Assessing PTFE’s role in robotic gripper surface optimization

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Robotic Grippers: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a pivotal material in the optimization of robotic gripper surfaces. The evolution of robotic grippers has been driven by the need for enhanced precision, reliability, and versatility in various industrial and research applications. PTFE's unique properties, including its low friction coefficient, chemical inertness, and thermal stability, have positioned it as a material of significant interest in this field.

The journey of PTFE in robotic gripper technology began with its initial use as a coating material to reduce friction and improve grip performance. As the demands on robotic systems increased, researchers and engineers recognized the potential of PTFE to address more complex challenges in gripper design. The material's ability to maintain its properties across a wide range of temperatures and its resistance to chemical degradation opened new possibilities for grippers operating in harsh or varied environments.

The technological trajectory of PTFE in robotic grippers has been marked by continuous innovation. Early applications focused primarily on leveraging PTFE's non-stick properties to prevent adhesion of materials to gripper surfaces. This basic utilization gradually evolved into more sophisticated implementations, such as the development of composite materials incorporating PTFE to achieve specific performance characteristics.

Recent advancements have seen the integration of PTFE into micro-structured surfaces, enabling fine-tuned control over grip strength and object manipulation. This progress aligns with the broader trend towards more adaptive and intelligent robotic systems capable of handling a diverse range of objects with varying shapes, sizes, and material properties.

The primary objectives of incorporating PTFE into robotic gripper surfaces are multifaceted. Researchers aim to enhance the overall efficiency and reliability of robotic manipulation tasks across various industries, including manufacturing, healthcare, and logistics. Specific goals include improving grip stability, reducing wear and tear on gripper components, and expanding the range of materials that can be effectively handled by a single gripper design.

Furthermore, there is a growing emphasis on developing PTFE-based solutions that can adapt to dynamic environments and varying task requirements. This includes the creation of smart surfaces that can modify their properties in real-time, potentially through the integration of PTFE with other advanced materials or the incorporation of embedded sensors and actuators.

As we look towards the future, the role of PTFE in robotic gripper surface optimization is expected to expand further. Ongoing research is exploring novel ways to manipulate the material at the molecular level, potentially unlocking new functionalities and performance enhancements. The convergence of PTFE technology with other emerging fields, such as nanotechnology and artificial intelligence, promises to push the boundaries of what is possible in robotic manipulation and grasping.

The journey of PTFE in robotic gripper technology began with its initial use as a coating material to reduce friction and improve grip performance. As the demands on robotic systems increased, researchers and engineers recognized the potential of PTFE to address more complex challenges in gripper design. The material's ability to maintain its properties across a wide range of temperatures and its resistance to chemical degradation opened new possibilities for grippers operating in harsh or varied environments.

The technological trajectory of PTFE in robotic grippers has been marked by continuous innovation. Early applications focused primarily on leveraging PTFE's non-stick properties to prevent adhesion of materials to gripper surfaces. This basic utilization gradually evolved into more sophisticated implementations, such as the development of composite materials incorporating PTFE to achieve specific performance characteristics.

Recent advancements have seen the integration of PTFE into micro-structured surfaces, enabling fine-tuned control over grip strength and object manipulation. This progress aligns with the broader trend towards more adaptive and intelligent robotic systems capable of handling a diverse range of objects with varying shapes, sizes, and material properties.

The primary objectives of incorporating PTFE into robotic gripper surfaces are multifaceted. Researchers aim to enhance the overall efficiency and reliability of robotic manipulation tasks across various industries, including manufacturing, healthcare, and logistics. Specific goals include improving grip stability, reducing wear and tear on gripper components, and expanding the range of materials that can be effectively handled by a single gripper design.

Furthermore, there is a growing emphasis on developing PTFE-based solutions that can adapt to dynamic environments and varying task requirements. This includes the creation of smart surfaces that can modify their properties in real-time, potentially through the integration of PTFE with other advanced materials or the incorporation of embedded sensors and actuators.

