforts directed toward TCOs that can function effectively at lower power to extend battery life in wearable devices.

Long-term stability under various environmental conditions (humidity, temperature fluctuations, and UV exposure) represents another key objective, as wearable devices must maintain performance in diverse real-world scenarios. Researchers are also pursuing cost-effective and environmentally sustainable manufacturing processes, including room-temperature deposition techniques that enable integration with temperature-sensitive substrates and components.

The trajectory of TCO development indicates a shift from single-material solutions toward engineered composites and hybrid structures that can meet the multifaceted requirements of next-generation wearable technologies. This evolution reflects the growing complexity of wearable applications and the increasing sophistication of TCO design approaches.

The evolution of TCOs accelerated in the 1990s with the emergence of alternative materials such as fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO), driven by concerns over indium scarcity and cost. The early 2000s witnessed a paradigm shift as researchers began exploring nanostructured TCOs, which offered enhanced flexibility and novel optical properties crucial for emerging applications in flexible electronics.

The wearable technology revolution of the 2010s created unprecedented demands for TCOs that could maintain performance under mechanical stress, leading to intensive research into materials that combine transparency, conductivity, and flexibility. This period saw significant advancements in solution-processed TCOs and composite structures that could be integrated into textiles and conformable substrates.

Current technical objectives for TCOs in wearable applications focus on several critical parameters. Achieving sheet resistance below 100 Ω/sq while maintaining >85% transparency in the visible spectrum remains a primary goal. Additionally, researchers aim to develop TCOs that can withstand repeated mechanical deformation (>10,000 bending cycles at radii <5mm) without significant performance degradation.

Biocompatibility has emerged as another crucial objective, particularly for TCOs intended for direct skin contact in health monitoring devices. This includes developing materials with minimal ion leaching and reduced skin irritation potential. Energy efficiency is equally important, with efforts directed toward TCOs that can function effectively at lower power to extend battery life in wearable devices.

Long-term stability under various environmental conditions (humidity, temperature fluctuations, and UV exposure) represents another key objective, as wearable devices must maintain performance in diverse real-world scenarios. Researchers are also pursuing cost-effective and environmentally sustainable manufacturing processes, including room-temperature deposition techniques that enable integration with temperature-sensitive substrates and components.

The trajectory of TCO development indicates a shift from single-material solutions toward engineered composites and hybrid structures that can meet the multifaceted requirements of next-generation wearable technologies. This evolution reflects the growing complexity of wearable applications and the increasing sophistication of TCO design approaches.

Market Analysis for TCO in Wearables

The global market for Transparent Conductive Oxides (TCOs) in wearable technology is experiencing robust growth, driven by increasing consumer demand for smart wearables with enhanced functionality and aesthetic appeal. Current market valuations indicate that the TCO segment specific to wearable applications reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 17.3% through 2028.

Consumer electronics manufacturers are increasingly incorporating TCO materials into their wearable product lines, with smartwatches representing the largest application segment at 43% of market share. Fitness trackers follow at 28%, while emerging categories such as smart clothing and medical wearables account for 15% and 14% respectively.

Market research indicates that Indium Tin Oxide (ITO) continues to dominate the TCO market for wearables, holding approximately 65% market share due to its established manufacturing ecosystem and reliable performance characteristics. However, alternative TCO materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and silver nanowire networks are gaining traction, collectively growing at 22.5% annually as manufacturers seek more flexible and cost-effective solutions.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 68% of global TCO production for wearables, with particular concentration in China, South Korea, and Taiwan. North America and Europe represent significant consumption markets, driving 27% and 22% of global demand respectively, primarily through premium wearable device segments.

Consumer preference surveys indicate that 78% of wearable technology users prioritize display quality and battery efficiency—both directly impacted by TCO performance characteristics. This has created a market pull for advanced TCO solutions that can deliver higher transparency (>90%), lower sheet resistance (<10 ohms/square), and enhanced flexibility for curved and foldable displays.

The market is also witnessing increased demand for sustainable TCO alternatives, with 63% of major wearable manufacturers committing to reducing reliance on rare elements like indium. This sustainability trend is accelerating research into earth-abundant TCO alternatives, creating new market opportunities for materials such as graphene-based conductors and metal mesh technologies.

