Comparing Strategies for Preventing Battery Thermal Runaway in EVs

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Thermal Runaway Background and Objectives

Thermal runaway in electric vehicle (EV) batteries represents one of the most significant safety challenges facing the automotive industry today. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can rapidly spread to adjacent cells, potentially resulting in fires, explosions, and catastrophic vehicle damage. The evolution of this technical challenge traces back to the early 2010s when lithium-ion batteries began widespread adoption in the automotive sector, with notable incidents including the Tesla Model S fires in 2013 and the Chevrolet Bolt recalls in 2020-2021.

The technical trajectory has been marked by continuous improvements in battery chemistry, from early lithium cobalt oxide (LCO) formulations to more thermally stable options like lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) variants. Despite these advancements, the fundamental challenge persists due to the inherent energy density requirements of modern EVs, creating an ongoing tension between performance and safety.

Current industry trends indicate a multi-faceted approach to thermal runaway prevention, combining advanced battery management systems (BMS), innovative thermal management solutions, and improved cell design. The integration of artificial intelligence for predictive failure analysis represents the cutting edge of this technical evolution, with companies like Tesla, CATL, and LG Energy Solution leading development efforts.

The regulatory landscape has simultaneously evolved, with standards like UN ECE R100, GB/T 31485, and SAE J2464 establishing increasingly stringent safety requirements. These standards have significantly shaped technical development priorities across the industry, pushing manufacturers toward more robust safety systems and redundancies.

The primary technical objectives in this domain include developing early detection systems capable of identifying precursors to thermal events, creating more effective isolation mechanisms to prevent propagation between cells, and designing inherently safer battery chemistries that maintain high energy density while reducing thermal instability risks.

Secondary objectives focus on reducing the cost impact of safety systems, minimizing the weight penalties associated with thermal management solutions, and ensuring that safety enhancements do not significantly compromise vehicle range or performance. The industry also aims to establish standardized testing protocols that can accurately predict real-world thermal runaway risks across different operating conditions and use cases.

The ultimate goal remains achieving a zero-incident rate for battery thermal events while supporting the continued growth of the EV market through consumer confidence in vehicle safety. This represents a critical enabling factor for broader transportation electrification and the associated environmental benefits.

The technical trajectory has been marked by continuous improvements in battery chemistry, from early lithium cobalt oxide (LCO) formulations to more thermally stable options like lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) variants. Despite these advancements, the fundamental challenge persists due to the inherent energy density requirements of modern EVs, creating an ongoing tension between performance and safety.

Current industry trends indicate a multi-faceted approach to thermal runaway prevention, combining advanced battery management systems (BMS), innovative thermal management solutions, and improved cell design. The integration of artificial intelligence for predictive failure analysis represents the cutting edge of this technical evolution, with companies like Tesla, CATL, and LG Energy Solution leading development efforts.

The regulatory landscape has simultaneously evolved, with standards like UN ECE R100, GB/T 31485, and SAE J2464 establishing increasingly stringent safety requirements. These standards have significantly shaped technical development priorities across the industry, pushing manufacturers toward more robust safety systems and redundancies.

The primary technical objectives in this domain include developing early detection systems capable of identifying precursors to thermal events, creating more effective isolation mechanisms to prevent propagation between cells, and designing inherently safer battery chemistries that maintain high energy density while reducing thermal instability risks.

Secondary objectives focus on reducing the cost impact of safety systems, minimizing the weight penalties associated with thermal management solutions, and ensuring that safety enhancements do not significantly compromise vehicle range or performance. The industry also aims to establish standardized testing protocols that can accurately predict real-world thermal runaway risks across different operating conditions and use cases.

The ultimate goal remains achieving a zero-incident rate for battery thermal events while supporting the continued growth of the EV market through consumer confidence in vehicle safety. This represents a critical enabling factor for broader transportation electrification and the associated environmental benefits.

Market Demand Analysis for Safer EV Batteries

The global electric vehicle (EV) market has witnessed unprecedented growth, with sales surpassing 10 million units in 2022, representing a 55% increase from the previous year. This rapid expansion has intensified the demand for safer battery technologies, particularly solutions addressing thermal runaway prevention. Market research indicates that safety concerns remain a significant barrier to EV adoption, with approximately 72% of potential buyers citing battery safety as a major consideration in purchasing decisions.