As we look towards the future, the role of PTFE in robotic gripper surface optimization is expected to expand further. Ongoing research is exploring novel ways to manipulate the material at the molecular level, potentially unlocking new functionalities and performance enhancements. The convergence of PTFE technology with other emerging fields, such as nanotechnology and artificial intelligence, promises to push the boundaries of what is possible in robotic manipulation and grasping.

Market Analysis for PTFE-Enhanced Robotic Grippers

The market for PTFE-enhanced robotic grippers is experiencing significant growth, driven by the increasing adoption of automation across various industries. The global robotic gripper market, which includes PTFE-enhanced solutions, is projected to reach $2.5 billion by 2025, with a compound annual growth rate (CAGR) of 8.5% from 2020 to 2025. This growth is primarily fueled by the rising demand for precision handling in manufacturing, logistics, and healthcare sectors.

PTFE-enhanced robotic grippers are gaining traction due to their superior performance characteristics. The non-stick and low friction properties of PTFE contribute to improved grip stability and reduced wear, addressing key challenges in robotic manipulation. Industries such as electronics, automotive, and food processing are particularly interested in PTFE-enhanced grippers for their ability to handle delicate components and maintain cleanliness standards.

The market demand for PTFE-enhanced robotic grippers is closely tied to the broader trends in industrial automation. As manufacturers seek to improve efficiency and reduce labor costs, the integration of advanced robotic systems, including those with PTFE-enhanced grippers, is becoming increasingly prevalent. This trend is especially pronounced in regions with high labor costs, such as North America and Western Europe.

In the electronics industry, the demand for PTFE-enhanced grippers is driven by the need for precision handling of sensitive components. The automotive sector is adopting these grippers for assembly processes that require a delicate touch, such as handling glass or painted surfaces. The food processing industry values PTFE-enhanced grippers for their non-stick properties, which ensure hygienic handling of food products.

Emerging applications in collaborative robotics are also contributing to market growth. As human-robot collaboration becomes more common in manufacturing environments, PTFE-enhanced grippers are being developed to ensure safe interaction and improved performance in shared workspaces. This trend is expected to open new market opportunities in small and medium-sized enterprises that are adopting flexible automation solutions.

The Asia-Pacific region is anticipated to be the fastest-growing market for PTFE-enhanced robotic grippers, driven by rapid industrialization in countries like China and India. North America and Europe remain significant markets, with a focus on high-value applications in aerospace, medical devices, and advanced manufacturing.

Despite the positive outlook, challenges such as the high initial cost of PTFE-enhanced grippers and the need for specialized maintenance may limit market penetration in some sectors. However, ongoing research and development efforts are expected to address these issues, potentially expanding the market reach of PTFE-enhanced robotic grippers in the coming years.

PTFE-enhanced robotic grippers are gaining traction due to their superior performance characteristics. The non-stick and low friction properties of PTFE contribute to improved grip stability and reduced wear, addressing key challenges in robotic manipulation. Industries such as electronics, automotive, and food processing are particularly interested in PTFE-enhanced grippers for their ability to handle delicate components and maintain cleanliness standards.

The market demand for PTFE-enhanced robotic grippers is closely tied to the broader trends in industrial automation. As manufacturers seek to improve efficiency and reduce labor costs, the integration of advanced robotic systems, including those with PTFE-enhanced grippers, is becoming increasingly prevalent. This trend is especially pronounced in regions with high labor costs, such as North America and Western Europe.

In the electronics industry, the demand for PTFE-enhanced grippers is driven by the need for precision handling of sensitive components. The automotive sector is adopting these grippers for assembly processes that require a delicate touch, such as handling glass or painted surfaces. The food processing industry values PTFE-enhanced grippers for their non-stick properties, which ensure hygienic handling of food products.

