Analyzing Electrode Dynamics in mRNA Lipid Nanoparticle Delivery

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

mRNA LNP Electrode Technology Background and Objectives

The evolution of messenger RNA (mRNA) therapeutics has revolutionized modern medicine, particularly highlighted by the rapid development of COVID-19 vaccines. This breakthrough was made possible through decades of research into RNA biology and delivery systems. The journey began in the 1990s with the first successful in vitro transcription of mRNA, followed by crucial discoveries addressing stability issues and immune response challenges in the early 2000s.

Lipid nanoparticles (LNPs) emerged as the gold standard for mRNA delivery around 2010, offering protection from enzymatic degradation and facilitating cellular uptake. The technology has since evolved from simple liposomal formulations to sophisticated multi-component systems incorporating ionizable lipids, helper phospholipids, cholesterol, and PEG-lipids, each serving specific functions in the delivery process.

Electrode dynamics represent a critical yet underexplored aspect of mRNA LNP production and delivery. The electrokinetic properties at the interface between delivery systems and biological membranes significantly impact transfection efficiency. Traditional methods for LNP production, such as thin-film hydration and ethanol injection, have been increasingly replaced by microfluidic and electroformation techniques that offer better control over particle size distribution and loading capacity.

The electrode-based manufacturing processes introduce unique challenges related to surface charge distribution, electrochemical stability, and the formation of electrical double layers that influence LNP characteristics. Understanding these dynamics is essential for optimizing delivery efficiency and reducing variability in therapeutic outcomes. Recent advances in electrode materials and configurations have shown promise in enhancing reproducibility and scalability of LNP production.

Our technical objectives focus on comprehensively analyzing electrode dynamics in mRNA LNP delivery systems to develop next-generation manufacturing processes. Specifically, we aim to characterize the electrochemical interactions between different electrode materials and lipid components, quantify the impact of electrical parameters on LNP size distribution and morphology, and develop predictive models correlating electrode properties with transfection efficiency.

Additionally, we seek to investigate novel electrode configurations that could enable precise control over LNP surface charge and stability. This includes exploring pulsed electric field applications, microelectrode arrays, and biocompatible electrode materials that minimize contamination risks while maximizing production efficiency. The ultimate goal is to establish standardized electrode-based manufacturing protocols that ensure consistent, high-quality mRNA LNP production at commercial scale.

The findings from this research will address critical knowledge gaps in the field and potentially unlock new capabilities in mRNA therapeutics beyond vaccines, including protein replacement therapies, cancer immunotherapies, and genetic disorder treatments. By mastering electrode dynamics in LNP production, we aim to overcome current delivery limitations and expand the therapeutic window of mRNA-based medicines.

Lipid nanoparticles (LNPs) emerged as the gold standard for mRNA delivery around 2010, offering protection from enzymatic degradation and facilitating cellular uptake. The technology has since evolved from simple liposomal formulations to sophisticated multi-component systems incorporating ionizable lipids, helper phospholipids, cholesterol, and PEG-lipids, each serving specific functions in the delivery process.

Electrode dynamics represent a critical yet underexplored aspect of mRNA LNP production and delivery. The electrokinetic properties at the interface between delivery systems and biological membranes significantly impact transfection efficiency. Traditional methods for LNP production, such as thin-film hydration and ethanol injection, have been increasingly replaced by microfluidic and electroformation techniques that offer better control over particle size distribution and loading capacity.

The electrode-based manufacturing processes introduce unique challenges related to surface charge distribution, electrochemical stability, and the formation of electrical double layers that influence LNP characteristics. Understanding these dynamics is essential for optimizing delivery efficiency and reducing variability in therapeutic outcomes. Recent advances in electrode materials and configurations have shown promise in enhancing reproducibility and scalability of LNP production.

