Research on Transparent Conductive Oxides and Electrolyte Compatibility

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCO Background and Research Objectives

Transparent Conductive Oxides (TCOs) represent a critical class of materials that combine electrical conductivity with optical transparency, properties that are typically mutually exclusive in conventional materials. The development of TCOs dates back to the early 20th century, with significant advancements occurring in the 1970s through the commercialization of indium tin oxide (ITO). Over the past decades, TCOs have evolved from simple binary compounds to complex multi-component systems with tailored properties for specific applications.

The technological evolution of TCOs has been driven by increasing demands in optoelectronic devices, particularly in display technologies, photovoltaics, and smart windows. Traditional TCO materials include ITO, fluorine-doped tin oxide (FTO), and aluminum-doped zinc oxide (AZO). However, concerns regarding indium scarcity and cost have accelerated research into alternative materials and novel deposition techniques to enhance performance while reducing dependency on critical raw materials.

Recent technological trends indicate a shift toward more sustainable and earth-abundant TCO materials, including doped zinc oxide variants, titanium-based compounds, and emerging 2D materials. Additionally, there is growing interest in flexible and stretchable TCOs to support next-generation flexible electronics and wearable devices, requiring innovative approaches to material design and fabrication processes.

The interface between TCOs and electrolytes represents a particularly challenging research area, as the stability and performance of these interfaces significantly impact the functionality of electrochemical devices such as batteries, fuel cells, and electrochromic systems. Understanding and optimizing the compatibility between TCOs and various electrolyte systems is crucial for advancing these technologies.

The primary objectives of this research are threefold: first, to comprehensively evaluate the current state of TCO materials with specific focus on their electrochemical stability in various electrolyte environments; second, to identify and characterize degradation mechanisms at TCO-electrolyte interfaces under operational conditions; and third, to develop strategies for enhancing compatibility through surface modifications, protective coatings, or novel material compositions.

This research aims to bridge fundamental materials science with practical applications, addressing critical challenges in energy storage, conversion technologies, and smart optical systems. By establishing clear correlations between TCO composition, structure, and electrolyte compatibility, we seek to provide design guidelines for next-generation materials with enhanced performance and durability in electrochemical environments.

The technological evolution of TCOs has been driven by increasing demands in optoelectronic devices, particularly in display technologies, photovoltaics, and smart windows. Traditional TCO materials include ITO, fluorine-doped tin oxide (FTO), and aluminum-doped zinc oxide (AZO). However, concerns regarding indium scarcity and cost have accelerated research into alternative materials and novel deposition techniques to enhance performance while reducing dependency on critical raw materials.

Recent technological trends indicate a shift toward more sustainable and earth-abundant TCO materials, including doped zinc oxide variants, titanium-based compounds, and emerging 2D materials. Additionally, there is growing interest in flexible and stretchable TCOs to support next-generation flexible electronics and wearable devices, requiring innovative approaches to material design and fabrication processes.

The interface between TCOs and electrolytes represents a particularly challenging research area, as the stability and performance of these interfaces significantly impact the functionality of electrochemical devices such as batteries, fuel cells, and electrochromic systems. Understanding and optimizing the compatibility between TCOs and various electrolyte systems is crucial for advancing these technologies.

The primary objectives of this research are threefold: first, to comprehensively evaluate the current state of TCO materials with specific focus on their electrochemical stability in various electrolyte environments; second, to identify and characterize degradation mechanisms at TCO-electrolyte interfaces under operational conditions; and third, to develop strategies for enhancing compatibility through surface modifications, protective coatings, or novel material compositions.

This research aims to bridge fundamental materials science with practical applications, addressing critical challenges in energy storage, conversion technologies, and smart optical systems. By establishing clear correlations between TCO composition, structure, and electrolyte compatibility, we seek to provide design guidelines for next-generation materials with enhanced performance and durability in electrochemical environments.

Market Analysis for TCO Applications

The global market for Transparent Conductive Oxides (TCOs) has experienced significant growth in recent years, driven primarily by the expanding electronics industry and increasing demand for touchscreen devices. The TCO market was valued at approximately $6.9 billion in 2022 and is projected to reach $11.2 billion by 2028, growing at a CAGR of 8.4% during the forecast period.

