Transparent Conductive Oxides and Their Place in the Circular Economy

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCO Technology Background and Objectives

Transparent Conductive Oxides (TCOs) represent a critical class of materials that combine electrical conductivity with optical transparency, properties that are typically mutually exclusive in conventional materials. The development of TCOs dates back to the early 20th century, with significant advancements occurring in the 1970s through the commercialization of indium tin oxide (ITO). Since then, the evolution of TCOs has been driven by the exponential growth of display technologies, photovoltaics, and smart windows, establishing these materials as indispensable components in modern optoelectronic devices.

The technological trajectory of TCOs has been characterized by continuous improvements in performance metrics, including higher transparency in the visible spectrum, enhanced electrical conductivity, and increased mechanical flexibility. Recent research has focused on developing TCOs with lower processing temperatures, compatibility with flexible substrates, and reduced reliance on scarce elements like indium, which faces supply constraints due to its limited natural abundance and geopolitical factors affecting its extraction and distribution.

Within the context of the circular economy, TCOs present both challenges and opportunities. The traditional linear economic model of "take-make-dispose" has resulted in significant material wastage and environmental degradation in the electronics industry. TCOs, particularly ITO, contain valuable and scarce resources that are often lost at the end of product lifecycles. This has prompted a paradigm shift toward circular approaches that emphasize resource efficiency, product longevity, and material recovery.

The primary technical objectives for TCOs in a circular economy framework include developing cost-effective recycling methodologies for existing TCO materials, designing new TCO compositions with abundant and environmentally benign elements, and creating manufacturing processes that minimize waste and energy consumption. Additionally, there is a growing emphasis on extending the functional lifespan of TCO-containing devices through improved durability and reparability.

Emerging research directions include the development of self-healing TCO films that can repair microcracks and defects, biodegradable TCOs for transient electronics, and hybrid organic-inorganic TCO systems that combine the best properties of both material classes. These innovations aim to address the inherent tension between technological advancement and sustainability in the electronics sector.

The integration of TCOs into circular economy models necessitates a holistic approach that considers the entire lifecycle of these materials, from raw material extraction to end-of-life recovery. This requires collaborative efforts across disciplines, including materials science, chemical engineering, environmental science, and economics, to develop comprehensive solutions that balance performance requirements with environmental sustainability.

The technological trajectory of TCOs has been characterized by continuous improvements in performance metrics, including higher transparency in the visible spectrum, enhanced electrical conductivity, and increased mechanical flexibility. Recent research has focused on developing TCOs with lower processing temperatures, compatibility with flexible substrates, and reduced reliance on scarce elements like indium, which faces supply constraints due to its limited natural abundance and geopolitical factors affecting its extraction and distribution.

Within the context of the circular economy, TCOs present both challenges and opportunities. The traditional linear economic model of "take-make-dispose" has resulted in significant material wastage and environmental degradation in the electronics industry. TCOs, particularly ITO, contain valuable and scarce resources that are often lost at the end of product lifecycles. This has prompted a paradigm shift toward circular approaches that emphasize resource efficiency, product longevity, and material recovery.

The primary technical objectives for TCOs in a circular economy framework include developing cost-effective recycling methodologies for existing TCO materials, designing new TCO compositions with abundant and environmentally benign elements, and creating manufacturing processes that minimize waste and energy consumption. Additionally, there is a growing emphasis on extending the functional lifespan of TCO-containing devices through improved durability and reparability.

Emerging research directions include the development of self-healing TCO films that can repair microcracks and defects, biodegradable TCOs for transient electronics, and hybrid organic-inorganic TCO systems that combine the best properties of both material classes. These innovations aim to address the inherent tension between technological advancement and sustainability in the electronics sector.

The integration of TCOs into circular economy models necessitates a holistic approach that considers the entire lifecycle of these materials, from raw material extraction to end-of-life recovery. This requires collaborative efforts across disciplines, including materials science, chemical engineering, environmental science, and economics, to develop comprehensive solutions that balance performance requirements with environmental sustainability.