Consumer awareness regarding battery thermal incidents has heightened following several high-profile EV fires reported in media. This awareness has translated into market pressure for manufacturers to implement more robust safety measures. The insurance industry has also become a key stakeholder, with some providers implementing premium adjustments based on the battery safety systems employed in different EV models.

Regulatory frameworks worldwide are evolving to address these safety concerns. The United Nations Global Technical Regulation No. 20 (GTR 20) has established international standards for EV battery safety, while regional authorities like the European Union's Battery Directive and China's GB/T standards are implementing increasingly stringent safety requirements. These regulations are creating immediate market demand for advanced thermal runaway prevention technologies.

From a market segmentation perspective, premium EV manufacturers have been early adopters of sophisticated thermal management systems, with luxury vehicle buyers willing to pay a premium for enhanced safety features. However, the mid-market segment now represents the largest growth opportunity, as these vehicles balance cost constraints with safety requirements.

The aftermarket for battery safety solutions is emerging as a significant sector, projected to reach $2.7 billion by 2028. This includes retrofitting existing EVs with improved thermal management systems and advanced battery monitoring technologies. Fleet operators, particularly in public transportation and logistics, represent a substantial portion of this market as they seek to minimize operational risks and downtime.

Geographic analysis reveals varying market demands based on regional conditions. Extreme climate regions show stronger preference for robust thermal management systems, with sales of vehicles featuring advanced cooling technologies growing 35% faster in these areas compared to moderate climate regions.

The market for battery safety components, including thermal interface materials, fire-resistant barriers, and advanced battery management systems, is projected to grow at a compound annual growth rate of 24% through 2030. This growth is driven by both consumer demand and regulatory requirements, creating substantial opportunities for component manufacturers and technology providers specializing in thermal runaway prevention solutions.

Consumer awareness regarding battery thermal incidents has heightened following several high-profile EV fires reported in media. This awareness has translated into market pressure for manufacturers to implement more robust safety measures. The insurance industry has also become a key stakeholder, with some providers implementing premium adjustments based on the battery safety systems employed in different EV models.

Regulatory frameworks worldwide are evolving to address these safety concerns. The United Nations Global Technical Regulation No. 20 (GTR 20) has established international standards for EV battery safety, while regional authorities like the European Union's Battery Directive and China's GB/T standards are implementing increasingly stringent safety requirements. These regulations are creating immediate market demand for advanced thermal runaway prevention technologies.

From a market segmentation perspective, premium EV manufacturers have been early adopters of sophisticated thermal management systems, with luxury vehicle buyers willing to pay a premium for enhanced safety features. However, the mid-market segment now represents the largest growth opportunity, as these vehicles balance cost constraints with safety requirements.

The aftermarket for battery safety solutions is emerging as a significant sector, projected to reach $2.7 billion by 2028. This includes retrofitting existing EVs with improved thermal management systems and advanced battery monitoring technologies. Fleet operators, particularly in public transportation and logistics, represent a substantial portion of this market as they seek to minimize operational risks and downtime.

Geographic analysis reveals varying market demands based on regional conditions. Extreme climate regions show stronger preference for robust thermal management systems, with sales of vehicles featuring advanced cooling technologies growing 35% faster in these areas compared to moderate climate regions.

The market for battery safety components, including thermal interface materials, fire-resistant barriers, and advanced battery management systems, is projected to grow at a compound annual growth rate of 24% through 2030. This growth is driven by both consumer demand and regulatory requirements, creating substantial opportunities for component manufacturers and technology providers specializing in thermal runaway prevention solutions.

Current Thermal Runaway Prevention Technologies and Challenges

The current landscape of thermal runaway prevention in electric vehicle (EV) batteries presents a complex interplay of technological solutions and persistent challenges. Battery thermal runaway—a catastrophic failure mode where uncontrolled temperature increases lead to fire or explosion—remains one of the most significant safety concerns in EV development.

Prevention technologies have evolved along several parallel tracks, with Battery Management Systems (BMS) serving as the first line of defense. Modern BMS implementations continuously monitor cell-level parameters including temperature, voltage, and current to detect early warning signs of thermal anomalies. Advanced algorithms can predict potential failures before critical thresholds are reached, enabling preventive measures to be activated.