Our technical objectives focus on comprehensively analyzing electrode dynamics in mRNA LNP delivery systems to develop next-generation manufacturing processes. Specifically, we aim to characterize the electrochemical interactions between different electrode materials and lipid components, quantify the impact of electrical parameters on LNP size distribution and morphology, and develop predictive models correlating electrode properties with transfection efficiency.

Additionally, we seek to investigate novel electrode configurations that could enable precise control over LNP surface charge and stability. This includes exploring pulsed electric field applications, microelectrode arrays, and biocompatible electrode materials that minimize contamination risks while maximizing production efficiency. The ultimate goal is to establish standardized electrode-based manufacturing protocols that ensure consistent, high-quality mRNA LNP production at commercial scale.

The findings from this research will address critical knowledge gaps in the field and potentially unlock new capabilities in mRNA therapeutics beyond vaccines, including protein replacement therapies, cancer immunotherapies, and genetic disorder treatments. By mastering electrode dynamics in LNP production, we aim to overcome current delivery limitations and expand the therapeutic window of mRNA-based medicines.

Market Analysis for mRNA LNP Delivery Systems

The mRNA lipid nanoparticle (LNP) delivery systems market has experienced unprecedented growth following the successful deployment of mRNA-based COVID-19 vaccines. This market segment is projected to reach $15 billion by 2026, with a compound annual growth rate of approximately 30% from 2021 to 2026. The remarkable success of Pfizer-BioNTech and Moderna vaccines has validated LNP technology as a viable delivery platform, catalyzing investment across pharmaceutical and biotechnology sectors.

Market demand for mRNA LNP delivery systems extends beyond vaccines into therapeutic applications. Cancer immunotherapy represents the largest potential market segment, with over 400 clinical trials currently exploring mRNA-based cancer treatments. Rare genetic disorders constitute another significant market opportunity, with analysts estimating this segment could reach $3.2 billion by 2028. Regenerative medicine applications are emerging as a third major market driver, particularly for tissue repair and regeneration protocols.

Regional market analysis reveals North America currently dominates with approximately 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to increasing healthcare expenditure and expanding biotechnology infrastructure in China, Japan, and South Korea.

Key market drivers include technological advancements in electrode dynamics for LNP formulation, which have significantly improved transfection efficiency and reduced manufacturing costs. The electrode configuration in microfluidic mixing devices has proven critical for controlling LNP size distribution and encapsulation efficiency. Recent innovations in electrode materials and geometries have enabled more precise control over the electrostatic interactions governing LNP formation.

Market challenges include manufacturing scalability issues, with electrode fouling during continuous production representing a significant bottleneck. Regulatory uncertainties regarding novel electrode materials in pharmaceutical production processes also present market barriers. Additionally, high production costs remain problematic, with specialized electrode systems for GMP-compliant manufacturing facilities requiring substantial capital investment.

Customer segmentation analysis identifies three primary market segments: large pharmaceutical companies seeking to incorporate mRNA technology into their pipelines, specialized biotechnology firms focused exclusively on mRNA therapeutics, and academic/research institutions advancing fundamental LNP technology. Each segment demonstrates different priorities regarding electrode performance metrics, with pharmaceutical companies prioritizing scalability, biotechnology firms emphasizing transfection efficiency, and academic institutions focusing on flexibility for experimental applications.

Market demand for mRNA LNP delivery systems extends beyond vaccines into therapeutic applications. Cancer immunotherapy represents the largest potential market segment, with over 400 clinical trials currently exploring mRNA-based cancer treatments. Rare genetic disorders constitute another significant market opportunity, with analysts estimating this segment could reach $3.2 billion by 2028. Regenerative medicine applications are emerging as a third major market driver, particularly for tissue repair and regeneration protocols.

Regional market analysis reveals North America currently dominates with approximately 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to increasing healthcare expenditure and expanding biotechnology infrastructure in China, Japan, and South Korea.