Market Demand Analysis for Transparent Conductive Materials

The global market for transparent conductive materials has experienced significant growth over the past decade, primarily driven by the expanding electronics industry and the increasing adoption of touchscreen devices. Transparent Conductive Oxides (TCOs), particularly Indium Tin Oxide (ITO), currently dominate approximately 85% of the market due to their excellent combination of optical transparency and electrical conductivity.

The demand for TCOs is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2028, with the market value expected to reach $7.5 billion by 2028. This growth is largely attributed to the rising production of smartphones, tablets, flat panel displays, and emerging applications in photovoltaics and smart windows. The Asia-Pacific region, particularly China, South Korea, and Taiwan, represents the largest market share due to the concentration of electronics manufacturing facilities.

Consumer electronics continue to be the primary application sector, accounting for nearly 60% of TCO consumption. However, the renewable energy sector, specifically photovoltaic applications, is emerging as the fastest-growing segment with an estimated CAGR of 12.3%. This shift reflects the global transition toward sustainable energy solutions and highlights the critical role TCOs play in green technology development.

Despite the strong market position of ITO, supply chain vulnerabilities and sustainability concerns are reshaping market dynamics. Indium's limited global reserves, concentrated production in few countries, and price volatility have intensified the search for alternative materials. This situation has created a growing demand for more sustainable and recyclable TCO solutions that align with circular economy principles.

Recent market surveys indicate that 73% of electronics manufacturers are actively seeking alternatives to traditional ITO, with sustainability and supply security cited as primary motivators. Materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and various nanostructured materials are gaining traction as potential replacements.

The circular economy perspective is increasingly influencing purchasing decisions, with 68% of OEMs reporting that recyclability and end-of-life considerations now factor into their materials selection process. This represents a significant shift from just five years ago when only 24% considered these factors important. Government regulations, particularly in the EU with its Circular Economy Action Plan and Extended Producer Responsibility frameworks, are accelerating this trend by mandating improved recyclability and reduced environmental impact of electronic products.

The demand for TCOs is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2028, with the market value expected to reach $7.5 billion by 2028. This growth is largely attributed to the rising production of smartphones, tablets, flat panel displays, and emerging applications in photovoltaics and smart windows. The Asia-Pacific region, particularly China, South Korea, and Taiwan, represents the largest market share due to the concentration of electronics manufacturing facilities.

Consumer electronics continue to be the primary application sector, accounting for nearly 60% of TCO consumption. However, the renewable energy sector, specifically photovoltaic applications, is emerging as the fastest-growing segment with an estimated CAGR of 12.3%. This shift reflects the global transition toward sustainable energy solutions and highlights the critical role TCOs play in green technology development.

Despite the strong market position of ITO, supply chain vulnerabilities and sustainability concerns are reshaping market dynamics. Indium's limited global reserves, concentrated production in few countries, and price volatility have intensified the search for alternative materials. This situation has created a growing demand for more sustainable and recyclable TCO solutions that align with circular economy principles.

Recent market surveys indicate that 73% of electronics manufacturers are actively seeking alternatives to traditional ITO, with sustainability and supply security cited as primary motivators. Materials such as fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), and various nanostructured materials are gaining traction as potential replacements.

The circular economy perspective is increasingly influencing purchasing decisions, with 68% of OEMs reporting that recyclability and end-of-life considerations now factor into their materials selection process. This represents a significant shift from just five years ago when only 24% considered these factors important. Government regulations, particularly in the EU with its Circular Economy Action Plan and Extended Producer Responsibility frameworks, are accelerating this trend by mandating improved recyclability and reduced environmental impact of electronic products.

Current Status and Challenges in TCO Development

Transparent Conductive Oxides (TCOs) currently represent a critical component in numerous optoelectronic applications, with Indium Tin Oxide (ITO) dominating approximately 90% of the global market. The widespread adoption of ITO stems from its exceptional combination of high optical transparency (>85%) and low electrical resistivity (<10^-4 Ω·cm). However, the TCO landscape faces significant challenges that necessitate urgent attention from both research and industrial perspectives.

The primary concern surrounding ITO relates to indium's scarcity and geopolitical supply constraints. Indium is classified as a critical raw material with limited global reserves, predominantly concentrated in China (approximately 70% of world production). This concentration creates supply vulnerabilities and price volatility, with indium prices fluctuating between $200-800/kg over the past decade, significantly impacting manufacturing costs for display technologies and photovoltaics.

