Battery Pack Thermal Runaway Prevention Mechanisms

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in modern energy storage systems. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can rapidly propagate to adjacent cells, potentially resulting in catastrophic failure of the entire battery pack. The evolution of battery technology has been marked by significant improvements in energy density and performance, but these advancements have simultaneously increased the risk and severity of thermal runaway incidents.

The historical development of battery thermal management systems reveals a progressive understanding of thermal runaway mechanisms. Early lithium-ion batteries, introduced commercially in the 1990s, had limited safety features. As energy densities increased through the 2000s, several high-profile incidents involving consumer electronics highlighted the inherent risks of lithium-ion technology. These events catalyzed intensive research into thermal runaway prevention, particularly as batteries scaled up for electric vehicle and grid storage applications.

From a technical perspective, thermal runaway typically initiates through one of several pathways: mechanical damage causing internal short circuits, manufacturing defects, overcharging, external heating, or aging-related degradation. Once triggered, the process follows a cascading sequence: electrolyte decomposition, separator failure, and exothermic reactions that generate heat, gases, and potentially toxic compounds. Without intervention, temperatures can exceed 600°C, leading to fire, explosion, or violent cell rupture.

The primary objective of thermal runaway prevention mechanisms is to interrupt this cascade at multiple points, creating redundant safety systems. This includes early detection of precursor events, isolation of affected cells, heat dissipation strategies, and containment of thermal propagation. Secondary objectives include minimizing system weight and volume penalties, maintaining overall battery performance, and ensuring cost-effectiveness of safety solutions.

Current prevention strategies operate across multiple scales: at the material level (flame-retardant electrolytes, stable electrode materials), cell level (safety vents, shutdown separators), module level (thermal barriers, cooling systems), and pack level (sophisticated battery management systems, fire suppression). The technical evolution trend points toward integrated approaches that combine passive safety features with active monitoring and intervention systems.

The ultimate goal of thermal runaway prevention research is to develop battery systems with "fail-safe" characteristics—where even under worst-case scenarios, failures remain contained and non-catastrophic. This objective has gained urgency as battery applications expand into increasingly demanding environments and as regulatory frameworks evolve to address emerging safety concerns.

The historical development of battery thermal management systems reveals a progressive understanding of thermal runaway mechanisms. Early lithium-ion batteries, introduced commercially in the 1990s, had limited safety features. As energy densities increased through the 2000s, several high-profile incidents involving consumer electronics highlighted the inherent risks of lithium-ion technology. These events catalyzed intensive research into thermal runaway prevention, particularly as batteries scaled up for electric vehicle and grid storage applications.

From a technical perspective, thermal runaway typically initiates through one of several pathways: mechanical damage causing internal short circuits, manufacturing defects, overcharging, external heating, or aging-related degradation. Once triggered, the process follows a cascading sequence: electrolyte decomposition, separator failure, and exothermic reactions that generate heat, gases, and potentially toxic compounds. Without intervention, temperatures can exceed 600°C, leading to fire, explosion, or violent cell rupture.

The primary objective of thermal runaway prevention mechanisms is to interrupt this cascade at multiple points, creating redundant safety systems. This includes early detection of precursor events, isolation of affected cells, heat dissipation strategies, and containment of thermal propagation. Secondary objectives include minimizing system weight and volume penalties, maintaining overall battery performance, and ensuring cost-effectiveness of safety solutions.

Current prevention strategies operate across multiple scales: at the material level (flame-retardant electrolytes, stable electrode materials), cell level (safety vents, shutdown separators), module level (thermal barriers, cooling systems), and pack level (sophisticated battery management systems, fire suppression). The technical evolution trend points toward integrated approaches that combine passive safety features with active monitoring and intervention systems.

The ultimate goal of thermal runaway prevention research is to develop battery systems with "fail-safe" characteristics—where even under worst-case scenarios, failures remain contained and non-catastrophic. This objective has gained urgency as battery applications expand into increasingly demanding environments and as regulatory frameworks evolve to address emerging safety concerns.

Market Demand for Battery Safety Solutions

The global market for battery safety solutions has witnessed exponential growth in recent years, primarily driven by the rapid adoption of electric vehicles (EVs) and renewable energy storage systems. As of 2023, the market for battery thermal management systems alone is valued at approximately $3.5 billion, with projections indicating a compound annual growth rate of 22.7% through 2030. This surge in demand directly correlates with increasing concerns about battery thermal runaway incidents that have resulted in high-profile product recalls and safety concerns.

