Battery Pack Integration in Hybrid Power Engineered Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Power Battery Integration Background and Objectives

The integration of battery packs into hybrid power engineered systems represents a critical technological evolution in the pursuit of more efficient, sustainable, and versatile power solutions. This technological domain has evolved significantly over the past two decades, transitioning from rudimentary hybrid configurations to sophisticated energy management systems that optimize the interplay between conventional power sources and battery storage.

The historical trajectory of battery pack integration began with simple parallel configurations in early hybrid vehicles around the early 2000s, where batteries primarily served auxiliary functions. By the 2010s, more complex integration architectures emerged, enabling dynamic power distribution and regenerative capabilities across various applications including automotive, marine, aerospace, and stationary power systems.

Current technological trends indicate a shift toward modular battery pack designs that facilitate scalability, serviceability, and thermal management optimization. The industry is witnessing increased emphasis on battery management systems (BMS) that enable real-time monitoring, predictive maintenance, and adaptive control strategies to maximize battery lifespan and system efficiency.

The primary objectives of battery pack integration in hybrid systems encompass several dimensions. Technical objectives include achieving optimal power density-to-weight ratios, minimizing thermal constraints, and ensuring seamless power transitions between different energy sources. Performance objectives focus on extending operational range, reducing fuel consumption, and maintaining consistent power delivery across varying load conditions.

Economic considerations drive objectives related to total cost of ownership reduction, including initial capital expenditure optimization and operational cost minimization through intelligent energy management. Meanwhile, sustainability objectives target emissions reduction, resource conservation, and end-of-life recyclability of battery components.

Safety and reliability remain paramount objectives, with emphasis on thermal runaway prevention, structural integrity during impact scenarios, and fail-safe operational protocols. These objectives are increasingly shaped by evolving regulatory frameworks across different regions and application domains.

The technological roadmap for battery pack integration is increasingly influenced by advances in materials science, particularly in electrode compositions and electrolyte formulations that promise higher energy densities and faster charging capabilities. Simultaneously, computational modeling and digital twin technologies are enabling more sophisticated simulation of battery behavior under diverse operational conditions, accelerating the development cycle.

As the field progresses, the convergence of battery technology with artificial intelligence and edge computing is expected to enable more adaptive and predictive energy management strategies, further optimizing the performance of hybrid power systems across diverse applications and operational environments.

The historical trajectory of battery pack integration began with simple parallel configurations in early hybrid vehicles around the early 2000s, where batteries primarily served auxiliary functions. By the 2010s, more complex integration architectures emerged, enabling dynamic power distribution and regenerative capabilities across various applications including automotive, marine, aerospace, and stationary power systems.

Current technological trends indicate a shift toward modular battery pack designs that facilitate scalability, serviceability, and thermal management optimization. The industry is witnessing increased emphasis on battery management systems (BMS) that enable real-time monitoring, predictive maintenance, and adaptive control strategies to maximize battery lifespan and system efficiency.

The primary objectives of battery pack integration in hybrid systems encompass several dimensions. Technical objectives include achieving optimal power density-to-weight ratios, minimizing thermal constraints, and ensuring seamless power transitions between different energy sources. Performance objectives focus on extending operational range, reducing fuel consumption, and maintaining consistent power delivery across varying load conditions.

Economic considerations drive objectives related to total cost of ownership reduction, including initial capital expenditure optimization and operational cost minimization through intelligent energy management. Meanwhile, sustainability objectives target emissions reduction, resource conservation, and end-of-life recyclability of battery components.

Safety and reliability remain paramount objectives, with emphasis on thermal runaway prevention, structural integrity during impact scenarios, and fail-safe operational protocols. These objectives are increasingly shaped by evolving regulatory frameworks across different regions and application domains.

The technological roadmap for battery pack integration is increasingly influenced by advances in materials science, particularly in electrode compositions and electrolyte formulations that promise higher energy densities and faster charging capabilities. Simultaneously, computational modeling and digital twin technologies are enabling more sophisticated simulation of battery behavior under diverse operational conditions, accelerating the development cycle.

