Battery Thermal Runaway Evolution in High-Capacity Cells

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in modern energy storage systems. The phenomenon has gained significant attention since the early 2000s, coinciding with the widespread adoption of lithium-ion batteries in consumer electronics and, subsequently, electric vehicles and grid storage applications. Thermal runaway occurs when a battery cell enters an uncontrollable, self-heating state that can lead to violent cell rupture, fire, or explosion, potentially triggering cascading failures in adjacent cells.

The evolution of this safety concern has paralleled the development of high-capacity cells, which pack increasingly higher energy densities into compact formats. From the initial 18650 cylindrical cells with capacities below 2Ah to today's large-format pouch and prismatic cells exceeding 100Ah, the potential energy release during thermal events has grown exponentially, magnifying safety risks.

Historical data indicates that thermal runaway incidents have shaped industry regulations and design practices. Notable cases include the 2006 laptop battery recalls, the 2013 Boeing 787 Dreamliner battery fires, and various electric vehicle thermal events that have prompted intensive research into prevention and mitigation strategies. These incidents have established thermal runaway as a primary barrier to further energy density increases in commercial battery systems.

The technical progression in understanding thermal runaway has moved from empirical observations to sophisticated multi-physics modeling approaches. Early research focused on identifying triggering mechanisms, while current efforts emphasize real-time detection, propagation prevention, and system-level safety architectures. This evolution reflects the growing recognition that thermal runaway must be addressed holistically across multiple scales—from electrode chemistry to pack design.

The primary objective of this technical research is to comprehensively analyze the unique characteristics of thermal runaway evolution in high-capacity cells (>50Ah), which present distinct challenges compared to smaller formats. Specifically, we aim to: (1) identify the critical thresholds and progression patterns specific to large-format cells; (2) evaluate the effectiveness of current detection and prevention technologies; (3) establish predictive models that account for the complex thermal, mechanical, and electrochemical interactions in high-capacity systems; and (4) propose innovative approaches to mitigate propagation risks in multi-cell configurations.

By establishing a thorough understanding of thermal runaway mechanisms in high-capacity cells, this research seeks to inform next-generation battery designs that can safely push energy density boundaries while maintaining acceptable safety margins for demanding applications in transportation, aerospace, and stationary storage sectors.

The evolution of this safety concern has paralleled the development of high-capacity cells, which pack increasingly higher energy densities into compact formats. From the initial 18650 cylindrical cells with capacities below 2Ah to today's large-format pouch and prismatic cells exceeding 100Ah, the potential energy release during thermal events has grown exponentially, magnifying safety risks.

Historical data indicates that thermal runaway incidents have shaped industry regulations and design practices. Notable cases include the 2006 laptop battery recalls, the 2013 Boeing 787 Dreamliner battery fires, and various electric vehicle thermal events that have prompted intensive research into prevention and mitigation strategies. These incidents have established thermal runaway as a primary barrier to further energy density increases in commercial battery systems.

The technical progression in understanding thermal runaway has moved from empirical observations to sophisticated multi-physics modeling approaches. Early research focused on identifying triggering mechanisms, while current efforts emphasize real-time detection, propagation prevention, and system-level safety architectures. This evolution reflects the growing recognition that thermal runaway must be addressed holistically across multiple scales—from electrode chemistry to pack design.

The primary objective of this technical research is to comprehensively analyze the unique characteristics of thermal runaway evolution in high-capacity cells (>50Ah), which present distinct challenges compared to smaller formats. Specifically, we aim to: (1) identify the critical thresholds and progression patterns specific to large-format cells; (2) evaluate the effectiveness of current detection and prevention technologies; (3) establish predictive models that account for the complex thermal, mechanical, and electrochemical interactions in high-capacity systems; and (4) propose innovative approaches to mitigate propagation risks in multi-cell configurations.

By establishing a thorough understanding of thermal runaway mechanisms in high-capacity cells, this research seeks to inform next-generation battery designs that can safely push energy density boundaries while maintaining acceptable safety margins for demanding applications in transportation, aerospace, and stationary storage sectors.