Display technologies represent the largest application segment for TCOs, accounting for nearly 45% of the market share. This includes smartphones, tablets, laptops, and large-format displays, where TCOs serve as essential components for touch functionality and visual clarity. The rapid adoption of OLED and flexible display technologies has further accelerated demand for advanced TCO materials that can maintain conductivity while offering flexibility.

Photovoltaic applications constitute the second-largest market segment, representing approximately 30% of TCO utilization. The global push toward renewable energy has significantly boosted solar panel production, where TCOs function as critical front electrodes. Notably, the compatibility between TCOs and various electrolytes in next-generation solar cells has become a crucial research focus, as it directly impacts device efficiency and longevity.

The automotive sector has emerged as a rapidly growing application area, particularly with the increasing integration of smart displays in vehicle interiors and the development of electrochromic windows. This sector is expected to grow at the highest CAGR of 10.2% through 2028, driven by the electrification trend in transportation.

Regionally, Asia-Pacific dominates the TCO market with approximately 65% share, attributed to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 14% market shares respectively, with significant research activities focused on TCO-electrolyte compatibility for advanced energy applications.

Indium Tin Oxide (ITO) continues to lead the market with approximately 70% share despite supply chain concerns regarding indium scarcity. Alternative TCOs such as Fluorine-doped Tin Oxide (FTO), Aluminum-doped Zinc Oxide (AZO), and graphene-based composites are gaining traction, particularly in applications requiring specific electrolyte compatibility.

The market is witnessing a shift toward TCO materials that offer enhanced stability when in contact with various electrolytes, especially for electrochemical devices like batteries, fuel cells, and electrochromic systems. This trend is creating new market opportunities for specialized TCO formulations designed for specific electrolyte environments.

Display technologies represent the largest application segment for TCOs, accounting for nearly 45% of the market share. This includes smartphones, tablets, laptops, and large-format displays, where TCOs serve as essential components for touch functionality and visual clarity. The rapid adoption of OLED and flexible display technologies has further accelerated demand for advanced TCO materials that can maintain conductivity while offering flexibility.

Photovoltaic applications constitute the second-largest market segment, representing approximately 30% of TCO utilization. The global push toward renewable energy has significantly boosted solar panel production, where TCOs function as critical front electrodes. Notably, the compatibility between TCOs and various electrolytes in next-generation solar cells has become a crucial research focus, as it directly impacts device efficiency and longevity.

The automotive sector has emerged as a rapidly growing application area, particularly with the increasing integration of smart displays in vehicle interiors and the development of electrochromic windows. This sector is expected to grow at the highest CAGR of 10.2% through 2028, driven by the electrification trend in transportation.

Regionally, Asia-Pacific dominates the TCO market with approximately 65% share, attributed to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 14% market shares respectively, with significant research activities focused on TCO-electrolyte compatibility for advanced energy applications.

Indium Tin Oxide (ITO) continues to lead the market with approximately 70% share despite supply chain concerns regarding indium scarcity. Alternative TCOs such as Fluorine-doped Tin Oxide (FTO), Aluminum-doped Zinc Oxide (AZO), and graphene-based composites are gaining traction, particularly in applications requiring specific electrolyte compatibility.

The market is witnessing a shift toward TCO materials that offer enhanced stability when in contact with various electrolytes, especially for electrochemical devices like batteries, fuel cells, and electrochromic systems. This trend is creating new market opportunities for specialized TCO formulations designed for specific electrolyte environments.

Current TCO-Electrolyte Interface Challenges

The interface between transparent conductive oxides (TCOs) and electrolytes represents a critical junction in numerous electrochemical devices, including solar cells, electrochromic windows, and various sensing applications. Current challenges at this interface significantly impact device performance, stability, and commercial viability. One of the primary issues is the chemical instability of TCO materials when in prolonged contact with electrolytes, particularly under applied electrical potentials.

Indium tin oxide (ITO), the most widely used TCO, exhibits notable degradation when exposed to both aqueous and non-aqueous electrolytes. This degradation manifests as increased resistivity, reduced optical transparency, and physical deterioration of the TCO layer. Studies have shown that ITO can undergo reduction reactions at negative potentials, leading to the formation of metallic indium and subsequent delamination from substrates.

