Assessing structural expansion control in PTFE‑filled composites

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Composite Background

Polytetrafluoroethylene (PTFE) composites have emerged as a significant material in various industrial applications due to their unique combination of properties. PTFE, a synthetic fluoropolymer of tetrafluoroethylene, was discovered accidentally by Roy Plunkett at DuPont in 1938. Its exceptional chemical resistance, low friction coefficient, and high thermal stability quickly made it a valuable material in numerous fields.

The development of PTFE composites began in the 1960s as researchers sought to enhance the mechanical properties of pure PTFE while maintaining its desirable characteristics. By incorporating fillers such as glass fibers, carbon fibers, or mineral particles, scientists were able to create composites with improved wear resistance, dimensional stability, and load-bearing capacity.

Over the years, PTFE composites have found applications in aerospace, automotive, chemical processing, and electronics industries. Their ability to withstand extreme temperatures, resist chemical attack, and provide low friction surfaces has made them indispensable in seals, bearings, and gaskets for demanding environments.

The evolution of PTFE composites has been driven by the need to address specific challenges in various applications. For instance, the development of electrically conductive PTFE composites has opened up new possibilities in EMI shielding and static dissipation applications. Similarly, the creation of nano-filled PTFE composites has led to materials with enhanced mechanical properties and reduced wear rates.

One of the ongoing challenges in PTFE composite technology is controlling structural expansion. PTFE has a relatively high coefficient of thermal expansion compared to many engineering materials, which can lead to dimensional instability in composite structures. This issue becomes particularly critical in applications involving temperature fluctuations or when PTFE composites are used in conjunction with other materials having different thermal expansion characteristics.

Recent research efforts have focused on developing strategies to mitigate the expansion issues in PTFE-filled composites. These include the use of novel filler materials, optimization of filler content and distribution, and the development of hybrid composite systems. Understanding and controlling the structural expansion of PTFE composites is crucial for enhancing their performance and expanding their application range in advanced engineering systems.

As we look towards the future, the field of PTFE composites continues to evolve. Emerging trends include the development of self-lubricating PTFE composites, bio-based fillers for improved sustainability, and smart PTFE composites with sensing capabilities. The ongoing research in this area promises to unlock new possibilities and overcome existing limitations, further cementing the role of PTFE composites in cutting-edge technological applications.

The development of PTFE composites began in the 1960s as researchers sought to enhance the mechanical properties of pure PTFE while maintaining its desirable characteristics. By incorporating fillers such as glass fibers, carbon fibers, or mineral particles, scientists were able to create composites with improved wear resistance, dimensional stability, and load-bearing capacity.

Over the years, PTFE composites have found applications in aerospace, automotive, chemical processing, and electronics industries. Their ability to withstand extreme temperatures, resist chemical attack, and provide low friction surfaces has made them indispensable in seals, bearings, and gaskets for demanding environments.

The evolution of PTFE composites has been driven by the need to address specific challenges in various applications. For instance, the development of electrically conductive PTFE composites has opened up new possibilities in EMI shielding and static dissipation applications. Similarly, the creation of nano-filled PTFE composites has led to materials with enhanced mechanical properties and reduced wear rates.

One of the ongoing challenges in PTFE composite technology is controlling structural expansion. PTFE has a relatively high coefficient of thermal expansion compared to many engineering materials, which can lead to dimensional instability in composite structures. This issue becomes particularly critical in applications involving temperature fluctuations or when PTFE composites are used in conjunction with other materials having different thermal expansion characteristics.

Recent research efforts have focused on developing strategies to mitigate the expansion issues in PTFE-filled composites. These include the use of novel filler materials, optimization of filler content and distribution, and the development of hybrid composite systems. Understanding and controlling the structural expansion of PTFE composites is crucial for enhancing their performance and expanding their application range in advanced engineering systems.

As we look towards the future, the field of PTFE composites continues to evolve. Emerging trends include the development of self-lubricating PTFE composites, bio-based fillers for improved sustainability, and smart PTFE composites with sensing capabilities. The ongoing research in this area promises to unlock new possibilities and overcome existing limitations, further cementing the role of PTFE composites in cutting-edge technological applications.

Market Demand Analysis

The market demand for PTFE-filled composites with controlled structural expansion is experiencing significant growth across various industries. This demand is primarily driven by the unique properties of PTFE, including its low friction coefficient, chemical resistance, and thermal stability, combined with the need for dimensional stability in high-performance applications.