As the field progresses, the convergence of battery technology with artificial intelligence and edge computing is expected to enable more adaptive and predictive energy management strategies, further optimizing the performance of hybrid power systems across diverse applications and operational environments.

Market Analysis for Hybrid Power Systems

The hybrid power systems market is experiencing robust growth, driven by increasing demand for reliable, efficient, and environmentally sustainable power solutions across various sectors. The global market for hybrid power systems was valued at approximately $4.5 billion in 2022 and is projected to reach $7.2 billion by 2028, representing a compound annual growth rate (CAGR) of 8.1%. This growth trajectory is particularly pronounced in regions with unreliable grid infrastructure or remote locations where traditional power solutions are impractical.

Key market segments for hybrid power systems include telecommunications, residential and commercial buildings, industrial applications, and remote military installations. The telecommunications sector currently represents the largest market share at 32%, as telecom companies increasingly adopt hybrid solutions to ensure uninterrupted service in areas with unstable power supply. The industrial sector follows closely at 28%, driven by the need for reliable backup power and reduced operational costs.

Geographically, Asia-Pacific dominates the market with a 35% share, fueled by rapid industrialization, expanding telecom infrastructure, and government initiatives promoting renewable energy integration. North America and Europe collectively account for 45% of the market, with growth primarily driven by sustainability goals and the modernization of aging power infrastructure.

Consumer demand patterns reveal a strong preference for systems that combine solar photovoltaic technology with battery storage, accounting for 42% of all hybrid power installations. Wind-diesel-battery configurations represent another significant segment at 27%, particularly in regions with favorable wind conditions.

Market research indicates that cost reduction remains the primary adoption driver, with organizations reporting average operational cost savings of 25-30% after implementing hybrid power solutions. Environmental considerations rank as the second most important factor, with 68% of surveyed organizations citing carbon footprint reduction as a key decision criterion.

The competitive landscape is characterized by both established power equipment manufacturers and emerging specialized providers. Major players include Siemens, ABB, General Electric, and Schneider Electric, who collectively hold approximately 45% market share. However, innovative startups focusing exclusively on hybrid power solutions are gaining traction, capturing an additional 15% of the market in the past three years.

Customer satisfaction metrics indicate that reliability (rated 4.7/5) and fuel efficiency (rated 4.5/5) are the most valued performance attributes of hybrid power systems. Integration complexity and initial capital costs remain the primary barriers to adoption, with 58% of potential customers citing these factors as significant concerns.

Key market segments for hybrid power systems include telecommunications, residential and commercial buildings, industrial applications, and remote military installations. The telecommunications sector currently represents the largest market share at 32%, as telecom companies increasingly adopt hybrid solutions to ensure uninterrupted service in areas with unstable power supply. The industrial sector follows closely at 28%, driven by the need for reliable backup power and reduced operational costs.

Geographically, Asia-Pacific dominates the market with a 35% share, fueled by rapid industrialization, expanding telecom infrastructure, and government initiatives promoting renewable energy integration. North America and Europe collectively account for 45% of the market, with growth primarily driven by sustainability goals and the modernization of aging power infrastructure.

Consumer demand patterns reveal a strong preference for systems that combine solar photovoltaic technology with battery storage, accounting for 42% of all hybrid power installations. Wind-diesel-battery configurations represent another significant segment at 27%, particularly in regions with favorable wind conditions.

Market research indicates that cost reduction remains the primary adoption driver, with organizations reporting average operational cost savings of 25-30% after implementing hybrid power solutions. Environmental considerations rank as the second most important factor, with 68% of surveyed organizations citing carbon footprint reduction as a key decision criterion.

The competitive landscape is characterized by both established power equipment manufacturers and emerging specialized providers. Major players include Siemens, ABB, General Electric, and Schneider Electric, who collectively hold approximately 45% market share. However, innovative startups focusing exclusively on hybrid power solutions are gaining traction, capturing an additional 15% of the market in the past three years.

