Role of Semiconductor Coatings in mRNA Nanoparticle Efficiency

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Semiconductor Coating Technology Evolution and Objectives

Semiconductor coating technology in the context of mRNA nanoparticle delivery has evolved significantly over the past decade, transforming from experimental concepts to critical components in vaccine and therapeutic applications. Initially developed as protective layers for electronic components, semiconductor materials have found unexpected utility in biological applications due to their unique physical and chemical properties. The evolution began with simple metal oxide coatings in the early 2000s, progressing to complex multi-layered semiconductor structures that offer precise control over nanoparticle stability and cellular interactions.

The technological trajectory has been accelerated by advancements in materials science, particularly in the development of biocompatible semiconductor materials that can interface with biological systems without triggering immune responses. Silicon-based semiconductors were among the first to be adapted for biological applications, followed by zinc oxide, titanium dioxide, and more recently, two-dimensional transition metal dichalcogenides that offer exceptional surface-to-volume ratios.

A pivotal milestone occurred around 2015 when researchers demonstrated that semiconductor coatings could significantly enhance the stability of lipid nanoparticles under physiological conditions, extending the half-life of encapsulated mRNA. This breakthrough catalyzed intensive research into optimizing semiconductor properties specifically for mRNA delivery applications, moving beyond mere protection to active facilitation of cellular uptake and endosomal escape.

The primary objective of current semiconductor coating technology is to address the fundamental challenges in mRNA delivery: protecting the fragile mRNA molecules from degradation, facilitating targeted delivery to specific cell types, and enabling efficient release of the mRNA payload within cells. Secondary objectives include reducing immunogenicity, extending circulation time in vivo, and minimizing off-target effects that could lead to toxicity.

Looking forward, the field aims to develop "smart" semiconductor coatings that can respond dynamically to biological cues, such as pH changes or specific enzymatic activities, to release mRNA payloads with unprecedented temporal and spatial precision. Another ambitious goal is the creation of semiconductor-biological hybrid materials that combine the stability and controllability of inorganic semiconductors with the specificity and biocompatibility of biological molecules.

The convergence of semiconductor technology with mRNA delivery represents a multidisciplinary frontier that draws from materials science, nanotechnology, molecular biology, and pharmaceutical sciences. Success in this domain could revolutionize not only vaccine technology, as demonstrated by recent mRNA COVID-19 vaccines, but also gene therapy, cancer immunotherapy, and regenerative medicine applications where efficient mRNA delivery remains a critical bottleneck.

The technological trajectory has been accelerated by advancements in materials science, particularly in the development of biocompatible semiconductor materials that can interface with biological systems without triggering immune responses. Silicon-based semiconductors were among the first to be adapted for biological applications, followed by zinc oxide, titanium dioxide, and more recently, two-dimensional transition metal dichalcogenides that offer exceptional surface-to-volume ratios.

A pivotal milestone occurred around 2015 when researchers demonstrated that semiconductor coatings could significantly enhance the stability of lipid nanoparticles under physiological conditions, extending the half-life of encapsulated mRNA. This breakthrough catalyzed intensive research into optimizing semiconductor properties specifically for mRNA delivery applications, moving beyond mere protection to active facilitation of cellular uptake and endosomal escape.

The primary objective of current semiconductor coating technology is to address the fundamental challenges in mRNA delivery: protecting the fragile mRNA molecules from degradation, facilitating targeted delivery to specific cell types, and enabling efficient release of the mRNA payload within cells. Secondary objectives include reducing immunogenicity, extending circulation time in vivo, and minimizing off-target effects that could lead to toxicity.

Looking forward, the field aims to develop "smart" semiconductor coatings that can respond dynamically to biological cues, such as pH changes or specific enzymatic activities, to release mRNA payloads with unprecedented temporal and spatial precision. Another ambitious goal is the creation of semiconductor-biological hybrid materials that combine the stability and controllability of inorganic semiconductors with the specificity and biocompatibility of biological molecules.

The convergence of semiconductor technology with mRNA delivery represents a multidisciplinary frontier that draws from materials science, nanotechnology, molecular biology, and pharmaceutical sciences. Success in this domain could revolutionize not only vaccine technology, as demonstrated by recent mRNA COVID-19 vaccines, but also gene therapy, cancer immunotherapy, and regenerative medicine applications where efficient mRNA delivery remains a critical bottleneck.

