Comparative Challenges of Battery Thermal Runaway in Industrial Robots

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in energy storage systems, particularly in the context of industrial robotics where operational demands are high and safety margins are narrow. The phenomenon, characterized by an uncontrolled, self-accelerating exothermic reaction within battery cells, has evolved from a theoretical concern to a documented hazard as lithium-ion battery adoption has expanded across industrial applications over the past two decades.

The evolution of battery technology in industrial robotics has followed a trajectory from lead-acid and nickel-based chemistries toward lithium-ion dominance due to superior energy density and cycle life characteristics. This transition, while beneficial for performance metrics, has introduced heightened thermal runaway risks due to the reactive nature of lithium-ion chemistry and the energy-dense configurations required for industrial robot operation.

Current technical objectives in addressing thermal runaway challenges focus on three primary dimensions: prevention through advanced battery management systems (BMS), containment through innovative thermal management designs, and mitigation through rapid detection and response protocols. These objectives are increasingly critical as industrial robots transition from controlled factory environments to more variable conditions in collaborative and field robotics applications.

The technical progression in this domain has been marked by significant milestones, including the development of solid-state electrolytes, advanced separator materials, and thermal propagation barriers. However, the unique operational profile of industrial robots—characterized by high-power demands, rapid charge/discharge cycles, and potential physical impacts—creates distinct thermal runaway risk factors compared to electric vehicles or stationary storage applications.

Industry standards and regulatory frameworks have evolved in response to documented thermal incidents, with organizations such as UL, IEC, and ISO establishing increasingly stringent safety requirements specific to robotic applications. The technical objective landscape now encompasses not only preventing initial cell failure but also ensuring fail-safe system responses that maintain operational integrity even during thermal events.

Research trajectories indicate growing emphasis on comparative analysis of thermal runaway characteristics across different battery chemistries and form factors specifically optimized for industrial robotics. This includes evaluation of lithium iron phosphate (LFP) versus nickel manganese cobalt (NMC) chemistries, prismatic versus cylindrical cell architectures, and various thermal management approaches ranging from passive systems to active liquid cooling technologies.

The ultimate technical goal remains the development of battery systems that deliver the energy density and power output required for advanced industrial robotics while eliminating thermal runaway risks through fundamental materials innovation and system-level safety engineering.

The evolution of battery technology in industrial robotics has followed a trajectory from lead-acid and nickel-based chemistries toward lithium-ion dominance due to superior energy density and cycle life characteristics. This transition, while beneficial for performance metrics, has introduced heightened thermal runaway risks due to the reactive nature of lithium-ion chemistry and the energy-dense configurations required for industrial robot operation.

Current technical objectives in addressing thermal runaway challenges focus on three primary dimensions: prevention through advanced battery management systems (BMS), containment through innovative thermal management designs, and mitigation through rapid detection and response protocols. These objectives are increasingly critical as industrial robots transition from controlled factory environments to more variable conditions in collaborative and field robotics applications.

The technical progression in this domain has been marked by significant milestones, including the development of solid-state electrolytes, advanced separator materials, and thermal propagation barriers. However, the unique operational profile of industrial robots—characterized by high-power demands, rapid charge/discharge cycles, and potential physical impacts—creates distinct thermal runaway risk factors compared to electric vehicles or stationary storage applications.

Industry standards and regulatory frameworks have evolved in response to documented thermal incidents, with organizations such as UL, IEC, and ISO establishing increasingly stringent safety requirements specific to robotic applications. The technical objective landscape now encompasses not only preventing initial cell failure but also ensuring fail-safe system responses that maintain operational integrity even during thermal events.

Research trajectories indicate growing emphasis on comparative analysis of thermal runaway characteristics across different battery chemistries and form factors specifically optimized for industrial robotics. This includes evaluation of lithium iron phosphate (LFP) versus nickel manganese cobalt (NMC) chemistries, prismatic versus cylindrical cell architectures, and various thermal management approaches ranging from passive systems to active liquid cooling technologies.

The ultimate technical goal remains the development of battery systems that deliver the energy density and power output required for advanced industrial robotics while eliminating thermal runaway risks through fundamental materials innovation and system-level safety engineering.