Supply chain analysis reveals potential vulnerabilities, with 74% of high-quality ITO production concentrated among just five global suppliers. This concentration has prompted wearable technology companies to diversify their TCO sourcing strategies, with 38% of major manufacturers actively investing in alternative TCO development programs to mitigate supply risks.

Consumer electronics manufacturers are increasingly incorporating TCO materials into their wearable product lines, with smartwatches representing the largest application segment at 43% of market share. Fitness trackers follow at 28%, while emerging categories such as smart clothing and medical wearables account for 15% and 14% respectively.

Market research indicates that Indium Tin Oxide (ITO) continues to dominate the TCO market for wearables, holding approximately 65% market share due to its established manufacturing ecosystem and reliable performance characteristics. However, alternative TCO materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and silver nanowire networks are gaining traction, collectively growing at 22.5% annually as manufacturers seek more flexible and cost-effective solutions.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 68% of global TCO production for wearables, with particular concentration in China, South Korea, and Taiwan. North America and Europe represent significant consumption markets, driving 27% and 22% of global demand respectively, primarily through premium wearable device segments.

Consumer preference surveys indicate that 78% of wearable technology users prioritize display quality and battery efficiency—both directly impacted by TCO performance characteristics. This has created a market pull for advanced TCO solutions that can deliver higher transparency (>90%), lower sheet resistance (<10 ohms/square), and enhanced flexibility for curved and foldable displays.

The market is also witnessing increased demand for sustainable TCO alternatives, with 63% of major wearable manufacturers committing to reducing reliance on rare elements like indium. This sustainability trend is accelerating research into earth-abundant TCO alternatives, creating new market opportunities for materials such as graphene-based conductors and metal mesh technologies.

Supply chain analysis reveals potential vulnerabilities, with 74% of high-quality ITO production concentrated among just five global suppliers. This concentration has prompted wearable technology companies to diversify their TCO sourcing strategies, with 38% of major manufacturers actively investing in alternative TCO development programs to mitigate supply risks.

Current TCO Technologies and Barriers

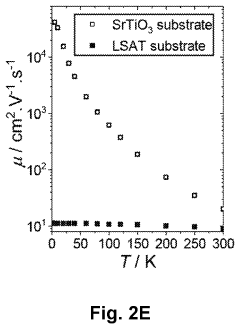

Transparent Conductive Oxides (TCOs) represent a critical component in modern wearable technology, serving as essential materials that combine optical transparency with electrical conductivity. Currently, the market is dominated by Indium Tin Oxide (ITO), which accounts for approximately 85% of the TCO market due to its excellent balance of transparency (>90% in visible spectrum) and conductivity (sheet resistance <100 Ω/sq). ITO is primarily deposited through sputtering techniques, allowing for precise control of film thickness and properties.

Despite ITO's prevalence, significant barriers exist for its application in next-generation wearable devices. The inherent brittleness of ITO limits its use in flexible applications, with cracks forming at strain levels as low as 2-3%. This fragility presents a fundamental challenge for wearable technologies that require repeated bending, stretching, or conforming to body contours.

Alternative TCO materials have emerged to address these limitations. Fluorine-doped Tin Oxide (FTO) offers enhanced durability and lower production costs but typically exhibits higher sheet resistance (150-200 Ω/sq) compared to ITO. Aluminum-doped Zinc Oxide (AZO) presents another viable alternative with comparable optical properties to ITO and improved flexibility, though its environmental stability remains inferior, particularly in humid conditions.

Supply chain vulnerabilities constitute another significant barrier, with indium being classified as a critical raw material due to its limited geographical availability and extraction challenges. Current estimates suggest that indium reserves may face significant constraints within the next two decades, driving material costs upward and threatening long-term sustainability of ITO-based solutions.

Recent technological developments have focused on novel deposition methods to enhance TCO performance in wearable applications. Solution-based processing techniques, including sol-gel and spray pyrolysis, offer potential for large-area, low-cost deposition but currently struggle to achieve the conductivity levels of vacuum-deposited films. Atomic Layer Deposition (ALD) provides exceptional thickness control and film uniformity but faces scalability challenges for mass production.