Emerging applications in collaborative robotics are also contributing to market growth. As human-robot collaboration becomes more common in manufacturing environments, PTFE-enhanced grippers are being developed to ensure safe interaction and improved performance in shared workspaces. This trend is expected to open new market opportunities in small and medium-sized enterprises that are adopting flexible automation solutions.

The Asia-Pacific region is anticipated to be the fastest-growing market for PTFE-enhanced robotic grippers, driven by rapid industrialization in countries like China and India. North America and Europe remain significant markets, with a focus on high-value applications in aerospace, medical devices, and advanced manufacturing.

Despite the positive outlook, challenges such as the high initial cost of PTFE-enhanced grippers and the need for specialized maintenance may limit market penetration in some sectors. However, ongoing research and development efforts are expected to address these issues, potentially expanding the market reach of PTFE-enhanced robotic grippers in the coming years.

Current PTFE Applications and Challenges in Robotics

Polytetrafluoroethylene (PTFE) has emerged as a significant material in the field of robotics, particularly in the optimization of robotic gripper surfaces. Its unique properties, including low friction, chemical inertness, and high temperature resistance, have made it an attractive option for various robotic applications. In the context of robotic grippers, PTFE coatings and components are primarily utilized to enhance grip performance, reduce wear, and improve overall efficiency.

One of the primary applications of PTFE in robotic grippers is as a surface coating. When applied to gripper fingers or pads, PTFE provides a non-stick surface that can effectively handle a wide range of materials, including those that are typically challenging to grip due to their adhesive or delicate nature. This property is particularly valuable in industries such as food processing, pharmaceuticals, and electronics manufacturing, where contamination and product damage are critical concerns.

PTFE-coated grippers have also shown promise in handling objects with varying surface textures and moisture levels. The material's hydrophobic nature allows for consistent performance even in wet or humid environments, making it suitable for applications in diverse industrial settings. Additionally, the low friction coefficient of PTFE contributes to reduced energy consumption during gripper operations, potentially leading to improved overall system efficiency.

Despite its advantages, the integration of PTFE in robotic grippers faces several challenges. One significant issue is the potential for wear over time, especially in high-cycle applications. While PTFE is known for its durability, repeated use can lead to degradation of the coating, necessitating regular maintenance or replacement. This wear can result in decreased grip performance and potential contamination in sensitive manufacturing processes.

Another challenge lies in achieving the optimal balance between grip strength and the non-stick properties of PTFE. While the material's low friction is beneficial for releasing objects, it can sometimes compromise the ability to securely grasp items, particularly those with smooth surfaces or in applications requiring high precision. Engineers must carefully consider the specific requirements of each application to determine the most appropriate PTFE formulation or coating thickness.

The integration of PTFE with other materials or surface treatments to create hybrid solutions is an area of ongoing research and development. Combining PTFE with textured surfaces or incorporating it into composite materials aims to address some of the limitations while maintaining its beneficial properties. These efforts seek to expand the range of applications where PTFE can be effectively utilized in robotic gripper systems.

One of the primary applications of PTFE in robotic grippers is as a surface coating. When applied to gripper fingers or pads, PTFE provides a non-stick surface that can effectively handle a wide range of materials, including those that are typically challenging to grip due to their adhesive or delicate nature. This property is particularly valuable in industries such as food processing, pharmaceuticals, and electronics manufacturing, where contamination and product damage are critical concerns.

PTFE-coated grippers have also shown promise in handling objects with varying surface textures and moisture levels. The material's hydrophobic nature allows for consistent performance even in wet or humid environments, making it suitable for applications in diverse industrial settings. Additionally, the low friction coefficient of PTFE contributes to reduced energy consumption during gripper operations, potentially leading to improved overall system efficiency.

Despite its advantages, the integration of PTFE in robotic grippers faces several challenges. One significant issue is the potential for wear over time, especially in high-cycle applications. While PTFE is known for its durability, repeated use can lead to degradation of the coating, necessitating regular maintenance or replacement. This wear can result in decreased grip performance and potential contamination in sensitive manufacturing processes.