Market Analysis for Industrial Robot Battery Safety

The industrial robot battery safety market is experiencing significant growth driven by the increasing adoption of autonomous and mobile robots across manufacturing, logistics, and service sectors. As industrial robots become more prevalent, the demand for advanced battery safety solutions has intensified, particularly regarding thermal runaway prevention and management systems. Current market valuations indicate the global industrial robot battery safety segment reached approximately 1.2 billion USD in 2023, with projections suggesting a compound annual growth rate of 18.7% through 2030.

Market demand is primarily fueled by stringent safety regulations across major industrial economies, with the European Union's Machinery Directive and OSHA standards in the United States serving as key regulatory drivers. Additionally, high-profile battery failure incidents in industrial settings have heightened awareness among end-users, creating a market pull for enhanced safety solutions.

The market segmentation reveals distinct categories based on robot type and application environment. Collaborative robots (cobots) represent the fastest-growing segment due to their direct human interaction requirements, necessitating superior battery safety measures. Meanwhile, autonomous mobile robots (AMRs) constitute the largest market share by volume, as their continuous operation and charging cycles present unique thermal management challenges.

Geographically, East Asia dominates the market with approximately 42% share, driven by the high concentration of robot manufacturers and industrial automation in China, Japan, and South Korea. North America follows at 28%, with Europe accounting for 23% of the global market. Emerging economies in Southeast Asia and Latin America represent the fastest-growing regional markets, albeit from smaller bases.

Customer segmentation analysis reveals automotive manufacturing as the largest end-user segment (31%), followed by electronics manufacturing (24%), logistics and warehousing (18%), and general industrial applications (27%). Large enterprises currently account for approximately 65% of market revenue, though small and medium enterprises are adopting battery safety solutions at an accelerating rate as costs decrease and modular solutions become available.

The market exhibits a price sensitivity correlation with robot value, with premium safety systems commanding higher margins in high-value robot applications. Notably, the total cost of ownership calculation increasingly factors in battery safety systems as insurance providers adjust premiums based on implemented safety measures. Market research indicates customers are willing to pay a 15-20% premium for robots with advanced thermal runaway protection systems, reflecting the growing recognition of battery safety as a critical operational consideration rather than merely a compliance requirement.

Market demand is primarily fueled by stringent safety regulations across major industrial economies, with the European Union's Machinery Directive and OSHA standards in the United States serving as key regulatory drivers. Additionally, high-profile battery failure incidents in industrial settings have heightened awareness among end-users, creating a market pull for enhanced safety solutions.

The market segmentation reveals distinct categories based on robot type and application environment. Collaborative robots (cobots) represent the fastest-growing segment due to their direct human interaction requirements, necessitating superior battery safety measures. Meanwhile, autonomous mobile robots (AMRs) constitute the largest market share by volume, as their continuous operation and charging cycles present unique thermal management challenges.

Geographically, East Asia dominates the market with approximately 42% share, driven by the high concentration of robot manufacturers and industrial automation in China, Japan, and South Korea. North America follows at 28%, with Europe accounting for 23% of the global market. Emerging economies in Southeast Asia and Latin America represent the fastest-growing regional markets, albeit from smaller bases.

Customer segmentation analysis reveals automotive manufacturing as the largest end-user segment (31%), followed by electronics manufacturing (24%), logistics and warehousing (18%), and general industrial applications (27%). Large enterprises currently account for approximately 65% of market revenue, though small and medium enterprises are adopting battery safety solutions at an accelerating rate as costs decrease and modular solutions become available.

The market exhibits a price sensitivity correlation with robot value, with premium safety systems commanding higher margins in high-value robot applications. Notably, the total cost of ownership calculation increasingly factors in battery safety systems as insurance providers adjust premiums based on implemented safety measures. Market research indicates customers are willing to pay a 15-20% premium for robots with advanced thermal runaway protection systems, reflecting the growing recognition of battery safety as a critical operational consideration rather than merely a compliance requirement.