In the aerospace sector, there is a growing requirement for materials that can withstand extreme temperatures and maintain their structural integrity. PTFE-filled composites with controlled expansion are increasingly being used in aircraft components, satellite systems, and space exploration equipment. The market in this sector is expected to expand as space exploration and commercial space flight activities increase.

The automotive industry is another major driver of demand for these materials. As vehicles become more advanced and incorporate more electronic components, the need for materials that can maintain their properties under varying temperatures and environmental conditions grows. PTFE-filled composites are being utilized in engine components, seals, and bearings, where controlled expansion is crucial for maintaining performance and longevity.

In the electronics sector, the miniaturization trend and the need for reliable performance in diverse environments are fueling the demand for PTFE-filled composites. These materials are used in printed circuit boards, connectors, and insulation components where dimensional stability is paramount. The rapid growth of 5G technology and the Internet of Things (IoT) is expected to further boost this demand.

The chemical processing industry is also a significant consumer of PTFE-filled composites with controlled expansion. These materials are used in pumps, valves, and seals that are exposed to corrosive chemicals and extreme temperatures. The growing emphasis on process efficiency and safety in chemical plants is likely to drive further adoption of these materials.

In the medical field, PTFE-filled composites are finding applications in implants, surgical instruments, and diagnostic equipment. The biocompatibility of PTFE, combined with controlled expansion properties, makes these materials ideal for use in the human body. As the global population ages and healthcare technologies advance, this market segment is poised for substantial growth.

The energy sector, particularly in oil and gas exploration and renewable energy technologies, is another area where demand for these materials is increasing. PTFE-filled composites are used in seals, gaskets, and insulation materials in harsh environments where temperature fluctuations and chemical exposure are common.

Overall, the market for PTFE-filled composites with controlled structural expansion is expected to grow steadily in the coming years. This growth is driven by the increasing need for high-performance materials in advanced applications across multiple industries. As research and development in this field continue, new applications and improved properties are likely to emerge, further expanding the market potential for these innovative materials.

In the aerospace sector, there is a growing requirement for materials that can withstand extreme temperatures and maintain their structural integrity. PTFE-filled composites with controlled expansion are increasingly being used in aircraft components, satellite systems, and space exploration equipment. The market in this sector is expected to expand as space exploration and commercial space flight activities increase.

The automotive industry is another major driver of demand for these materials. As vehicles become more advanced and incorporate more electronic components, the need for materials that can maintain their properties under varying temperatures and environmental conditions grows. PTFE-filled composites are being utilized in engine components, seals, and bearings, where controlled expansion is crucial for maintaining performance and longevity.

In the electronics sector, the miniaturization trend and the need for reliable performance in diverse environments are fueling the demand for PTFE-filled composites. These materials are used in printed circuit boards, connectors, and insulation components where dimensional stability is paramount. The rapid growth of 5G technology and the Internet of Things (IoT) is expected to further boost this demand.

The chemical processing industry is also a significant consumer of PTFE-filled composites with controlled expansion. These materials are used in pumps, valves, and seals that are exposed to corrosive chemicals and extreme temperatures. The growing emphasis on process efficiency and safety in chemical plants is likely to drive further adoption of these materials.

In the medical field, PTFE-filled composites are finding applications in implants, surgical instruments, and diagnostic equipment. The biocompatibility of PTFE, combined with controlled expansion properties, makes these materials ideal for use in the human body. As the global population ages and healthcare technologies advance, this market segment is poised for substantial growth.

The energy sector, particularly in oil and gas exploration and renewable energy technologies, is another area where demand for these materials is increasing. PTFE-filled composites are used in seals, gaskets, and insulation materials in harsh environments where temperature fluctuations and chemical exposure are common.

Overall, the market for PTFE-filled composites with controlled structural expansion is expected to grow steadily in the coming years. This growth is driven by the increasing need for high-performance materials in advanced applications across multiple industries. As research and development in this field continue, new applications and improved properties are likely to emerge, further expanding the market potential for these innovative materials.

Technical Challenges

The development of PTFE-filled composites faces several significant technical challenges that require innovative solutions. One of the primary obstacles is controlling the structural expansion of these materials, which is crucial for maintaining their dimensional stability and performance under various environmental conditions.

A major challenge lies in the inherent thermal expansion properties of PTFE. This material exhibits a high coefficient of thermal expansion (CTE), which can lead to significant dimensional changes when subjected to temperature fluctuations. In composite structures, this expansion can cause internal stresses, delamination, and potential failure of the material. Balancing the expansion characteristics of PTFE with other composite components is a complex task that demands precise engineering and material science expertise.