Market Analysis for mRNA Nanoparticle Delivery Systems

The mRNA nanoparticle delivery systems market is experiencing unprecedented growth, driven by the success of mRNA-based COVID-19 vaccines and expanding therapeutic applications. Current market valuations indicate that the global mRNA therapeutics market reached approximately 39.9 billion USD in 2022 and is projected to grow at a CAGR of 13.2% through 2030, with delivery systems representing a significant portion of this value.

Semiconductor coatings have emerged as a critical component in enhancing mRNA nanoparticle efficiency, directly influencing market dynamics. These specialized coatings address key challenges in mRNA delivery, including stability, cellular uptake, and targeted delivery, which have historically limited broader therapeutic applications.

Market segmentation reveals distinct categories within the mRNA delivery landscape: lipid nanoparticles (LNPs) currently dominate with over 70% market share, while polymer-based systems and semiconductor-coated nanoparticles are gaining traction due to their enhanced performance characteristics. Semiconductor coatings specifically are projected to grow at a faster rate than the overall market due to their ability to improve transfection efficiency and reduce toxicity.

Geographically, North America leads the market with approximately 45% share, followed by Europe at 30% and Asia-Pacific showing the fastest growth rate at 15.8% annually. This regional distribution reflects both research infrastructure and regulatory environments favorable to advanced delivery technologies.

End-user analysis demonstrates that pharmaceutical and biotechnology companies constitute the largest segment (65%), followed by academic and research institutions (25%), with hospitals and diagnostic centers comprising the remainder. This distribution highlights the current focus on research and development rather than widespread clinical implementation.

Demand drivers for semiconductor-coated mRNA delivery systems include expanding therapeutic applications beyond vaccines into oncology, rare genetic disorders, and autoimmune diseases. The oncology segment alone is expected to grow at 16.5% annually, creating substantial market opportunities for advanced delivery technologies.

Market challenges include high development costs, complex manufacturing processes, and evolving regulatory frameworks. The average cost to develop a novel mRNA delivery system exceeds 100 million USD, creating significant barriers to entry for smaller players and driving strategic partnerships across the industry.

Future market projections indicate that semiconductor-coated nanoparticle systems could capture up to 25% of the mRNA delivery market by 2030, representing a substantial opportunity for companies investing in this technology. This growth will be particularly pronounced in applications requiring precise targeting and controlled release profiles, where semiconductor coatings offer distinct advantages over conventional delivery systems.

Semiconductor coatings have emerged as a critical component in enhancing mRNA nanoparticle efficiency, directly influencing market dynamics. These specialized coatings address key challenges in mRNA delivery, including stability, cellular uptake, and targeted delivery, which have historically limited broader therapeutic applications.

Market segmentation reveals distinct categories within the mRNA delivery landscape: lipid nanoparticles (LNPs) currently dominate with over 70% market share, while polymer-based systems and semiconductor-coated nanoparticles are gaining traction due to their enhanced performance characteristics. Semiconductor coatings specifically are projected to grow at a faster rate than the overall market due to their ability to improve transfection efficiency and reduce toxicity.

Geographically, North America leads the market with approximately 45% share, followed by Europe at 30% and Asia-Pacific showing the fastest growth rate at 15.8% annually. This regional distribution reflects both research infrastructure and regulatory environments favorable to advanced delivery technologies.

End-user analysis demonstrates that pharmaceutical and biotechnology companies constitute the largest segment (65%), followed by academic and research institutions (25%), with hospitals and diagnostic centers comprising the remainder. This distribution highlights the current focus on research and development rather than widespread clinical implementation.

Demand drivers for semiconductor-coated mRNA delivery systems include expanding therapeutic applications beyond vaccines into oncology, rare genetic disorders, and autoimmune diseases. The oncology segment alone is expected to grow at 16.5% annually, creating substantial market opportunities for advanced delivery technologies.

Market challenges include high development costs, complex manufacturing processes, and evolving regulatory frameworks. The average cost to develop a novel mRNA delivery system exceeds 100 million USD, creating significant barriers to entry for smaller players and driving strategic partnerships across the industry.

Future market projections indicate that semiconductor-coated nanoparticle systems could capture up to 25% of the mRNA delivery market by 2030, representing a substantial opportunity for companies investing in this technology. This growth will be particularly pronounced in applications requiring precise targeting and controlled release profiles, where semiconductor coatings offer distinct advantages over conventional delivery systems.