Customer satisfaction metrics indicate that reliability (rated 4.7/5) and fuel efficiency (rated 4.5/5) are the most valued performance attributes of hybrid power systems. Integration complexity and initial capital costs remain the primary barriers to adoption, with 58% of potential customers citing these factors as significant concerns.

Battery Pack Technology Landscape and Challenges

Battery pack technology has evolved significantly over the past decade, transitioning from simple energy storage components to sophisticated systems that integrate advanced battery management, thermal regulation, and safety features. The landscape is characterized by a diverse range of chemistries, with lithium-ion dominating due to its high energy density and relatively long cycle life. However, emerging technologies such as solid-state batteries, lithium-sulfur, and sodium-ion batteries are gaining traction as potential alternatives that address some of the limitations of conventional lithium-ion systems.

The integration of battery packs in hybrid power engineered systems presents unique challenges that span multiple domains. Energy density remains a primary concern, with current lithium-ion technologies typically delivering 150-250 Wh/kg at the cell level, but only 100-150 Wh/kg at the pack level due to packaging inefficiencies. This energy density gap significantly impacts the overall system performance, particularly in weight-sensitive applications like electric vehicles and portable power systems.

Thermal management represents another critical challenge, as battery performance, safety, and longevity are highly temperature-dependent. Hybrid systems often operate under variable load conditions, creating complex thermal profiles that must be managed effectively. Current cooling solutions range from passive air cooling to sophisticated liquid cooling systems, each with trade-offs between complexity, cost, and effectiveness.

Safety concerns continue to be paramount in battery pack design, with thermal runaway being the most significant risk. The integration of battery packs with other power sources in hybrid systems introduces additional failure modes and safety considerations that must be addressed through robust design practices, advanced monitoring systems, and effective isolation mechanisms.

Standardization remains underdeveloped across the industry, with limited consensus on design approaches, testing protocols, and integration methodologies. This lack of standardization complicates system design and increases development costs, particularly for smaller manufacturers without extensive in-house expertise.

Cost factors present ongoing challenges, with battery packs typically representing 30-40% of the total system cost in many hybrid applications. While cell costs have decreased substantially (from approximately $1,000/kWh in 2010 to $130/kWh in 2022), pack-level costs have not declined at the same rate due to persistent challenges in manufacturing automation, quality control, and integration.

Recycling and sustainability considerations are increasingly important, with current recycling rates for lithium-ion batteries remaining below 5% globally. The complex mixture of materials in modern battery packs makes efficient recycling technically challenging and often economically unviable without regulatory incentives or technological breakthroughs.

The integration of battery packs in hybrid power engineered systems presents unique challenges that span multiple domains. Energy density remains a primary concern, with current lithium-ion technologies typically delivering 150-250 Wh/kg at the cell level, but only 100-150 Wh/kg at the pack level due to packaging inefficiencies. This energy density gap significantly impacts the overall system performance, particularly in weight-sensitive applications like electric vehicles and portable power systems.

Thermal management represents another critical challenge, as battery performance, safety, and longevity are highly temperature-dependent. Hybrid systems often operate under variable load conditions, creating complex thermal profiles that must be managed effectively. Current cooling solutions range from passive air cooling to sophisticated liquid cooling systems, each with trade-offs between complexity, cost, and effectiveness.

Safety concerns continue to be paramount in battery pack design, with thermal runaway being the most significant risk. The integration of battery packs with other power sources in hybrid systems introduces additional failure modes and safety considerations that must be addressed through robust design practices, advanced monitoring systems, and effective isolation mechanisms.

Standardization remains underdeveloped across the industry, with limited consensus on design approaches, testing protocols, and integration methodologies. This lack of standardization complicates system design and increases development costs, particularly for smaller manufacturers without extensive in-house expertise.

Cost factors present ongoing challenges, with battery packs typically representing 30-40% of the total system cost in many hybrid applications. While cell costs have decreased substantially (from approximately $1,000/kWh in 2010 to $130/kWh in 2022), pack-level costs have not declined at the same rate due to persistent challenges in manufacturing automation, quality control, and integration.