Thermal management systems represent another crucial prevention strategy, with liquid cooling emerging as the preferred approach for high-performance EVs. These systems maintain optimal operating temperatures across the battery pack, preventing localized hotspots that could trigger thermal runaway. Some manufacturers have implemented phase-change materials that absorb excess heat during rapid charging or high-power discharge events.

At the cell design level, manufacturers have introduced safer cathode chemistries such as lithium iron phosphate (LFP) that demonstrate superior thermal stability compared to nickel-manganese-cobalt (NMC) alternatives. Physical safeguards including ceramic separators, pressure-relief mechanisms, and thermal fuses provide additional protection layers within the cell architecture.

Despite these advancements, significant challenges persist. The fundamental trade-off between energy density and safety continues to constrain design options, as higher energy density cells typically carry increased thermal runaway risk. This creates a difficult balancing act for manufacturers seeking to maximize vehicle range while maintaining safety standards.

Detection sensitivity remains problematic, particularly in distinguishing between normal operational fluctuations and genuine pre-failure conditions. False positives can unnecessarily limit battery performance, while missed warning signs can have catastrophic consequences. The industry still lacks standardized testing protocols that accurately represent real-world failure scenarios.

Cost considerations present another substantial hurdle. Advanced thermal management systems and sophisticated BMS solutions add significant expense to vehicle production. This cost pressure often leads to compromises in thermal safety systems, particularly in more affordable EV segments where price competition is intense.

Aging effects introduce additional complexity, as degradation mechanisms can alter thermal behavior over a battery's lifetime. Current prevention technologies struggle to adapt to these changing characteristics, potentially leaving older vehicles with reduced thermal runaway protection despite being otherwise functional.

Prevention technologies have evolved along several parallel tracks, with Battery Management Systems (BMS) serving as the first line of defense. Modern BMS implementations continuously monitor cell-level parameters including temperature, voltage, and current to detect early warning signs of thermal anomalies. Advanced algorithms can predict potential failures before critical thresholds are reached, enabling preventive measures to be activated.

Thermal management systems represent another crucial prevention strategy, with liquid cooling emerging as the preferred approach for high-performance EVs. These systems maintain optimal operating temperatures across the battery pack, preventing localized hotspots that could trigger thermal runaway. Some manufacturers have implemented phase-change materials that absorb excess heat during rapid charging or high-power discharge events.

At the cell design level, manufacturers have introduced safer cathode chemistries such as lithium iron phosphate (LFP) that demonstrate superior thermal stability compared to nickel-manganese-cobalt (NMC) alternatives. Physical safeguards including ceramic separators, pressure-relief mechanisms, and thermal fuses provide additional protection layers within the cell architecture.

Despite these advancements, significant challenges persist. The fundamental trade-off between energy density and safety continues to constrain design options, as higher energy density cells typically carry increased thermal runaway risk. This creates a difficult balancing act for manufacturers seeking to maximize vehicle range while maintaining safety standards.

Detection sensitivity remains problematic, particularly in distinguishing between normal operational fluctuations and genuine pre-failure conditions. False positives can unnecessarily limit battery performance, while missed warning signs can have catastrophic consequences. The industry still lacks standardized testing protocols that accurately represent real-world failure scenarios.

Cost considerations present another substantial hurdle. Advanced thermal management systems and sophisticated BMS solutions add significant expense to vehicle production. This cost pressure often leads to compromises in thermal safety systems, particularly in more affordable EV segments where price competition is intense.

Aging effects introduce additional complexity, as degradation mechanisms can alter thermal behavior over a battery's lifetime. Current prevention technologies struggle to adapt to these changing characteristics, potentially leaving older vehicles with reduced thermal runaway protection despite being otherwise functional.