Another technical hurdle is the interface compatibility between PTFE and other materials in the composite. PTFE's low surface energy and non-stick properties, while beneficial in many applications, can lead to poor adhesion with matrix materials. This weak interfacial bonding can result in reduced mechanical strength and compromised overall performance of the composite. Developing effective surface treatment methods or coupling agents to enhance the PTFE-matrix interface without compromising the desirable properties of PTFE remains a significant challenge.

The processing of PTFE-filled composites also presents technical difficulties. PTFE's high melting point and melt viscosity make it challenging to achieve uniform dispersion within the composite matrix. Inadequate dispersion can lead to inconsistent material properties and reduced performance. Additionally, the processing temperatures required for PTFE can be detrimental to other components in the composite, necessitating careful selection of compatible materials and processing techniques.

Controlling the crystallinity of PTFE within the composite structure is another critical challenge. The degree of crystallinity significantly affects the mechanical and thermal properties of the material. Achieving the optimal balance of crystalline and amorphous regions in PTFE, while considering the influence of other composite components and processing conditions, requires sophisticated control mechanisms and in-depth understanding of polymer physics.

Furthermore, predicting and modeling the long-term behavior of PTFE-filled composites under various environmental conditions and stress states remains a complex task. The interaction between PTFE and other materials in the composite can lead to unexpected changes in properties over time, particularly under cyclic loading or extreme temperatures. Developing accurate predictive models and accelerated testing methods to assess long-term performance and structural integrity is essential for the reliable application of these materials in critical industries.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in materials science, polymer chemistry, mechanical engineering, and advanced manufacturing techniques. Overcoming these hurdles will be crucial for expanding the application range of PTFE-filled composites and fully leveraging their unique properties in demanding industrial applications.

A major challenge lies in the inherent thermal expansion properties of PTFE. This material exhibits a high coefficient of thermal expansion (CTE), which can lead to significant dimensional changes when subjected to temperature fluctuations. In composite structures, this expansion can cause internal stresses, delamination, and potential failure of the material. Balancing the expansion characteristics of PTFE with other composite components is a complex task that demands precise engineering and material science expertise.

Another technical hurdle is the interface compatibility between PTFE and other materials in the composite. PTFE's low surface energy and non-stick properties, while beneficial in many applications, can lead to poor adhesion with matrix materials. This weak interfacial bonding can result in reduced mechanical strength and compromised overall performance of the composite. Developing effective surface treatment methods or coupling agents to enhance the PTFE-matrix interface without compromising the desirable properties of PTFE remains a significant challenge.

The processing of PTFE-filled composites also presents technical difficulties. PTFE's high melting point and melt viscosity make it challenging to achieve uniform dispersion within the composite matrix. Inadequate dispersion can lead to inconsistent material properties and reduced performance. Additionally, the processing temperatures required for PTFE can be detrimental to other components in the composite, necessitating careful selection of compatible materials and processing techniques.

Controlling the crystallinity of PTFE within the composite structure is another critical challenge. The degree of crystallinity significantly affects the mechanical and thermal properties of the material. Achieving the optimal balance of crystalline and amorphous regions in PTFE, while considering the influence of other composite components and processing conditions, requires sophisticated control mechanisms and in-depth understanding of polymer physics.

Furthermore, predicting and modeling the long-term behavior of PTFE-filled composites under various environmental conditions and stress states remains a complex task. The interaction between PTFE and other materials in the composite can lead to unexpected changes in properties over time, particularly under cyclic loading or extreme temperatures. Developing accurate predictive models and accelerated testing methods to assess long-term performance and structural integrity is essential for the reliable application of these materials in critical industries.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in materials science, polymer chemistry, mechanical engineering, and advanced manufacturing techniques. Overcoming these hurdles will be crucial for expanding the application range of PTFE-filled composites and fully leveraging their unique properties in demanding industrial applications.

Current Control Methods

01 PTFE-filled composite materials for structural applications

PTFE-filled composites are used in structural applications due to their unique properties. These composites combine the low friction and chemical resistance of PTFE with the strength and stability of other materials, making them suitable for various structural components that require expansion capabilities.- PTFE-filled composite materials for structural applications: PTFE-filled composites are used in structural applications due to their unique properties. These composites combine the low friction and chemical resistance of PTFE with the strength and stability of other materials, making them suitable for various structural components that require expansion capabilities.