From a technical standpoint, conventional TCO manufacturing processes present substantial environmental challenges. Magnetron sputtering, the predominant deposition technique for high-quality TCO films, exhibits material utilization efficiency of merely 30-40%, resulting in considerable material waste. Additionally, the high-temperature annealing processes required for optimal conductivity contribute significantly to the carbon footprint of TCO production, with energy consumption reaching 15-20 kWh/m² of coated surface.

The mechanical properties of current TCOs pose another significant limitation. Most commercially available TCOs exhibit brittle characteristics with limited flexibility (maximum bending radius of 20-30mm), restricting their application in emerging flexible electronics. This brittleness results in microcracks forming under minimal strain (typically at 1-2% elongation), leading to conductivity degradation and device failure.

Recycling and end-of-life management represent perhaps the most pressing challenges in the TCO lifecycle. Current recovery rates for indium from end-of-life products remain below 1%, primarily due to the complex nature of multilayer device architectures and the absence of economically viable separation technologies. The diffuse distribution of TCOs in consumer electronics further complicates collection and recycling efforts.

Emerging alternatives such as silver nanowires, carbon-based materials (graphene, carbon nanotubes), and conductive polymers show promise but face their own challenges regarding scalability, long-term stability, and cost-effectiveness. PEDOT:PSS, while offering excellent flexibility, still struggles with conductivity limitations and moisture sensitivity that restrict its widespread adoption as a complete ITO replacement.

The primary concern surrounding ITO relates to indium's scarcity and geopolitical supply constraints. Indium is classified as a critical raw material with limited global reserves, predominantly concentrated in China (approximately 70% of world production). This concentration creates supply vulnerabilities and price volatility, with indium prices fluctuating between $200-800/kg over the past decade, significantly impacting manufacturing costs for display technologies and photovoltaics.

From a technical standpoint, conventional TCO manufacturing processes present substantial environmental challenges. Magnetron sputtering, the predominant deposition technique for high-quality TCO films, exhibits material utilization efficiency of merely 30-40%, resulting in considerable material waste. Additionally, the high-temperature annealing processes required for optimal conductivity contribute significantly to the carbon footprint of TCO production, with energy consumption reaching 15-20 kWh/m² of coated surface.

The mechanical properties of current TCOs pose another significant limitation. Most commercially available TCOs exhibit brittle characteristics with limited flexibility (maximum bending radius of 20-30mm), restricting their application in emerging flexible electronics. This brittleness results in microcracks forming under minimal strain (typically at 1-2% elongation), leading to conductivity degradation and device failure.

Recycling and end-of-life management represent perhaps the most pressing challenges in the TCO lifecycle. Current recovery rates for indium from end-of-life products remain below 1%, primarily due to the complex nature of multilayer device architectures and the absence of economically viable separation technologies. The diffuse distribution of TCOs in consumer electronics further complicates collection and recycling efforts.

Emerging alternatives such as silver nanowires, carbon-based materials (graphene, carbon nanotubes), and conductive polymers show promise but face their own challenges regarding scalability, long-term stability, and cost-effectiveness. PEDOT:PSS, while offering excellent flexibility, still struggles with conductivity limitations and moisture sensitivity that restrict its widespread adoption as a complete ITO replacement.

Current TCO Material Solutions and Applications

01 Composition and structure of transparent conductive oxides

Transparent conductive oxides (TCOs) are materials that combine electrical conductivity with optical transparency. These materials typically consist of metal oxides doped with specific elements to enhance their electrical properties while maintaining high optical transmittance. Common TCO compositions include indium tin oxide (ITO), zinc oxide (ZnO), and tin oxide (SnO2) with various dopants. The crystalline structure and composition significantly influence the performance characteristics of these materials.- Indium-based transparent conductive oxides: Indium-based materials, particularly indium tin oxide (ITO), are widely used as transparent conductive oxides in various electronic applications. These materials offer excellent electrical conductivity while maintaining high optical transparency in the visible spectrum. The formulation and deposition methods of indium-based TCOs can be optimized to achieve desired properties for specific applications such as touch screens, displays, and photovoltaic devices.