Comparative Analysis of Thermal Runaway Prevention Strategies

01 Thermal management systems for battery packs

Advanced thermal management systems are designed to prevent thermal runaway in battery packs by efficiently dissipating heat. These systems include cooling plates, heat sinks, and liquid cooling circuits that maintain optimal operating temperatures. By controlling temperature distribution across battery cells, these systems prevent hotspots that could trigger thermal runaway events. Some designs incorporate phase change materials that absorb excess heat during high-load operations.- Thermal management systems: Advanced thermal management systems are designed to prevent battery thermal runaway by efficiently dissipating heat. These systems include liquid cooling circuits, heat sinks, and thermal interface materials that help maintain optimal operating temperatures. By controlling temperature distribution and preventing hotspots, these systems can significantly reduce the risk of thermal runaway events in battery packs, especially in high-power applications like electric vehicles.

- Battery cell design and materials: Innovative battery cell designs and materials play a crucial role in preventing thermal runaway. This includes the development of safer electrode materials, improved separators with thermal shutdown properties, and flame-retardant electrolytes. These advancements help to increase the thermal stability of battery cells and reduce the likelihood of internal short circuits that can lead to thermal runaway events.

- Battery management systems (BMS): Sophisticated battery management systems continuously monitor critical parameters such as temperature, voltage, and current to detect early signs of potential thermal runaway. These systems implement protective algorithms that can trigger preventive measures like load reduction or emergency shutdown when abnormal conditions are detected. Advanced BMS solutions also incorporate predictive analytics to anticipate and mitigate thermal issues before they escalate.

- Structural safety features: Structural safety features are integrated into battery pack designs to contain thermal runaway events and prevent propagation between cells. These include physical barriers, thermal fuses, pressure relief mechanisms, and explosion-proof enclosures. Such features help isolate affected cells and vent hazardous gases safely, minimizing the risk of catastrophic failure and enhancing overall battery system safety.

- Early detection and diagnostic systems: Advanced diagnostic technologies enable early detection of conditions that may lead to thermal runaway. These systems utilize sensors, imaging techniques, and artificial intelligence to identify abnormalities such as internal short circuits, mechanical deformation, or chemical degradation. By providing early warnings, these systems allow for timely intervention before thermal runaway occurs, significantly enhancing battery safety in various applications.

02 Battery cell design and materials for thermal stability

Innovative battery cell designs incorporate thermally stable materials and structures to mitigate thermal runaway risks. These include flame-retardant separators, heat-resistant electrode materials, and specialized electrolyte formulations with reduced flammability. Some designs feature internal safety mechanisms such as shutdown separators that increase resistance at elevated temperatures. Advanced cathode and anode materials with higher thermal decomposition thresholds help prevent the cascade of exothermic reactions that lead to thermal runaway.Expand Specific Solutions03 Battery management systems with early detection capabilities

Sophisticated battery management systems (BMS) employ algorithms and sensors to detect early signs of thermal abnormalities. These systems monitor parameters such as cell voltage, current, and temperature in real-time to identify potential thermal runaway precursors. When anomalies are detected, the BMS can implement protective measures such as reducing charging current, disconnecting affected cells, or activating cooling systems. Some advanced systems use machine learning to improve prediction accuracy and response time to thermal events.Expand Specific Solutions04 Physical isolation and containment strategies

Physical barriers and isolation techniques are implemented to prevent thermal runaway propagation between battery cells. These include fire-resistant partitions, thermal barriers, and cell-to-cell spacing designs that limit heat transfer. Some battery packs incorporate pressure relief mechanisms to safely vent gases during thermal events. Advanced containment systems can isolate thermal runaway to a single cell or module, preventing catastrophic failure of the entire battery system. These physical protection strategies are particularly important in high-energy density applications.Expand Specific Solutions05 Emergency response and fail-safe mechanisms

Fail-safe mechanisms are integrated into battery systems to respond to thermal events that cannot be prevented. These include emergency shutdown circuits, fuses, and circuit breakers that disconnect power when critical temperature thresholds are exceeded. Some systems incorporate fire suppression technologies that automatically deploy when thermal runaway is detected. Advanced battery packs feature redundant safety systems and isolation contactors that can rapidly disconnect individual modules from the electrical circuit, limiting the energy available to fuel thermal runaway reactions.Expand Specific Solutions