- Thermal expansion control in PTFE-filled composites: The thermal expansion of PTFE-filled composites can be controlled by adjusting the filler content and type. This allows for the creation of materials with specific expansion characteristics, which is crucial for applications where dimensional stability under varying temperatures is required.

- Manufacturing processes for PTFE-filled composite structures: Various manufacturing processes are employed to create PTFE-filled composite structures with controlled expansion properties. These may include compression molding, extrusion, and sintering techniques, which allow for the precise control of material composition and structural characteristics.

- Applications of PTFE-filled composites in expandable structures: PTFE-filled composites are utilized in expandable structures such as seals, gaskets, and expansion joints. These materials can accommodate structural movements while maintaining their integrity and performance, making them ideal for applications in various industries including aerospace, automotive, and construction.

- Enhancing mechanical properties of PTFE-filled composites: Research focuses on improving the mechanical properties of PTFE-filled composites to enhance their structural performance. This includes optimizing filler distribution, incorporating reinforcing fibers, and developing novel processing techniques to achieve better strength, stiffness, and expansion characteristics.

02 Thermal expansion control in PTFE composites

The thermal expansion of PTFE-filled composites can be controlled by adjusting the filler content and type. This allows for the creation of materials with specific expansion characteristics, which is crucial for applications where dimensional stability under varying temperatures is required.Expand Specific Solutions03 Manufacturing processes for PTFE-filled expandable composites

Various manufacturing processes are employed to create PTFE-filled composites with controlled expansion properties. These may include compression molding, extrusion, and sintering techniques, which allow for the precise control of material composition and structure.Expand Specific Solutions04 Applications of PTFE-filled composites in sealing and gasket technology

PTFE-filled composites are widely used in sealing and gasket applications where controlled expansion is crucial. These materials can provide effective sealing under various temperature and pressure conditions, making them ideal for use in industries such as automotive, aerospace, and chemical processing.Expand Specific Solutions05 Nanocomposites with PTFE for enhanced expansion properties

Research is being conducted on PTFE-based nanocomposites to achieve enhanced expansion properties. By incorporating nanoparticles or nanofibers into the PTFE matrix, it is possible to create materials with improved thermal expansion characteristics and mechanical properties.Expand Specific Solutions

Key Industry Players

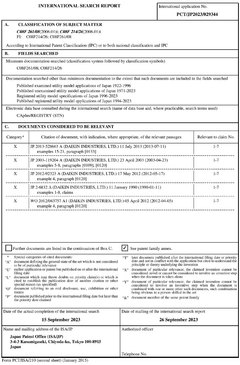

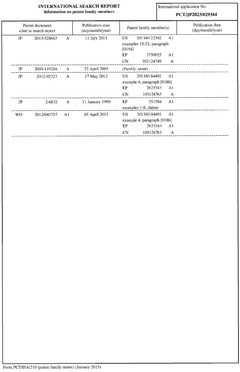

The structural expansion control in PTFE-filled composites market is in a growth phase, driven by increasing demand across various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing performance and sustainability. Key players like W. L. Gore & Associates, DAIKIN INDUSTRIES, and The Chemours Co. are leading the market with advanced R&D capabilities and extensive product portfolios. Emerging companies such as Shandong Dongyue Polymer Material Co. Ltd. and Chengdu Xirui Fangxiao Technology Co., Ltd. are also contributing to market dynamics with specialized offerings and regional focus.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-filled composites with controlled structural expansion. Their approach involves a unique microstructure design that incorporates PTFE particles within a polymer matrix. This design allows for precise control of thermal expansion and mechanical properties. The company utilizes a proprietary manufacturing process that involves careful selection of PTFE particle size, distribution, and orientation within the composite[1]. Additionally, they have implemented surface modification techniques to enhance the interfacial bonding between PTFE particles and the matrix material, resulting in improved overall performance[3].

Strengths: Excellent control over thermal expansion, superior mechanical properties, and enhanced chemical resistance. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

DAIKIN INDUSTRIES Ltd.

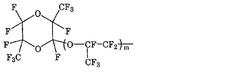

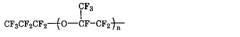

Technical Solution: DAIKIN has developed a novel approach to control structural expansion in PTFE-filled composites through their proprietary "OPTOOL" technology. This method involves the use of fluoropolymer nanoparticles with carefully engineered surface properties. The nanoparticles are dispersed throughout the composite matrix, creating a network that effectively controls thermal expansion. DAIKIN's process also incorporates a unique curing method that optimizes the interaction between the PTFE filler and the matrix material[2]. This results in composites with significantly reduced coefficient of thermal expansion (CTE) compared to conventional PTFE-filled materials[4].