Another challenge lies in achieving the optimal balance between grip strength and the non-stick properties of PTFE. While the material's low friction is beneficial for releasing objects, it can sometimes compromise the ability to securely grasp items, particularly those with smooth surfaces or in applications requiring high precision. Engineers must carefully consider the specific requirements of each application to determine the most appropriate PTFE formulation or coating thickness.

The integration of PTFE with other materials or surface treatments to create hybrid solutions is an area of ongoing research and development. Combining PTFE with textured surfaces or incorporating it into composite materials aims to address some of the limitations while maintaining its beneficial properties. These efforts seek to expand the range of applications where PTFE can be effectively utilized in robotic gripper systems.

Existing PTFE Integration Methods for Gripper Surfaces

01 Surface modification techniques

Various methods are employed to optimize PTFE surfaces, including plasma treatment, chemical etching, and physical abrasion. These techniques alter the surface properties of PTFE, enhancing its adhesion, wettability, and overall performance for specific applications.- Surface modification techniques: Various surface modification techniques can be applied to optimize PTFE surfaces. These methods include plasma treatment, chemical etching, and physical abrasion. Such modifications can enhance the surface properties of PTFE, improving its adhesion, wettability, and overall performance in different applications.

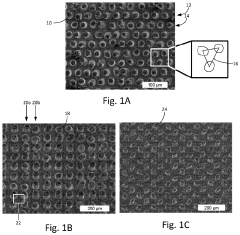

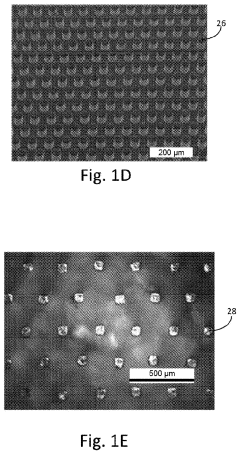

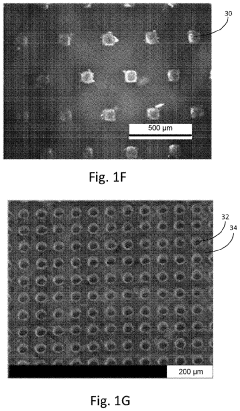

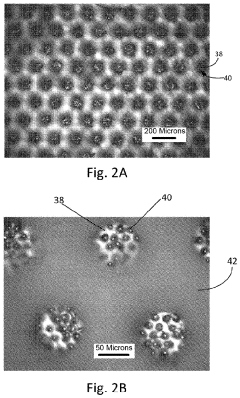

- Nanostructure formation on PTFE surfaces: Creating nanostructures on PTFE surfaces can significantly improve their properties. Techniques such as nanoimprinting, electrospinning, and template-assisted methods can be used to form these nanostructures. The resulting nanostructured PTFE surfaces often exhibit enhanced hydrophobicity, self-cleaning properties, and improved mechanical characteristics.

- Coating and composite formation: Applying coatings or forming composites with PTFE can optimize its surface properties. This can involve the use of other polymers, nanoparticles, or functional materials to create a hybrid surface. Such approaches can lead to improved wear resistance, thermal stability, and chemical resistance of the PTFE surface.

- Surface texturing and patterning: Texturing and patterning PTFE surfaces can enhance their functional properties. Techniques such as laser ablation, photolithography, and micro-molding can be used to create specific surface patterns. These textured surfaces can exhibit improved tribological properties, controlled wettability, and enhanced optical characteristics.

- Chemical functionalization of PTFE surfaces: Chemical functionalization involves modifying the PTFE surface by introducing specific functional groups. This can be achieved through methods such as grafting, oxidation, or fluorination. Functionalized PTFE surfaces can exhibit improved adhesion, biocompatibility, and reactivity, making them suitable for various specialized applications.