Alternative TCO materials such as fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO) demonstrate improved chemical stability but face their own compatibility challenges. FTO exhibits better resistance to electrolyte-induced degradation but suffers from higher sheet resistance compared to ITO. AZO shows promising optical and electrical properties but remains highly susceptible to corrosion in acidic and basic environments.

The electrochemical stability window—the potential range within which minimal degradation occurs—varies significantly among TCO materials and electrolyte compositions. This variability complicates material selection for specific applications and necessitates extensive compatibility testing for each TCO-electrolyte combination. Recent research indicates that surface modifications, such as thin protective oxide layers or self-assembled monolayers, can extend this stability window but often at the cost of increased interfacial resistance.

Ion intercalation presents another significant challenge, particularly in lithium-ion based systems. TCO materials can experience structural changes and performance degradation due to ion insertion into their lattice structure. This phenomenon is especially problematic in electrochromic devices and certain battery applications where repeated ion movement across the interface is fundamental to device operation.

Interface energetics and charge transfer kinetics also remain poorly understood for many TCO-electrolyte combinations. The formation of electrical double layers, surface states, and potential-dependent adsorption phenomena can significantly alter charge transfer rates and overall device efficiency. Advanced characterization techniques such as impedance spectroscopy and in-situ spectroelectrochemistry have revealed complex interfacial behaviors that traditional models fail to predict accurately.

Manufacturing challenges further complicate the situation, as techniques to improve TCO-electrolyte compatibility often involve complex processing steps that are difficult to scale economically. The trade-off between enhanced interface stability and increased production costs represents a significant barrier to commercial implementation of many promising solutions.

Indium tin oxide (ITO), the most widely used TCO, exhibits notable degradation when exposed to both aqueous and non-aqueous electrolytes. This degradation manifests as increased resistivity, reduced optical transparency, and physical deterioration of the TCO layer. Studies have shown that ITO can undergo reduction reactions at negative potentials, leading to the formation of metallic indium and subsequent delamination from substrates.

Alternative TCO materials such as fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO) demonstrate improved chemical stability but face their own compatibility challenges. FTO exhibits better resistance to electrolyte-induced degradation but suffers from higher sheet resistance compared to ITO. AZO shows promising optical and electrical properties but remains highly susceptible to corrosion in acidic and basic environments.

The electrochemical stability window—the potential range within which minimal degradation occurs—varies significantly among TCO materials and electrolyte compositions. This variability complicates material selection for specific applications and necessitates extensive compatibility testing for each TCO-electrolyte combination. Recent research indicates that surface modifications, such as thin protective oxide layers or self-assembled monolayers, can extend this stability window but often at the cost of increased interfacial resistance.

Ion intercalation presents another significant challenge, particularly in lithium-ion based systems. TCO materials can experience structural changes and performance degradation due to ion insertion into their lattice structure. This phenomenon is especially problematic in electrochromic devices and certain battery applications where repeated ion movement across the interface is fundamental to device operation.

Interface energetics and charge transfer kinetics also remain poorly understood for many TCO-electrolyte combinations. The formation of electrical double layers, surface states, and potential-dependent adsorption phenomena can significantly alter charge transfer rates and overall device efficiency. Advanced characterization techniques such as impedance spectroscopy and in-situ spectroelectrochemistry have revealed complex interfacial behaviors that traditional models fail to predict accurately.

Manufacturing challenges further complicate the situation, as techniques to improve TCO-electrolyte compatibility often involve complex processing steps that are difficult to scale economically. The trade-off between enhanced interface stability and increased production costs represents a significant barrier to commercial implementation of many promising solutions.

Current TCO-Electrolyte Compatibility Solutions

01 Compatibility of TCOs with substrate materials

Transparent conductive oxides (TCOs) must be compatible with various substrate materials to ensure proper adhesion and functionality. Different substrate materials, such as glass, polymers, or flexible substrates, require specific TCO formulations and deposition methods to maintain transparency and conductivity while ensuring good adhesion. The compatibility between TCOs and substrates affects the overall performance and durability of electronic devices, particularly in applications like displays and solar cells.- Compatibility of TCOs with substrate materials: Transparent conductive oxides (TCOs) must be compatible with various substrate materials to ensure proper adhesion and functionality. Different substrate materials, such as glass, polymers, or flexible substrates, require specific TCO formulations and deposition methods to achieve optimal compatibility. The interface between TCOs and substrates plays a crucial role in determining the overall performance and durability of electronic devices, particularly in applications like solar cells and displays.