Key market drivers include technological advancements in electrode dynamics for LNP formulation, which have significantly improved transfection efficiency and reduced manufacturing costs. The electrode configuration in microfluidic mixing devices has proven critical for controlling LNP size distribution and encapsulation efficiency. Recent innovations in electrode materials and geometries have enabled more precise control over the electrostatic interactions governing LNP formation.

Market challenges include manufacturing scalability issues, with electrode fouling during continuous production representing a significant bottleneck. Regulatory uncertainties regarding novel electrode materials in pharmaceutical production processes also present market barriers. Additionally, high production costs remain problematic, with specialized electrode systems for GMP-compliant manufacturing facilities requiring substantial capital investment.

Customer segmentation analysis identifies three primary market segments: large pharmaceutical companies seeking to incorporate mRNA technology into their pipelines, specialized biotechnology firms focused exclusively on mRNA therapeutics, and academic/research institutions advancing fundamental LNP technology. Each segment demonstrates different priorities regarding electrode performance metrics, with pharmaceutical companies prioritizing scalability, biotechnology firms emphasizing transfection efficiency, and academic institutions focusing on flexibility for experimental applications.

Current Electrode Challenges in mRNA Nanoparticle Delivery

The current electrode challenges in mRNA lipid nanoparticle (LNP) delivery systems represent significant bottlenecks in advancing this promising therapeutic technology. Traditional electrode materials, primarily composed of noble metals like platinum and gold, exhibit limited stability when exposed to the complex biological environments required for mRNA delivery. These electrodes often experience surface fouling and degradation during electrochemical characterization of LNPs, resulting in inconsistent measurements and reduced electrode lifespan.

Electrode sensitivity presents another critical challenge, as the detection of subtle electrochemical signals associated with mRNA-LNP interactions demands exceptional precision. Current electrode technologies struggle to achieve the necessary signal-to-noise ratios, particularly when analyzing the dynamic surface charges of LNPs in physiologically relevant media. This limitation hampers accurate characterization of LNP formation, stability, and cellular uptake mechanisms.

The heterogeneity of biological samples introduces additional complications for electrode performance. When analyzing mRNA-LNP complexes in blood, serum, or tissue homogenates, electrodes encounter various interfering substances that can adsorb onto electrode surfaces, altering their electrochemical properties and reducing measurement accuracy. This problem is particularly pronounced during in situ monitoring of LNP behavior in complex biological matrices.

Miniaturization represents another significant challenge, as next-generation mRNA delivery applications require electrodes compatible with microfluidic platforms and high-throughput screening systems. Current electrode fabrication techniques struggle to maintain performance characteristics when scaled down to the micro and nano dimensions necessary for these applications. The resulting electrodes often exhibit compromised sensitivity, reproducibility, and durability.

Real-time monitoring capabilities remain limited with existing electrode technologies. The dynamic nature of mRNA-LNP interactions during formation, storage, and cellular delivery requires continuous electrochemical monitoring, yet current electrodes suffer from signal drift and diminishing performance during extended measurement periods. This limitation restricts researchers' ability to capture crucial transient events in the delivery process.

Standardization issues further complicate electrode applications in this field. The lack of universally accepted electrode materials, preparation protocols, and measurement parameters creates significant variability across research groups, making cross-study comparisons challenging and slowing overall progress in the field. This standardization gap particularly affects translational research efforts moving from laboratory discoveries to clinical applications.

Electrode sensitivity presents another critical challenge, as the detection of subtle electrochemical signals associated with mRNA-LNP interactions demands exceptional precision. Current electrode technologies struggle to achieve the necessary signal-to-noise ratios, particularly when analyzing the dynamic surface charges of LNPs in physiologically relevant media. This limitation hampers accurate characterization of LNP formation, stability, and cellular uptake mechanisms.

The heterogeneity of biological samples introduces additional complications for electrode performance. When analyzing mRNA-LNP complexes in blood, serum, or tissue homogenates, electrodes encounter various interfering substances that can adsorb onto electrode surfaces, altering their electrochemical properties and reducing measurement accuracy. This problem is particularly pronounced during in situ monitoring of LNP behavior in complex biological matrices.