Strengths: Excellent thermal stability, improved dimensional accuracy, and enhanced wear resistance. Weaknesses: Potential challenges in achieving uniform dispersion of nanoparticles and higher material costs.

Innovative Solutions

Modified polytetrafluoroethylene

PatentPendingEP4570838A1

Innovation

- A modified PTFE is developed by incorporating a tetrafluoroethylene (TFE) unit and a chlorotrifluoroethylene (CTFE) unit, with the CTFE unit present in an amount of 1.0% by mass or less, resulting in a polymer with enhanced expandability and improved mechanical properties.

Polytetrafluoroethylene composition

PatentWO2019225434A1

Innovation

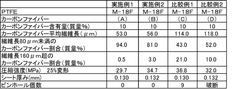

- A PTFE composition comprising PTFE and a fibrous filler with an average fiber length of 100 μm or less and a proportion of fiber lengths exceeding 160 μm of 15% or less, preferably using carbon or glass fibers, which enhances mechanical strength and stretchability.

Environmental Impact

The environmental impact of PTFE-filled composites, particularly in the context of structural expansion control, is a critical consideration in their development and application. These materials, while offering significant advantages in terms of performance and durability, also present unique environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of PTFE-filled composites involves energy-intensive processes and the use of potentially harmful chemicals. The synthesis of PTFE itself requires fluorine-based compounds, which can contribute to greenhouse gas emissions if not properly managed. Additionally, the incorporation of fillers into the PTFE matrix may involve additional processing steps that consume energy and resources.

In terms of product use, PTFE-filled composites generally exhibit excellent longevity and resistance to wear, which can lead to reduced replacement frequency and, consequently, lower overall material consumption. This durability aspect positively contributes to resource conservation and waste reduction. However, the expansion control properties of these composites may necessitate the use of additional materials or structures, potentially increasing the overall environmental footprint of the final product.

End-of-life considerations for PTFE-filled composites present significant challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling of these composites is complex due to the heterogeneous nature of the material, often requiring specialized processes that may not be widely available. Incineration of PTFE-containing materials can release harmful substances, including fluorinated compounds, necessitating advanced emission control systems.

The potential for microplastic pollution is another environmental concern associated with PTFE-filled composites. As these materials wear over time, they may release microscopic particles into the environment, contributing to the growing issue of microplastic contamination in ecosystems.

On the positive side, the use of PTFE-filled composites in certain applications can lead to improved energy efficiency and reduced emissions. For instance, in automotive and aerospace industries, the lightweight nature and low friction properties of these materials can contribute to fuel savings and decreased carbon emissions over the lifespan of vehicles and aircraft.

Research into more environmentally friendly alternatives and improved recycling technologies for PTFE-filled composites is ongoing. Efforts are being made to develop bio-based fillers, explore alternative polymer matrices with similar properties to PTFE, and enhance end-of-life management strategies. These initiatives aim to mitigate the environmental impact while maintaining the beneficial properties of structural expansion control in composite materials.

During the production phase, the manufacturing of PTFE-filled composites involves energy-intensive processes and the use of potentially harmful chemicals. The synthesis of PTFE itself requires fluorine-based compounds, which can contribute to greenhouse gas emissions if not properly managed. Additionally, the incorporation of fillers into the PTFE matrix may involve additional processing steps that consume energy and resources.

In terms of product use, PTFE-filled composites generally exhibit excellent longevity and resistance to wear, which can lead to reduced replacement frequency and, consequently, lower overall material consumption. This durability aspect positively contributes to resource conservation and waste reduction. However, the expansion control properties of these composites may necessitate the use of additional materials or structures, potentially increasing the overall environmental footprint of the final product.

End-of-life considerations for PTFE-filled composites present significant challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling of these composites is complex due to the heterogeneous nature of the material, often requiring specialized processes that may not be widely available. Incineration of PTFE-containing materials can release harmful substances, including fluorinated compounds, necessitating advanced emission control systems.

The potential for microplastic pollution is another environmental concern associated with PTFE-filled composites. As these materials wear over time, they may release microscopic particles into the environment, contributing to the growing issue of microplastic contamination in ecosystems.