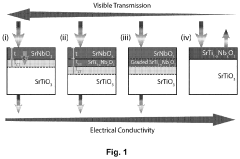

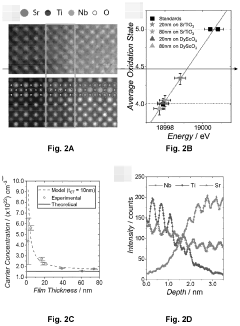

Composite approaches combining TCOs with other materials represent an emerging trend. TCO/metal/TCO multilayer structures have demonstrated improved conductivity while maintaining optical transparency, and TCO/nanowire hybrid systems offer enhanced mechanical flexibility. However, these composite systems introduce additional manufacturing complexity and potential reliability concerns at material interfaces.

Energy consumption during TCO production presents another barrier, with traditional vacuum deposition methods requiring significant energy input. This factor impacts both production costs and environmental sustainability, driving research into low-temperature processing techniques that could enable direct deposition on temperature-sensitive polymer substrates commonly used in wearable devices.

Despite ITO's prevalence, significant barriers exist for its application in next-generation wearable devices. The inherent brittleness of ITO limits its use in flexible applications, with cracks forming at strain levels as low as 2-3%. This fragility presents a fundamental challenge for wearable technologies that require repeated bending, stretching, or conforming to body contours.

Alternative TCO materials have emerged to address these limitations. Fluorine-doped Tin Oxide (FTO) offers enhanced durability and lower production costs but typically exhibits higher sheet resistance (150-200 Ω/sq) compared to ITO. Aluminum-doped Zinc Oxide (AZO) presents another viable alternative with comparable optical properties to ITO and improved flexibility, though its environmental stability remains inferior, particularly in humid conditions.

Supply chain vulnerabilities constitute another significant barrier, with indium being classified as a critical raw material due to its limited geographical availability and extraction challenges. Current estimates suggest that indium reserves may face significant constraints within the next two decades, driving material costs upward and threatening long-term sustainability of ITO-based solutions.

Recent technological developments have focused on novel deposition methods to enhance TCO performance in wearable applications. Solution-based processing techniques, including sol-gel and spray pyrolysis, offer potential for large-area, low-cost deposition but currently struggle to achieve the conductivity levels of vacuum-deposited films. Atomic Layer Deposition (ALD) provides exceptional thickness control and film uniformity but faces scalability challenges for mass production.

Composite approaches combining TCOs with other materials represent an emerging trend. TCO/metal/TCO multilayer structures have demonstrated improved conductivity while maintaining optical transparency, and TCO/nanowire hybrid systems offer enhanced mechanical flexibility. However, these composite systems introduce additional manufacturing complexity and potential reliability concerns at material interfaces.

Energy consumption during TCO production presents another barrier, with traditional vacuum deposition methods requiring significant energy input. This factor impacts both production costs and environmental sustainability, driving research into low-temperature processing techniques that could enable direct deposition on temperature-sensitive polymer substrates commonly used in wearable devices.

Mainstream TCO Solutions for Wearables

01 Composition and structure of transparent conductive oxides

Transparent conductive oxides (TCOs) are materials that combine optical transparency with electrical conductivity. These materials typically consist of metal oxides such as indium tin oxide (ITO), zinc oxide (ZnO), or tin oxide (SnO2) that have been doped with various elements to enhance their electrical properties while maintaining optical transparency. The composition and crystal structure of these materials significantly influence their performance characteristics, making them suitable for various electronic and optoelectronic applications.- Composition and structure of transparent conductive oxides: Transparent conductive oxides (TCOs) are materials that combine electrical conductivity with optical transparency. These materials typically consist of metal oxides such as indium tin oxide (ITO), zinc oxide (ZnO), or tin oxide (SnO2) that have been doped with specific elements to enhance their electrical properties while maintaining transparency. The composition and crystal structure of these materials significantly influence their performance characteristics, including conductivity, transparency, and stability.