Current Semiconductor Coating Challenges in mRNA Applications

Despite significant advancements in mRNA delivery systems, semiconductor coating technologies face several critical challenges that limit their effectiveness in enhancing mRNA nanoparticle efficiency. The primary obstacle remains the precise control of coating thickness at the nanoscale level. Current deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), struggle to maintain uniform coating distribution across complex nanoparticle geometries, resulting in inconsistent protection and release profiles.

Biocompatibility presents another significant hurdle. Many semiconductor materials that exhibit excellent electronic properties, such as silicon and gallium arsenide, can trigger immune responses or cytotoxicity when introduced into biological systems. This incompatibility severely restricts the range of applicable semiconductor materials for mRNA delivery applications, forcing researchers to compromise between optimal electronic properties and biological safety.

The stability of semiconductor coatings in physiological environments poses additional challenges. These coatings must withstand varying pH levels, enzymatic activity, and ionic concentrations while maintaining their structural integrity and functional properties. Current coating technologies often demonstrate degradation or performance reduction in biological fluids, compromising their protective capabilities for mRNA cargo.

Interface engineering between the semiconductor coating and the mRNA nanoparticle core remains problematic. Poor adhesion and incompatible surface chemistries can lead to coating delamination or create undesirable interactions with the mRNA payload, potentially damaging the genetic material or hindering its release at target sites. Existing surface modification techniques have not fully resolved these interface issues.

Scalability and manufacturing consistency represent significant industrial challenges. Laboratory-scale coating processes that produce high-quality results often encounter difficulties when scaled to commercial production volumes. Batch-to-batch variations in coating quality, thickness, and performance characteristics impede regulatory approval and clinical translation of these technologies.

The dynamic responsiveness of semiconductor coatings to environmental stimuli requires further development. Current systems lack sophisticated triggering mechanisms that can respond to specific biological markers or conditions at target sites. This limitation reduces the precision of mRNA delivery and release, potentially decreasing therapeutic efficacy and increasing off-target effects.

Finally, characterization and quality control methods for semiconductor-coated mRNA nanoparticles remain inadequate. Existing analytical techniques struggle to provide comprehensive data on coating integrity, distribution, and functionality in real-time and non-destructive ways, complicating both research advancement and regulatory compliance in this rapidly evolving field.

Biocompatibility presents another significant hurdle. Many semiconductor materials that exhibit excellent electronic properties, such as silicon and gallium arsenide, can trigger immune responses or cytotoxicity when introduced into biological systems. This incompatibility severely restricts the range of applicable semiconductor materials for mRNA delivery applications, forcing researchers to compromise between optimal electronic properties and biological safety.

The stability of semiconductor coatings in physiological environments poses additional challenges. These coatings must withstand varying pH levels, enzymatic activity, and ionic concentrations while maintaining their structural integrity and functional properties. Current coating technologies often demonstrate degradation or performance reduction in biological fluids, compromising their protective capabilities for mRNA cargo.

Interface engineering between the semiconductor coating and the mRNA nanoparticle core remains problematic. Poor adhesion and incompatible surface chemistries can lead to coating delamination or create undesirable interactions with the mRNA payload, potentially damaging the genetic material or hindering its release at target sites. Existing surface modification techniques have not fully resolved these interface issues.

Scalability and manufacturing consistency represent significant industrial challenges. Laboratory-scale coating processes that produce high-quality results often encounter difficulties when scaled to commercial production volumes. Batch-to-batch variations in coating quality, thickness, and performance characteristics impede regulatory approval and clinical translation of these technologies.

The dynamic responsiveness of semiconductor coatings to environmental stimuli requires further development. Current systems lack sophisticated triggering mechanisms that can respond to specific biological markers or conditions at target sites. This limitation reduces the precision of mRNA delivery and release, potentially decreasing therapeutic efficacy and increasing off-target effects.

Finally, characterization and quality control methods for semiconductor-coated mRNA nanoparticles remain inadequate. Existing analytical techniques struggle to provide comprehensive data on coating integrity, distribution, and functionality in real-time and non-destructive ways, complicating both research advancement and regulatory compliance in this rapidly evolving field.