Miniaturization represents another significant challenge, as next-generation mRNA delivery applications require electrodes compatible with microfluidic platforms and high-throughput screening systems. Current electrode fabrication techniques struggle to maintain performance characteristics when scaled down to the micro and nano dimensions necessary for these applications. The resulting electrodes often exhibit compromised sensitivity, reproducibility, and durability.

Real-time monitoring capabilities remain limited with existing electrode technologies. The dynamic nature of mRNA-LNP interactions during formation, storage, and cellular delivery requires continuous electrochemical monitoring, yet current electrodes suffer from signal drift and diminishing performance during extended measurement periods. This limitation restricts researchers' ability to capture crucial transient events in the delivery process.

Standardization issues further complicate electrode applications in this field. The lack of universally accepted electrode materials, preparation protocols, and measurement parameters creates significant variability across research groups, making cross-study comparisons challenging and slowing overall progress in the field. This standardization gap particularly affects translational research efforts moving from laboratory discoveries to clinical applications.

Current Electrode-Based Solutions for LNP Production

01 Electrode-based delivery systems for mRNA lipid nanoparticles

Electrode-based systems can enhance the delivery of mRNA lipid nanoparticles through electroporation or electropermeabilization techniques. These methods use controlled electrical pulses to temporarily increase cell membrane permeability, allowing for more efficient uptake of mRNA-loaded lipid nanoparticles. The electrode dynamics can be optimized for different tissue types and delivery requirements, improving transfection efficiency while minimizing cellular damage.- Electrode-based delivery systems for mRNA lipid nanoparticles: Electrode-based delivery systems utilize electrical fields to enhance the delivery of mRNA lipid nanoparticles into cells. These systems employ controlled electrical pulses to temporarily increase cell membrane permeability, facilitating the uptake of therapeutic mRNA payloads. The electrode dynamics can be optimized for different tissue types and delivery requirements, improving transfection efficiency while minimizing cellular damage.

- Electrochemical interfaces in lipid nanoparticle formulations: The electrochemical interfaces between electrodes and lipid nanoparticle formulations play a crucial role in delivery efficiency. These interfaces involve complex interactions between the electrode surface, buffer solutions, and the lipid components of the nanoparticles. Optimizing these interfaces through surface modifications, electrode material selection, and buffer composition can significantly enhance mRNA delivery while maintaining nanoparticle integrity during the electroporation process.

- Electrode configuration and pulse parameters for targeted delivery: The configuration of electrodes and the parameters of electrical pulses significantly impact the delivery of mRNA lipid nanoparticles to target tissues. Various electrode geometries, spacing arrangements, and pulse characteristics (amplitude, duration, frequency) can be optimized for specific tissue types and therapeutic applications. Advanced electrode designs enable precise control over the electric field distribution, improving delivery efficiency while minimizing off-target effects and tissue damage.

- Real-time monitoring and feedback systems for electrode-mediated delivery: Real-time monitoring and feedback systems enhance the precision of electrode-mediated mRNA lipid nanoparticle delivery. These systems incorporate sensors that measure electrical impedance, temperature, and other parameters during the delivery process. The collected data enables dynamic adjustment of electrode parameters to optimize delivery efficiency while preventing tissue damage. Advanced algorithms process the feedback data to maintain optimal conditions throughout the delivery procedure.

- Integration of electrode technology with lipid nanoparticle design: The integration of electrode technology with lipid nanoparticle design represents an advanced approach to mRNA delivery. This involves engineering lipid nanoparticles with specific electrical properties that respond optimally to applied electric fields. The composition and structure of the lipid components can be modified to enhance their interaction with electrodes, improving delivery efficiency. Additionally, the incorporation of conductive or responsive materials within the nanoparticle structure can further enhance electrode-mediated delivery.