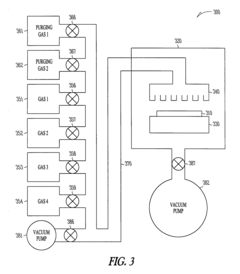

- Fabrication methods for transparent conductive oxide films: Various deposition techniques are employed to fabricate transparent conductive oxide films, including sputtering, chemical vapor deposition, sol-gel processing, and atomic layer deposition. These methods allow for precise control over film thickness, composition, and microstructure, which directly affect the electrical and optical properties of the resulting films. Process parameters such as temperature, pressure, and gas composition during deposition play crucial roles in determining the quality and performance of the transparent conductive oxide layers.

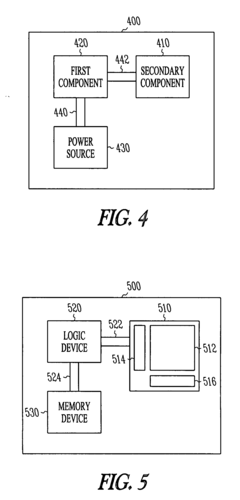

- Applications of transparent conductive oxides in electronic devices: Transparent conductive oxides are widely used in various electronic and optoelectronic devices, including touch screens, flat panel displays, solar cells, and smart windows. Their unique combination of electrical conductivity and optical transparency makes them ideal for applications requiring transparent electrodes. The integration of these materials into device structures requires careful consideration of interface properties, stability, and compatibility with other device components to ensure optimal performance and reliability.

- Enhancement of transparent conductive oxide properties: Various approaches are employed to enhance the properties of transparent conductive oxides, including doping with different elements, creating composite structures, and post-deposition treatments. These methods aim to improve electrical conductivity, optical transparency, mechanical flexibility, and environmental stability. Innovations in material design and processing techniques continue to push the performance boundaries of transparent conductive oxides, enabling their use in increasingly demanding applications.

- Alternative materials and structures for transparent conductors: Research on alternative materials and structures for transparent conductors focuses on addressing limitations of conventional transparent conductive oxides, such as scarcity of indium and brittleness. These alternatives include metal nanowire networks, carbon-based materials like graphene, conductive polymers, and hybrid structures combining different types of materials. These novel approaches offer potential advantages in terms of flexibility, cost, and specific performance characteristics tailored for particular applications.

02 Fabrication methods for transparent conductive oxide films

Various deposition techniques are employed to fabricate transparent conductive oxide films, including sputtering, chemical vapor deposition (CVD), sol-gel processes, and atomic layer deposition (ALD). These methods allow for precise control over film thickness, composition, and microstructure, which directly affect the electrical and optical properties of the resulting films. Post-deposition treatments such as annealing can further enhance the performance of these materials by improving crystallinity and reducing defects.Expand Specific Solutions03 Applications in display and touch screen technologies

Transparent conductive oxides are widely used in display and touch screen technologies due to their unique combination of optical transparency and electrical conductivity. These materials serve as transparent electrodes in liquid crystal displays (LCDs), organic light-emitting diodes (OLEDs), and capacitive touch panels. The performance requirements for these applications include high visible light transmission, low sheet resistance, good uniformity, and mechanical durability to withstand repeated touch interactions.Expand Specific Solutions04 Transparent conductive oxides for photovoltaic applications

In photovoltaic devices, transparent conductive oxides serve as front electrodes that allow light to pass through while collecting generated charge carriers. These materials are crucial components in solar cells, including thin-film, crystalline silicon, and emerging perovskite technologies. For photovoltaic applications, TCOs must exhibit high transparency in the solar spectrum, low resistivity, and good interface properties with adjacent semiconductor layers to minimize recombination losses and maximize energy conversion efficiency.Expand Specific Solutions05 Novel transparent conductive oxide materials and enhancements

Research on transparent conductive oxides focuses on developing alternative materials to replace conventional options like indium tin oxide, which faces supply constraints and cost issues. Novel TCO materials include aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and various ternary compounds. Additionally, enhancements to existing TCOs through nanostructuring, composite formation, and innovative doping strategies aim to improve electrical conductivity without sacrificing optical transparency, while also addressing challenges related to mechanical flexibility and environmental stability.Expand Specific Solutions

