Investigating Transparent Conductive Oxide Coatings for Thermal Stability

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCO Coatings Background and Objectives

Transparent Conductive Oxide (TCO) coatings represent a critical class of materials at the intersection of optoelectronics, renewable energy, and advanced display technologies. These unique materials combine seemingly contradictory properties - electrical conductivity and optical transparency - making them indispensable components in numerous high-tech applications. The evolution of TCO technology dates back to the early 20th century, with significant advancements occurring in the 1970s through the development of indium tin oxide (ITO) coatings. Since then, the field has expanded dramatically, driven by growing demands in solar cells, touch screens, smart windows, and flexible electronics.

The current technological trajectory of TCO coatings is focused on addressing several key challenges, particularly thermal stability under extreme operating conditions. As applications increasingly require materials that can maintain performance at elevated temperatures or during thermal cycling, traditional TCO formulations have shown limitations. The degradation of electrical and optical properties at high temperatures represents a significant barrier to the expansion of TCO applications in harsh environments such as concentrated solar power systems, high-temperature sensors, and aerospace components.

Recent research trends indicate a shift toward exploring novel material compositions and nanostructured designs to enhance thermal resilience. Multi-component oxides, doped zinc oxide systems, and perovskite-based TCOs have emerged as promising candidates for thermally stable applications. Additionally, advances in deposition techniques, including atomic layer deposition and high-power impulse magnetron sputtering, have enabled more precise control over film microstructure and interfacial properties, which directly influence thermal behavior.

The primary objectives of investigating thermal stability in TCO coatings are multifaceted. First, we aim to establish comprehensive understanding of degradation mechanisms under thermal stress, including phase transformations, diffusion processes, and interfacial reactions. Second, we seek to develop standardized testing protocols that accurately predict long-term performance under various thermal conditions. Third, our goal is to identify or engineer novel TCO materials that maintain optical transparency above 80% and sheet resistance below 10 Ω/sq after exposure to temperatures exceeding 500°C.

Beyond material performance, this investigation addresses broader industry needs for cost-effective, environmentally sustainable alternatives to scarce elements like indium. The development of thermally stable TCOs based on earth-abundant elements would significantly impact supply chain resilience and manufacturing economics. Furthermore, enhanced thermal stability would enable new application domains where TCOs have been previously unsuitable due to temperature constraints.

The convergence of computational materials science, advanced characterization techniques, and high-throughput experimentation is accelerating progress in this field, suggesting that breakthrough materials may emerge within the next five years. This technological evolution aligns with broader industry trends toward more durable, efficient, and sustainable electronic and energy conversion systems.

The current technological trajectory of TCO coatings is focused on addressing several key challenges, particularly thermal stability under extreme operating conditions. As applications increasingly require materials that can maintain performance at elevated temperatures or during thermal cycling, traditional TCO formulations have shown limitations. The degradation of electrical and optical properties at high temperatures represents a significant barrier to the expansion of TCO applications in harsh environments such as concentrated solar power systems, high-temperature sensors, and aerospace components.

Recent research trends indicate a shift toward exploring novel material compositions and nanostructured designs to enhance thermal resilience. Multi-component oxides, doped zinc oxide systems, and perovskite-based TCOs have emerged as promising candidates for thermally stable applications. Additionally, advances in deposition techniques, including atomic layer deposition and high-power impulse magnetron sputtering, have enabled more precise control over film microstructure and interfacial properties, which directly influence thermal behavior.

The primary objectives of investigating thermal stability in TCO coatings are multifaceted. First, we aim to establish comprehensive understanding of degradation mechanisms under thermal stress, including phase transformations, diffusion processes, and interfacial reactions. Second, we seek to develop standardized testing protocols that accurately predict long-term performance under various thermal conditions. Third, our goal is to identify or engineer novel TCO materials that maintain optical transparency above 80% and sheet resistance below 10 Ω/sq after exposure to temperatures exceeding 500°C.

Beyond material performance, this investigation addresses broader industry needs for cost-effective, environmentally sustainable alternatives to scarce elements like indium. The development of thermally stable TCOs based on earth-abundant elements would significantly impact supply chain resilience and manufacturing economics. Furthermore, enhanced thermal stability would enable new application domains where TCOs have been previously unsuitable due to temperature constraints.