Consumer electronics manufacturers represent a significant segment of this market, as lithium-ion battery failures in smartphones, laptops, and wearable devices have led to stringent safety regulations and consumer wariness. The consumer electronics industry has consequently increased investment in advanced thermal management solutions by 34% since 2020, reflecting the critical nature of this technology for product reliability and brand reputation.

The automotive sector demonstrates the most aggressive growth trajectory for battery safety solutions. With EV sales increasing by 35% annually in major markets, automakers are prioritizing battery safety as a key differentiator. Market research indicates that 78% of potential EV buyers cite battery safety concerns as a significant factor in their purchasing decisions, highlighting the commercial imperative for robust thermal runaway prevention mechanisms.

Energy storage system (ESS) deployments for grid applications and residential use represent another rapidly expanding market segment. The global ESS market is expected to reach $12.1 billion by 2025, with safety systems accounting for approximately 15% of total system costs. Recent incidents involving grid-scale battery fires have intensified regulatory scrutiny and accelerated demand for advanced safety solutions in this sector.

Geographically, the Asia-Pacific region dominates the market for battery safety solutions, accounting for 45% of global demand, followed by North America (28%) and Europe (22%). This distribution closely mirrors the concentration of battery manufacturing capacity and EV production facilities worldwide.

Insurance providers have emerged as unexpected market drivers, with many companies now offering premium reductions of up to 18% for energy storage systems and electric vehicles equipped with advanced thermal runaway prevention technologies. This financial incentive has further accelerated market adoption across multiple sectors.

The regulatory landscape continues to evolve rapidly, with new safety standards being implemented across major markets. These regulations are increasingly prescriptive regarding thermal management requirements, creating immediate market opportunities for companies with proven prevention technologies while simultaneously raising barriers to entry for new market participants.

Consumer electronics manufacturers represent a significant segment of this market, as lithium-ion battery failures in smartphones, laptops, and wearable devices have led to stringent safety regulations and consumer wariness. The consumer electronics industry has consequently increased investment in advanced thermal management solutions by 34% since 2020, reflecting the critical nature of this technology for product reliability and brand reputation.

The automotive sector demonstrates the most aggressive growth trajectory for battery safety solutions. With EV sales increasing by 35% annually in major markets, automakers are prioritizing battery safety as a key differentiator. Market research indicates that 78% of potential EV buyers cite battery safety concerns as a significant factor in their purchasing decisions, highlighting the commercial imperative for robust thermal runaway prevention mechanisms.

Energy storage system (ESS) deployments for grid applications and residential use represent another rapidly expanding market segment. The global ESS market is expected to reach $12.1 billion by 2025, with safety systems accounting for approximately 15% of total system costs. Recent incidents involving grid-scale battery fires have intensified regulatory scrutiny and accelerated demand for advanced safety solutions in this sector.

Geographically, the Asia-Pacific region dominates the market for battery safety solutions, accounting for 45% of global demand, followed by North America (28%) and Europe (22%). This distribution closely mirrors the concentration of battery manufacturing capacity and EV production facilities worldwide.

Insurance providers have emerged as unexpected market drivers, with many companies now offering premium reductions of up to 18% for energy storage systems and electric vehicles equipped with advanced thermal runaway prevention technologies. This financial incentive has further accelerated market adoption across multiple sectors.

The regulatory landscape continues to evolve rapidly, with new safety standards being implemented across major markets. These regulations are increasingly prescriptive regarding thermal management requirements, creating immediate market opportunities for companies with proven prevention technologies while simultaneously raising barriers to entry for new market participants.

Current Thermal Runaway Prevention Technologies

The current landscape of thermal runaway prevention technologies in battery packs encompasses multiple layers of protection strategies, each addressing different aspects of thermal management and safety. These technologies can be broadly categorized into passive and active prevention mechanisms, with varying degrees of implementation complexity and effectiveness.

Passive prevention technologies include thermal insulation materials that physically separate battery cells, preventing heat propagation between adjacent cells. Advanced ceramic-based insulators, aerogels, and phase change materials (PCMs) are increasingly being deployed to absorb and dissipate heat during temperature spikes. These materials can effectively delay thermal runaway propagation by 30-50% compared to traditional insulators, providing critical response time.