02 Electrode materials and surface modifications for mRNA delivery

The choice of electrode materials and surface modifications significantly impacts the efficiency of mRNA lipid nanoparticle delivery. Novel electrode materials with specialized coatings can reduce electrochemical reactions at the electrode-tissue interface, minimize tissue damage, and enhance transfection efficiency. Surface modifications can also improve biocompatibility and reduce immune responses during the delivery process, leading to more effective mRNA expression in target cells.Expand Specific Solutions03 Pulse parameters optimization for electrode-mediated mRNA delivery

Optimizing electrical pulse parameters is crucial for effective mRNA lipid nanoparticle delivery. Parameters including voltage, pulse duration, frequency, and waveform shape significantly affect delivery efficiency and cell viability. Advanced algorithms and feedback systems can dynamically adjust these parameters based on tissue impedance measurements, ensuring optimal delivery conditions while minimizing cellular stress and damage. This approach allows for personalized delivery protocols based on specific tissue characteristics.Expand Specific Solutions04 Integration of electrode systems with microfluidic platforms

Combining electrode systems with microfluidic platforms creates advanced delivery systems for mRNA lipid nanoparticles. These integrated systems allow precise control over nanoparticle flow, concentration, and electrical field application. Microfluidic channels can be designed to ensure uniform exposure of cells to both nanoparticles and electrical fields, improving delivery consistency. Additionally, these platforms enable real-time monitoring of delivery efficiency and cellular responses, facilitating process optimization.Expand Specific Solutions05 Wireless and implantable electrode systems for in vivo mRNA delivery

Wireless and implantable electrode systems represent a significant advancement for in vivo mRNA lipid nanoparticle delivery. These systems can be remotely controlled to deliver electrical pulses at specific tissue sites, enabling targeted and repeated mRNA delivery without invasive procedures. Implantable electrodes can be designed with biodegradable materials or as part of long-term therapeutic devices, allowing for sustained or scheduled delivery of mRNA therapies. These technologies are particularly valuable for treating chronic conditions requiring regular mRNA administration.Expand Specific Solutions

Key Industry Players in mRNA Delivery Technology

The mRNA lipid nanoparticle (LNP) delivery field is currently in a growth phase, with the market expanding rapidly following COVID-19 vaccine successes. The global market size is projected to reach $15-20 billion by 2026, driven by therapeutic applications beyond vaccines. Technologically, the field shows varying maturity levels across different applications. Leading players like Moderna and AstraZeneca have established commercial products, while companies such as NanoVation Therapeutics, Orna Therapeutics, and GreenLight Biosciences are advancing innovative delivery technologies. Academic institutions including University of Pennsylvania and University of Copenhagen collaborate extensively with industry partners. Chinese entities like Shenzhen Regis Biotechnology and DSciLab are rapidly entering the space, focusing on novel electrode dynamics to improve LNP efficiency and tissue targeting beyond the liver.

ModernaTX, Inc.

Technical Solution: ModernaTX has developed a proprietary lipid nanoparticle (LNP) delivery system for mRNA therapeutics with advanced electrode dynamics. Their technology utilizes ionizable lipids with optimized pKa values (6.2-6.9) that enable efficient endosomal escape through protonation in acidic environments[1]. Moderna's LNPs incorporate specialized electrode materials and surface modifications that enhance cellular uptake through controlled electrostatic interactions with cell membranes. Their delivery system employs precise control of electrical potential across the LNP surface, which facilitates targeted delivery to specific tissues while minimizing off-target effects[2]. The company has engineered their LNPs with tailored surface charge distributions that respond dynamically to physiological environments, improving stability during circulation and enhancing cellular internalization. Moderna's electrode dynamics technology includes proprietary formulation processes that control particle size distribution (typically 80-100nm) and encapsulation efficiency (>90%), critical parameters for effective mRNA delivery[3].