Key Industry Players in EV Battery Safety Solutions

The thermal runaway prevention market in EVs is currently in a growth phase, with increasing market size driven by safety concerns and regulatory pressures. The competitive landscape features established automakers like Toyota, Volkswagen, and BYD alongside specialized technology providers such as Honeywell and CEA. Technical maturity varies significantly across solutions, with companies like BYD and Geely leading with integrated battery management systems, while Toyota and Volkswagen focus on structural safety innovations. Chinese manufacturers including BAIC and Hozon are rapidly advancing thermal management technologies, while Western players like GM and FCA emphasize predictive analytics approaches. This market is expected to grow substantially as EV adoption accelerates globally, with thermal safety becoming a critical competitive differentiator.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated approach to battery thermal runaway prevention that leverages their expertise in aerospace safety systems. Their solution combines advanced materials science with sophisticated detection and suppression technologies. Honeywell's system features proprietary thermal barrier materials derived from aerospace applications that can withstand extreme temperatures, strategically placed between battery modules to prevent thermal propagation. Their early detection system utilizes specialized gas sensors capable of detecting the volatile organic compounds released during the early stages of battery degradation, providing warning signs before thermal runaway initiates. Honeywell's active suppression technology incorporates microencapsulated fire retardants embedded within battery pack structures that automatically release when exposed to specific temperature thresholds. Additionally, they've developed a rapid venting system that can safely channel and cool hot gases away from the battery enclosure. Their comprehensive solution also includes an intelligent control unit that integrates with vehicle systems to initiate emergency protocols when thermal anomalies are detected, including power reduction, emergency cooling activation, and driver alerts.

Strengths: Leverages proven aerospace safety technologies and materials; multi-layered approach combining prevention, detection and active suppression; specialized gas sensing provides earlier warning than temperature monitoring alone. Weaknesses: Potentially higher implementation cost due to specialized materials and sensors; additional weight from comprehensive safety systems; requires integration with vehicle manufacturer's existing battery management systems.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology, which utilizes lithium iron phosphate (LFP) chemistry in a novel cell-to-pack design specifically engineered to prevent thermal runaway. The cells are arranged in a blade-like formation that maximizes space utilization while allowing for improved heat dissipation. BYD's approach includes a multi-layered safety system with real-time monitoring through advanced Battery Management Systems (BMS) that can detect abnormal temperature increases and voltage fluctuations. Their thermal management solution incorporates liquid cooling channels integrated directly between battery cells, maintaining optimal operating temperatures even under high discharge rates. The Blade Battery has demonstrated exceptional safety in nail penetration tests, showing minimal temperature increase compared to conventional batteries that typically experience violent thermal runaway events.

Strengths: Superior thermal stability due to LFP chemistry; innovative structural design that inherently resists propagation of thermal events; demonstrated extreme safety in penetration tests with temperatures remaining below 60°C. Weaknesses: Lower energy density compared to NMC/NCA alternatives; slightly heavier battery packs; potentially higher manufacturing complexity due to unique form factor.

Critical Patents and Research in Battery Thermal Management

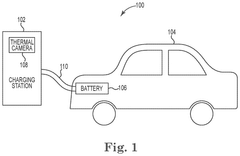

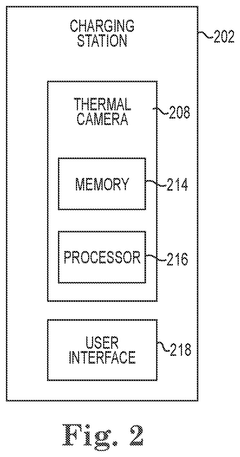

Determining thermal runaway in an electric vehicle battery

PatentPendingUS20250030252A1

Innovation

- A system comprising a thermal camera integrated with an electric vehicle charging station, which uses a Kalman filter algorithm to predict thermal runaway by monitoring temperature changes during charging and comparing them to a predefined temperature gradient.