Current Challenges and Limitations in Battery Thermal Management

Despite significant advancements in battery technology for industrial robots, thermal management remains a critical challenge that limits performance and poses safety risks. Current lithium-ion battery systems used in industrial robotics face several thermal management limitations that require urgent attention. The high energy density that makes these batteries attractive for mobile robotics simultaneously creates concentrated heat generation during operation, particularly under high-load conditions common in industrial applications.

The primary challenge lies in the spatial constraints of industrial robots, which severely restrict the implementation of conventional cooling systems. Unlike electric vehicles with dedicated battery compartments, industrial robots must integrate batteries within their existing form factors, leaving minimal space for thermal management hardware. This constraint forces engineers to make significant compromises between cooling efficiency and maintaining the robot's operational capabilities.

Heat dissipation mechanisms currently employed in industrial robots often prove inadequate during peak operational demands. Passive cooling systems lack the capacity to manage thermal loads during continuous operation or rapid charging cycles, while active cooling systems consume valuable energy and add weight—both critical factors in robot performance metrics. This creates a technical paradox where addressing thermal issues may simultaneously degrade other performance parameters.

Detection and prevention systems for thermal runaway events remain insufficiently developed for the unique operational profiles of industrial robots. Current battery management systems (BMS) typically rely on temperature sensors with limited spatial resolution, creating potential blind spots where hotspots can develop undetected. The integration of more comprehensive sensing networks is hampered by the aforementioned space limitations and the complex articulated structures of industrial robots.

Material limitations further exacerbate these challenges. Current thermal interface materials and phase change solutions demonstrate degraded performance over time, particularly under the vibration and movement patterns characteristic of industrial robots. This degradation creates a maintenance burden and introduces unpredictability into thermal management performance over the robot's operational lifespan.

The industry also faces standardization challenges, with no unified approach to thermal management in robotic applications. This has resulted in fragmented solutions that complicate fleet management for industrial users deploying robots from multiple manufacturers. The lack of standardized testing protocols specifically designed for evaluating thermal management in industrial robotics further impedes comparative assessment and regulatory oversight.

Environmental factors introduce additional variables, as industrial robots often operate in diverse thermal environments ranging from refrigerated warehouses to foundries. Current thermal management systems struggle to adapt to these varying ambient conditions, creating inconsistent performance and safety profiles across different deployment scenarios.

The primary challenge lies in the spatial constraints of industrial robots, which severely restrict the implementation of conventional cooling systems. Unlike electric vehicles with dedicated battery compartments, industrial robots must integrate batteries within their existing form factors, leaving minimal space for thermal management hardware. This constraint forces engineers to make significant compromises between cooling efficiency and maintaining the robot's operational capabilities.

Heat dissipation mechanisms currently employed in industrial robots often prove inadequate during peak operational demands. Passive cooling systems lack the capacity to manage thermal loads during continuous operation or rapid charging cycles, while active cooling systems consume valuable energy and add weight—both critical factors in robot performance metrics. This creates a technical paradox where addressing thermal issues may simultaneously degrade other performance parameters.

Detection and prevention systems for thermal runaway events remain insufficiently developed for the unique operational profiles of industrial robots. Current battery management systems (BMS) typically rely on temperature sensors with limited spatial resolution, creating potential blind spots where hotspots can develop undetected. The integration of more comprehensive sensing networks is hampered by the aforementioned space limitations and the complex articulated structures of industrial robots.

Material limitations further exacerbate these challenges. Current thermal interface materials and phase change solutions demonstrate degraded performance over time, particularly under the vibration and movement patterns characteristic of industrial robots. This degradation creates a maintenance burden and introduces unpredictability into thermal management performance over the robot's operational lifespan.

The industry also faces standardization challenges, with no unified approach to thermal management in robotic applications. This has resulted in fragmented solutions that complicate fleet management for industrial users deploying robots from multiple manufacturers. The lack of standardized testing protocols specifically designed for evaluating thermal management in industrial robotics further impedes comparative assessment and regulatory oversight.

Environmental factors introduce additional variables, as industrial robots often operate in diverse thermal environments ranging from refrigerated warehouses to foundries. Current thermal management systems struggle to adapt to these varying ambient conditions, creating inconsistent performance and safety profiles across different deployment scenarios.