- Alternative TCO materials to replace indium: Due to the scarcity and high cost of indium, alternative transparent conductive oxide materials are being developed. These include zinc oxide-based compounds (ZnO), tin oxide (SnO2), and other metal oxides that can be doped with various elements to enhance conductivity while maintaining transparency. These alternative materials aim to provide comparable performance to ITO while reducing dependency on rare and expensive elements.

- Deposition and manufacturing techniques for TCOs: Various deposition techniques are employed for fabricating transparent conductive oxide films, including sputtering, chemical vapor deposition, sol-gel methods, and atomic layer deposition. These techniques influence the microstructure, crystallinity, and interface properties of the TCO films, which in turn affect their electrical and optical performance. Optimization of deposition parameters is crucial for achieving high-quality TCO films with desired characteristics.

- TCO applications in optoelectronic devices: Transparent conductive oxides are essential components in various optoelectronic devices including solar cells, light-emitting diodes, touch panels, and smart windows. The specific requirements for TCOs vary depending on the application, with some requiring higher transparency while others prioritizing conductivity or flexibility. Tailoring the composition and structure of TCOs to meet these application-specific requirements is an active area of research and development.

- Nanostructured and composite TCO materials: Nanostructuring and creating composite materials represent advanced approaches to enhancing TCO performance. These include nanoparticle-based TCOs, multilayer structures, and hybrid organic-inorganic materials. Nanostructured TCOs can offer improved electrical properties through enhanced carrier mobility and reduced scattering, while maintaining high optical transparency. Composite structures can combine the advantages of different materials to achieve superior overall performance for specific applications.

02 Deposition methods for transparent conductive oxide films

Various deposition techniques are employed to create thin films of transparent conductive oxides on different substrates. These methods include sputtering, chemical vapor deposition (CVD), pulsed laser deposition, and sol-gel processes. Each technique offers distinct advantages in terms of film quality, uniformity, and scalability. The deposition parameters significantly affect the electrical conductivity, optical transparency, and mechanical properties of the resulting TCO films.Expand Specific Solutions03 Applications of transparent conductive oxides in electronic devices

Transparent conductive oxides are widely used in various electronic and optoelectronic devices. They serve as transparent electrodes in displays, touchscreens, solar cells, and light-emitting diodes. The unique combination of electrical conductivity and optical transparency makes TCOs essential components in modern electronic devices. Recent developments focus on enhancing the performance of TCOs for specific applications, such as flexible electronics and high-efficiency photovoltaics.Expand Specific Solutions04 Novel TCO materials and doping strategies

Research on transparent conductive oxides includes the development of novel materials and doping strategies to improve their properties. Alternative TCO materials are being explored to replace conventional indium-based compounds due to the scarcity and high cost of indium. Doping with various elements can enhance electrical conductivity while maintaining optical transparency. Advanced TCO materials with improved stability, flexibility, and performance characteristics are being developed for next-generation electronic devices.Expand Specific Solutions05 Processing techniques for enhanced TCO performance

Various processing techniques are employed to enhance the performance of transparent conductive oxide films. These include post-deposition treatments such as annealing, plasma treatment, and surface modification. Such processes can improve crystallinity, reduce defects, and optimize the electrical and optical properties of TCO films. Advanced processing methods aim to achieve TCO films with higher conductivity, better transparency, and improved stability under various operating conditions.Expand Specific Solutions

Key Industry Players in TCO Manufacturing and Research

Transparent Conductive Oxides (TCOs) are currently in a growth phase within the circular economy, with the market expected to expand significantly due to increasing demand in electronics, photovoltaics, and smart windows. The global TCO market demonstrates moderate maturity but is evolving rapidly through innovations in sustainability and recycling processes. Leading companies like Applied Materials, Micron Technology, and TDK Corp are advancing TCO technologies with improved performance and reduced environmental impact. Research institutions including Zhejiang University, ICFO, and the Shanghai Institute of Ceramics are developing next-generation TCO materials with enhanced recyclability. The competitive landscape features established industrial players alongside emerging specialized manufacturers, all working toward integrating TCOs into sustainable product lifecycles.