- TCO compatibility with semiconductor layers: The compatibility between transparent conductive oxides and semiconductor layers is essential for efficient charge transport in optoelectronic devices. This compatibility involves considerations of band alignment, interface states, and chemical interactions between the TCO and semiconductor materials. Proper matching of TCOs with semiconductor layers can significantly improve device performance by reducing interface resistance and enhancing charge collection efficiency in applications such as thin-film transistors and photovoltaic cells.

- Chemical stability and environmental compatibility of TCOs: The chemical stability of transparent conductive oxides in various environments is critical for long-term device reliability. TCOs must maintain their electrical and optical properties when exposed to moisture, heat, chemicals, and other environmental factors. Different TCO materials exhibit varying degrees of stability, with some requiring protective layers or specific processing conditions to ensure compatibility with their operating environment. Enhancing the chemical stability of TCOs is particularly important for applications in harsh environments or devices with long expected lifetimes.

- Process compatibility of TCOs in multilayer device fabrication: The process compatibility of transparent conductive oxides during multilayer device fabrication is crucial for maintaining the integrity and functionality of all device components. TCOs must withstand subsequent processing steps such as etching, annealing, and deposition of additional layers without degradation. The selection of deposition methods, process temperatures, and etching chemistries must be carefully considered to ensure compatibility with other materials in the device stack. Optimizing process compatibility can lead to higher manufacturing yields and better device performance.

- Compatibility of TCOs with electrode materials and contact interfaces: The compatibility between transparent conductive oxides and electrode materials is essential for creating low-resistance electrical contacts in electronic devices. This compatibility involves considerations of work function matching, interface reactions, and adhesion between the TCO and metal electrodes. Proper selection and treatment of contact interfaces can significantly reduce contact resistance and improve overall device performance. Various techniques, such as interface modification layers or specific annealing processes, can be employed to enhance the compatibility between TCOs and electrode materials.

02 TCO compatibility with semiconductor layers

The interface between transparent conductive oxides and semiconductor layers is critical for device performance. Chemical and physical compatibility between TCOs and semiconductors affects charge transfer efficiency, interface states, and overall device functionality. Proper selection of TCO materials that are compatible with specific semiconductor layers can minimize interface defects and improve electrical characteristics in applications such as thin-film transistors, solar cells, and light-emitting diodes.Expand Specific Solutions03 Environmental stability and compatibility of TCOs

Transparent conductive oxides must maintain their properties under various environmental conditions. Factors such as humidity, temperature, and exposure to chemicals can affect the stability and performance of TCOs. Enhancing the environmental compatibility of TCOs through protective coatings, doping, or compositional modifications improves their longevity and reliability in electronic devices, particularly those exposed to harsh conditions or outdoor environments.Expand Specific Solutions04 Process compatibility of TCOs in multilayer structures

The integration of transparent conductive oxides in multilayer device structures requires process compatibility with subsequent manufacturing steps. TCOs must withstand various processing conditions such as high temperatures, plasma treatments, and chemical exposures without degradation. Developing TCO materials and deposition methods that are compatible with established manufacturing processes is essential for successful integration in complex electronic devices like displays, touch panels, and photovoltaic cells.Expand Specific Solutions05 Compatibility of TCOs with electrode materials

The interface between transparent conductive oxides and metal electrodes significantly impacts device performance. Achieving good electrical contact between TCOs and various electrode materials while minimizing contact resistance is crucial. Proper selection of compatible TCO and electrode materials, along with appropriate interface engineering techniques, can enhance charge transfer efficiency and overall device functionality in applications such as touch screens, organic light-emitting diodes, and thin-film solar cells.Expand Specific Solutions