Existing Thermal Runaway Prevention Solutions

01 Thermal management systems for preventing thermal runaway

Various thermal management systems can be implemented to prevent battery thermal runaway. These systems monitor temperature changes and provide cooling mechanisms to maintain optimal operating conditions. Advanced cooling technologies including liquid cooling, phase change materials, and heat dissipation structures help regulate battery temperature and prevent the cascade effect of thermal runaway. These systems often incorporate sensors for early detection of temperature anomalies.- Thermal management systems for battery safety: Advanced thermal management systems are crucial for preventing thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring technologies that work together to maintain optimal operating temperatures. By effectively managing heat distribution and dissipation, these systems can prevent the cascade of exothermic reactions that lead to thermal runaway, significantly enhancing battery safety and reliability in various applications.

- Battery cell design and materials for thermal stability: Innovative battery cell designs and materials play a critical role in mitigating thermal runaway risks. These include advanced electrode materials, separator technologies with thermal shutdown capabilities, and novel electrolyte formulations with flame-retardant properties. The integration of thermally stable components and structural improvements helps contain potential thermal events within individual cells, preventing propagation throughout the battery pack and enhancing overall safety performance.

- Early detection and warning systems: Early detection systems are essential for identifying potential thermal runaway conditions before they escalate. These systems utilize various sensors, monitoring algorithms, and diagnostic tools to detect abnormal temperature increases, voltage fluctuations, or gas emissions that may indicate the onset of thermal instability. By providing timely warnings and triggering preventive measures, these detection systems enable proactive intervention to mitigate thermal runaway risks and prevent catastrophic battery failures.

- Battery pack architecture and isolation strategies: Strategic battery pack architecture and isolation techniques are designed to contain thermal events and prevent propagation between cells. These approaches include physical barriers, thermal fuses, insulation materials, and compartmentalization strategies that limit heat transfer. By implementing effective isolation mechanisms, thermal runaway in one cell can be prevented from spreading to adjacent cells, significantly reducing the risk of catastrophic failure in the entire battery system.

- Safety mechanisms and emergency response features: Integrated safety mechanisms and emergency response features provide critical protection against thermal runaway consequences. These include pressure relief valves, current interrupt devices, thermal cutoffs, and automated shutdown systems that activate during abnormal conditions. Additionally, fire suppression technologies and venting mechanisms help manage thermal events when they occur. These multi-layered safety approaches work together to minimize damage and protect users when thermal stability is compromised.

02 Battery cell design and materials to mitigate thermal runaway

Innovative battery cell designs and materials can significantly reduce the risk of thermal runaway. This includes the development of advanced electrode materials, separators with thermal shutdown properties, and flame-retardant electrolytes. Structural modifications to battery cells, such as improved insulation between cells and the use of thermally stable components, help contain thermal events and prevent propagation throughout the battery pack.Expand Specific Solutions03 Detection and early warning systems for thermal runaway

Early detection systems are crucial for identifying potential thermal runaway conditions before they escalate. These systems utilize various sensors to monitor parameters such as temperature, voltage, current, and gas emissions. Advanced algorithms analyze these parameters to identify abnormal patterns indicative of impending thermal events. When potential issues are detected, warning systems alert users or activate preventive measures to mitigate risks.Expand Specific Solutions04 Battery management systems (BMS) for thermal runaway prevention

Battery management systems play a critical role in preventing thermal runaway by continuously monitoring and controlling battery operating conditions. These systems regulate charging and discharging processes, balance cell voltages, and implement protective measures when abnormal conditions are detected. Advanced BMS incorporate machine learning algorithms to predict potential thermal events based on historical data and battery behavior patterns.Expand Specific Solutions05 Safety mechanisms and containment strategies for thermal runaway

Various safety mechanisms and containment strategies are employed to minimize the impact of thermal runaway events. These include pressure relief mechanisms, thermal fuses, and physical barriers between cells to prevent propagation. Specialized containment structures are designed to isolate affected cells and direct heat and gases away from other components. Fire-resistant materials and enclosures help contain thermal events and prevent catastrophic failures in battery systems.Expand Specific Solutions