Market Analysis for High-Capacity Battery Safety

The high-capacity battery market has experienced exponential growth over the past decade, primarily driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. The global market for high-capacity batteries reached approximately $112 billion in 2022 and is projected to grow at a CAGR of 18.7% through 2030, potentially reaching $410 billion by the end of the decade.

Safety concerns, particularly thermal runaway events, have emerged as critical factors influencing market dynamics. Following several high-profile incidents involving battery fires in EVs and consumer electronics between 2016-2022, consumer confidence has been periodically shaken, creating market volatility and regulatory scrutiny. This has established battery safety as a primary competitive differentiator rather than merely a compliance requirement.

The automotive sector represents the largest market segment for high-capacity batteries, accounting for roughly 60% of demand. Within this segment, premium vehicle manufacturers have increasingly positioned enhanced battery safety features as key selling points, with consumers demonstrating willingness to pay 8-12% price premiums for vehicles with advanced battery safety systems.

Energy storage systems constitute the fastest-growing application segment, with a 24.3% annual growth rate. This acceleration is largely attributed to grid-scale installations where the financial and safety implications of thermal events are particularly severe. Utility companies and commercial property developers have begun specifying thermal runaway prevention systems as standard requirements in procurement contracts.

Regional analysis reveals significant market variations. Asia-Pacific dominates manufacturing capacity with 73% of global production, while North American and European markets lead in implementing stringent safety standards and technologies. Notably, China has recently accelerated its battery safety regulations following domestic incidents, potentially reshaping global supply chains.

Consumer awareness regarding battery safety has increased substantially, with 67% of potential EV buyers citing battery safety concerns as a "very important" purchasing consideration in recent surveys. This represents a 22% increase from similar surveys conducted in 2018, indicating growing market sensitivity to thermal runaway risks.

Insurance providers have also become influential market stakeholders, with several major insurers implementing premium adjustments based on battery safety certifications. This financial incentive structure is creating additional market pressure for manufacturers to invest in advanced thermal management and early detection systems for thermal runaway prevention.

Safety concerns, particularly thermal runaway events, have emerged as critical factors influencing market dynamics. Following several high-profile incidents involving battery fires in EVs and consumer electronics between 2016-2022, consumer confidence has been periodically shaken, creating market volatility and regulatory scrutiny. This has established battery safety as a primary competitive differentiator rather than merely a compliance requirement.

The automotive sector represents the largest market segment for high-capacity batteries, accounting for roughly 60% of demand. Within this segment, premium vehicle manufacturers have increasingly positioned enhanced battery safety features as key selling points, with consumers demonstrating willingness to pay 8-12% price premiums for vehicles with advanced battery safety systems.

Energy storage systems constitute the fastest-growing application segment, with a 24.3% annual growth rate. This acceleration is largely attributed to grid-scale installations where the financial and safety implications of thermal events are particularly severe. Utility companies and commercial property developers have begun specifying thermal runaway prevention systems as standard requirements in procurement contracts.

Regional analysis reveals significant market variations. Asia-Pacific dominates manufacturing capacity with 73% of global production, while North American and European markets lead in implementing stringent safety standards and technologies. Notably, China has recently accelerated its battery safety regulations following domestic incidents, potentially reshaping global supply chains.

Consumer awareness regarding battery safety has increased substantially, with 67% of potential EV buyers citing battery safety concerns as a "very important" purchasing consideration in recent surveys. This represents a 22% increase from similar surveys conducted in 2018, indicating growing market sensitivity to thermal runaway risks.

Insurance providers have also become influential market stakeholders, with several major insurers implementing premium adjustments based on battery safety certifications. This financial incentive structure is creating additional market pressure for manufacturers to invest in advanced thermal management and early detection systems for thermal runaway prevention.

Current Challenges in Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in high-capacity lithium-ion cells. The fundamental issue stems from the inherent instability of lithium-ion chemistry when subjected to thermal, mechanical, or electrical abuse conditions. As energy densities continue to increase to meet market demands, the severity and probability of thermal events have correspondingly escalated, creating a complex safety-performance trade-off.