Alliance for Sustainable Energy LLC

Technical Solution: The Alliance for Sustainable Energy, which manages the National Renewable Energy Laboratory (NREL), has pioneered sustainable TCO technologies specifically designed for renewable energy applications. Their earth-abundant TCO research program has developed aluminum-doped zinc oxide (AZO) and molybdenum-doped indium oxide (IMO) formulations that reduce or eliminate critical raw material dependencies while achieving performance metrics suitable for solar applications. Their combinatorial materials science approach has screened over 10,000 TCO compositions to identify optimal sustainability-performance balance points. NREL's advanced manufacturing initiative has demonstrated roll-to-roll atmospheric pressure spatial atomic layer deposition (AP-SALD) for TCO deposition, reducing energy consumption by approximately 65% compared to vacuum-based processes. Their circular manufacturing framework includes design-for-recycling guidelines specifically for TCO-containing solar panels, with demonstrated pilot projects achieving TCO recovery rates of 80-90%. NREL's life cycle analysis tools specifically quantify critical material intensity and recycling potential for different TCO formulations, enabling manufacturers to make informed sustainability decisions while maintaining performance requirements for renewable energy applications.

Strengths: Comprehensive research on earth-abundant TCO alternatives reduces supply chain risks; energy-efficient deposition technologies align with renewable energy values; integrated approach connecting materials development with end-of-life considerations. Weaknesses: Some alternative TCO formulations still show performance gaps compared to conventional ITO; scale-up challenges for novel deposition methods; economic viability dependent on policy support for sustainable manufacturing.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced physical vapor deposition (PVD) and chemical vapor deposition (CVD) systems specifically optimized for transparent conductive oxide (TCO) production. Their Endura® PVD platform enables precise deposition of indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), and fluorine-doped tin oxide (FTO) with thickness uniformity control within ±2%. The company's proprietary rotary target technology allows for material utilization rates exceeding 85%, significantly reducing indium waste in ITO production. Their circular economy approach includes on-site recycling systems that can recover up to 90% of target materials from manufacturing waste streams. Applied Materials has also pioneered low-temperature deposition processes that reduce energy consumption by approximately 30% compared to conventional methods, while maintaining film quality with transmittance >90% and sheet resistance <10 ohms/square.

Strengths: Industry-leading material utilization efficiency (>85%) significantly reduces rare material waste; integrated recycling systems support circular economy principles; advanced process control enables high-performance TCOs with excellent optical and electrical properties. Weaknesses: High capital equipment costs create barriers for smaller manufacturers; some processes still rely on critical raw materials like indium that face supply constraints.

Critical Patents and Technical Innovations in TCO Field

Transparent conducting oxide material and methods of producing same

PatentInactiveUS20140151611A1

Innovation

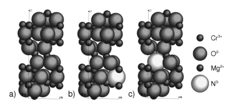

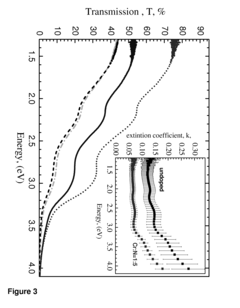

- A transparent conducting oxide material is developed by employing a corundum-type host oxide doped with specific cationic and anionic elements like Magnesium and Nitrogen, enhancing transparency and conductivity through a co-doping strategy, which modifies the lattice structure and improves hole mobility.

Method of preparing an electrically conductive material, and an electrically conductive material

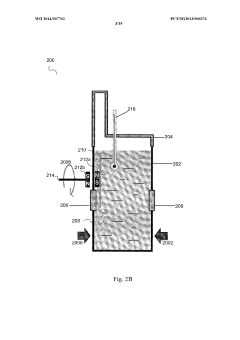

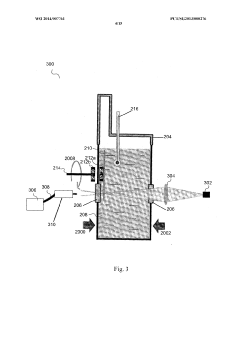

PatentWO2014007761A1

Innovation

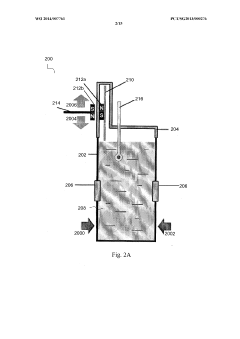

- A method involving a substrate with growth sites contacted by a growth solution containing metal ions to form a continuous, transparent crystalline metal oxide layer, which can be grown under non-vacuum conditions and is scalable, using zinc oxide or titanium dioxide, with optional doping for enhanced properties.