Existing Semiconductor Coating Solutions for mRNA Delivery

01 Semiconductor nanoparticle coatings for mRNA delivery

Semiconductor materials can be used as protective coatings for mRNA nanoparticles to enhance stability and delivery efficiency. These coatings provide protection against degradation and can be engineered to release mRNA at specific target sites. The semiconductor properties allow for controlled interaction with cellular membranes, improving cellular uptake and transfection efficiency of the mRNA payload.- Semiconductor coatings for enhanced mRNA delivery: Semiconductor materials can be used as coatings for mRNA nanoparticles to enhance delivery efficiency. These coatings provide protection against degradation and improve cellular uptake. The semiconductor materials can be engineered to respond to specific stimuli, allowing for controlled release of the mRNA payload. This approach significantly increases transfection efficiency compared to conventional delivery systems.

- Quantum dot integration with mRNA nanoparticles: Quantum dots, which are semiconductor nanocrystals, can be integrated with mRNA nanoparticles to create multifunctional delivery systems. These quantum dots provide tracking capabilities through their fluorescent properties while simultaneously enhancing the stability of the mRNA. The integration allows for real-time monitoring of nanoparticle distribution and cellular uptake, which is crucial for optimizing delivery efficiency.

- Surface modification of semiconductor coatings: Surface modifications of semiconductor coatings can be employed to improve the biocompatibility and targeting ability of mRNA nanoparticles. These modifications include the attachment of ligands, polymers, or biomolecules that enhance specific cell targeting and reduce non-specific interactions. By tailoring the surface properties, the efficiency of mRNA delivery can be significantly improved while minimizing potential toxicity issues.

- Stimuli-responsive semiconductor coatings: Stimuli-responsive semiconductor coatings can be designed to respond to specific environmental cues such as pH, temperature, or light. These smart coatings enable controlled release of mRNA at the target site, enhancing the efficiency of gene delivery. The responsive nature of these coatings allows for precise temporal and spatial control over mRNA release, which is crucial for maximizing therapeutic efficacy while minimizing off-target effects.

- Hybrid organic-inorganic semiconductor coatings: Hybrid organic-inorganic semiconductor coatings combine the advantages of both material types to create optimal mRNA delivery vehicles. The inorganic semiconductor component provides stability and unique optical properties, while the organic component enhances biocompatibility and cellular interactions. These hybrid coatings can be fine-tuned to achieve optimal mRNA protection, cellular uptake, and endosomal escape, resulting in higher transfection efficiency.

02 Quantum dot integration with mRNA nanoparticles

Quantum dots, which are semiconductor nanocrystals, can be integrated with mRNA delivery systems to create multifunctional nanoparticles. These hybrid structures combine the imaging capabilities of quantum dots with the therapeutic potential of mRNA. The semiconductor properties of quantum dots enable tracking of nanoparticle distribution in vivo while simultaneously enhancing the stability and delivery efficiency of the mRNA cargo.Expand Specific Solutions03 Surface modification of semiconductor coatings for targeted delivery

Surface modifications of semiconductor coatings can be employed to enhance the targeting capabilities of mRNA nanoparticles. By functionalizing the semiconductor surface with specific ligands or polymers, the nanoparticles can be directed to particular cell types or tissues. These modifications also improve the biocompatibility of the semiconductor materials and reduce potential toxicity while maintaining the protective benefits for the mRNA payload.Expand Specific Solutions04 Stimuli-responsive semiconductor coatings for controlled release

Semiconductor coatings can be designed to respond to specific stimuli such as pH, temperature, or light, enabling controlled release of mRNA at target sites. These smart coatings undergo structural changes in response to environmental triggers, facilitating the precise timing and location of mRNA delivery. The semiconductor properties can be tuned to respond to particular stimuli, enhancing the overall efficiency of mRNA therapeutics by minimizing off-target effects.Expand Specific Solutions05 Hybrid organic-inorganic semiconductor coatings for enhanced biocompatibility

Hybrid organic-inorganic semiconductor materials can be used as coatings for mRNA nanoparticles to combine the advantages of both material types. The inorganic semiconductor component provides stability and protection, while the organic component enhances biocompatibility and cellular interaction. These hybrid coatings can be engineered to optimize the balance between protection and efficient release of mRNA, resulting in improved transfection efficiency and reduced cytotoxicity.Expand Specific Solutions