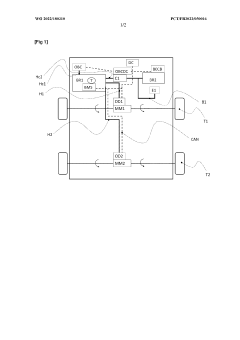

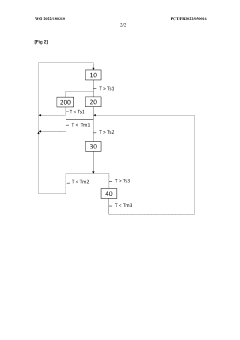

Method and device for controlling a battery to prevent thermal runaway

PatentWO2022180310A1

Innovation

- A method and device that implement closed-loop temperature regulation, switching to maximum cooling and limiting battery power when temperature thresholds are exceeded, and include a driver warning to reduce power consumption, with additional steps to inhibit electrical energy recovery and reduce power to zero when temperatures reach critical levels, ensuring maximum cooling efficiency and safety.

Regulatory Framework and Safety Standards for EV Batteries

The regulatory landscape for electric vehicle (EV) battery safety has evolved significantly in response to the growing concerns about thermal runaway incidents. At the international level, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines specific requirements for the construction, functional safety, and hydrogen emission performance of rechargeable energy storage systems in electric vehicles. This regulation serves as a foundational framework adopted by many countries globally.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety through Federal Motor Vehicle Safety Standards (FMVSS). Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2929, which specifically addresses electric and hybrid vehicle battery safety requirements for lithium-based rechargeable energy storage systems. These standards mandate rigorous testing protocols including thermal shock, vibration, mechanical impact, and overcharge protection.

The European Union implements battery safety regulations through the ECE R100 standard and the General Safety Regulation (GSR). These frameworks require manufacturers to demonstrate compliance through extensive testing and documentation before vehicles can be approved for market entry. Recent updates to these regulations have placed increased emphasis on thermal management systems and early detection mechanisms for potential thermal runaway conditions.

In Asia, China has established the GB/T 31467 standard specifically addressing safety requirements for lithium-ion batteries in electric vehicles. This standard is particularly stringent regarding thermal propagation prevention and includes detailed requirements for battery management systems. Japan follows technical standards set by the Ministry of Land, Infrastructure, Transport and Tourism, which incorporate specific provisions for preventing and containing thermal runaway events.

Industry standards complement regulatory frameworks, with organizations like Underwriters Laboratories (UL) developing standards such as UL 2580 for batteries used in electric vehicles. These standards often exceed minimum regulatory requirements and focus on comprehensive safety testing under extreme conditions.

Recent regulatory trends show a shift toward performance-based standards rather than prescriptive requirements, allowing manufacturers greater flexibility in implementing innovative thermal runaway prevention strategies. There is also increasing emphasis on the entire battery lifecycle, including requirements for second-life applications and end-of-life disposal or recycling.

Compliance with these evolving regulations presents significant challenges for manufacturers, particularly as they navigate different requirements across global markets. However, these standards have been instrumental in driving innovation in thermal management systems, battery design, and safety mechanisms, ultimately contributing to safer electric vehicle technologies.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety through Federal Motor Vehicle Safety Standards (FMVSS). Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2929, which specifically addresses electric and hybrid vehicle battery safety requirements for lithium-based rechargeable energy storage systems. These standards mandate rigorous testing protocols including thermal shock, vibration, mechanical impact, and overcharge protection.

The European Union implements battery safety regulations through the ECE R100 standard and the General Safety Regulation (GSR). These frameworks require manufacturers to demonstrate compliance through extensive testing and documentation before vehicles can be approved for market entry. Recent updates to these regulations have placed increased emphasis on thermal management systems and early detection mechanisms for potential thermal runaway conditions.

In Asia, China has established the GB/T 31467 standard specifically addressing safety requirements for lithium-ion batteries in electric vehicles. This standard is particularly stringent regarding thermal propagation prevention and includes detailed requirements for battery management systems. Japan follows technical standards set by the Ministry of Land, Infrastructure, Transport and Tourism, which incorporate specific provisions for preventing and containing thermal runaway events.

Industry standards complement regulatory frameworks, with organizations like Underwriters Laboratories (UL) developing standards such as UL 2580 for batteries used in electric vehicles. These standards often exceed minimum regulatory requirements and focus on comprehensive safety testing under extreme conditions.

Recent regulatory trends show a shift toward performance-based standards rather than prescriptive requirements, allowing manufacturers greater flexibility in implementing innovative thermal runaway prevention strategies. There is also increasing emphasis on the entire battery lifecycle, including requirements for second-life applications and end-of-life disposal or recycling.