Structural design innovations represent another passive approach, with cell-to-cell spacing optimization and strategic vent placement allowing for controlled gas release during thermal events. Manufacturers have developed flame-retardant battery casings and intumescent materials that expand upon heating to create additional insulation barriers, significantly reducing propagation risks.

Active prevention systems utilize real-time monitoring and intervention capabilities. Battery Management Systems (BMS) with sophisticated algorithms can detect early warning signs of thermal anomalies through continuous monitoring of cell voltage, current, and temperature parameters. Advanced BMS implementations incorporate machine learning algorithms that can predict potential thermal events minutes before traditional threshold-based systems, enabling preemptive action.

Liquid cooling systems have evolved from simple heat exchangers to complex microfluidic cooling networks that target specific hotspots within battery packs. Direct liquid immersion cooling, where cells are submerged in dielectric fluids, has demonstrated up to 3x greater heat dissipation capacity compared to conventional air or indirect liquid cooling methods.

Gas-based suppression systems represent the latest advancement in active prevention. These systems detect early thermal events and release specialized fire suppression agents directly into battery enclosures. Newer non-toxic suppression agents can effectively neutralize thermal events while maintaining environmental safety standards.

Hybrid approaches combining multiple technologies are becoming the industry standard. For instance, Tesla's battery packs incorporate structural firewalls between modules, advanced cooling systems, and sophisticated BMS algorithms working in concert. Similarly, contemporary electric vehicles from manufacturers like BYD utilize cell-level fusing combined with multi-layer thermal management systems.

The effectiveness of these technologies varies significantly based on battery chemistry, pack design, and operating conditions. While no single solution provides complete protection, the integration of complementary technologies has demonstrated substantial improvements in overall safety metrics, with modern systems capable of containing single-cell thermal events without pack-level propagation in over 95% of test cases.

Passive prevention technologies include thermal insulation materials that physically separate battery cells, preventing heat propagation between adjacent cells. Advanced ceramic-based insulators, aerogels, and phase change materials (PCMs) are increasingly being deployed to absorb and dissipate heat during temperature spikes. These materials can effectively delay thermal runaway propagation by 30-50% compared to traditional insulators, providing critical response time.

Structural design innovations represent another passive approach, with cell-to-cell spacing optimization and strategic vent placement allowing for controlled gas release during thermal events. Manufacturers have developed flame-retardant battery casings and intumescent materials that expand upon heating to create additional insulation barriers, significantly reducing propagation risks.

Active prevention systems utilize real-time monitoring and intervention capabilities. Battery Management Systems (BMS) with sophisticated algorithms can detect early warning signs of thermal anomalies through continuous monitoring of cell voltage, current, and temperature parameters. Advanced BMS implementations incorporate machine learning algorithms that can predict potential thermal events minutes before traditional threshold-based systems, enabling preemptive action.

Liquid cooling systems have evolved from simple heat exchangers to complex microfluidic cooling networks that target specific hotspots within battery packs. Direct liquid immersion cooling, where cells are submerged in dielectric fluids, has demonstrated up to 3x greater heat dissipation capacity compared to conventional air or indirect liquid cooling methods.

Gas-based suppression systems represent the latest advancement in active prevention. These systems detect early thermal events and release specialized fire suppression agents directly into battery enclosures. Newer non-toxic suppression agents can effectively neutralize thermal events while maintaining environmental safety standards.

Hybrid approaches combining multiple technologies are becoming the industry standard. For instance, Tesla's battery packs incorporate structural firewalls between modules, advanced cooling systems, and sophisticated BMS algorithms working in concert. Similarly, contemporary electric vehicles from manufacturers like BYD utilize cell-level fusing combined with multi-layer thermal management systems.

The effectiveness of these technologies varies significantly based on battery chemistry, pack design, and operating conditions. While no single solution provides complete protection, the integration of complementary technologies has demonstrated substantial improvements in overall safety metrics, with modern systems capable of containing single-cell thermal events without pack-level propagation in over 95% of test cases.