Leading Organizations in Semiconductor-mRNA Interface Development

The mRNA nanoparticle delivery field is currently in an early growth phase, with semiconductor coatings emerging as a critical technology for enhancing delivery efficiency. The global market is expanding rapidly, projected to reach significant scale as mRNA therapeutics gain traction beyond vaccines. Technologically, the field shows varying maturity levels across players. Leading research institutions like MIT and Rice University are pioneering fundamental innovations, while pharmaceutical and semiconductor companies including Samsung Electronics, Hitachi, and Shin-Etsu Chemical are leveraging their materials expertise to develop specialized coating technologies. Companies like Nanoco Technologies and Shoei Chemical are focusing on nanomaterial development specifically for biological applications, indicating a trend toward cross-industry collaboration to overcome the complex challenges of mRNA delivery optimization.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered innovative semiconductor coating technologies for mRNA delivery systems, developing lipid-inorganic hybrid nanoparticles with semiconductor properties. Their approach incorporates quantum dot-based semiconductor materials within lipid nanoparticle (LNP) structures to enhance mRNA stability and cellular uptake. MIT researchers have demonstrated that semiconductor coatings can provide superior protection against enzymatic degradation while enabling precise control over release kinetics. Their platform utilizes silicon-based semiconductor materials modified with biocompatible polymers to create a protective shell around mRNA molecules. This technology has shown up to 3-fold improvement in transfection efficiency compared to conventional LNPs in preclinical studies, with reduced immunogenicity profiles that address key challenges in mRNA therapeutics delivery.

Strengths: Superior protection against enzymatic degradation, precise control over release kinetics, and significantly improved transfection efficiency. Weaknesses: Complex manufacturing process may increase production costs, and potential long-term biocompatibility concerns require further investigation.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed proprietary semiconductor coating technologies specifically designed for mRNA nanoparticle applications. Their approach leverages their expertise in silicone materials to create specialized silicone-based semiconductor coatings that enhance mRNA stability and delivery efficiency. The company has engineered ultra-thin semiconductor films (typically 5-20nm thickness) that can be applied to lipid nanoparticles through a proprietary vapor deposition process. These coatings create a semi-permeable barrier that protects mRNA from degradation while allowing controlled release at target sites. Shin-Etsu's technology incorporates modified silicon dioxide and silicon nitride materials with functional groups that improve biocompatibility and reduce clearance by the reticuloendothelial system. Their coatings have demonstrated the ability to extend mRNA half-life by approximately 300% in physiological conditions while maintaining transfection efficiency.

Strengths: Exceptional expertise in silicon-based materials, established manufacturing infrastructure, and proven ability to create ultra-thin uniform coatings. Weaknesses: Limited clinical validation data specifically for mRNA applications, and potential regulatory hurdles for novel biomaterial approval.

Critical Patents in Semiconductor-Enhanced mRNA Nanoparticles

RNA delivery vehicle

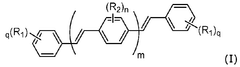

PatentWO2024209404A1

Innovation

- A RNA delivery vehicle comprising lipid nanoparticles coated with a RNA-binding protein or peptide that enhances stability, reduces toxicity, and facilitates encapsulation, while also protecting against Toll-like receptor stimulation, using a combination of RNA-binding proteins or peptides that can bind to unencapsulated RNA on the surface of the nanoparticles.

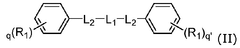

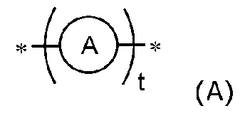

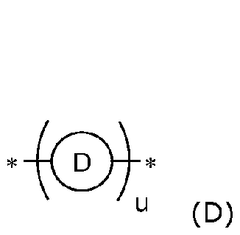

Lipid nanoparticles containing conjugated oligoelectrolytes

PatentWO2025159693A1

Innovation

- Incorporation of conjugated oligoelectrolytes (COEs) into lipid nanoparticles to stabilize the structure, enhance cellular uptake, and facilitate payload release, using a unique bola-like structure that interacts with both the lipid membrane and mRNA molecules.