Current detection methods present significant limitations in early identification of thermal runaway precursors. Conventional temperature sensors typically detect thermal events only after they have progressed beyond preventable stages. The temperature gradient between the cell core and surface creates a critical detection lag, often rendering preventive measures ineffective. This detection latency problem is particularly pronounced in large-format cells where heat generation and dissipation dynamics are more complex.

Material degradation mechanisms pose another substantial challenge. The solid-electrolyte interphase (SEI) layer, crucial for battery stability, can decompose at elevated temperatures (typically starting around 80-120°C), initiating exothermic reactions. This decomposition releases heat that accelerates further degradation in a dangerous positive feedback loop. Current electrolyte formulations still exhibit flammability issues, and while flame retardants can be added, they often compromise battery performance.

Propagation control between cells in battery packs represents a persistent engineering challenge. Even with sophisticated thermal management systems, preventing cell-to-cell propagation in high-density packs remains difficult. The close proximity required for energy density optimization creates thermal pathways that can facilitate runaway spread. Current isolation materials and techniques often add significant weight and volume, contradicting the industry's push toward higher energy density.

Balancing safety with performance creates fundamental design conflicts. Safety features such as shutdown separators, pressure relief mechanisms, and conservative voltage windows invariably reduce energy density, power capability, or cycle life. This trade-off becomes increasingly problematic as applications demand both higher performance and enhanced safety, particularly in electric vehicles and grid storage systems.

Regulatory frameworks and testing protocols have not fully kept pace with rapid technological developments. Current standards may not adequately address all failure modes in next-generation high-capacity cells, creating uncertainty in safety validation. The lack of standardized approaches to thermal runaway prevention across different applications and regions further complicates the development of universal safety solutions.

Current detection methods present significant limitations in early identification of thermal runaway precursors. Conventional temperature sensors typically detect thermal events only after they have progressed beyond preventable stages. The temperature gradient between the cell core and surface creates a critical detection lag, often rendering preventive measures ineffective. This detection latency problem is particularly pronounced in large-format cells where heat generation and dissipation dynamics are more complex.

Material degradation mechanisms pose another substantial challenge. The solid-electrolyte interphase (SEI) layer, crucial for battery stability, can decompose at elevated temperatures (typically starting around 80-120°C), initiating exothermic reactions. This decomposition releases heat that accelerates further degradation in a dangerous positive feedback loop. Current electrolyte formulations still exhibit flammability issues, and while flame retardants can be added, they often compromise battery performance.

Propagation control between cells in battery packs represents a persistent engineering challenge. Even with sophisticated thermal management systems, preventing cell-to-cell propagation in high-density packs remains difficult. The close proximity required for energy density optimization creates thermal pathways that can facilitate runaway spread. Current isolation materials and techniques often add significant weight and volume, contradicting the industry's push toward higher energy density.

Balancing safety with performance creates fundamental design conflicts. Safety features such as shutdown separators, pressure relief mechanisms, and conservative voltage windows invariably reduce energy density, power capability, or cycle life. This trade-off becomes increasingly problematic as applications demand both higher performance and enhanced safety, particularly in electric vehicles and grid storage systems.

Regulatory frameworks and testing protocols have not fully kept pace with rapid technological developments. Current standards may not adequately address all failure modes in next-generation high-capacity cells, creating uncertainty in safety validation. The lack of standardized approaches to thermal runaway prevention across different applications and regions further complicates the development of universal safety solutions.