Recycling and sustainability considerations are increasingly important, with current recycling rates for lithium-ion batteries remaining below 5% globally. The complex mixture of materials in modern battery packs makes efficient recycling technically challenging and often economically unviable without regulatory incentives or technological breakthroughs.

Current Battery Pack Integration Solutions

01 Battery Pack Structural Integration

Various structural designs for integrating battery packs into vehicles and devices, focusing on mechanical mounting systems, housing configurations, and physical integration methods. These designs address challenges related to space optimization, weight distribution, and structural integrity while ensuring proper protection of battery cells from environmental factors and mechanical stress.- Battery pack thermal management systems: Thermal management systems are crucial for battery pack integration to maintain optimal operating temperatures and prevent overheating. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to ensure battery safety and longevity. Effective thermal management improves battery performance, extends lifespan, and prevents thermal runaway situations in various applications including electric vehicles and portable electronics.

- Structural integration of battery packs in vehicles: Battery packs can be structurally integrated into vehicles to optimize space utilization and weight distribution. This approach involves designing battery housings that serve dual purposes as both energy storage and structural components of the vehicle chassis. Such integration enhances vehicle rigidity, improves crash safety, and maximizes interior space while maintaining proper weight balance for better handling and performance.

- Battery management systems for monitoring and control: Battery management systems (BMS) are essential for monitoring and controlling battery pack performance. These systems track parameters such as voltage, current, state of charge, and cell balancing to ensure safe and efficient operation. Advanced BMS implementations include predictive analytics for battery health, fault detection algorithms, and communication interfaces that enable integration with broader energy management systems in applications ranging from consumer electronics to grid storage.

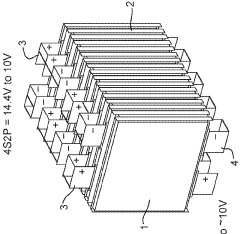

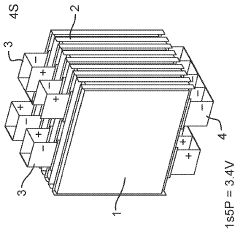

- Modular battery pack designs for scalability: Modular battery pack designs enable scalable energy storage solutions that can be adapted to different applications and power requirements. These systems feature standardized battery modules that can be connected in series or parallel configurations to achieve desired voltage and capacity specifications. Modular approaches facilitate easier maintenance, replacement of individual components, and system upgrades while maintaining compatibility with existing infrastructure.

- Battery pack integration with renewable energy systems: Battery packs can be integrated with renewable energy systems such as solar panels and wind turbines to store excess energy for later use. These integrated systems include power conversion equipment, energy management controllers, and grid connection interfaces that enable seamless operation between energy generation, storage, and consumption. Such integration improves the reliability of renewable energy sources by addressing intermittency issues and providing consistent power output regardless of weather conditions.

02 Thermal Management Systems

Thermal management solutions for battery packs that maintain optimal operating temperatures through cooling and heating mechanisms. These systems include liquid cooling circuits, air cooling channels, heat exchangers, and thermal interface materials designed to dissipate heat efficiently from battery cells, preventing thermal runaway and extending battery life while ensuring consistent performance across various operating conditions.Expand Specific Solutions03 Battery Management and Control Systems

Electronic control systems for monitoring and managing battery pack performance, including voltage regulation, charge/discharge control, and cell balancing. These systems incorporate sensors, microcontrollers, and communication interfaces to optimize battery utilization, prevent overcharging or deep discharging, and provide diagnostic information about battery health and status to users or main control systems.Expand Specific Solutions04 Modular Battery Pack Designs

Modular approaches to battery pack design that allow for scalable configurations, easy maintenance, and replacement of individual components. These designs feature standardized battery modules that can be combined in various arrangements to meet specific power requirements, simplifying manufacturing, servicing, and upgrading of battery systems while providing flexibility for different applications and power needs.Expand Specific Solutions05 Safety and Protection Mechanisms