Key Industrial Players in Robot Battery Systems

The battery thermal runaway challenge in industrial robots is evolving within a rapidly maturing market, currently transitioning from early adoption to growth phase. The competitive landscape features established automotive players like Tesla, Hyundai Mobis, and Bosch alongside specialized battery technology firms such as Samsung SDI, EVE Energy, and American Lithium Energy. Academic-industry partnerships are accelerating innovation, with institutions like Nanjing Tech University and University of South Florida collaborating with companies on thermal management solutions. The market is characterized by increasing technical sophistication in battery safety systems, with companies like Aspen Aerogels and NeoGraf Solutions developing advanced thermal barrier materials. Competition is intensifying as industrial robotics adoption grows, driving demand for safer, more reliable power solutions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive thermal management system specifically addressing thermal runaway in industrial robot applications. Their solution integrates multi-layered safety mechanisms including: (1) A proprietary ceramic-coated separator technology that maintains structural integrity at temperatures up to 200°C, significantly higher than conventional separators; (2) Advanced thermal propagation prevention through strategic cell spacing and fire-resistant barriers between modules; (3) Real-time thermal monitoring using distributed temperature sensors with predictive analytics to detect anomalies before critical thresholds are reached. Samsung's system employs phase-change materials (PCMs) strategically positioned between cells to absorb excess heat during operation, maintaining optimal temperature ranges even under high-load industrial robot operations. Their Battery Management System (BMS) incorporates machine learning algorithms that continuously adapt to usage patterns specific to industrial robotics applications, preemptively adjusting charging parameters and operational limits to prevent conditions conducive to thermal runaway.

Strengths: Superior thermal stability through proprietary separator technology; Comprehensive multi-layered approach combining hardware and software solutions; Adaptive learning capabilities tailored to industrial robot operational patterns. Weaknesses: Higher implementation cost compared to standard solutions; System complexity requires specialized maintenance; Additional weight and space requirements may impact robot design parameters.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a comprehensive approach to addressing thermal runaway in industrial robotics applications through their Advanced Battery Research facilities. Their solution integrates fundamental materials science with systems-level engineering: (1) Advanced in-situ diagnostic techniques including synchrotron X-ray imaging that provides unprecedented visibility into battery failure mechanisms under the dynamic loading conditions typical in industrial robots; (2) Computational models that accurately predict thermal propagation pathways specific to the compact battery configurations required in robotics applications; (3) Novel electrolyte additives that significantly increase thermal stability thresholds without compromising performance. Argonne's approach includes the development of specialized non-flammable electrolytes that maintain performance under the wide temperature ranges and variable load profiles characteristic of industrial robots. Their research has produced advanced battery management algorithms that incorporate early warning indicators specific to industrial applications, detecting subtle precursors to thermal events before conventional systems. Additionally, Argonne has pioneered testing methodologies that accurately simulate the unique operational conditions of industrial robots, including rapid charge/discharge cycles, vibration profiles, and mechanical stress factors.

Strengths: World-class research capabilities leveraging national laboratory facilities; Fundamental materials innovations addressing root causes of thermal runaway; Comprehensive testing methodologies specifically developed for robotics applications. Weaknesses: Solutions often require significant adaptation for commercial implementation; Longer development timelines compared to industry-developed approaches; May require specialized manufacturing capabilities for advanced materials.