The convergence of computational materials science, advanced characterization techniques, and high-throughput experimentation is accelerating progress in this field, suggesting that breakthrough materials may emerge within the next five years. This technological evolution aligns with broader industry trends toward more durable, efficient, and sustainable electronic and energy conversion systems.

Market Analysis for Thermally Stable TCO Applications

The global market for Transparent Conductive Oxide (TCO) coatings with enhanced thermal stability is experiencing robust growth, driven primarily by expanding applications in optoelectronic devices, solar cells, and smart windows. Current market valuation stands at approximately 8.7 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028.

The display industry remains the largest consumer of thermally stable TCO materials, accounting for nearly 42% of market share. This dominance stems from increasing demand for high-resolution displays in consumer electronics that must withstand elevated processing temperatures during manufacturing. The photovoltaic sector represents the fastest-growing application segment, with demand increasing as manufacturers seek TCO materials capable of maintaining performance integrity during high-temperature thin-film deposition processes.

Regionally, East Asia dominates production and consumption, with China, Japan, and South Korea collectively representing 58% of global market volume. North America and Europe follow with approximately 22% and 17% market share respectively, primarily driven by research activities and premium applications in aerospace and specialized electronics.

Customer requirements are evolving toward TCO coatings that maintain optical transparency and electrical conductivity at temperatures exceeding 500°C, particularly for next-generation flexible electronics and building-integrated photovoltaics. This represents a significant shift from previous industry standards that typically required stability only up to 300-350°C.

Price sensitivity varies significantly by application sector. While consumer electronics manufacturers remain highly cost-conscious, seeking TCO solutions at competitive price points, specialized applications in aerospace and defense demonstrate willingness to pay premium prices for materials with exceptional thermal stability characteristics.

Supply chain analysis reveals potential vulnerabilities, particularly regarding raw material sourcing for indium-based TCOs. With indium supplies facing constraints and price volatility, market participants are increasingly investing in alternative material systems such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) that offer comparable thermal stability with reduced supply risks.

Industry forecasts suggest that demand for thermally stable TCO coatings will be particularly strong in emerging applications such as perovskite solar cells, flexible displays, and smart architectural glass. These applications require processing temperatures that exceed the capabilities of conventional TCO formulations, creating significant market opportunities for advanced materials with enhanced thermal stability profiles.

The display industry remains the largest consumer of thermally stable TCO materials, accounting for nearly 42% of market share. This dominance stems from increasing demand for high-resolution displays in consumer electronics that must withstand elevated processing temperatures during manufacturing. The photovoltaic sector represents the fastest-growing application segment, with demand increasing as manufacturers seek TCO materials capable of maintaining performance integrity during high-temperature thin-film deposition processes.

Regionally, East Asia dominates production and consumption, with China, Japan, and South Korea collectively representing 58% of global market volume. North America and Europe follow with approximately 22% and 17% market share respectively, primarily driven by research activities and premium applications in aerospace and specialized electronics.

Customer requirements are evolving toward TCO coatings that maintain optical transparency and electrical conductivity at temperatures exceeding 500°C, particularly for next-generation flexible electronics and building-integrated photovoltaics. This represents a significant shift from previous industry standards that typically required stability only up to 300-350°C.

Price sensitivity varies significantly by application sector. While consumer electronics manufacturers remain highly cost-conscious, seeking TCO solutions at competitive price points, specialized applications in aerospace and defense demonstrate willingness to pay premium prices for materials with exceptional thermal stability characteristics.

Supply chain analysis reveals potential vulnerabilities, particularly regarding raw material sourcing for indium-based TCOs. With indium supplies facing constraints and price volatility, market participants are increasingly investing in alternative material systems such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) that offer comparable thermal stability with reduced supply risks.

Industry forecasts suggest that demand for thermally stable TCO coatings will be particularly strong in emerging applications such as perovskite solar cells, flexible displays, and smart architectural glass. These applications require processing temperatures that exceed the capabilities of conventional TCO formulations, creating significant market opportunities for advanced materials with enhanced thermal stability profiles.