Safety features integrated into battery packs to prevent hazardous conditions such as short circuits, overheating, and mechanical damage. These mechanisms include isolation systems, fuses, circuit breakers, pressure relief valves, and reinforced enclosures designed to contain failures and prevent cascading thermal events, ensuring safe operation even under abnormal conditions or in case of accidents.Expand Specific Solutions

Key Industry Players in Hybrid Power Systems

The battery pack integration market in hybrid power engineered systems is currently in a growth phase, with increasing demand driven by electrification trends across multiple industries. The market size is expanding rapidly, projected to reach significant volumes as automotive and industrial sectors transition to hybrid solutions. Technologically, the field shows varying maturity levels, with established players like Robert Bosch GmbH, Samsung SDI, and LG Energy Solution leading with advanced integration capabilities. Automotive OEMs such as Ford, GM, and Changan are accelerating development, while specialized innovators like Rimac Technology are pushing boundaries in high-performance applications. The competitive landscape features traditional tier-1 suppliers competing with battery manufacturers and emerging technology companies, creating a dynamic ecosystem where cross-industry partnerships are becoming increasingly critical for market success.

Robert Bosch GmbH

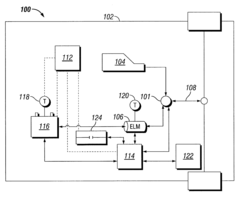

Technical Solution: Bosch has developed an integrated Battery Management System (BMS) for hybrid power systems that combines hardware and software solutions to optimize battery performance and longevity. Their system features cell balancing technology that ensures uniform charge distribution across all cells, extending battery life by up to 25%. The BMS incorporates predictive analytics algorithms that continuously monitor battery health parameters and adapt charging strategies accordingly. Bosch's thermal management solution uses a liquid cooling system integrated directly into the battery pack structure, maintaining optimal operating temperatures between 15-35°C even under high load conditions. Their modular design approach allows for scalable integration across various vehicle platforms, from mild hybrids to plug-in hybrid systems, with standardized communication protocols enabling seamless integration with existing vehicle architectures.

Strengths: Superior thermal management capabilities and advanced predictive analytics for battery health monitoring provide excellent reliability and longevity. Weaknesses: Higher initial implementation costs compared to competitors and proprietary communication protocols may limit compatibility with some third-party systems.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a hybrid battery pack integration system that focuses on packaging efficiency and thermal optimization. Their solution incorporates a dual-voltage architecture that combines a traditional 12V system with high-voltage battery packs, allowing for more efficient power distribution across vehicle systems. Ford's battery pack design features a structural integration approach where the battery pack serves as a load-bearing element in the vehicle chassis, improving overall vehicle rigidity while reducing weight. Their thermal management system employs a combination of active and passive cooling strategies, with intelligent control algorithms that adjust cooling intensity based on driving conditions and battery load. Ford has also developed specialized manufacturing techniques that allow for automated assembly of battery modules with high precision, reducing production variability and improving quality consistency. The system includes advanced diagnostics capabilities that can predict potential failures before they occur, enabling preventive maintenance.

Strengths: Excellent packaging efficiency and structural integration that contributes to overall vehicle performance; sophisticated dual-voltage architecture provides flexibility for different power demands. Weaknesses: Relatively complex thermal management system requires more maintenance compared to simpler solutions; higher initial engineering costs for vehicle platform integration.

Critical Technologies in Battery Management Systems

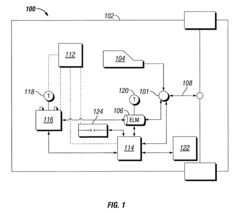

System, method, and apparatus for battery pack thermal management

PatentActiveUS9090250B2

Innovation

- A thermal management system for hybrid power system battery packs that includes a controller, temperature sensors, and devices such as thermoelectric and shape memory alloy (SMA) components to capture and manage excess heat, ensuring the battery pack operates within a target temperature range by selectively coupling ultracapacitors, auxiliary loads, and other devices to dissipate or generate heat as needed.