Compliance with these evolving regulations presents significant challenges for manufacturers, particularly as they navigate different requirements across global markets. However, these standards have been instrumental in driving innovation in thermal management systems, battery design, and safety mechanisms, ultimately contributing to safer electric vehicle technologies.

Environmental Impact of Battery Safety Technologies

The environmental implications of battery safety technologies in electric vehicles extend far beyond their primary function of preventing thermal runaway. These technologies create a complex ecological footprint throughout their lifecycle, from raw material extraction to end-of-life disposal.

Battery safety systems typically incorporate flame-retardant materials, thermal management components, and specialized monitoring electronics. The production of these materials often involves energy-intensive processes and extraction of rare earth elements. For instance, flame retardants may contain halogenated compounds that persist in the environment, while thermal management systems frequently utilize refrigerants with varying global warming potentials.

Different thermal runaway prevention strategies present distinct environmental trade-offs. Passive cooling systems generally have lower operational environmental impacts but may require more resource-intensive manufacturing. Active cooling technologies consume energy during vehicle operation, contributing to indirect emissions in regions where electricity generation relies heavily on fossil fuels. However, they may extend battery lifespan, reducing the frequency of battery replacement and associated environmental impacts.

The environmental benefits of effective battery safety technologies are substantial. By preventing catastrophic thermal events, these systems reduce the incidence of fires that release toxic gases and particulates into the atmosphere. The combustion of lithium-ion batteries can emit hydrogen fluoride, carbon monoxide, and various volatile organic compounds that pose significant environmental hazards.

Life cycle assessment studies indicate that the environmental burden of implementing robust safety technologies is typically outweighed by the ecological damage prevented through averting thermal runaway incidents. Additionally, enhanced battery safety extends the useful life of energy storage systems, delaying the environmental impacts associated with battery replacement and disposal.

Emerging safety technologies show promising environmental profiles. Phase change materials used for thermal management can be derived from bio-based sources, while advanced battery management systems optimize charging patterns to reduce degradation without additional material inputs. Fire-resistant battery casings made from recyclable materials represent another environmentally conscious approach to battery safety.

Regulatory frameworks increasingly recognize the environmental dimension of battery safety, with the European Battery Directive and similar initiatives worldwide beginning to incorporate ecological considerations into safety standards. These regulations are driving innovation toward safety solutions with reduced environmental footprints.

Battery safety systems typically incorporate flame-retardant materials, thermal management components, and specialized monitoring electronics. The production of these materials often involves energy-intensive processes and extraction of rare earth elements. For instance, flame retardants may contain halogenated compounds that persist in the environment, while thermal management systems frequently utilize refrigerants with varying global warming potentials.

Different thermal runaway prevention strategies present distinct environmental trade-offs. Passive cooling systems generally have lower operational environmental impacts but may require more resource-intensive manufacturing. Active cooling technologies consume energy during vehicle operation, contributing to indirect emissions in regions where electricity generation relies heavily on fossil fuels. However, they may extend battery lifespan, reducing the frequency of battery replacement and associated environmental impacts.

The environmental benefits of effective battery safety technologies are substantial. By preventing catastrophic thermal events, these systems reduce the incidence of fires that release toxic gases and particulates into the atmosphere. The combustion of lithium-ion batteries can emit hydrogen fluoride, carbon monoxide, and various volatile organic compounds that pose significant environmental hazards.

Life cycle assessment studies indicate that the environmental burden of implementing robust safety technologies is typically outweighed by the ecological damage prevented through averting thermal runaway incidents. Additionally, enhanced battery safety extends the useful life of energy storage systems, delaying the environmental impacts associated with battery replacement and disposal.

Emerging safety technologies show promising environmental profiles. Phase change materials used for thermal management can be derived from bio-based sources, while advanced battery management systems optimize charging patterns to reduce degradation without additional material inputs. Fire-resistant battery casings made from recyclable materials represent another environmentally conscious approach to battery safety.

Regulatory frameworks increasingly recognize the environmental dimension of battery safety, with the European Battery Directive and similar initiatives worldwide beginning to incorporate ecological considerations into safety standards. These regulations are driving innovation toward safety solutions with reduced environmental footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!