Critical Battery Safety Patents and Research

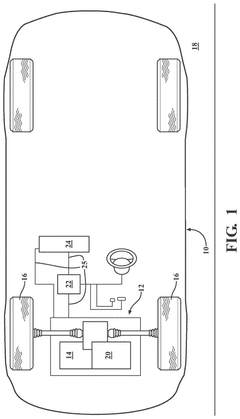

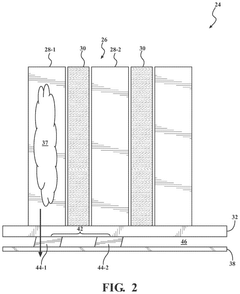

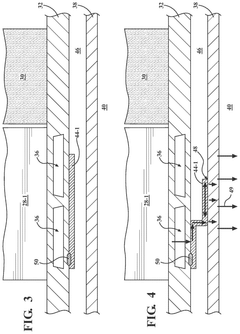

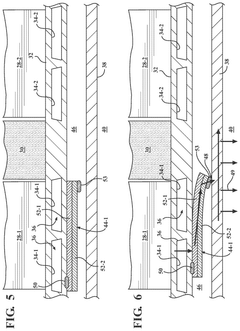

Mitigation of thermal runaway in a battery module

PatentActiveUS12308404B2

Innovation

- The battery module incorporates a heat sink in contact with each battery cell to absorb thermal energy, along with a heat transfer mechanism featuring a switch that detects temperature exceeding a predetermined value, bridging an air gap to direct thermal energy from the overheated cell to the module enclosure, thereby controlling the propagation of thermal runaway.

Safety Standards and Compliance Requirements

The regulatory landscape for industrial robot battery safety has evolved significantly in response to thermal runaway incidents across various sectors. IEC 62368-1, which replaced IEC 60950-1 and IEC 60065, now serves as the primary international standard addressing lithium battery safety in electronic equipment, including industrial robots. This standard specifically addresses thermal runaway prevention through requirements for proper thermal management systems, battery monitoring capabilities, and emergency shutdown protocols.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries in industrial applications, with specific provisions for thermal runaway mitigation. The National Fire Protection Association (NFPA) has also developed NFPA 855, which establishes requirements for the installation of energy storage systems, including those used in industrial robotics. These standards mandate rigorous testing protocols, including nail penetration tests, crush tests, and thermal abuse tests to evaluate battery resilience under extreme conditions.

European regulations, particularly EN 62133 and the more recent EN IEC 63056, impose stringent requirements on battery safety in industrial environments. The EU Machinery Directive 2006/42/EC further mandates that all industrial robots must undergo comprehensive risk assessment, with specific attention to battery systems and their potential for thermal events. Additionally, the ATEX Directive 2014/34/EU applies to robots operating in potentially explosive atmospheres, requiring specialized battery safety measures.

ISO 10218-1 and ISO 10218-2, which govern robot safety requirements, have been updated to include provisions for battery-powered systems, with specific attention to thermal management. The newer ISO/TS 15066, focused on collaborative robots, includes additional safety requirements for battery systems in close human-robot interaction scenarios. These standards establish performance levels for safety functions related to battery monitoring and emergency response.

Compliance with these standards requires manufacturers to implement multi-layered safety approaches. This includes Battery Management Systems (BMS) with real-time temperature monitoring, thermal isolation between cells, automated shutdown mechanisms, and fire suppression systems. Documentation requirements have also become more stringent, with detailed risk assessments, testing reports, and emergency response protocols now mandatory for certification.

The regulatory landscape continues to evolve, with standards bodies currently developing more specific requirements for lithium battery applications in mobile robotics. Industry stakeholders are actively participating in these developments, recognizing that compliance with emerging standards will be crucial for market access and liability protection in the rapidly expanding industrial robotics sector.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries in industrial applications, with specific provisions for thermal runaway mitigation. The National Fire Protection Association (NFPA) has also developed NFPA 855, which establishes requirements for the installation of energy storage systems, including those used in industrial robotics. These standards mandate rigorous testing protocols, including nail penetration tests, crush tests, and thermal abuse tests to evaluate battery resilience under extreme conditions.

European regulations, particularly EN 62133 and the more recent EN IEC 63056, impose stringent requirements on battery safety in industrial environments. The EU Machinery Directive 2006/42/EC further mandates that all industrial robots must undergo comprehensive risk assessment, with specific attention to battery systems and their potential for thermal events. Additionally, the ATEX Directive 2014/34/EU applies to robots operating in potentially explosive atmospheres, requiring specialized battery safety measures.

ISO 10218-1 and ISO 10218-2, which govern robot safety requirements, have been updated to include provisions for battery-powered systems, with specific attention to thermal management. The newer ISO/TS 15066, focused on collaborative robots, includes additional safety requirements for battery systems in close human-robot interaction scenarios. These standards establish performance levels for safety functions related to battery monitoring and emergency response.