Hybrid energy pack

PatentInactiveGB2570112A

Innovation

- The hybrid energy pack design interleaves lithium-ion battery cells and supercapacitor cells in a strictly alternating fashion, using non-flammable electrolytes in supercapacitor cells to reduce size and weight, and employs specific ionic liquid electrolytes and carbon-containing electrodes to prevent fire spread, with supercapacitors acting as spacers or encapsulators.

Thermal Management Strategies for Battery Packs

Effective thermal management is critical for battery pack integration in hybrid power engineered systems, as temperature significantly impacts battery performance, safety, and longevity. Modern thermal management strategies employ multiple approaches to maintain optimal operating temperatures between 15°C and 35°C across diverse operating conditions.

Air cooling systems represent the most basic and cost-effective solution, utilizing forced convection through strategically placed fans and air channels. While simple to implement, these systems offer limited cooling capacity and efficiency, particularly in high-power applications or extreme ambient conditions. They remain suitable for mild-duty hybrid applications with moderate power requirements.

Liquid cooling has emerged as the industry standard for high-performance hybrid systems, offering superior thermal conductivity and heat transfer capabilities. These systems circulate coolant through plates or channels in direct contact with battery cells or modules. Advanced designs incorporate dedicated cooling circuits with temperature-controlled valves, heat exchangers, and intelligent control algorithms to optimize thermal performance across varying load profiles.

Phase-change materials (PCMs) represent an innovative passive thermal management approach, absorbing excess heat during high-load operations and releasing it when temperatures drop. PCMs can be integrated into battery pack structures as dedicated layers or combined with active cooling systems to create hybrid thermal management solutions with enhanced temperature stability and reduced energy consumption.

Direct refrigerant cooling systems utilize the refrigeration cycle to provide precise temperature control, particularly valuable in extreme environments. Though offering excellent cooling capacity, these systems add complexity, weight, and cost to hybrid power systems, limiting their application primarily to premium or specialized vehicles.

Emerging technologies include immersion cooling, where battery cells are directly submerged in dielectric fluids with excellent thermal properties, and thermoelectric cooling, which leverages the Peltier effect to create temperature differentials without moving parts. These approaches show promise for next-generation hybrid systems but currently face challenges related to cost, integration complexity, and efficiency.

The selection of appropriate thermal management strategies must balance performance requirements, system architecture, operating environment, cost constraints, and energy efficiency. Increasingly, manufacturers are implementing multi-modal approaches that combine different cooling technologies to optimize performance across diverse operating conditions while minimizing energy consumption and system complexity.

Air cooling systems represent the most basic and cost-effective solution, utilizing forced convection through strategically placed fans and air channels. While simple to implement, these systems offer limited cooling capacity and efficiency, particularly in high-power applications or extreme ambient conditions. They remain suitable for mild-duty hybrid applications with moderate power requirements.

Liquid cooling has emerged as the industry standard for high-performance hybrid systems, offering superior thermal conductivity and heat transfer capabilities. These systems circulate coolant through plates or channels in direct contact with battery cells or modules. Advanced designs incorporate dedicated cooling circuits with temperature-controlled valves, heat exchangers, and intelligent control algorithms to optimize thermal performance across varying load profiles.

Phase-change materials (PCMs) represent an innovative passive thermal management approach, absorbing excess heat during high-load operations and releasing it when temperatures drop. PCMs can be integrated into battery pack structures as dedicated layers or combined with active cooling systems to create hybrid thermal management solutions with enhanced temperature stability and reduced energy consumption.

Direct refrigerant cooling systems utilize the refrigeration cycle to provide precise temperature control, particularly valuable in extreme environments. Though offering excellent cooling capacity, these systems add complexity, weight, and cost to hybrid power systems, limiting their application primarily to premium or specialized vehicles.

Emerging technologies include immersion cooling, where battery cells are directly submerged in dielectric fluids with excellent thermal properties, and thermoelectric cooling, which leverages the Peltier effect to create temperature differentials without moving parts. These approaches show promise for next-generation hybrid systems but currently face challenges related to cost, integration complexity, and efficiency.