02 Nanostructure incorporation

Incorporating nanostructures or nanoparticles into PTFE surfaces can significantly improve their properties. This approach enhances wear resistance, thermal conductivity, and mechanical strength while maintaining the inherent non-stick characteristics of PTFE.Expand Specific Solutions03 Coating and composite formulations

Developing specialized coating formulations or composite materials that incorporate PTFE can optimize surface properties. These formulations may include additives, fillers, or other polymers to enhance specific characteristics such as durability, chemical resistance, or friction reduction.Expand Specific Solutions04 Surface texturing and patterning

Creating specific surface textures or patterns on PTFE can optimize its performance for particular applications. This may involve techniques such as laser etching, embossing, or micro-molding to achieve desired surface topographies that enhance properties like fluid flow or anti-fouling capabilities.Expand Specific Solutions05 Heat treatment and annealing processes

Optimizing PTFE surfaces through controlled heat treatment or annealing processes can improve crystallinity, reduce internal stresses, and enhance overall material properties. These thermal processes can be tailored to achieve specific surface characteristics or to prepare the material for further modifications.Expand Specific Solutions

Key Players in PTFE and Robotic Gripper Industries

The market for PTFE in robotic gripper surface optimization is in a growth phase, driven by increasing automation across industries. The global market size for robotic grippers is expanding rapidly, with PTFE playing a crucial role in enhancing grip performance. Technologically, PTFE applications in this field are maturing, with companies like W. L. Gore & Associates, DuPont de Nemours, and Daikin Industries leading innovation. These firms, along with specialized players such as Hoowaki LLC and Nanjing Comptech Composites Corp., are advancing PTFE formulations and surface treatments to improve grip characteristics. Research institutions like Yanshan University and the University of Louisville are contributing to technological advancements, indicating a collaborative ecosystem driving progress in this niche but growing market segment.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based materials for robotic gripper surfaces. Their proprietary expanded PTFE (ePTFE) technology offers a unique combination of properties beneficial for gripper optimization. The company's GORE-TEX Grip Fabric incorporates ePTFE to create a surface with high friction coefficients under both dry and wet conditions[1]. This material demonstrates excellent wear resistance and maintains its gripping properties over extended use. Gore has also developed PTFE-based coatings that can be applied to various gripper substrates, enhancing surface properties without significantly altering the gripper's dimensions or weight[2]. These coatings provide a balance of slip and grip characteristics, allowing for precise object manipulation in robotic applications.

Strengths: Exceptional chemical resistance, wide temperature range operability, and low friction properties. Weaknesses: Higher cost compared to conventional materials, potential for static charge buildup in certain applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has made significant strides in PTFE technology for robotic applications, including gripper surface optimization. Their NEOFLON series of PTFE products offers a range of formulations tailored for specific performance requirements. For robotic grippers, DAIKIN has developed a modified PTFE compound that exhibits enhanced wear resistance and improved grip characteristics[3]. This material incorporates nano-scale fillers that increase the surface roughness at a microscopic level, thereby improving friction properties without compromising the inherent benefits of PTFE. DAIKIN's research has also focused on creating PTFE-based composite materials that combine the low friction of PTFE with the structural integrity of other polymers or reinforcing agents, resulting in gripper surfaces that maintain precision over long operational periods[4].

Strengths: Advanced formulation capabilities, wide range of PTFE grades for specific applications. Weaknesses: Limited direct experience in robotic systems integration, potential for higher material costs due to specialized formulations.

Innovative PTFE Formulations for Robotic Applications

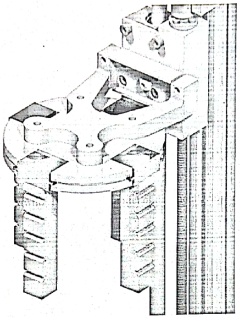

Microstructure arrangement for gripping low coefficient of friction materials

PatentInactiveUS20220168904A1

Innovation

- A microstructure pattern with pillars of specific dimensions and arrangements on a gripping surface, increasing the coefficient of friction to over 0.90, allowing for effective gripping without damage or pain, by forming a pattern of microstructure features on the gripping pad with a Young's modulus greater than the material being gripped.