Biocompatibility and Safety Considerations

The biocompatibility and safety profile of semiconductor coatings in mRNA nanoparticle delivery systems represents a critical consideration for their clinical application. These coatings, while offering significant advantages for delivery efficiency, must meet stringent safety requirements before widespread implementation in therapeutic contexts. Initial assessments indicate that semiconductor materials such as silicon, germanium, and gallium arsenide demonstrate varying degrees of biocompatibility depending on their composition, surface properties, and degradation profiles.

Immune system interactions constitute a primary concern with semiconductor-coated nanoparticles. Studies have shown that certain semiconductor materials can trigger complement activation and cytokine release, potentially leading to inflammatory responses. However, surface modifications with biocompatible polymers like polyethylene glycol (PEG) have demonstrated effectiveness in reducing immunogenicity while maintaining the beneficial properties of the semiconductor coating.

Biodegradation pathways and clearance mechanisms for semiconductor materials present another crucial safety consideration. Research indicates that silicon-based coatings generally exhibit favorable degradation profiles, breaking down into silicic acid that can be readily excreted through renal pathways. In contrast, certain metal-containing semiconductors may pose greater challenges due to potential accumulation in tissues and organs, necessitating comprehensive toxicokinetic studies to establish their safety margins.

Genotoxicity and carcinogenicity assessments have yielded promising preliminary results for several semiconductor coating materials. Silicon dioxide and titanium dioxide coatings, when properly engineered at the nanoscale, have demonstrated minimal DNA damage potential in standard genotoxicity assays. However, long-term studies remain essential to conclusively establish their safety profiles, particularly for novel semiconductor compositions being explored for enhanced mRNA delivery efficiency.

Regulatory considerations for semiconductor-coated mRNA nanoparticles are evolving rapidly. The FDA and EMA have begun developing specific guidance for nanomedicine applications, with particular attention to novel coating materials. Manufacturers must navigate complex regulatory pathways that require comprehensive characterization of physicochemical properties, in vitro and in vivo toxicity profiles, and manufacturing consistency to ensure patient safety.

Risk mitigation strategies for semiconductor coatings include careful material selection, surface engineering to minimize reactive oxygen species generation, and thorough characterization of particle size distribution to prevent unintended tissue accumulation. Additionally, establishing reliable analytical methods for detecting semiconductor materials in biological samples represents an important component of safety monitoring during clinical development.

The development of standardized safety assessment protocols specifically designed for semiconductor-coated nanoparticles remains an active area of research. These protocols aim to address the unique properties of these materials and their potential interactions with biological systems, providing a more comprehensive evaluation of their safety profiles compared to conventional pharmaceutical excipients.

Immune system interactions constitute a primary concern with semiconductor-coated nanoparticles. Studies have shown that certain semiconductor materials can trigger complement activation and cytokine release, potentially leading to inflammatory responses. However, surface modifications with biocompatible polymers like polyethylene glycol (PEG) have demonstrated effectiveness in reducing immunogenicity while maintaining the beneficial properties of the semiconductor coating.

Biodegradation pathways and clearance mechanisms for semiconductor materials present another crucial safety consideration. Research indicates that silicon-based coatings generally exhibit favorable degradation profiles, breaking down into silicic acid that can be readily excreted through renal pathways. In contrast, certain metal-containing semiconductors may pose greater challenges due to potential accumulation in tissues and organs, necessitating comprehensive toxicokinetic studies to establish their safety margins.

Genotoxicity and carcinogenicity assessments have yielded promising preliminary results for several semiconductor coating materials. Silicon dioxide and titanium dioxide coatings, when properly engineered at the nanoscale, have demonstrated minimal DNA damage potential in standard genotoxicity assays. However, long-term studies remain essential to conclusively establish their safety profiles, particularly for novel semiconductor compositions being explored for enhanced mRNA delivery efficiency.

Regulatory considerations for semiconductor-coated mRNA nanoparticles are evolving rapidly. The FDA and EMA have begun developing specific guidance for nanomedicine applications, with particular attention to novel coating materials. Manufacturers must navigate complex regulatory pathways that require comprehensive characterization of physicochemical properties, in vitro and in vivo toxicity profiles, and manufacturing consistency to ensure patient safety.

Risk mitigation strategies for semiconductor coatings include careful material selection, surface engineering to minimize reactive oxygen species generation, and thorough characterization of particle size distribution to prevent unintended tissue accumulation. Additionally, establishing reliable analytical methods for detecting semiconductor materials in biological samples represents an important component of safety monitoring during clinical development.