Current Mitigation Strategies for Thermal Events

01 Thermal management systems for high-capacity batteries

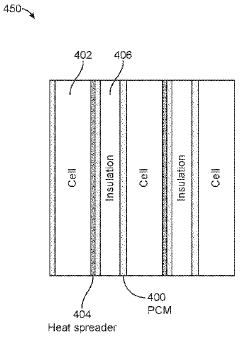

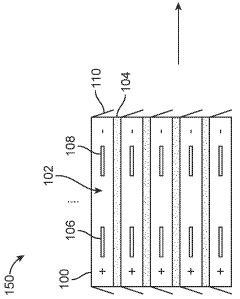

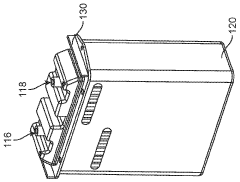

Thermal management systems are crucial for preventing thermal runaway in high-capacity battery cells. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal operating temperatures. Advanced thermal management solutions incorporate liquid cooling channels, phase change materials, or air cooling systems strategically positioned to remove excess heat from battery cells, particularly during high-discharge operations or fast charging.- Thermal management systems for high-capacity batteries: Thermal management systems are crucial for preventing thermal runaway in high-capacity battery cells. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that help maintain optimal operating temperatures. Advanced thermal management solutions incorporate liquid cooling channels, phase change materials, or air cooling systems to efficiently remove heat from battery cells, particularly during high-discharge operations or fast charging.

- Safety mechanisms to prevent thermal propagation: Various safety mechanisms can be implemented to prevent the propagation of thermal runaway from one cell to adjacent cells in battery packs. These include physical barriers, thermal fuses, pressure relief mechanisms, and isolation structures. By compartmentalizing cells or incorporating fire-resistant materials between cells, the risk of catastrophic failure across the entire battery system can be significantly reduced, enhancing overall safety of high-capacity battery installations.

- Advanced battery cell materials and designs: Innovative materials and cell designs can inherently improve thermal stability of high-capacity batteries. This includes the development of novel electrode materials, electrolyte formulations with flame-retardant additives, and separator technologies with enhanced thermal resistance. Structural modifications such as improved current collector designs and optimized electrode thickness can also help distribute heat more evenly and reduce hotspot formation that might trigger thermal runaway events.

- Battery management systems for early detection: Sophisticated battery management systems (BMS) employ sensors and algorithms to detect early signs of potential thermal runaway conditions. These systems continuously monitor parameters such as cell voltage, current, and temperature patterns to identify abnormalities. When potential issues are detected, the BMS can implement protective measures such as reducing charging rates, disconnecting affected cells, or activating cooling systems before thermal runaway occurs, significantly enhancing battery safety.

- Testing and simulation methods for thermal runaway: Advanced testing protocols and simulation methods have been developed to evaluate thermal runaway risks in high-capacity battery cells. These include accelerated aging tests, abuse testing under controlled conditions, and computational models that predict thermal behavior. By understanding the mechanisms and triggers of thermal runaway through these methods, manufacturers can design more robust battery systems with improved safety features tailored to specific operating conditions and applications.

02 Safety mechanisms to prevent thermal propagation

Various safety mechanisms can be implemented to prevent thermal runaway from propagating between adjacent cells in high-capacity battery packs. These include physical barriers, thermal fuses, current interrupt devices, and specialized separator materials. When one cell experiences thermal runaway, these mechanisms isolate the affected cell, preventing heat transfer to neighboring cells and containing the thermal event to minimize damage to the entire battery system.Expand Specific Solutions03 Advanced battery cell materials and designs

Innovative materials and cell designs can significantly reduce the risk of thermal runaway in high-capacity batteries. These include flame-retardant electrolytes, ceramic-coated separators, and novel cathode/anode materials with enhanced thermal stability. Structural modifications such as internal current collectors with thermal shutdown properties and specialized electrode designs help maintain cell integrity under extreme conditions, preventing the cascade of chemical reactions that lead to thermal runaway.Expand Specific Solutions04 Battery management systems for early detection

Sophisticated battery management systems (BMS) employ sensors and algorithms to detect early signs of potential thermal runaway. These systems continuously monitor parameters such as cell voltage, internal resistance, temperature gradients, and gas evolution. When abnormal patterns are detected, the BMS can take preventive actions such as reducing charging current, activating cooling systems, or disconnecting affected cells before thermal runaway occurs, thereby enhancing overall battery safety.Expand Specific Solutions05 Venting and pressure relief mechanisms