Current Challenges in TCO Thermal Stability

Transparent Conductive Oxide (TCO) coatings face significant thermal stability challenges that limit their application in high-temperature environments. The most prevalent issue is the degradation of electrical conductivity when TCOs are exposed to elevated temperatures. This degradation occurs through multiple mechanisms, including oxygen vacancy diffusion, crystallographic changes, and interfacial reactions with substrate materials. For instance, Indium Tin Oxide (ITO), the most widely used TCO, begins to show marked performance deterioration at temperatures above 300°C due to tin segregation and oxygen incorporation.

Mechanical integrity presents another critical challenge. Thermal cycling induces stress at the coating-substrate interface due to coefficient of thermal expansion (CTE) mismatches. These stresses can lead to microcracking, delamination, and ultimately complete coating failure. Research indicates that TCO films thicker than 500nm are particularly susceptible to these mechanical failures during thermal cycling between room temperature and operational temperatures.

Optical property stability under thermal stress remains problematic for applications requiring consistent transparency. Heat exposure can trigger crystallization in amorphous TCO films, altering their band structure and consequently their optical transmission characteristics. Studies on Aluminum-doped Zinc Oxide (AZO) demonstrate that annealing at temperatures above 400°C can reduce visible light transmission by up to 15% due to increased light scattering from crystallite formation.

Chemical stability at elevated temperatures introduces additional complications. Many TCOs react with atmospheric gases at high temperatures, particularly in humid conditions. For example, Fluorine-doped Tin Oxide (FTO) can gradually lose fluorine dopants through volatilization when exposed to temperatures above 500°C for extended periods, resulting in increased sheet resistance.

Manufacturing challenges compound these issues. Achieving uniform thermal stability across large-area coatings remains difficult due to thickness variations and compositional inhomogeneities introduced during deposition processes. Current industrial deposition techniques struggle to maintain consistent dopant distribution, which directly impacts thermal stability performance.

The economic viability of thermally stable TCOs presents a market barrier. Alternative materials with superior thermal properties, such as metal nanowire networks or graphene-based composites, currently involve prohibitively expensive production processes for many applications. The cost-performance balance remains unfavorable for widespread adoption in temperature-critical environments like concentrated solar power systems or high-temperature sensing applications.

Addressing these challenges requires interdisciplinary approaches combining materials science, surface engineering, and advanced manufacturing techniques to develop next-generation TCOs with enhanced thermal resilience while maintaining their essential electrical and optical properties.

Mechanical integrity presents another critical challenge. Thermal cycling induces stress at the coating-substrate interface due to coefficient of thermal expansion (CTE) mismatches. These stresses can lead to microcracking, delamination, and ultimately complete coating failure. Research indicates that TCO films thicker than 500nm are particularly susceptible to these mechanical failures during thermal cycling between room temperature and operational temperatures.

Optical property stability under thermal stress remains problematic for applications requiring consistent transparency. Heat exposure can trigger crystallization in amorphous TCO films, altering their band structure and consequently their optical transmission characteristics. Studies on Aluminum-doped Zinc Oxide (AZO) demonstrate that annealing at temperatures above 400°C can reduce visible light transmission by up to 15% due to increased light scattering from crystallite formation.

Chemical stability at elevated temperatures introduces additional complications. Many TCOs react with atmospheric gases at high temperatures, particularly in humid conditions. For example, Fluorine-doped Tin Oxide (FTO) can gradually lose fluorine dopants through volatilization when exposed to temperatures above 500°C for extended periods, resulting in increased sheet resistance.

Manufacturing challenges compound these issues. Achieving uniform thermal stability across large-area coatings remains difficult due to thickness variations and compositional inhomogeneities introduced during deposition processes. Current industrial deposition techniques struggle to maintain consistent dopant distribution, which directly impacts thermal stability performance.

The economic viability of thermally stable TCOs presents a market barrier. Alternative materials with superior thermal properties, such as metal nanowire networks or graphene-based composites, currently involve prohibitively expensive production processes for many applications. The cost-performance balance remains unfavorable for widespread adoption in temperature-critical environments like concentrated solar power systems or high-temperature sensing applications.

Addressing these challenges requires interdisciplinary approaches combining materials science, surface engineering, and advanced manufacturing techniques to develop next-generation TCOs with enhanced thermal resilience while maintaining their essential electrical and optical properties.