Leading Institutions and Companies in TCO Research

The transparent conductive oxides (TCO) and electrolyte compatibility market is currently in a growth phase, with increasing applications in displays, photovoltaics, and energy storage. The global market is expanding at approximately 6-8% annually, driven by demand for advanced electronic devices and renewable energy solutions. Technologically, the field shows moderate maturity with established players like Samsung Electronics and AGC Inc. leading commercial applications, while research institutions such as ICFO and Gwangju Institute of Science & Technology drive innovation. Companies including Konica Minolta, TDK Corp., and Merck Patent GmbH are developing specialized formulations to address interface stability challenges. The competitive landscape features both large materials manufacturers (BASF, Sumitomo Chemical) and specialized electronics firms collaborating with research organizations to overcome persistent technical barriers in electrolyte-TCO interactions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced transparent conductive oxide (TCO) materials, particularly focusing on indium tin oxide (ITO) alternatives for flexible displays and energy storage applications. Their proprietary amorphous indium zinc oxide (a-IZO) technology offers superior conductivity while maintaining over 90% transparency in the visible spectrum. For electrolyte compatibility, Samsung has engineered specialized interface layers that prevent degradation between TCOs and various electrolytes in battery and display applications. Their research includes aluminum-doped zinc oxide (AZO) films deposited via atomic layer deposition, which demonstrate excellent stability when in contact with both aqueous and organic electrolytes. Samsung has also pioneered the development of self-healing TCO-electrolyte interfaces that can recover from electrochemical stress during device operation, significantly extending component lifespan in energy storage applications.

Strengths: Superior optical transparency while maintaining high conductivity; excellent flexibility for next-generation displays; advanced interface engineering for improved electrolyte compatibility. Weaknesses: Higher production costs compared to traditional ITO; some formulations still rely on scarce indium resources; limited thermal stability in certain high-temperature applications.

AGC, Inc. (Japan)

Technical Solution: AGC has pioneered innovative transparent conductive oxide (TCO) technologies specifically designed for optimal electrolyte compatibility in various applications. Their flagship product, EXCLEAR®, utilizes a proprietary fluorine-doped tin oxide (FTO) formulation that demonstrates exceptional chemical stability when in contact with both acidic and alkaline electrolytes. AGC's research has focused on developing TCO materials with controlled surface morphology and crystallinity to enhance electrolyte wetting and interface stability. Their patented deposition techniques create TCO films with precisely engineered porosity that facilitates ion transport while maintaining structural integrity. For energy storage applications, AGC has developed composite TCO structures incorporating protective interlayers that prevent degradation from electrolyte exposure during charge-discharge cycles. Their recent advancements include self-passivating TCO materials that form stable solid-electrolyte interphases, significantly improving long-term performance in electrochemical devices.

Strengths: Exceptional chemical stability in diverse electrolyte environments; industry-leading transparency-to-conductivity ratio; scalable manufacturing processes suitable for large-area applications. Weaknesses: Higher initial production costs compared to conventional TCOs; limited flexibility for certain curved or bendable applications; requires specialized deposition equipment for optimal performance.

Key Patents and Publications on TCO-Electrolyte Interfaces

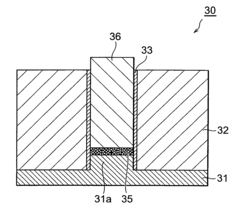

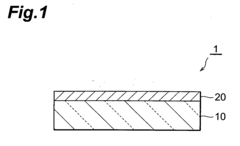

Transparent Conductive Material, Transparent Conductive Paste, Transparent Conductive Film and Transparent Electrode

PatentInactiveUS20080014452A1

Innovation

- Developing transparent conductive materials with specific pH levels and halogen element concentrations, such as indium oxide or tin oxide doped with certain elements, to minimize the generation of insulating compounds like In(OH)3 and maintain stable conductivity.