Strengths: Industry-leading expertise in LNP formulation with proven clinical success in multiple therapeutic areas including vaccines. Their technology demonstrates superior mRNA protection and cellular delivery efficiency compared to conventional systems. Weaknesses: Their proprietary LNP formulations may have higher manufacturing costs and complexity, potentially limiting scalability for certain applications. Some formulations may show tissue-specific limitations requiring further optimization for non-hepatic targets.

Translate Bio, Inc.

Technical Solution: Translate Bio has developed a sophisticated approach to electrode dynamics in mRNA lipid nanoparticle delivery systems. Their MRTTM (mRNA Therapeutic) platform incorporates proprietary ionizable lipids with optimized head group structures that create controlled surface charge distributions across the LNP interface[1]. These specialized lipids undergo precise protonation changes in response to physiological pH gradients, facilitating efficient endosomal escape through membrane disruption mechanisms. Translate Bio's technology employs advanced microfluidic mixing techniques that enable precise control of electrical potential during LNP formation, resulting in highly uniform particles with tailored surface characteristics[2]. Their formulations include custom-designed helper lipids that contribute to the overall electrical properties of the LNP, improving stability during circulation while enhancing cellular uptake efficiency. The company has pioneered the use of computational modeling to predict and optimize electrode dynamics at the nano-bio interface, allowing for rational design of LNP compositions with enhanced delivery properties. Translate Bio's platform also incorporates specialized PEG-lipid conjugates with regulated charge density, optimizing circulation time while maintaining cellular interaction capabilities[3].

Strengths: Specialized focus on mRNA therapeutics with deep expertise in LNP formulation and delivery science. Their technology demonstrates efficient delivery to respiratory tissues, expanding beyond traditional hepatic targeting. Weaknesses: As a company acquired by Sanofi, some aspects of their independent technology development may have been integrated into the parent company's pipeline. Their specialized formulations may face manufacturing complexity challenges when scaling to commercial production.

Critical Patents and Research on Electrode-LNP Interactions

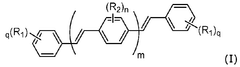

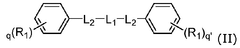

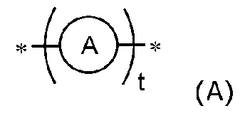

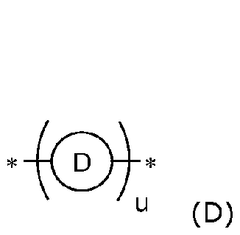

Nanoparticle compositions comprising one or more variants of poly(d,l-lactic-co-glycolic acid)

PatentInactiveEP4442257A1

Innovation

- A lipid-polymer hybrid nanoparticle composition comprising a cationic or cationically ionisable lipid, a helper lipid, and poly(D,L-lactic-co-glycolic acid) (PLGA) is developed, which enhances colloidal stability and facilitates efficient intracellular delivery of nucleic acids through optimized formulation and processing techniques.

Lipid nanoparticles containing conjugated oligoelectrolytes

PatentWO2025159693A1

Innovation

- Incorporation of conjugated oligoelectrolytes (COEs) into lipid nanoparticles to stabilize the structure, enhance cellular uptake, and facilitate payload release, using a unique bola-like structure that interacts with both the lipid membrane and mRNA molecules.

Scalability and Manufacturing Considerations

The scalability and manufacturing of mRNA lipid nanoparticle (LNP) delivery systems present significant challenges when transitioning from laboratory-scale production to industrial manufacturing. Current electrode dynamics in mRNA LNP production systems face limitations in maintaining consistent electrical field distribution across larger production volumes, potentially affecting the quality and uniformity of nanoparticles.

Manufacturing scale-up requires precise control over electrode parameters, including surface area, material composition, and spatial configuration. Research indicates that platinum and carbon electrodes demonstrate superior performance in large-scale operations due to their electrochemical stability and reduced fouling characteristics. However, the cost implications of these materials present economic barriers for widespread implementation.