Current TCO Thermal Stabilization Methods

01 Composition and structure of TCO coatings for thermal stability

Transparent conductive oxide (TCO) coatings with enhanced thermal stability can be achieved through specific composition formulations and structural designs. These include multi-layered structures, doping with specific elements, and controlling the crystalline structure. The composition often involves materials like indium tin oxide (ITO), zinc oxide (ZnO), or aluminum-doped zinc oxide (AZO) with carefully controlled stoichiometry to maintain transparency and conductivity at elevated temperatures.- Composition and structure of thermally stable TCO coatings: Transparent conductive oxide (TCO) coatings with enhanced thermal stability can be achieved through specific material compositions and structural designs. These include multi-layered structures, doped metal oxides such as indium tin oxide (ITO), zinc oxide (ZnO), and aluminum-doped zinc oxide (AZO). The thermal stability of these materials can be significantly improved by controlling the crystallinity, grain size, and interface properties during deposition processes, allowing them to maintain their electrical conductivity and optical transparency at elevated temperatures.

- Deposition methods for thermally stable TCO films: Various deposition techniques can be employed to create thermally stable transparent conductive oxide coatings. These methods include sputtering, chemical vapor deposition (CVD), pulsed laser deposition, and sol-gel processes. The deposition parameters such as temperature, pressure, and gas flow rates significantly influence the thermal stability of the resulting films. Post-deposition treatments like annealing in controlled atmospheres can further enhance the thermal resistance of TCO coatings by improving crystallinity and reducing defects.

- Barrier layers and interface engineering for TCO thermal stability: The thermal stability of transparent conductive oxide coatings can be significantly improved through the implementation of barrier layers and interface engineering. Thin barrier layers of materials such as silicon dioxide, aluminum oxide, or titanium dioxide can prevent diffusion and chemical reactions at elevated temperatures. Interface engineering techniques, including gradient composition layers and surface treatments, help to reduce thermal stress and prevent delamination when TCO coatings are subjected to high temperatures or thermal cycling.

- Doping strategies to enhance TCO thermal stability: Strategic doping of transparent conductive oxides can significantly enhance their thermal stability. Incorporating elements such as aluminum, gallium, or fluorine into zinc oxide, or niobium into titanium dioxide, can create more robust crystal structures that resist degradation at high temperatures. Co-doping with multiple elements can provide synergistic effects, further improving thermal stability while maintaining or enhancing electrical conductivity and optical transparency. The concentration and distribution of dopants play crucial roles in determining the overall thermal performance of TCO coatings.

- Applications of thermally stable TCO coatings: Thermally stable transparent conductive oxide coatings find applications in various high-temperature environments. These include solar cells that operate under intense sunlight, touch panels and displays that generate heat during operation, architectural glass for energy-efficient buildings, and automotive glazing. In these applications, TCO coatings must maintain their electrical conductivity and optical transparency despite exposure to elevated temperatures, thermal cycling, or harsh environmental conditions. The development of thermally stable TCO coatings has enabled the expansion of transparent electronics into more demanding operational environments.

02 Heat treatment processes for improving TCO thermal stability

Various heat treatment processes can significantly improve the thermal stability of transparent conductive oxide coatings. These processes include annealing under controlled atmospheres, rapid thermal processing, and post-deposition heat treatments. Such treatments help in crystallization, defect reduction, and interface optimization, resulting in TCO films that maintain their optical and electrical properties even after exposure to high temperatures during device fabrication or operation.Expand Specific Solutions03 Substrate influence on TCO thermal stability

The choice of substrate material and its properties significantly affect the thermal stability of transparent conductive oxide coatings. Substrates with thermal expansion coefficients matching the TCO material, high temperature resistance, and good adhesion properties contribute to enhanced thermal stability of the overall structure. Surface treatments of substrates before deposition can also improve the interface quality and subsequent thermal stability of the TCO layer.Expand Specific Solutions04 Deposition techniques for thermally stable TCO coatings

Specific deposition techniques and parameters play crucial roles in achieving thermally stable transparent conductive oxide coatings. Methods such as sputtering with controlled power and pressure, atomic layer deposition, pulsed laser deposition, and chemical vapor deposition with optimized precursors and flow rates can produce TCO films with superior thermal stability. The deposition temperature, rate, and atmosphere are particularly important parameters that influence the microstructure and subsequent thermal behavior.Expand Specific Solutions05 Protective layers and interface engineering for TCO thermal stability