Leading TCO Manufacturers and Competitors

The transparent conductive oxides (TCO) market for wearable technology is currently in a growth phase, with increasing demand driven by the expansion of smart wearables. The market is projected to reach significant scale as TCOs offer essential properties for flexible displays and sensors. Technologically, the field shows varying maturity levels across applications, with companies like Corning, Samsung Electronics, and TDK leading commercial development. Research institutions including ICFO, IMEC, and CEA are advancing fundamental innovations, while industrial players such as LG Chem and Micron Technology focus on application-specific developments. The competitive landscape features collaboration between academic and industrial entities, with emerging players from Asia gaining market share alongside established Western corporations.

Corning, Inc.

Technical Solution: Corning has developed advanced transparent conductive oxide (TCO) solutions specifically engineered for wearable technology applications. Their flagship product in this space is Corning® Willow® Glass, an ultra-thin, flexible glass substrate that can be combined with their proprietary TCO coatings. The company utilizes a specialized RF magnetron sputtering process to deposit indium tin oxide (ITO) and other alternative TCOs like aluminum-doped zinc oxide (AZO) onto flexible substrates. Their technology achieves sheet resistances below 100 ohms/square while maintaining over 90% optical transparency in the visible spectrum. Corning has also pioneered a unique "cold forming" process that allows their TCO-coated glass to be bent to radii of less than 2mm without cracking or significant conductivity loss, making it ideal for curved wearable displays and sensors. Recent innovations include antimicrobial TCO coatings that incorporate silver nanoparticles, addressing hygiene concerns in wearable devices that contact skin for extended periods.

Strengths: Superior optical clarity and scratch resistance compared to polymer-based alternatives; excellent barrier properties against moisture and oxygen; established manufacturing infrastructure for large-scale production. Weaknesses: Higher cost compared to some polymer-based solutions; requires specialized handling during device assembly due to glass substrate properties; slightly heavier than pure polymer alternatives.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed a specialized transparent conductive oxide technology called "SELMETTM" (Sumitomo Environmentally-friendly Low-cost Metal TCO) specifically optimized for wearable applications. Their approach focuses on indium conservation through precisely controlled sputtering techniques that achieve high performance with minimal material usage. Sumitomo's latest TCO formulations incorporate zinc-tin oxide (ZTO) and fluorine-doped tin oxide (FTO) compositions that achieve sheet resistances of 80-100 ohms/square while maintaining transparency above 88%. A key innovation is their "stress-relief" layer technology, where an intermediate organic-inorganic hybrid buffer is inserted between the TCO and substrate, allowing the composite to withstand repeated flexing without degradation. For health monitoring wearables, Sumitomo has developed biocompatible TCO formulations that minimize skin irritation during prolonged contact. Their manufacturing process employs roll-to-roll deposition techniques that enable cost-effective production of TCO films on flexible substrates up to 1.2m wide, with thickness uniformity variation below 5% across the entire width.

Strengths: Exceptional expertise in materials science and metallurgy; strong vertical integration from raw material sourcing to final TCO production; advanced manufacturing capabilities for large-scale production. Weaknesses: More focused on materials supply than end-device integration; some formulations still require trace amounts of indium; moderate flexibility compared to some newer carbon-based alternatives.

Key TCO Patents and Technical Innovations

Composition of Transparent Conductive Material and Method for Fabricating the same

PatentPendingUS20240038912A1

Innovation

- A film structure comprising a transparent conductive oxide layer, a wide-bandgap semiconductor oxide layer, and an interface layer with controlled doping and composition, allowing for enhanced carrier mobility and conductivity while maintaining transparency, achieved through pulsed laser deposition and careful layer engineering.

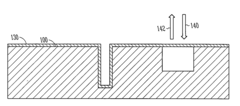

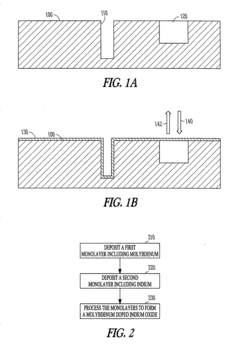

Molybdenum-doped indium oxide structures and methods

PatentActiveUS20080191351A1

Innovation

- The use of monolayer deposition techniques, specifically atomic layer deposition (ALD), to form molybdenum-doped indium oxide layers with precise control over thickness and composition, enabling superior step coverage and crystallinity, and the formation of amorphous or nanocrystalline structures that enhance durability.