Circular Economy Integration Strategies for TCO Materials

Integrating Transparent Conductive Oxides (TCOs) into circular economy frameworks requires strategic approaches that balance technological innovation with sustainability principles. The transition from linear "take-make-dispose" models to circular systems necessitates redesigning TCO production, application, and end-of-life management to minimize waste and maximize resource efficiency.

Material design strategies represent the first critical intervention point. Developing TCOs with recyclability as a core design parameter involves selecting constituent elements that can be more easily separated and recovered. This includes exploring alternatives to indium-based compounds, given indium's scarcity and high recovery costs. Research into zinc-based and aluminum-doped zinc oxide systems shows promising circular potential due to their abundant constituent materials.

Manufacturing process optimization forms another essential strategy. Implementing cleaner production techniques such as sol-gel methods and low-temperature deposition processes significantly reduces energy consumption and hazardous waste generation. Advanced thin-film deposition technologies that minimize material usage while maintaining performance characteristics further enhance circularity potential.

Product design for disassembly enables more effective recovery of TCO materials from end-of-life electronics and photovoltaics. Modular design approaches that facilitate the separation of TCO-containing components from substrate materials increase recovery rates and quality of reclaimed materials. This strategy requires collaboration between materials scientists and product designers to ensure both functionality and recyclability.

Recovery infrastructure development remains crucial for closing the TCO material loop. Establishing specialized recycling facilities capable of handling complex electronic waste streams containing TCOs requires significant investment but offers long-term economic and environmental benefits. Hydrometallurgical and bioleaching techniques show particular promise for selective recovery of TCO constituent materials with lower environmental impacts than conventional methods.

Policy frameworks and economic incentives serve as enabling mechanisms for TCO circularity. Extended producer responsibility schemes, material passports for TCO-containing products, and tax incentives for using recycled content can drive market transformation. International standards for TCO recyclability would further accelerate adoption of circular practices across global supply chains.

Cross-sector partnerships between TCO manufacturers, electronics producers, waste management companies, and research institutions create innovation ecosystems that can overcome technical and logistical barriers to circularity. These collaborative networks facilitate knowledge sharing and technology transfer essential for scaling circular solutions.

Material design strategies represent the first critical intervention point. Developing TCOs with recyclability as a core design parameter involves selecting constituent elements that can be more easily separated and recovered. This includes exploring alternatives to indium-based compounds, given indium's scarcity and high recovery costs. Research into zinc-based and aluminum-doped zinc oxide systems shows promising circular potential due to their abundant constituent materials.

Manufacturing process optimization forms another essential strategy. Implementing cleaner production techniques such as sol-gel methods and low-temperature deposition processes significantly reduces energy consumption and hazardous waste generation. Advanced thin-film deposition technologies that minimize material usage while maintaining performance characteristics further enhance circularity potential.

Product design for disassembly enables more effective recovery of TCO materials from end-of-life electronics and photovoltaics. Modular design approaches that facilitate the separation of TCO-containing components from substrate materials increase recovery rates and quality of reclaimed materials. This strategy requires collaboration between materials scientists and product designers to ensure both functionality and recyclability.

Recovery infrastructure development remains crucial for closing the TCO material loop. Establishing specialized recycling facilities capable of handling complex electronic waste streams containing TCOs requires significant investment but offers long-term economic and environmental benefits. Hydrometallurgical and bioleaching techniques show particular promise for selective recovery of TCO constituent materials with lower environmental impacts than conventional methods.

Policy frameworks and economic incentives serve as enabling mechanisms for TCO circularity. Extended producer responsibility schemes, material passports for TCO-containing products, and tax incentives for using recycled content can drive market transformation. International standards for TCO recyclability would further accelerate adoption of circular practices across global supply chains.