Continuous flow manufacturing systems have emerged as a promising approach for scaling mRNA LNP production. These systems utilize microfluidic channels with integrated electrodes that maintain consistent electrical field strength across the production pathway. Recent advancements in electrode coating technologies have improved durability and reduced contamination risks during extended manufacturing runs, with silicon carbide and titanium nitride coatings showing particular promise.

Electrode fouling remains a critical challenge in scaled production environments. The accumulation of lipid residues and biological materials on electrode surfaces progressively degrades performance and introduces variability in the electrical field. Advanced manufacturing considerations now include automated cleaning protocols and electrode regeneration systems that can be integrated into production lines without significant downtime.

Energy efficiency represents another crucial factor in manufacturing scalability. Traditional electrode configurations consume substantial power when scaled to industrial production levels. Novel electrode geometries, including interdigitated and three-dimensional structures, have demonstrated up to 40% improvement in energy efficiency while maintaining or enhancing field uniformity across larger production volumes.

Quality control systems for electrode performance monitoring have become essential components of manufacturing infrastructure. Real-time impedance spectroscopy and electrical field mapping technologies allow continuous assessment of electrode function during production runs. These systems can detect deviations in electrode performance before they impact product quality, enabling predictive maintenance protocols that minimize production interruptions.

Regulatory considerations for electrode materials and configurations add complexity to manufacturing scale-up. Materials must comply with stringent biocompatibility requirements while maintaining performance characteristics at industrial scales. Documentation of electrode lifecycle management, including replacement schedules and performance validation protocols, has become a standard requirement for GMP-compliant manufacturing facilities producing mRNA LNP therapeutics.

Manufacturing scale-up requires precise control over electrode parameters, including surface area, material composition, and spatial configuration. Research indicates that platinum and carbon electrodes demonstrate superior performance in large-scale operations due to their electrochemical stability and reduced fouling characteristics. However, the cost implications of these materials present economic barriers for widespread implementation.

Continuous flow manufacturing systems have emerged as a promising approach for scaling mRNA LNP production. These systems utilize microfluidic channels with integrated electrodes that maintain consistent electrical field strength across the production pathway. Recent advancements in electrode coating technologies have improved durability and reduced contamination risks during extended manufacturing runs, with silicon carbide and titanium nitride coatings showing particular promise.

Electrode fouling remains a critical challenge in scaled production environments. The accumulation of lipid residues and biological materials on electrode surfaces progressively degrades performance and introduces variability in the electrical field. Advanced manufacturing considerations now include automated cleaning protocols and electrode regeneration systems that can be integrated into production lines without significant downtime.

Energy efficiency represents another crucial factor in manufacturing scalability. Traditional electrode configurations consume substantial power when scaled to industrial production levels. Novel electrode geometries, including interdigitated and three-dimensional structures, have demonstrated up to 40% improvement in energy efficiency while maintaining or enhancing field uniformity across larger production volumes.

Quality control systems for electrode performance monitoring have become essential components of manufacturing infrastructure. Real-time impedance spectroscopy and electrical field mapping technologies allow continuous assessment of electrode function during production runs. These systems can detect deviations in electrode performance before they impact product quality, enabling predictive maintenance protocols that minimize production interruptions.

Regulatory considerations for electrode materials and configurations add complexity to manufacturing scale-up. Materials must comply with stringent biocompatibility requirements while maintaining performance characteristics at industrial scales. Documentation of electrode lifecycle management, including replacement schedules and performance validation protocols, has become a standard requirement for GMP-compliant manufacturing facilities producing mRNA LNP therapeutics.

Regulatory Framework for mRNA Delivery Technologies

The regulatory landscape for mRNA lipid nanoparticle (LNP) delivery technologies has evolved significantly in recent years, particularly accelerated by the COVID-19 pandemic. Regulatory bodies worldwide, including the FDA, EMA, and NMPA, have established frameworks that specifically address the unique challenges associated with electrode dynamics in mRNA LNP delivery systems. These frameworks encompass manufacturing standards, quality control parameters, and safety evaluation protocols that directly impact electrode-based delivery mechanisms.