Existing Thermal Runaway Prevention Solutions

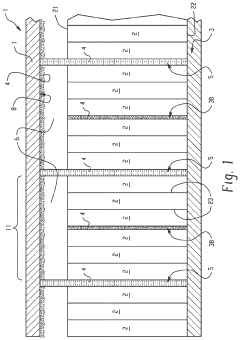

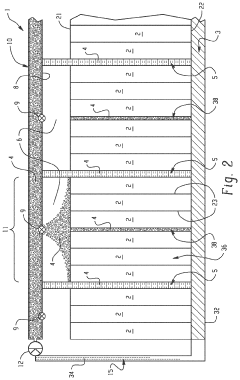

01 Thermal management systems for battery packs

Various thermal management systems are designed to prevent thermal runaway in battery packs. These systems include cooling mechanisms, heat dissipation structures, and temperature control devices that maintain optimal operating temperatures. Advanced thermal management solutions incorporate liquid cooling, phase change materials, or air circulation systems to efficiently remove heat from battery cells, preventing the cascade effect of thermal runaway across multiple cells.- Thermal management systems for battery packs: Various thermal management systems are designed to prevent thermal runaway in battery packs. These systems include cooling mechanisms, heat dissipation structures, and temperature control systems that maintain optimal operating temperatures. Advanced designs incorporate liquid cooling channels, phase change materials, and intelligent thermal regulation to efficiently remove heat from battery cells and prevent cascading thermal events.

- Battery cell isolation and containment structures: Specialized structures are implemented to isolate individual battery cells and contain potential thermal runaway events. These designs include physical barriers between cells, fire-resistant materials, and compartmentalized housings that prevent propagation of thermal events from one cell to adjacent cells. Such isolation strategies minimize the risk of cascading failures throughout the battery pack.

- Detection and early warning systems: Advanced sensor networks and monitoring systems are employed to detect early signs of thermal runaway. These systems utilize temperature sensors, gas detectors, and voltage monitoring to identify abnormal conditions before they escalate. Early detection allows for preventive measures such as load disconnection, cooling activation, or emergency shutdown procedures to be initiated automatically.

- Venting and pressure relief mechanisms: Battery packs incorporate specialized venting and pressure relief mechanisms to safely release gases and reduce internal pressure during thermal events. These designs include rupture discs, pressure relief valves, and controlled venting channels that direct hazardous gases away from sensitive components and users. Such mechanisms help prevent explosive failures and mitigate damage to surrounding battery cells.

- Fire suppression and extinguishing systems: Integrated fire suppression systems are designed to quickly respond to thermal runaway events. These systems include fire-retardant materials, automatic extinguishing agents, and heat-absorbing compounds that activate when thermal thresholds are exceeded. Some advanced designs incorporate encapsulated suppression agents that release only when needed, providing targeted protection while minimizing damage to functional battery components.

02 Battery cell isolation and containment technologies

Technologies focused on isolating individual cells within battery packs to prevent thermal runaway propagation. These include physical barriers, fire-resistant materials, and compartmentalization designs that contain thermal events to a single cell. Such isolation strategies often employ heat-resistant separators, flame-retardant materials, or specialized cell housings that prevent heat transfer between adjacent cells, limiting the spread of thermal runaway throughout the battery pack.Expand Specific Solutions03 Detection and early warning systems

Advanced monitoring systems designed to detect early signs of thermal runaway in battery packs. These systems utilize temperature sensors, voltage monitoring, gas detection, and predictive algorithms to identify abnormal conditions before they escalate. Early detection enables preventive measures such as load disconnection, cooling activation, or emergency shutdown procedures to be implemented before thermal runaway occurs, significantly reducing safety risks.Expand Specific Solutions04 Novel battery materials and cell designs

Innovative materials and cell designs that inherently reduce the risk of thermal runaway. These include advanced electrode materials, safer electrolytes, and structural modifications that enhance thermal stability. Some approaches incorporate self-healing components, flame-retardant additives, or thermally stable separators that maintain integrity at high temperatures, preventing the chain reactions that lead to thermal runaway events.Expand Specific Solutions05 Emergency response and venting mechanisms

Safety mechanisms designed to respond to thermal events by safely releasing pressure, heat, or gases. These include pressure relief valves, rupture discs, and controlled venting systems that prevent catastrophic failure during thermal runaway. Such mechanisms are engineered to direct hazardous emissions away from users and critical components, while some advanced designs incorporate fire suppression materials that activate automatically when triggered by excessive heat.Expand Specific Solutions