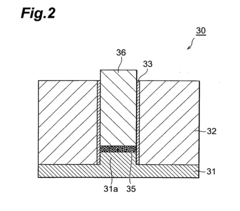

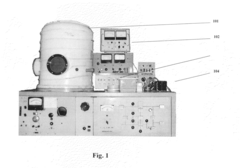

Transparent coductive oxide and method of production thereof

PatentInactiveUS20100021720A1

Innovation

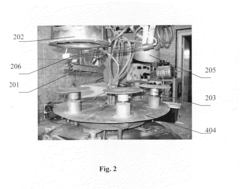

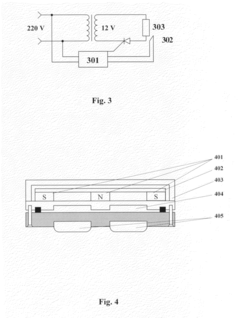

- A novel vacuum evaporation and deposition process is developed, involving a magnetron sputtering system with controlled gas supply and ion stimulation, using a mixture of argon and oxygen, and pre-treating the polymer substrate to enhance adhesion and conductivity, allowing for high transparency and low resistance without expensive additives.

Environmental Impact and Sustainability Considerations

The environmental impact of transparent conductive oxides (TCOs) and their compatibility with electrolytes represents a critical dimension in sustainable technology development. Traditional TCO materials such as indium tin oxide (ITO) contain rare earth elements that pose significant sustainability challenges due to limited global reserves and environmentally intensive mining processes. The extraction of indium, in particular, generates substantial carbon emissions and requires extensive land use, contributing to habitat destruction and biodiversity loss in mining regions.

Manufacturing processes for TCOs typically involve high-temperature deposition techniques that consume considerable energy, resulting in a substantial carbon footprint. Vacuum sputtering and chemical vapor deposition methods commonly employed in TCO production require specialized equipment operating under energy-intensive conditions, further exacerbating environmental concerns.

When considering electrolyte compatibility, the interaction between TCOs and electrolytes can lead to leaching of metal ions, particularly in applications exposed to environmental conditions or in contact with biological systems. This leaching presents potential ecotoxicological risks that must be carefully evaluated and mitigated through appropriate material selection and design strategies.

Recent advances in alternative TCO materials show promising environmental profiles. Zinc oxide-based compounds and carbon-based alternatives such as graphene and carbon nanotubes offer reduced environmental impact through more abundant material sources and potentially lower-energy manufacturing processes. Additionally, solution-processed TCOs are emerging as environmentally preferable options due to their reduced energy requirements and minimal waste generation compared to vacuum-based deposition methods.

End-of-life considerations for TCO-containing devices present another environmental challenge. The complex integration of these materials into electronic devices often complicates recycling efforts, resulting in valuable materials being discarded in landfills. Developing effective recycling technologies specifically targeting TCO recovery represents an important research direction for improving the circular economy profile of these materials.

Life cycle assessment (LCA) studies comparing various TCO materials and their electrolyte interactions reveal significant variations in environmental impact. These assessments consider factors including resource depletion, energy consumption, greenhouse gas emissions, and potential for toxicity throughout the material lifecycle. Such comprehensive evaluations are essential for guiding sustainable material selection and process optimization in transparent conductive applications.

Manufacturing processes for TCOs typically involve high-temperature deposition techniques that consume considerable energy, resulting in a substantial carbon footprint. Vacuum sputtering and chemical vapor deposition methods commonly employed in TCO production require specialized equipment operating under energy-intensive conditions, further exacerbating environmental concerns.

When considering electrolyte compatibility, the interaction between TCOs and electrolytes can lead to leaching of metal ions, particularly in applications exposed to environmental conditions or in contact with biological systems. This leaching presents potential ecotoxicological risks that must be carefully evaluated and mitigated through appropriate material selection and design strategies.

Recent advances in alternative TCO materials show promising environmental profiles. Zinc oxide-based compounds and carbon-based alternatives such as graphene and carbon nanotubes offer reduced environmental impact through more abundant material sources and potentially lower-energy manufacturing processes. Additionally, solution-processed TCOs are emerging as environmentally preferable options due to their reduced energy requirements and minimal waste generation compared to vacuum-based deposition methods.

End-of-life considerations for TCO-containing devices present another environmental challenge. The complex integration of these materials into electronic devices often complicates recycling efforts, resulting in valuable materials being discarded in landfills. Developing effective recycling technologies specifically targeting TCO recovery represents an important research direction for improving the circular economy profile of these materials.

Life cycle assessment (LCA) studies comparing various TCO materials and their electrolyte interactions reveal significant variations in environmental impact. These assessments consider factors including resource depletion, energy consumption, greenhouse gas emissions, and potential for toxicity throughout the material lifecycle. Such comprehensive evaluations are essential for guiding sustainable material selection and process optimization in transparent conductive applications.