Flexibility and Durability Considerations

The integration of Transparent Conductive Oxides (TCOs) into wearable technology necessitates careful consideration of flexibility and durability factors. Traditional TCO materials like Indium Tin Oxide (ITO) exhibit excellent optical transparency and electrical conductivity but suffer from inherent brittleness, limiting their application in flexible wearable devices. When subjected to repeated bending or stretching, ITO-based films typically develop microcracks that significantly degrade conductivity, rendering them unsuitable for applications requiring mechanical deformation.

Recent advancements have focused on enhancing the mechanical properties of TCOs through various approaches. One promising strategy involves the deposition of TCO materials on flexible substrates using low-temperature processes, which reduces internal stress and improves flexibility. Additionally, researchers have explored composite structures where TCO layers are sandwiched between protective polymeric materials that can absorb mechanical stress while maintaining optical transparency.

The incorporation of nanomaterials has shown remarkable potential for improving the durability of TCO-based wearable components. Nanowire networks of materials such as silver, copper, or zinc oxide provide alternative conductive pathways when localized damage occurs, thereby maintaining overall conductivity even under mechanical strain. These networks can withstand thousands of bending cycles without catastrophic failure, a critical requirement for daily-use wearable technology.

Environmental stability represents another crucial aspect of durability considerations. Wearable devices are frequently exposed to moisture, sweat, varying temperatures, and UV radiation. TCO materials must maintain their performance under these conditions to ensure reliable operation throughout the product lifecycle. Encapsulation techniques using hydrophobic coatings have demonstrated effectiveness in protecting TCO layers from environmental degradation while preserving their optical and electrical properties.

The trade-off between flexibility and other performance metrics requires careful optimization. As flexibility increases through reduced thickness or modified composition, electrical conductivity often decreases. This relationship necessitates application-specific engineering solutions where the balance between mechanical properties and electrical performance is tailored to particular use cases. For instance, medical monitoring wearables may prioritize flexibility for patient comfort, while augmented reality displays might emphasize conductivity and optical clarity.

Manufacturing scalability presents additional challenges for flexible TCO implementation. Techniques such as roll-to-roll processing show promise for mass production of flexible TCO films, but maintaining consistent quality across large areas remains difficult. Innovations in deposition methods and quality control processes are essential for transitioning laboratory successes to commercially viable wearable products incorporating flexible, durable TCO components.

Recent advancements have focused on enhancing the mechanical properties of TCOs through various approaches. One promising strategy involves the deposition of TCO materials on flexible substrates using low-temperature processes, which reduces internal stress and improves flexibility. Additionally, researchers have explored composite structures where TCO layers are sandwiched between protective polymeric materials that can absorb mechanical stress while maintaining optical transparency.

The incorporation of nanomaterials has shown remarkable potential for improving the durability of TCO-based wearable components. Nanowire networks of materials such as silver, copper, or zinc oxide provide alternative conductive pathways when localized damage occurs, thereby maintaining overall conductivity even under mechanical strain. These networks can withstand thousands of bending cycles without catastrophic failure, a critical requirement for daily-use wearable technology.

Environmental stability represents another crucial aspect of durability considerations. Wearable devices are frequently exposed to moisture, sweat, varying temperatures, and UV radiation. TCO materials must maintain their performance under these conditions to ensure reliable operation throughout the product lifecycle. Encapsulation techniques using hydrophobic coatings have demonstrated effectiveness in protecting TCO layers from environmental degradation while preserving their optical and electrical properties.

The trade-off between flexibility and other performance metrics requires careful optimization. As flexibility increases through reduced thickness or modified composition, electrical conductivity often decreases. This relationship necessitates application-specific engineering solutions where the balance between mechanical properties and electrical performance is tailored to particular use cases. For instance, medical monitoring wearables may prioritize flexibility for patient comfort, while augmented reality displays might emphasize conductivity and optical clarity.