High-capacity battery cells incorporate venting and pressure relief mechanisms to safely release gases generated during thermal events. These mechanisms include engineered rupture discs, pressure relief valves, and controlled venting channels that direct hazardous gases away from users. By preventing pressure buildup within cells, these features reduce the risk of explosive cell rupture during thermal runaway, minimizing potential damage and improving overall safety of battery systems.Expand Specific Solutions

Leading Battery Safety Solution Providers

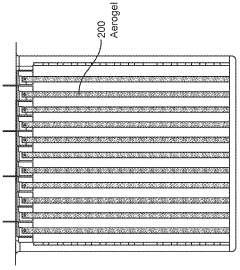

Battery thermal runaway in high-capacity cells represents a critical challenge in the evolving energy storage landscape. The market is in a growth phase, with an estimated global value exceeding $5 billion and projected CAGR of 15-20% through 2030. Leading players like Tesla, Samsung SDI, and BYD are advancing multi-layered safety systems, while emerging specialists such as Aspen Aerogels focus on thermal barrier materials. SK On and CATL are pioneering early detection systems, with Microvast and Automotive Cells Company developing novel electrolyte formulations. The competitive landscape is intensifying as EV manufacturers (BMW, Volkswagen) increasingly develop proprietary battery safety technologies, while traditional cell manufacturers enhance thermal management capabilities to meet stringent safety regulations.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a multi-layered thermal management system for high-capacity lithium-ion cells that combines active cooling with innovative materials to prevent thermal runaway propagation. Their approach includes a novel separator technology with ceramic coating that maintains structural integrity at high temperatures, preventing internal short circuits. The company has implemented early detection systems using real-time impedance monitoring to identify potential thermal events before they escalate. Samsung's solution also incorporates flame-retardant additives in the electrolyte composition that activate at elevated temperatures to suppress combustion reactions. Additionally, they've engineered cell-to-cell isolation barriers within battery modules that can contain thermal events to a single cell, preventing cascading failures across the entire battery pack.

Strengths: Samsung's multi-layered approach provides redundant safety mechanisms, significantly reducing thermal runaway risks. Their ceramic-coated separators maintain integrity at temperatures up to 200°C, far exceeding industry standards. Weaknesses: The complex thermal management system adds weight and cost to battery packs, potentially reducing energy density and increasing production expenses.

Tesla, Inc.

Technical Solution: Tesla has pioneered an integrated approach to thermal runaway prevention and containment in their high-capacity cells. Their technology combines advanced cell chemistry with sophisticated battery management systems (BMS) that continuously monitor individual cell temperatures, voltages, and internal resistance to detect anomalies before they escalate. Tesla's cells feature proprietary flame-retardant additives in the electrolyte and utilize a unique venting mechanism designed to release pressure in a controlled manner during thermal events. The company has developed a patented intumescent material between cells that expands when exposed to heat, creating physical barriers to prevent propagation. Tesla's cooling system employs a serpentine cooling plate design with high thermal conductivity that maintains uniform temperature distribution across the battery pack, eliminating hotspots that could trigger thermal runaway. Their battery packs also incorporate fireproof mica sheets between modules to compartmentalize potential thermal events.

Strengths: Tesla's integrated approach provides multiple layers of protection while maintaining high energy density. Their BMS can predict potential failures before they occur, enabling preventive measures. The cooling system design ensures temperature uniformity across large battery packs. Weaknesses: The sophisticated monitoring and cooling systems add complexity and cost to the battery architecture, and the proprietary nature of their technology creates potential supply chain vulnerabilities.

Key Thermal Runaway Mechanism Research

Battery module capable of delaying thermal runaway and vehicle using same

PatentInactiveEP4044346A1

Innovation

- A battery module design featuring thermal runaway sealing assemblies with U-shaped enclosures, foam for buffering and heat insulation, and multi-layer structures for directional heat management, including aerogel and mica sheets, to slow down heat diffusion and control thermal runaway.

Battery with selective phase change features

PatentActiveAU2021283348B2

Innovation

- Incorporating a phase change material (PCM) within the battery submodule to absorb excess heat and prevent temperature increases, thereby preventing thermal runaway events by providing an emergency cooling effect.