The selection of appropriate thermal management strategies must balance performance requirements, system architecture, operating environment, cost constraints, and energy efficiency. Increasingly, manufacturers are implementing multi-modal approaches that combine different cooling technologies to optimize performance across diverse operating conditions while minimizing energy consumption and system complexity.

Safety Standards and Regulatory Compliance

The integration of battery packs in hybrid power engineered systems necessitates strict adherence to comprehensive safety standards and regulatory frameworks. These regulations vary significantly across global markets, with major jurisdictions such as the United States, European Union, China, and Japan implementing distinct certification requirements. In the US, UL 1642 for lithium batteries and UL 2580 for batteries in electric vehicles represent critical standards, while the EU enforces compliance with ECE R100 for vehicle safety and IEC 62133 for battery cell safety.

Battery management systems must comply with functional safety standards such as ISO 26262, which establishes Automotive Safety Integrity Levels (ASIL) for risk assessment and mitigation. This standard has become increasingly important as hybrid systems grow more complex, requiring sophisticated fault detection and management capabilities.

Thermal runaway prevention represents a primary safety concern addressed by regulations like SAE J2464 and IEC 62660, which mandate specific testing protocols for thermal stability. These standards require manufacturers to implement robust thermal management systems and incorporate physical safeguards such as thermal fuses and pressure relief mechanisms.

Transportation regulations present another critical compliance area, with UN 38.3 establishing rigorous testing requirements for lithium batteries during shipping. These tests evaluate resistance to altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge conditions. Manufacturers must obtain certification before transporting battery packs internationally.

Environmental compliance frameworks, including RoHS and REACH in Europe, restrict the use of hazardous substances in battery manufacturing. These regulations aim to minimize environmental impact throughout the product lifecycle, from production to disposal. The EU Battery Directive further mandates collection rates and recycling efficiencies for end-of-life battery management.

Recent regulatory trends indicate movement toward harmonization of global standards, potentially reducing compliance complexity for manufacturers operating in multiple markets. Industry consortia are actively collaborating with regulatory bodies to develop unified testing methodologies and safety requirements that address emerging technologies such as solid-state batteries and advanced hybrid architectures.

Compliance documentation requirements have also expanded, with manufacturers now expected to maintain comprehensive technical files demonstrating conformity with applicable standards. These files must include detailed test reports, risk assessments, material declarations, and end-of-life management plans to satisfy regulatory scrutiny across different jurisdictions.

Battery management systems must comply with functional safety standards such as ISO 26262, which establishes Automotive Safety Integrity Levels (ASIL) for risk assessment and mitigation. This standard has become increasingly important as hybrid systems grow more complex, requiring sophisticated fault detection and management capabilities.

Thermal runaway prevention represents a primary safety concern addressed by regulations like SAE J2464 and IEC 62660, which mandate specific testing protocols for thermal stability. These standards require manufacturers to implement robust thermal management systems and incorporate physical safeguards such as thermal fuses and pressure relief mechanisms.

Transportation regulations present another critical compliance area, with UN 38.3 establishing rigorous testing requirements for lithium batteries during shipping. These tests evaluate resistance to altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge conditions. Manufacturers must obtain certification before transporting battery packs internationally.

Environmental compliance frameworks, including RoHS and REACH in Europe, restrict the use of hazardous substances in battery manufacturing. These regulations aim to minimize environmental impact throughout the product lifecycle, from production to disposal. The EU Battery Directive further mandates collection rates and recycling efficiencies for end-of-life battery management.

Recent regulatory trends indicate movement toward harmonization of global standards, potentially reducing compliance complexity for manufacturers operating in multiple markets. Industry consortia are actively collaborating with regulatory bodies to develop unified testing methodologies and safety requirements that address emerging technologies such as solid-state batteries and advanced hybrid architectures.

Compliance documentation requirements have also expanded, with manufacturers now expected to maintain comprehensive technical files demonstrating conformity with applicable standards. These files must include detailed test reports, risk assessments, material declarations, and end-of-life management plans to satisfy regulatory scrutiny across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!