Manufacturing scalability presents additional challenges for flexible TCO implementation. Techniques such as roll-to-roll processing show promise for mass production of flexible TCO films, but maintaining consistent quality across large areas remains difficult. Innovations in deposition methods and quality control processes are essential for transitioning laboratory successes to commercially viable wearable products incorporating flexible, durable TCO components.

Environmental Impact and Sustainability

The environmental footprint of Transparent Conductive Oxides (TCOs) in wearable technology represents a critical consideration as these materials gain widespread adoption. Manufacturing processes for TCOs, particularly indium tin oxide (ITO), involve energy-intensive sputtering techniques and high-temperature treatments that contribute significantly to carbon emissions. The extraction of rare elements like indium raises additional sustainability concerns due to limited global reserves and environmentally disruptive mining practices.

Recent life cycle assessments reveal that the production phase of TCO-based wearable devices accounts for approximately 70% of their total environmental impact. This has prompted research into alternative manufacturing methods such as solution-based processing and room-temperature deposition techniques, which can reduce energy consumption by up to 40% compared to conventional methods.

Material recyclability presents another significant challenge. Current TCO recovery rates from discarded wearable devices remain below 15%, primarily due to the complex multi-layer structures that make separation difficult. Innovative approaches using environmentally benign solvents and mechanical delamination techniques are showing promise for improving end-of-life management, potentially increasing recovery rates to over 35%.

Water consumption during TCO fabrication also warrants attention, with estimates suggesting that producing one square meter of TCO coating requires between 80-120 liters of ultrapure water. Closed-loop water recycling systems implemented by leading manufacturers have demonstrated potential water savings of up to 60%, though industry-wide adoption remains limited.

The substitution of scarce materials with earth-abundant alternatives represents a promising sustainability strategy. Aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) utilize more abundant elements while offering comparable performance in many applications. These alternatives can reduce resource depletion concerns while maintaining the functional requirements of wearable technology.

Emerging biodegradable substrates compatible with certain TCO formulations offer pathways to reduce electronic waste. Research demonstrates that cellulose-based substrates combined with carefully selected TCO compositions can achieve decomposition rates of 85% within six months under controlled conditions, compared to conventional devices that persist in landfills for decades.

Regulatory frameworks are increasingly addressing the environmental aspects of electronic materials, with the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide influencing TCO formulation and manufacturing practices. Forward-thinking companies are proactively developing TCO solutions that not only meet current standards but anticipate future regulatory requirements.

Recent life cycle assessments reveal that the production phase of TCO-based wearable devices accounts for approximately 70% of their total environmental impact. This has prompted research into alternative manufacturing methods such as solution-based processing and room-temperature deposition techniques, which can reduce energy consumption by up to 40% compared to conventional methods.

Material recyclability presents another significant challenge. Current TCO recovery rates from discarded wearable devices remain below 15%, primarily due to the complex multi-layer structures that make separation difficult. Innovative approaches using environmentally benign solvents and mechanical delamination techniques are showing promise for improving end-of-life management, potentially increasing recovery rates to over 35%.

Water consumption during TCO fabrication also warrants attention, with estimates suggesting that producing one square meter of TCO coating requires between 80-120 liters of ultrapure water. Closed-loop water recycling systems implemented by leading manufacturers have demonstrated potential water savings of up to 60%, though industry-wide adoption remains limited.

The substitution of scarce materials with earth-abundant alternatives represents a promising sustainability strategy. Aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) utilize more abundant elements while offering comparable performance in many applications. These alternatives can reduce resource depletion concerns while maintaining the functional requirements of wearable technology.

Emerging biodegradable substrates compatible with certain TCO formulations offer pathways to reduce electronic waste. Research demonstrates that cellulose-based substrates combined with carefully selected TCO compositions can achieve decomposition rates of 85% within six months under controlled conditions, compared to conventional devices that persist in landfills for decades.

Regulatory frameworks are increasingly addressing the environmental aspects of electronic materials, with the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide influencing TCO formulation and manufacturing practices. Forward-thinking companies are proactively developing TCO solutions that not only meet current standards but anticipate future regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!