Regulatory Framework for Battery Safety Standards

The global regulatory landscape for battery safety has evolved significantly in response to the increasing incidents of thermal runaway in high-capacity cells. International standards organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established comprehensive frameworks that address the specific risks associated with thermal runaway events. The IEC 62133 standard, which covers safety requirements for portable sealed secondary cells, has been updated to include more rigorous testing protocols specifically targeting thermal stability under extreme conditions.

In the United States, the Department of Transportation (DOT) and the Federal Aviation Administration (FAA) have implemented stringent regulations for the transportation of lithium-ion batteries, particularly following several high-profile incidents involving battery fires in aircraft cargo holds. These regulations mandate specific packaging, labeling, and quantity limitations to mitigate thermal runaway risks during transport. Similarly, the European Union's Battery Directive has been expanded to incorporate enhanced safety requirements, with particular emphasis on thermal management systems.

The UN Manual of Tests and Criteria, specifically UN 38.3, outlines mandatory testing procedures for lithium batteries before they can be transported. These tests include thermal cycling, external short circuit, impact, overcharge, and forced discharge tests—all designed to evaluate a battery's resilience against conditions that might trigger thermal runaway. Manufacturers must certify compliance with these standards before their products can enter the global supply chain.

China, as a major battery manufacturing hub, has implemented GB/T 31485-2015, which specifically addresses safety requirements for traction battery packs and systems in electric vehicles. This standard includes detailed protocols for thermal runaway testing and prevention, reflecting China's growing emphasis on electric vehicle safety.

Industry-specific standards have also emerged, with automotive standards such as ISO 6469 and SAE J2464 providing detailed requirements for electric vehicle battery safety, including thermal runaway prevention and containment strategies. These standards are continuously updated to address emerging risks associated with increasing energy densities in modern battery cells.

Regulatory compliance now increasingly requires manufacturers to implement Battery Management Systems (BMS) with sophisticated thermal monitoring capabilities. These systems must be capable of detecting early signs of thermal instability and taking preventive actions before a full thermal runaway event occurs. The trend toward predictive safety measures represents a significant shift from the reactive approaches that characterized earlier regulatory frameworks.

In the United States, the Department of Transportation (DOT) and the Federal Aviation Administration (FAA) have implemented stringent regulations for the transportation of lithium-ion batteries, particularly following several high-profile incidents involving battery fires in aircraft cargo holds. These regulations mandate specific packaging, labeling, and quantity limitations to mitigate thermal runaway risks during transport. Similarly, the European Union's Battery Directive has been expanded to incorporate enhanced safety requirements, with particular emphasis on thermal management systems.

The UN Manual of Tests and Criteria, specifically UN 38.3, outlines mandatory testing procedures for lithium batteries before they can be transported. These tests include thermal cycling, external short circuit, impact, overcharge, and forced discharge tests—all designed to evaluate a battery's resilience against conditions that might trigger thermal runaway. Manufacturers must certify compliance with these standards before their products can enter the global supply chain.

China, as a major battery manufacturing hub, has implemented GB/T 31485-2015, which specifically addresses safety requirements for traction battery packs and systems in electric vehicles. This standard includes detailed protocols for thermal runaway testing and prevention, reflecting China's growing emphasis on electric vehicle safety.

Industry-specific standards have also emerged, with automotive standards such as ISO 6469 and SAE J2464 providing detailed requirements for electric vehicle battery safety, including thermal runaway prevention and containment strategies. These standards are continuously updated to address emerging risks associated with increasing energy densities in modern battery cells.

Regulatory compliance now increasingly requires manufacturers to implement Battery Management Systems (BMS) with sophisticated thermal monitoring capabilities. These systems must be capable of detecting early signs of thermal instability and taking preventive actions before a full thermal runaway event occurs. The trend toward predictive safety measures represents a significant shift from the reactive approaches that characterized earlier regulatory frameworks.