Incorporating protective layers and employing interface engineering techniques can significantly enhance the thermal stability of transparent conductive oxide coatings. Thin barrier layers, gradient composition interfaces, and surface passivation treatments protect TCO films from thermal degradation, oxidation, and diffusion processes at elevated temperatures. These approaches help maintain the optical transparency and electrical conductivity of TCO coatings under thermal stress conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The transparent conductive oxide (TCO) coatings market for thermal stability applications is currently in a growth phase, with increasing demand driven by advancements in energy-efficient building materials and electronics. The global market size is estimated to reach $8.5 billion by 2027, expanding at a CAGR of approximately 6.8%. From a technological maturity perspective, the field shows varied development levels across applications. Industry leaders like Applied Materials and AGC Inc. are advancing high-performance TCO solutions, while specialized players such as Diamond Coatings and SCHOTT AG focus on niche applications requiring exceptional thermal stability. Research institutions including Oregon State University and Commissariat à l'énergie atomique are driving fundamental innovations, collaborating with manufacturers like Saint-Gobain and Sumitomo Metal Mining to bridge the gap between laboratory developments and commercial viability.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed advanced ITO and ATO (Antimony-doped Tin Oxide) formulations with exceptional thermal stability for display and solar applications. Their proprietary "SUMITOUGH" TCO technology utilizes a unique co-sputtering process that incorporates carefully selected stabilizing elements (including molybdenum and tantalum) at precise concentrations to inhibit grain boundary migration during thermal exposure. This results in TCO films that maintain over 90% of their initial conductivity after heating to 500°C. Sumitomo has also pioneered a gradient composition approach where the TCO composition gradually changes throughout the film thickness, creating an optimized structure that balances optical transparency, electrical conductivity, and thermal stability. Their manufacturing process includes a specialized post-deposition treatment that removes structural defects and strengthens grain boundaries, further enhancing thermal durability in demanding applications like OLED displays and CIGS solar cells.

Strengths: Vertically integrated supply chain with control over raw materials; extensive experience in high-purity materials processing; strong position in display industry. Weaknesses: Heavy reliance on indium-based formulations faces long-term sustainability challenges; limited presence in architectural glass applications; higher cost structure than some competitors.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) processes specifically for transparent conductive oxide coatings with enhanced thermal stability. Their Endura® platform utilizes rotary target magnetron sputtering technology to deposit ITO (Indium Tin Oxide), AZO (Aluminum-doped Zinc Oxide), and other TCO materials with precise thickness control and uniformity across large substrates. The company's proprietary process enables the creation of multi-layer TCO stacks with engineered interfaces that significantly improve thermal stability up to 600°C while maintaining over 85% optical transparency and sheet resistance below 10 ohms/square. Their TCO films demonstrate less than 5% degradation in conductivity after thermal cycling tests, making them suitable for high-temperature applications in solar cells, architectural glass, and display technologies.

Strengths: Industry-leading deposition equipment with exceptional uniformity control; proprietary multi-layer stack technology enhances thermal stability; global service infrastructure. Weaknesses: Higher capital equipment costs compared to competitors; ITO-based solutions face indium supply constraints; requires specialized technical expertise for process optimization.

Key Patents and Research on Heat-Resistant TCOs

Transparent electrode having thermal stability, method of fabricating the same and dye-sensitized solar cell comprising the same

PatentInactiveUS8053664B2

Innovation

- A transparent electrode composed of a pentavalent element-containing transparent conductive material, such as tin oxide doped with indium or fluorine, or indium tin oxide, is fabricated using a thermal treatment process with a pentavalent element source, enhancing thermal stability and conductivity.

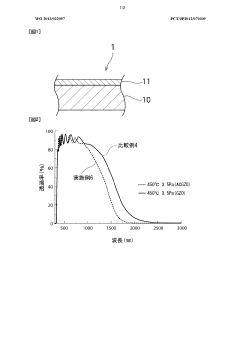

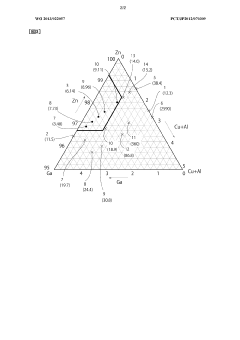

Transparent conductive material, substrate having transparent conductive layer, and method for producing substrate having transparent conductive layer

PatentWO2013022057A1

Innovation

- A transparent conductive material comprising zinc oxide with specific atomic percentages of Al, Cu, and Ga, formed using a physical vapor deposition method in an oxygen partial pressure of 1 Pa or less, which maintains low electrical resistance and high visible light transmittance, and provides heat ray reflective properties.