Manufacturing Scalability and Cost Analysis

The scalability of transparent conductive oxide (TCO) manufacturing processes represents a critical factor in determining their commercial viability for large-scale applications. Current industrial production of TCOs like ITO (Indium Tin Oxide) primarily relies on physical vapor deposition methods, particularly magnetron sputtering, which offers reasonable throughput but faces challenges in uniform coating over large areas. The capital expenditure for establishing high-volume TCO production lines typically ranges from $5-15 million, depending on capacity and precision requirements.

Cost analysis reveals that material expenses constitute 40-60% of total production costs for TCO films, with indium being a particularly significant cost driver due to its limited global supply and price volatility. Recent market data indicates indium prices fluctuating between $200-350/kg, creating substantial cost uncertainty for manufacturers. Alternative TCOs such as FTO (Fluorine-doped Tin Oxide) and AZO (Aluminum-doped Zinc Oxide) offer more stable material costs but often require process modifications that impact overall economics.

Energy consumption represents another substantial cost component, with vacuum-based deposition techniques requiring significant power input. Solution-based manufacturing approaches like sol-gel and spray pyrolysis demonstrate promising cost reductions of 30-45% compared to vacuum techniques, though they currently face challenges in achieving consistent electrical properties at scale.

Compatibility with existing manufacturing infrastructure presents varying challenges across different TCO materials. While ITO processing is well-established in display and photovoltaic production lines, newer TCO formulations optimized for electrolyte compatibility often require specialized equipment or process modifications. The estimated retooling costs for adapting existing production lines to accommodate these specialized TCOs range from $1-3 million per production line.

Yield rates significantly impact overall economics, with current industrial processes achieving 85-92% yields for standard TCO applications. However, when optimizing for electrolyte compatibility, these yields often decrease to 70-80% during initial production scaling, gradually improving with process refinement. This yield reduction temporarily increases per-unit costs by approximately 15-25% during early manufacturing scale-up phases.

Labor costs vary significantly by region, representing 5-15% of total production expenses. Automation trends are progressively reducing this proportion, with advanced manufacturing facilities implementing Industry 4.0 principles to optimize workforce utilization while maintaining quality control. The transition toward more automated TCO production processes typically delivers ROI within 2-3 years through improved consistency and reduced labor requirements.

Cost analysis reveals that material expenses constitute 40-60% of total production costs for TCO films, with indium being a particularly significant cost driver due to its limited global supply and price volatility. Recent market data indicates indium prices fluctuating between $200-350/kg, creating substantial cost uncertainty for manufacturers. Alternative TCOs such as FTO (Fluorine-doped Tin Oxide) and AZO (Aluminum-doped Zinc Oxide) offer more stable material costs but often require process modifications that impact overall economics.

Energy consumption represents another substantial cost component, with vacuum-based deposition techniques requiring significant power input. Solution-based manufacturing approaches like sol-gel and spray pyrolysis demonstrate promising cost reductions of 30-45% compared to vacuum techniques, though they currently face challenges in achieving consistent electrical properties at scale.

Compatibility with existing manufacturing infrastructure presents varying challenges across different TCO materials. While ITO processing is well-established in display and photovoltaic production lines, newer TCO formulations optimized for electrolyte compatibility often require specialized equipment or process modifications. The estimated retooling costs for adapting existing production lines to accommodate these specialized TCOs range from $1-3 million per production line.

Yield rates significantly impact overall economics, with current industrial processes achieving 85-92% yields for standard TCO applications. However, when optimizing for electrolyte compatibility, these yields often decrease to 70-80% during initial production scaling, gradually improving with process refinement. This yield reduction temporarily increases per-unit costs by approximately 15-25% during early manufacturing scale-up phases.

Labor costs vary significantly by region, representing 5-15% of total production expenses. Automation trends are progressively reducing this proportion, with advanced manufacturing facilities implementing Industry 4.0 principles to optimize workforce utilization while maintaining quality control. The transition toward more automated TCO production processes typically delivers ROI within 2-3 years through improved consistency and reduced labor requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!