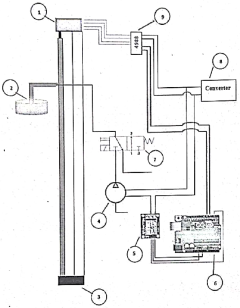

Design and develop a soft robotic gripper for objects of various shapes

PatentPendingIN202221046928A

Innovation

- A soft robotic gripper with advanced material properties, capable of changing finger orientation and sequence, utilizing a combination of stepper motors, air pumps, solenoid valves, and Arduino Uno for automated gripping, and featuring a flexible design that can handle a wide range of irregular shapes and delicate objects.

Environmental Impact of PTFE in Robotics

The use of Polytetrafluoroethylene (PTFE) in robotic grippers has raised concerns about its environmental impact. PTFE, while offering excellent properties for surface optimization in robotics, poses potential risks to the environment throughout its lifecycle. During production, the manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that can contaminate water sources and accumulate in living organisms. Although many manufacturers have phased out PFOA, alternative chemicals used may still have environmental implications.

In the application phase, PTFE-coated robotic grippers contribute to improved efficiency and longevity of robotic systems, potentially reducing the overall environmental footprint of industrial processes. However, the wear and tear of PTFE coatings during operation can lead to the release of microplastics into the environment. These microscopic particles can enter water systems and food chains, posing risks to aquatic life and potentially human health.

The disposal of PTFE-coated components at the end of their lifecycle presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrofluoric acid and perfluoroisobutylene, which are toxic and contribute to air pollution. Recycling PTFE is technically challenging and not widely practiced, leading to increased landfill waste.

Despite these concerns, ongoing research is focused on developing more environmentally friendly alternatives and improving PTFE's lifecycle management. Some initiatives include the development of bio-based fluoropolymers, which could reduce reliance on petroleum-derived raw materials. Additionally, advancements in recycling technologies are being explored to enable more efficient recovery and reuse of PTFE materials from discarded robotic components.

The robotics industry is increasingly adopting lifecycle assessment approaches to evaluate and mitigate the environmental impact of materials like PTFE. This holistic view considers factors such as resource depletion, energy consumption, and emissions throughout the material's lifecycle. As a result, some manufacturers are exploring alternative materials or surface treatments that offer similar performance to PTFE but with reduced environmental impact.

Balancing the benefits of PTFE in robotic gripper optimization with its environmental implications remains a challenge for the industry. As environmental regulations become more stringent and public awareness grows, there is a pressing need for continued innovation in materials science and manufacturing processes to develop more sustainable solutions for robotic surface optimization.

In the application phase, PTFE-coated robotic grippers contribute to improved efficiency and longevity of robotic systems, potentially reducing the overall environmental footprint of industrial processes. However, the wear and tear of PTFE coatings during operation can lead to the release of microplastics into the environment. These microscopic particles can enter water systems and food chains, posing risks to aquatic life and potentially human health.

The disposal of PTFE-coated components at the end of their lifecycle presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrofluoric acid and perfluoroisobutylene, which are toxic and contribute to air pollution. Recycling PTFE is technically challenging and not widely practiced, leading to increased landfill waste.

Despite these concerns, ongoing research is focused on developing more environmentally friendly alternatives and improving PTFE's lifecycle management. Some initiatives include the development of bio-based fluoropolymers, which could reduce reliance on petroleum-derived raw materials. Additionally, advancements in recycling technologies are being explored to enable more efficient recovery and reuse of PTFE materials from discarded robotic components.