Environmental Impact Assessment

The environmental impact of transparent conductive oxide (TCO) coatings extends beyond their functional performance, particularly when considering their thermal stability characteristics. Manufacturing processes for TCO materials such as indium tin oxide (ITO), fluorine-doped tin oxide (FTO), and aluminum-doped zinc oxide (AZO) involve energy-intensive deposition techniques including sputtering, chemical vapor deposition, and sol-gel methods, which contribute significantly to carbon emissions and resource consumption.

The extraction of raw materials for TCO production presents substantial environmental concerns. Indium, a critical component in ITO, is classified as a rare earth element with limited global reserves, raising sustainability questions about its long-term availability. Mining operations for these materials often result in habitat destruction, soil erosion, and water contamination in extraction regions, particularly in developing countries where environmental regulations may be less stringent.

Thermal stability enhancements for TCO coatings frequently involve additional processing steps or incorporation of supplementary materials, potentially increasing the environmental footprint of the final product. However, improved thermal stability also extends product lifespans, reducing replacement frequency and associated waste generation, which represents a positive environmental trade-off that must be considered in lifecycle assessments.

End-of-life considerations for TCO-coated products reveal challenges in recycling and disposal. The complex multi-layer structures typical in thermally stable TCO applications complicate material separation and recovery processes. Current recycling technologies struggle to efficiently extract valuable components from these composite materials, resulting in significant material loss and environmental burden through conventional disposal methods.

Water usage represents another critical environmental factor, with wet chemical processes in TCO manufacturing consuming substantial quantities of ultrapure water and generating contaminated wastewater streams containing metal ions and chemical reagents that require specialized treatment before discharge.

Recent advancements in green chemistry approaches show promise for reducing environmental impacts, including aqueous-based synthesis methods, lower-temperature processing techniques, and alternative precursor materials with reduced toxicity profiles. These innovations aim to maintain or enhance thermal stability while minimizing resource consumption and harmful emissions.

Life cycle assessment (LCA) studies indicate that the operational benefits of thermally stable TCO coatings in energy-efficient applications (such as smart windows and solar cells) can potentially offset their manufacturing impacts through energy savings over product lifetimes, highlighting the importance of considering environmental impacts across the entire product lifecycle rather than focusing solely on production phase impacts.

The extraction of raw materials for TCO production presents substantial environmental concerns. Indium, a critical component in ITO, is classified as a rare earth element with limited global reserves, raising sustainability questions about its long-term availability. Mining operations for these materials often result in habitat destruction, soil erosion, and water contamination in extraction regions, particularly in developing countries where environmental regulations may be less stringent.

Thermal stability enhancements for TCO coatings frequently involve additional processing steps or incorporation of supplementary materials, potentially increasing the environmental footprint of the final product. However, improved thermal stability also extends product lifespans, reducing replacement frequency and associated waste generation, which represents a positive environmental trade-off that must be considered in lifecycle assessments.

End-of-life considerations for TCO-coated products reveal challenges in recycling and disposal. The complex multi-layer structures typical in thermally stable TCO applications complicate material separation and recovery processes. Current recycling technologies struggle to efficiently extract valuable components from these composite materials, resulting in significant material loss and environmental burden through conventional disposal methods.

Water usage represents another critical environmental factor, with wet chemical processes in TCO manufacturing consuming substantial quantities of ultrapure water and generating contaminated wastewater streams containing metal ions and chemical reagents that require specialized treatment before discharge.

Recent advancements in green chemistry approaches show promise for reducing environmental impacts, including aqueous-based synthesis methods, lower-temperature processing techniques, and alternative precursor materials with reduced toxicity profiles. These innovations aim to maintain or enhance thermal stability while minimizing resource consumption and harmful emissions.