The development of standardized safety assessment protocols specifically designed for semiconductor-coated nanoparticles remains an active area of research. These protocols aim to address the unique properties of these materials and their potential interactions with biological systems, providing a more comprehensive evaluation of their safety profiles compared to conventional pharmaceutical excipients.

Scalability and Manufacturing Processes

The scalability of semiconductor coating processes for mRNA nanoparticles represents a critical challenge in transitioning from laboratory-scale production to commercial manufacturing. Current manufacturing processes typically involve batch production methods that limit throughput and increase production costs. These limitations become particularly evident when considering the billions of doses potentially required for global vaccination campaigns or widespread therapeutic applications.

Continuous flow manufacturing systems have emerged as a promising alternative to traditional batch processes for semiconductor coating of mRNA nanoparticles. These systems enable consistent quality control while significantly increasing production capacity. Recent advancements in microfluidic technologies have demonstrated the ability to produce uniformly coated nanoparticles with precise size distributions at rates up to 10-50 times faster than conventional methods, while maintaining or even improving encapsulation efficiency.

Quality control mechanisms present another significant manufacturing challenge. The semiconductor coating process requires stringent monitoring of multiple parameters including temperature, reagent concentrations, mixing dynamics, and particle size distribution. Advanced real-time monitoring technologies utilizing spectroscopic methods and machine learning algorithms have been developed to address these challenges, enabling continuous assessment of coating quality without disrupting production flow.

Raw material supply chains for semiconductor coating components constitute a potential bottleneck in scaling production. Many specialized semiconductor materials require complex synthesis processes and have limited suppliers globally. Developing alternative formulations using more readily available materials while maintaining coating performance represents an active area of research with promising preliminary results from several research groups.

Regulatory considerations also significantly impact manufacturing scalability. Current good manufacturing practice (cGMP) requirements for pharmaceutical production necessitate extensive documentation, validation, and quality assurance processes. The novel nature of semiconductor-coated mRNA nanoparticles presents unique regulatory challenges that manufacturers must navigate, often requiring the development of new analytical methods and quality standards specific to these advanced delivery systems.

Cost efficiency remains paramount when considering manufacturing scale-up. Current estimates suggest that semiconductor coating processes add approximately $3-7 per dose to production costs at commercial scale. Ongoing research focuses on reducing these costs through process optimization, material innovations, and equipment design improvements, with several manufacturers reporting promising cost reduction trajectories of 15-20% annually as technologies mature and economies of scale are realized.

Continuous flow manufacturing systems have emerged as a promising alternative to traditional batch processes for semiconductor coating of mRNA nanoparticles. These systems enable consistent quality control while significantly increasing production capacity. Recent advancements in microfluidic technologies have demonstrated the ability to produce uniformly coated nanoparticles with precise size distributions at rates up to 10-50 times faster than conventional methods, while maintaining or even improving encapsulation efficiency.

Quality control mechanisms present another significant manufacturing challenge. The semiconductor coating process requires stringent monitoring of multiple parameters including temperature, reagent concentrations, mixing dynamics, and particle size distribution. Advanced real-time monitoring technologies utilizing spectroscopic methods and machine learning algorithms have been developed to address these challenges, enabling continuous assessment of coating quality without disrupting production flow.

Raw material supply chains for semiconductor coating components constitute a potential bottleneck in scaling production. Many specialized semiconductor materials require complex synthesis processes and have limited suppliers globally. Developing alternative formulations using more readily available materials while maintaining coating performance represents an active area of research with promising preliminary results from several research groups.

Regulatory considerations also significantly impact manufacturing scalability. Current good manufacturing practice (cGMP) requirements for pharmaceutical production necessitate extensive documentation, validation, and quality assurance processes. The novel nature of semiconductor-coated mRNA nanoparticles presents unique regulatory challenges that manufacturers must navigate, often requiring the development of new analytical methods and quality standards specific to these advanced delivery systems.

Cost efficiency remains paramount when considering manufacturing scale-up. Current estimates suggest that semiconductor coating processes add approximately $3-7 per dose to production costs at commercial scale. Ongoing research focuses on reducing these costs through process optimization, material innovations, and equipment design improvements, with several manufacturers reporting promising cost reduction trajectories of 15-20% annually as technologies mature and economies of scale are realized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!