Key Industry Players in Battery Safety

The battery pack thermal runaway prevention market is in a growth phase, driven by increasing electric vehicle adoption and safety concerns. The market is expected to reach significant size as regulations tighten globally. Technology maturity varies across solutions, with industry leaders demonstrating different approaches. Tesla and BYD have pioneered advanced thermal management systems, while LG Energy Solution and Samsung SDI focus on cell-level safety innovations. Traditional automakers like GM and emerging players such as Xiaomi are investing heavily in proprietary prevention technologies. Chinese manufacturers including Microvast and CATL are rapidly advancing cost-effective solutions, while specialized firms like Nexcon Technology offer targeted battery management systems that address thermal runaway risks.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced multi-faceted approach to battery thermal runaway prevention following lessons learned from earlier safety incidents. Their current technology incorporates a Safety Reinforced Separator (SRS) with ceramic coating that maintains mechanical integrity at high temperatures, preventing internal short circuits. LG's battery packs feature a sophisticated cooling system with direct cell-to-coolant contact, maintaining temperature differentials below 2°C across modules. Their Battery Management System employs predictive analytics using over 200 parameters to detect potential thermal events before they occur, with response times under 300 milliseconds. LG has pioneered the use of "thermal fuses" within cell groups that physically disconnect cells when temperature thresholds are exceeded. Recent innovations include their "Z-stacking" cell arrangement that creates thermal isolation zones within modules, limiting propagation pathways. Testing shows their latest generation batteries can withstand nail penetration tests with minimal temperature increase and no propagation to adjacent cells.

Strengths: Industry-leading separator technology with proven thermal stability; extensive manufacturing capacity allowing rapid implementation of safety improvements; strong R&D capabilities with over 5,000 battery patents. Weaknesses: Past safety incidents have damaged reputation despite technological improvements; complex supply chain with multiple component sources creating quality control challenges; higher production costs for advanced safety features.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive multi-layered approach to battery thermal runaway prevention. Their system combines advanced battery management systems (BMS) with physical safeguards. Tesla's BMS continuously monitors individual cell temperatures, voltage, and current with millisecond precision, using proprietary algorithms to detect anomalies before they escalate. Their battery packs incorporate intumescent materials between cells that expand when heated, creating physical barriers to prevent propagation. Tesla has also pioneered the use of dedicated cooling channels with non-conductive coolants that maintain optimal temperature distribution across the entire pack. Their Model 3/Y packs feature a patented "fault isolation" design where cells are arranged in small groups with thermal barriers, limiting cascade failures to small sections rather than the entire pack. Recent data shows Tesla's thermal runaway incidents are approximately 11 times lower than industry average for comparable EVs.

Strengths: Industry-leading BMS with predictive analytics capabilities; proprietary cell-to-pack integration allowing for optimized thermal management; extensive real-world data from millions of vehicles to refine safety systems. Weaknesses: Higher manufacturing costs due to complex thermal management systems; reliance on specific cell formats limits flexibility; system complexity requires specialized maintenance expertise.

Critical Patents in Thermal Propagation Prevention

Thermal runaway detection and cotainment mechanism

PatentPendingUS20250286210A1

Innovation

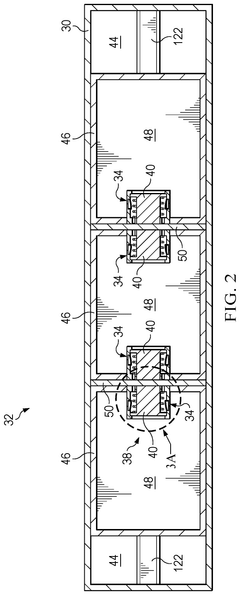

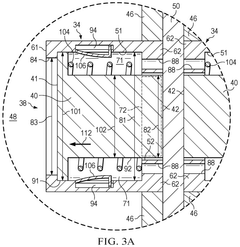

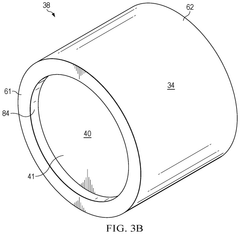

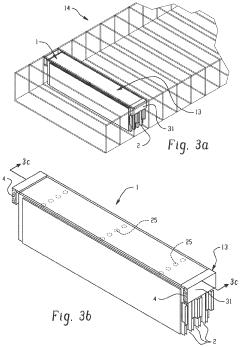

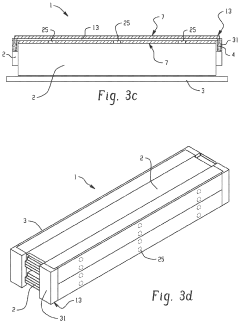

- A thermal runaway protection system incorporating a battery module enclosure, divider wall, protection structure, and piston mechanism that separates overheated modules to create a thermal barrier by converting pressure into a separation air gap, using a piston to move and separate the overheated module when pressure exceeds a threshold, with a spring and lock pawl system to maintain separation.