Cross-sector partnerships between TCO manufacturers, electronics producers, waste management companies, and research institutions create innovation ecosystems that can overcome technical and logistical barriers to circularity. These collaborative networks facilitate knowledge sharing and technology transfer essential for scaling circular solutions.

Environmental Impact Assessment of TCO Production and Recycling

The production and recycling of Transparent Conductive Oxides (TCOs) present significant environmental implications that warrant comprehensive assessment. Life cycle analyses reveal that the extraction of rare elements like indium and tin for TCO manufacturing generates substantial environmental burdens, including habitat disruption, water pollution, and high energy consumption. The sputtering processes commonly employed in TCO deposition are particularly energy-intensive, contributing to considerable carbon emissions—estimated at 15-20 kg CO2 equivalent per square meter of coated surface.

Water usage represents another critical environmental concern, with TCO production facilities consuming approximately 200-300 liters of ultra-pure water per square meter of material produced. Chemical waste streams containing heavy metals and acidic compounds require specialized treatment protocols to prevent environmental contamination, adding complexity to waste management systems.

Current recycling rates for TCOs remain suboptimal, with global recovery estimates below 30% for indium from end-of-life products. This inefficiency stems from technical challenges in separating thin TCO layers from substrate materials and the economic barriers of establishing dedicated recycling infrastructure. However, emerging hydrometallurgical and electrochemical recovery techniques demonstrate promising recovery efficiencies exceeding 85% in laboratory conditions.

Environmental impact assessments indicate that implementing closed-loop recycling systems could reduce the carbon footprint of TCO production by 40-60% compared to primary production pathways. Additionally, advanced manufacturing techniques such as solution-based deposition methods show potential for reducing both energy requirements and hazardous waste generation by up to 30% relative to conventional vacuum-based processes.

The geographical distribution of environmental impacts presents notable disparities, with extraction-related damages concentrated in mining regions of China, South America, and Africa, while processing-related pollution affects industrial centers in East Asia and Europe. This uneven distribution raises environmental justice concerns that must be addressed through international cooperation and equitable policy frameworks.

Forward-looking environmental strategies for TCO production include transitioning to renewable energy sources for manufacturing facilities, implementing water recycling systems, developing bio-based alternatives for certain process chemicals, and establishing product design standards that facilitate end-of-life recovery. These approaches align with circular economy principles and could significantly mitigate the environmental footprint of TCO technologies while preserving their critical functionality in sustainable energy applications.

Water usage represents another critical environmental concern, with TCO production facilities consuming approximately 200-300 liters of ultra-pure water per square meter of material produced. Chemical waste streams containing heavy metals and acidic compounds require specialized treatment protocols to prevent environmental contamination, adding complexity to waste management systems.

Current recycling rates for TCOs remain suboptimal, with global recovery estimates below 30% for indium from end-of-life products. This inefficiency stems from technical challenges in separating thin TCO layers from substrate materials and the economic barriers of establishing dedicated recycling infrastructure. However, emerging hydrometallurgical and electrochemical recovery techniques demonstrate promising recovery efficiencies exceeding 85% in laboratory conditions.

Environmental impact assessments indicate that implementing closed-loop recycling systems could reduce the carbon footprint of TCO production by 40-60% compared to primary production pathways. Additionally, advanced manufacturing techniques such as solution-based deposition methods show potential for reducing both energy requirements and hazardous waste generation by up to 30% relative to conventional vacuum-based processes.

The geographical distribution of environmental impacts presents notable disparities, with extraction-related damages concentrated in mining regions of China, South America, and Africa, while processing-related pollution affects industrial centers in East Asia and Europe. This uneven distribution raises environmental justice concerns that must be addressed through international cooperation and equitable policy frameworks.

Forward-looking environmental strategies for TCO production include transitioning to renewable energy sources for manufacturing facilities, implementing water recycling systems, developing bio-based alternatives for certain process chemicals, and establishing product design standards that facilitate end-of-life recovery. These approaches align with circular economy principles and could significantly mitigate the environmental footprint of TCO technologies while preserving their critical functionality in sustainable energy applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!