The robotics industry is increasingly adopting lifecycle assessment approaches to evaluate and mitigate the environmental impact of materials like PTFE. This holistic view considers factors such as resource depletion, energy consumption, and emissions throughout the material's lifecycle. As a result, some manufacturers are exploring alternative materials or surface treatments that offer similar performance to PTFE but with reduced environmental impact.

Balancing the benefits of PTFE in robotic gripper optimization with its environmental implications remains a challenge for the industry. As environmental regulations become more stringent and public awareness grows, there is a pressing need for continued innovation in materials science and manufacturing processes to develop more sustainable solutions for robotic surface optimization.

Standardization and Testing of PTFE-Enhanced Grippers

The standardization and testing of PTFE-enhanced grippers are crucial steps in validating the effectiveness and reliability of this technology in robotic applications. To ensure consistent performance across different manufacturing processes and applications, it is essential to establish standardized testing protocols and evaluation criteria.

One key aspect of standardization involves the development of uniform methods for applying PTFE coatings or incorporating PTFE materials into gripper surfaces. This includes specifying optimal thickness ranges, adhesion requirements, and surface preparation techniques. Standardized application processes help ensure reproducibility and comparability of results across different research and industrial settings.

Testing protocols for PTFE-enhanced grippers should encompass a wide range of performance metrics. These may include grip force measurements, slip resistance under various conditions, wear resistance, and durability over extended use cycles. Standardized test objects with known surface properties and geometries should be utilized to enable consistent comparisons between different gripper designs and PTFE formulations.

Environmental testing is another critical component of the standardization process. PTFE-enhanced grippers should be evaluated under various temperature ranges, humidity levels, and exposure to common industrial contaminants. This helps establish the operational limits and reliability of the grippers in real-world applications.

Longevity testing protocols are essential for assessing the long-term performance of PTFE-enhanced grippers. This involves cyclic testing to simulate repeated gripping operations, as well as accelerated aging tests to predict the degradation of PTFE properties over time. Standardized methods for quantifying changes in surface properties, such as contact angle measurements and surface roughness analyses, should be incorporated into these protocols.

To ensure widespread adoption and comparability of results, it is important to collaborate with industry stakeholders and standards organizations. This may involve working with bodies such as ISO, ASTM, or IEEE to develop and publish formal testing standards for PTFE-enhanced robotic grippers. Such standards would provide a common framework for evaluating and comparing different gripper designs and PTFE formulations across the robotics industry.

One key aspect of standardization involves the development of uniform methods for applying PTFE coatings or incorporating PTFE materials into gripper surfaces. This includes specifying optimal thickness ranges, adhesion requirements, and surface preparation techniques. Standardized application processes help ensure reproducibility and comparability of results across different research and industrial settings.

Testing protocols for PTFE-enhanced grippers should encompass a wide range of performance metrics. These may include grip force measurements, slip resistance under various conditions, wear resistance, and durability over extended use cycles. Standardized test objects with known surface properties and geometries should be utilized to enable consistent comparisons between different gripper designs and PTFE formulations.

Environmental testing is another critical component of the standardization process. PTFE-enhanced grippers should be evaluated under various temperature ranges, humidity levels, and exposure to common industrial contaminants. This helps establish the operational limits and reliability of the grippers in real-world applications.

Longevity testing protocols are essential for assessing the long-term performance of PTFE-enhanced grippers. This involves cyclic testing to simulate repeated gripping operations, as well as accelerated aging tests to predict the degradation of PTFE properties over time. Standardized methods for quantifying changes in surface properties, such as contact angle measurements and surface roughness analyses, should be incorporated into these protocols.

To ensure widespread adoption and comparability of results, it is important to collaborate with industry stakeholders and standards organizations. This may involve working with bodies such as ISO, ASTM, or IEEE to develop and publish formal testing standards for PTFE-enhanced robotic grippers. Such standards would provide a common framework for evaluating and comparing different gripper designs and PTFE formulations across the robotics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!