Battery pack system with thermal runaway mitigation features

PatentActiveUS20230369682A1

Innovation

- Incorporation of a thermochemical material within or adjacent to the battery cells that undergoes an endothermic reaction above 50°C, which can be released through a valve or gap system upon reaching a temperature threshold to absorb energy and inhibit thermal runaway propagation, combined with a thermal runaway propagation suppression element and a cooling system.

Regulatory Framework for Battery Safety Standards

The global regulatory landscape for battery safety has evolved significantly in response to the increasing adoption of lithium-ion batteries across various industries. International standards such as IEC 62133, UL 1642, and UN 38.3 have established comprehensive testing protocols specifically addressing thermal runaway risks in battery packs. These standards mandate rigorous testing including thermal abuse, overcharge protection, short circuit resilience, and mechanical integrity verification.

In the automotive sector, regulations have become increasingly stringent, with standards like ISO 6469 and SAE J2464 providing specific guidelines for electric vehicle battery safety. These frameworks require manufacturers to implement multiple layers of thermal runaway prevention mechanisms and demonstrate their effectiveness through standardized testing procedures. The Global Technical Regulation No. 20 (GTR 20) represents a significant harmonization effort, establishing consistent safety requirements across multiple jurisdictions.

Regional variations in regulatory approaches present challenges for global manufacturers. The European Union has implemented the Battery Directive and ECE R100, which emphasize both safety performance and end-of-life management. In North America, UL 2580 and FMVSS 305 govern electric vehicle battery safety with particular attention to thermal management systems. Meanwhile, China's GB/T standards have rapidly evolved to address the country's expanding electric vehicle market, often incorporating more prescriptive requirements for thermal runaway prevention.

Regulatory compliance timelines are becoming more compressed as safety incidents prompt accelerated rulemaking. Recent thermal runaway incidents have led to emergency regulatory responses, requiring manufacturers to implement enhanced safety features within shortened development cycles. This trend is particularly evident in energy storage system applications, where UL 9540A has established new testing protocols specifically targeting thermal runaway propagation.

The regulatory framework is increasingly focusing on system-level approaches rather than cell-level safety alone. Standards now require demonstration of thermal runaway containment strategies, early detection systems, and propagation prevention mechanisms at the pack and vehicle levels. This holistic approach recognizes that effective thermal runaway prevention requires integrated safety systems spanning from cell chemistry to pack design and vehicle integration.

Emerging regulations are beginning to address advanced battery chemistries and novel thermal management approaches. As solid-state batteries and other next-generation technologies advance, regulatory bodies are developing new testing methodologies to evaluate their unique safety characteristics and thermal runaway resistance profiles. These forward-looking standards aim to ensure safety frameworks remain relevant as battery technology continues to evolve.

In the automotive sector, regulations have become increasingly stringent, with standards like ISO 6469 and SAE J2464 providing specific guidelines for electric vehicle battery safety. These frameworks require manufacturers to implement multiple layers of thermal runaway prevention mechanisms and demonstrate their effectiveness through standardized testing procedures. The Global Technical Regulation No. 20 (GTR 20) represents a significant harmonization effort, establishing consistent safety requirements across multiple jurisdictions.

Regional variations in regulatory approaches present challenges for global manufacturers. The European Union has implemented the Battery Directive and ECE R100, which emphasize both safety performance and end-of-life management. In North America, UL 2580 and FMVSS 305 govern electric vehicle battery safety with particular attention to thermal management systems. Meanwhile, China's GB/T standards have rapidly evolved to address the country's expanding electric vehicle market, often incorporating more prescriptive requirements for thermal runaway prevention.

Regulatory compliance timelines are becoming more compressed as safety incidents prompt accelerated rulemaking. Recent thermal runaway incidents have led to emergency regulatory responses, requiring manufacturers to implement enhanced safety features within shortened development cycles. This trend is particularly evident in energy storage system applications, where UL 9540A has established new testing protocols specifically targeting thermal runaway propagation.