On the positive side, the use of PTFE-filled composites in certain applications can lead to improved energy efficiency and reduced emissions. For instance, in automotive and aerospace industries, the lightweight nature and low friction properties of these materials can contribute to fuel savings and decreased carbon emissions over the lifespan of vehicles and aircraft.

Research into more environmentally friendly alternatives and improved recycling technologies for PTFE-filled composites is ongoing. Efforts are being made to develop bio-based fillers, explore alternative polymer matrices with similar properties to PTFE, and enhance end-of-life management strategies. These initiatives aim to mitigate the environmental impact while maintaining the beneficial properties of structural expansion control in composite materials.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of PTFE-filled composites for structural expansion control. As these materials are increasingly used in various industries, including aerospace, automotive, and construction, adherence to relevant regulations and standards is essential to ensure safety, performance, and environmental protection.

In the United States, the Environmental Protection Agency (EPA) regulates the use of PTFE under the Toxic Substances Control Act (TSCA). Manufacturers and importers of PTFE-filled composites must comply with reporting requirements and potential restrictions on the production, use, and disposal of these materials. Additionally, the Occupational Safety and Health Administration (OSHA) sets guidelines for worker safety when handling PTFE and its composites during manufacturing and installation processes.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of PTFE-filled composites. Companies operating in or exporting to the EU must register PTFE and its associated substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, risks, and safe use.

For applications in the construction industry, compliance with building codes and standards is paramount. In the United States, the International Building Code (IBC) and ASTM International standards provide guidelines for the use of expansion control materials, including PTFE-filled composites. These standards outline requirements for fire resistance, durability, and performance under various environmental conditions.

In the aerospace sector, stringent regulations govern the use of materials in aircraft construction. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) set forth requirements for materials used in aircraft structures, including those for expansion control. Compliance with these regulations often involves extensive testing and certification processes to demonstrate the safety and reliability of PTFE-filled composites in aerospace applications.

Environmental considerations also factor into regulatory compliance for PTFE-filled composites. As concerns about per- and polyfluoroalkyl substances (PFAS) grow, manufacturers must be aware of potential future regulations limiting the use of fluoropolymers like PTFE. Some jurisdictions have already implemented restrictions on certain PFAS compounds, which may indirectly affect the production and use of PTFE-filled composites.

To ensure ongoing compliance, companies working with PTFE-filled composites for structural expansion control must stay informed about evolving regulations across different regions and industries. This may involve regular audits, updating safety data sheets, and participating in industry associations to stay abreast of regulatory changes. Furthermore, investing in research and development to find alternative materials or improve existing formulations can help companies adapt to stricter regulatory environments while maintaining product performance and safety.

In the United States, the Environmental Protection Agency (EPA) regulates the use of PTFE under the Toxic Substances Control Act (TSCA). Manufacturers and importers of PTFE-filled composites must comply with reporting requirements and potential restrictions on the production, use, and disposal of these materials. Additionally, the Occupational Safety and Health Administration (OSHA) sets guidelines for worker safety when handling PTFE and its composites during manufacturing and installation processes.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of PTFE-filled composites. Companies operating in or exporting to the EU must register PTFE and its associated substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, risks, and safe use.

For applications in the construction industry, compliance with building codes and standards is paramount. In the United States, the International Building Code (IBC) and ASTM International standards provide guidelines for the use of expansion control materials, including PTFE-filled composites. These standards outline requirements for fire resistance, durability, and performance under various environmental conditions.

In the aerospace sector, stringent regulations govern the use of materials in aircraft construction. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) set forth requirements for materials used in aircraft structures, including those for expansion control. Compliance with these regulations often involves extensive testing and certification processes to demonstrate the safety and reliability of PTFE-filled composites in aerospace applications.

Environmental considerations also factor into regulatory compliance for PTFE-filled composites. As concerns about per- and polyfluoroalkyl substances (PFAS) grow, manufacturers must be aware of potential future regulations limiting the use of fluoropolymers like PTFE. Some jurisdictions have already implemented restrictions on certain PFAS compounds, which may indirectly affect the production and use of PTFE-filled composites.

To ensure ongoing compliance, companies working with PTFE-filled composites for structural expansion control must stay informed about evolving regulations across different regions and industries. This may involve regular audits, updating safety data sheets, and participating in industry associations to stay abreast of regulatory changes. Furthermore, investing in research and development to find alternative materials or improve existing formulations can help companies adapt to stricter regulatory environments while maintaining product performance and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!