Environmental Impact of Battery Thermal Events

Thermal runaway events in high-capacity batteries pose significant environmental hazards that extend beyond immediate safety concerns. When batteries experience thermal failure, they release a complex mixture of toxic gases, particulate matter, and chemical compounds into the atmosphere. These emissions typically include carbon monoxide, hydrogen fluoride, phosphoryl fluoride, and various volatile organic compounds (VOCs), which can contribute to air pollution and pose respiratory risks to nearby populations.

The environmental impact varies significantly based on battery chemistry. Lithium-ion cells with nickel-manganese-cobalt (NMC) cathodes produce different emission profiles compared to lithium-iron-phosphate (LFP) or lithium-cobalt-oxide (LCO) chemistries. Research indicates that higher capacity cells generally release proportionally larger volumes of hazardous substances during thermal events, with some high-energy density formulations generating up to 2-3 liters of toxic gas per watt-hour of capacity.

Water contamination represents another critical environmental concern. Firefighting efforts to control battery fires often generate runoff containing dissolved heavy metals, electrolyte components, and other hazardous materials. These contaminants can infiltrate groundwater systems and surface water bodies, potentially affecting aquatic ecosystems and drinking water sources. Studies have documented elevated levels of fluoride, phosphates, and heavy metals in water samples collected after large-scale battery thermal events.

Soil contamination occurs when electrolyte components, electrode materials, and combustion byproducts are deposited onto surrounding terrain. These contaminants may persist in the environment, with certain battery components showing limited biodegradability. The leaching of metals like cobalt, nickel, and manganese from damaged cells presents long-term ecological concerns, as these elements can bioaccumulate in food chains and disrupt ecosystem functions.

The carbon footprint of thermal runaway events extends beyond direct emissions. The premature destruction of high-capacity batteries represents a significant loss of embodied energy—the energy invested in raw material extraction, processing, manufacturing, and transportation. This premature end-of-life scenario negates the environmental benefits that would have been realized through the battery's intended service life in renewable energy applications or electric mobility.

Waste management challenges are compounded by the complex nature of thermally damaged batteries. Conventional recycling processes are often unsuitable for cells that have undergone thermal runaway, as their altered chemical composition and physical state complicate material recovery efforts. This frequently results in lower recycling rates and increased disposal in hazardous waste facilities, further straining waste management infrastructure and increasing environmental burden.

The environmental impact varies significantly based on battery chemistry. Lithium-ion cells with nickel-manganese-cobalt (NMC) cathodes produce different emission profiles compared to lithium-iron-phosphate (LFP) or lithium-cobalt-oxide (LCO) chemistries. Research indicates that higher capacity cells generally release proportionally larger volumes of hazardous substances during thermal events, with some high-energy density formulations generating up to 2-3 liters of toxic gas per watt-hour of capacity.

Water contamination represents another critical environmental concern. Firefighting efforts to control battery fires often generate runoff containing dissolved heavy metals, electrolyte components, and other hazardous materials. These contaminants can infiltrate groundwater systems and surface water bodies, potentially affecting aquatic ecosystems and drinking water sources. Studies have documented elevated levels of fluoride, phosphates, and heavy metals in water samples collected after large-scale battery thermal events.

Soil contamination occurs when electrolyte components, electrode materials, and combustion byproducts are deposited onto surrounding terrain. These contaminants may persist in the environment, with certain battery components showing limited biodegradability. The leaching of metals like cobalt, nickel, and manganese from damaged cells presents long-term ecological concerns, as these elements can bioaccumulate in food chains and disrupt ecosystem functions.

The carbon footprint of thermal runaway events extends beyond direct emissions. The premature destruction of high-capacity batteries represents a significant loss of embodied energy—the energy invested in raw material extraction, processing, manufacturing, and transportation. This premature end-of-life scenario negates the environmental benefits that would have been realized through the battery's intended service life in renewable energy applications or electric mobility.

Waste management challenges are compounded by the complex nature of thermally damaged batteries. Conventional recycling processes are often unsuitable for cells that have undergone thermal runaway, as their altered chemical composition and physical state complicate material recovery efforts. This frequently results in lower recycling rates and increased disposal in hazardous waste facilities, further straining waste management infrastructure and increasing environmental burden.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!