Compliance with these standards requires manufacturers to implement multi-layered safety approaches. This includes Battery Management Systems (BMS) with real-time temperature monitoring, thermal isolation between cells, automated shutdown mechanisms, and fire suppression systems. Documentation requirements have also become more stringent, with detailed risk assessments, testing reports, and emergency response protocols now mandatory for certification.

The regulatory landscape continues to evolve, with standards bodies currently developing more specific requirements for lithium battery applications in mobile robotics. Industry stakeholders are actively participating in these developments, recognizing that compliance with emerging standards will be crucial for market access and liability protection in the rapidly expanding industrial robotics sector.

Economic Impact of Battery Failures in Industrial Settings

Battery thermal runaway incidents in industrial robots can lead to catastrophic economic consequences for manufacturing operations. The direct costs of battery replacement typically range from $2,000 to $10,000 per industrial robot, depending on the battery capacity and specifications. However, this represents only a fraction of the total economic impact when considering the broader implications of such failures.

Production downtime resulting from battery failures constitutes the most significant economic burden. In automotive manufacturing, for example, production line stoppages can cost between $22,000 and $50,000 per minute. A single thermal runaway incident may necessitate production shutdowns lasting several hours to days, depending on the severity of the incident and subsequent safety investigations.

Insurance premiums for facilities utilizing industrial robots with lithium-ion batteries have seen increases of 15-30% in recent years, directly correlated with the rising incidence of battery-related incidents. Companies with documented thermal runaway events often face premium increases of up to 50% following such occurrences.

The economic ripple effects extend throughout the supply chain. Just-in-time manufacturing systems are particularly vulnerable, with one study indicating that a 24-hour production delay can impact up to seven downstream companies, creating a multiplier effect that amplifies the original economic damage by 3-5 times.

Regulatory fines and legal liabilities present additional financial exposure. OSHA violations related to battery safety can result in penalties ranging from $13,653 per violation to $136,532 for willful or repeated violations. Worker compensation claims stemming from injuries during thermal runaway incidents average $120,000 per case, with severe injuries potentially resulting in multi-million dollar settlements.

Brand reputation damage, while difficult to quantify precisely, represents a significant long-term economic concern. A survey of manufacturing executives indicated that 78% believe safety incidents involving advanced technologies like industrial robots negatively impact customer confidence, with 62% reporting that such incidents influenced contract negotiations and renewal decisions.

Preventative measures, though requiring initial investment, demonstrate compelling economic returns. Companies implementing comprehensive battery management systems report ROI figures of 300-500% over a five-year period through reduced downtime, lower insurance premiums, and extended battery life.

Production downtime resulting from battery failures constitutes the most significant economic burden. In automotive manufacturing, for example, production line stoppages can cost between $22,000 and $50,000 per minute. A single thermal runaway incident may necessitate production shutdowns lasting several hours to days, depending on the severity of the incident and subsequent safety investigations.

Insurance premiums for facilities utilizing industrial robots with lithium-ion batteries have seen increases of 15-30% in recent years, directly correlated with the rising incidence of battery-related incidents. Companies with documented thermal runaway events often face premium increases of up to 50% following such occurrences.

The economic ripple effects extend throughout the supply chain. Just-in-time manufacturing systems are particularly vulnerable, with one study indicating that a 24-hour production delay can impact up to seven downstream companies, creating a multiplier effect that amplifies the original economic damage by 3-5 times.

Regulatory fines and legal liabilities present additional financial exposure. OSHA violations related to battery safety can result in penalties ranging from $13,653 per violation to $136,532 for willful or repeated violations. Worker compensation claims stemming from injuries during thermal runaway incidents average $120,000 per case, with severe injuries potentially resulting in multi-million dollar settlements.

Brand reputation damage, while difficult to quantify precisely, represents a significant long-term economic concern. A survey of manufacturing executives indicated that 78% believe safety incidents involving advanced technologies like industrial robots negatively impact customer confidence, with 62% reporting that such incidents influenced contract negotiations and renewal decisions.

Preventative measures, though requiring initial investment, demonstrate compelling economic returns. Companies implementing comprehensive battery management systems report ROI figures of 300-500% over a five-year period through reduced downtime, lower insurance premiums, and extended battery life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!