Life cycle assessment (LCA) studies indicate that the operational benefits of thermally stable TCO coatings in energy-efficient applications (such as smart windows and solar cells) can potentially offset their manufacturing impacts through energy savings over product lifetimes, highlighting the importance of considering environmental impacts across the entire product lifecycle rather than focusing solely on production phase impacts.

Manufacturing Scalability Analysis

The scalability of transparent conductive oxide (TCO) coating manufacturing processes represents a critical factor in their commercial viability for thermal stability applications. Current industrial production methods include magnetron sputtering, chemical vapor deposition (CVD), and sol-gel techniques, each with distinct throughput capabilities and capital requirements. Magnetron sputtering dominates large-scale production due to its excellent film uniformity and process control, achieving production rates of approximately 120-150 m²/hour for standard configurations.

Cost analysis reveals that material consumption constitutes 40-55% of total manufacturing expenses, with indium-containing compounds representing a significant cost driver due to indium's limited global supply. Alternative materials such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) offer more economical options, potentially reducing material costs by 30-45% compared to indium tin oxide (ITO) solutions.

Equipment scaling considerations indicate that roll-to-roll processing technologies enable continuous production with throughputs exceeding 500 m²/hour for certain TCO formulations. However, maintaining thermal stability properties during high-speed deposition remains challenging, with defect rates increasing by approximately 15-25% at maximum production speeds compared to optimized laboratory conditions.

Quality control systems for high-volume manufacturing employ advanced optical monitoring techniques, including in-line spectroscopic ellipsometry and four-point probe measurements. These systems can detect thermal stability degradation indicators in real-time, allowing for process adjustments that maintain consistent performance across production batches.

Energy consumption analysis shows that TCO coating processes require 3.5-7.2 kWh/m² depending on the specific technology employed. Newer plasma-enhanced deposition methods have demonstrated energy efficiency improvements of up to 30%, significantly reducing operational costs for large-scale production facilities.

Yield optimization strategies have evolved to address thermally-induced defects during manufacturing. Statistical process control implementations have improved first-pass yields from historical averages of 75-80% to current industry benchmarks of 88-92% for thermally stable TCO coatings. Advanced manufacturers employing machine learning algorithms for process optimization report achieving yields approaching 95% for specific applications.

Supply chain considerations reveal potential bottlenecks in raw material sourcing, particularly for rare elements used in high-performance TCO formulations. Vertical integration strategies adopted by leading manufacturers have reduced supply disruption risks while decreasing material costs by 15-20% through elimination of intermediary suppliers.

Cost analysis reveals that material consumption constitutes 40-55% of total manufacturing expenses, with indium-containing compounds representing a significant cost driver due to indium's limited global supply. Alternative materials such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) offer more economical options, potentially reducing material costs by 30-45% compared to indium tin oxide (ITO) solutions.

Equipment scaling considerations indicate that roll-to-roll processing technologies enable continuous production with throughputs exceeding 500 m²/hour for certain TCO formulations. However, maintaining thermal stability properties during high-speed deposition remains challenging, with defect rates increasing by approximately 15-25% at maximum production speeds compared to optimized laboratory conditions.

Quality control systems for high-volume manufacturing employ advanced optical monitoring techniques, including in-line spectroscopic ellipsometry and four-point probe measurements. These systems can detect thermal stability degradation indicators in real-time, allowing for process adjustments that maintain consistent performance across production batches.

Energy consumption analysis shows that TCO coating processes require 3.5-7.2 kWh/m² depending on the specific technology employed. Newer plasma-enhanced deposition methods have demonstrated energy efficiency improvements of up to 30%, significantly reducing operational costs for large-scale production facilities.

Yield optimization strategies have evolved to address thermally-induced defects during manufacturing. Statistical process control implementations have improved first-pass yields from historical averages of 75-80% to current industry benchmarks of 88-92% for thermally stable TCO coatings. Advanced manufacturers employing machine learning algorithms for process optimization report achieving yields approaching 95% for specific applications.

Supply chain considerations reveal potential bottlenecks in raw material sourcing, particularly for rare elements used in high-performance TCO formulations. Vertical integration strategies adopted by leading manufacturers have reduced supply disruption risks while decreasing material costs by 15-20% through elimination of intermediary suppliers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!