The regulatory framework is increasingly focusing on system-level approaches rather than cell-level safety alone. Standards now require demonstration of thermal runaway containment strategies, early detection systems, and propagation prevention mechanisms at the pack and vehicle levels. This holistic approach recognizes that effective thermal runaway prevention requires integrated safety systems spanning from cell chemistry to pack design and vehicle integration.

Emerging regulations are beginning to address advanced battery chemistries and novel thermal management approaches. As solid-state batteries and other next-generation technologies advance, regulatory bodies are developing new testing methodologies to evaluate their unique safety characteristics and thermal runaway resistance profiles. These forward-looking standards aim to ensure safety frameworks remain relevant as battery technology continues to evolve.

Environmental Impact of Battery Safety Technologies

The environmental implications of battery safety technologies, particularly those focused on thermal runaway prevention, extend far beyond immediate safety concerns. When thermal runaway events occur, they typically release toxic gases, particulate matter, and potentially harmful chemicals into the atmosphere. Modern prevention mechanisms significantly reduce these environmental hazards by containing or preventing such catastrophic failures.

Fire suppression systems integrated into battery packs often utilize environmentally-friendly materials compared to traditional fire extinguishing agents. For instance, phase change materials (PCMs) used for thermal management are increasingly being developed from bio-based sources rather than petroleum derivatives, reducing their carbon footprint and end-of-life environmental impact.

The lifecycle assessment of battery safety technologies reveals important sustainability considerations. Prevention mechanisms that extend battery life through better thermal management indirectly reduce resource consumption and waste generation. Each avoided battery replacement represents significant savings in raw materials, manufacturing energy, and transportation emissions. Studies indicate that effective thermal management can extend battery lifespans by 15-30%, translating to proportional reductions in environmental impact.

Recycling compatibility represents another critical environmental dimension. Some thermal barrier materials and fire-retardant additives can complicate end-of-life battery recycling processes. However, newer generation prevention technologies are increasingly designed with recyclability in mind, using materials that can be more easily separated during recycling processes or that don't interfere with hydrometallurgical recovery of valuable metals.

Water consumption during thermal runaway events presents a significant environmental concern. Traditional firefighting approaches for battery fires can require thousands of gallons of water, which often becomes contaminated with battery chemicals. Advanced prevention systems that contain thermal events reduce or eliminate this water usage and subsequent contamination of water systems.

The regulatory landscape increasingly recognizes these environmental dimensions. Several jurisdictions now require environmental impact assessments for battery safety systems, with particular attention to potential soil and groundwater contamination from fire suppression chemicals and battery materials. This regulatory pressure is driving innovation toward more environmentally benign safety technologies that maintain high performance standards while minimizing ecological footprints.

Fire suppression systems integrated into battery packs often utilize environmentally-friendly materials compared to traditional fire extinguishing agents. For instance, phase change materials (PCMs) used for thermal management are increasingly being developed from bio-based sources rather than petroleum derivatives, reducing their carbon footprint and end-of-life environmental impact.

The lifecycle assessment of battery safety technologies reveals important sustainability considerations. Prevention mechanisms that extend battery life through better thermal management indirectly reduce resource consumption and waste generation. Each avoided battery replacement represents significant savings in raw materials, manufacturing energy, and transportation emissions. Studies indicate that effective thermal management can extend battery lifespans by 15-30%, translating to proportional reductions in environmental impact.

Recycling compatibility represents another critical environmental dimension. Some thermal barrier materials and fire-retardant additives can complicate end-of-life battery recycling processes. However, newer generation prevention technologies are increasingly designed with recyclability in mind, using materials that can be more easily separated during recycling processes or that don't interfere with hydrometallurgical recovery of valuable metals.

Water consumption during thermal runaway events presents a significant environmental concern. Traditional firefighting approaches for battery fires can require thousands of gallons of water, which often becomes contaminated with battery chemicals. Advanced prevention systems that contain thermal events reduce or eliminate this water usage and subsequent contamination of water systems.

The regulatory landscape increasingly recognizes these environmental dimensions. Several jurisdictions now require environmental impact assessments for battery safety systems, with particular attention to potential soil and groundwater contamination from fire suppression chemicals and battery materials. This regulatory pressure is driving innovation toward more environmentally benign safety technologies that maintain high performance standards while minimizing ecological footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!