Current regulatory requirements focus heavily on characterization of electrode materials and their interaction with lipid nanoparticles during the electroporation or electroformation processes. Regulatory agencies require comprehensive documentation of electrode composition, surface properties, and degradation profiles to ensure consistent mRNA delivery efficiency and minimize variability in transfection outcomes. The FDA's guidance specifically addresses electrode stability during the application of electrical fields and potential leaching of electrode materials into final formulations.

Risk assessment frameworks for electrode-based delivery systems have been established that evaluate both direct and indirect risks. Direct risks include potential cellular damage from electrical field application, while indirect risks encompass possible contamination from electrode materials and unintended electrochemical reactions. Manufacturers must demonstrate that their electrode systems maintain consistent performance within specified electrical parameters throughout the manufacturing process.

Batch-to-batch consistency requirements present significant regulatory challenges for electrode-based mRNA LNP production. Regulatory bodies require validation of electrode performance across multiple production cycles, with defined acceptance criteria for electrical conductivity, surface morphology, and electrochemical stability. Companies must implement robust quality management systems that include regular electrode inspection and replacement protocols based on validated performance metrics.

International harmonization efforts are underway to standardize regulatory approaches to electrode dynamics in mRNA delivery. The International Council for Harmonisation (ICH) has initiated working groups focused specifically on establishing consistent guidelines for characterizing electrode-mediated delivery systems. These efforts aim to reduce regulatory barriers to global deployment of mRNA therapeutics while maintaining rigorous safety standards.

Emerging regulatory considerations include the development of specialized protocols for evaluating novel electrode materials and configurations designed to enhance mRNA delivery efficiency. Regulatory agencies are increasingly requesting real-time monitoring data of electrode performance during manufacturing processes, with emphasis on detecting early signs of electrode degradation that might impact product quality or safety profiles.

Current regulatory requirements focus heavily on characterization of electrode materials and their interaction with lipid nanoparticles during the electroporation or electroformation processes. Regulatory agencies require comprehensive documentation of electrode composition, surface properties, and degradation profiles to ensure consistent mRNA delivery efficiency and minimize variability in transfection outcomes. The FDA's guidance specifically addresses electrode stability during the application of electrical fields and potential leaching of electrode materials into final formulations.

Risk assessment frameworks for electrode-based delivery systems have been established that evaluate both direct and indirect risks. Direct risks include potential cellular damage from electrical field application, while indirect risks encompass possible contamination from electrode materials and unintended electrochemical reactions. Manufacturers must demonstrate that their electrode systems maintain consistent performance within specified electrical parameters throughout the manufacturing process.

Batch-to-batch consistency requirements present significant regulatory challenges for electrode-based mRNA LNP production. Regulatory bodies require validation of electrode performance across multiple production cycles, with defined acceptance criteria for electrical conductivity, surface morphology, and electrochemical stability. Companies must implement robust quality management systems that include regular electrode inspection and replacement protocols based on validated performance metrics.

International harmonization efforts are underway to standardize regulatory approaches to electrode dynamics in mRNA delivery. The International Council for Harmonisation (ICH) has initiated working groups focused specifically on establishing consistent guidelines for characterizing electrode-mediated delivery systems. These efforts aim to reduce regulatory barriers to global deployment of mRNA therapeutics while maintaining rigorous safety standards.

Emerging regulatory considerations include the development of specialized protocols for evaluating novel electrode materials and configurations designed to enhance mRNA delivery efficiency. Regulatory agencies are increasingly requesting real-time monitoring data of electrode performance during manufacturing processes, with emphasis on detecting early signs of electrode degradation that might impact product quality or safety profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!