Comparison of Battery Pack Enclosure Technologies

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Enclosure Evolution and Objectives

Battery pack enclosure technology has evolved significantly over the past two decades, transitioning from rudimentary protective shells to sophisticated engineered systems that address multiple critical functions. Initially, battery enclosures in early electric vehicles (EVs) were primarily designed for basic protection and isolation, with minimal consideration for weight optimization or thermal management. These first-generation enclosures typically utilized heavy steel constructions that significantly impacted vehicle range and performance.

The evolution accelerated around 2010-2015 when automotive manufacturers began dedicated EV platform development. This period marked a shift from adapted internal combustion engine (ICE) vehicle designs to purpose-built electric architectures, driving innovation in enclosure technologies. Material science advancements enabled the introduction of aluminum alloys and composite materials, reducing weight while maintaining structural integrity.

By 2018-2020, battery enclosure technology had progressed to incorporate multifunctional designs addressing thermal management, electromagnetic interference (EMI) shielding, and crash protection simultaneously. The integration of these functions into unified enclosure systems represented a significant technological leap, enabling improved energy density at the pack level.

Current technological objectives for battery enclosures center around five key areas: weight reduction, enhanced thermal management, improved crash safety, manufacturing scalability, and cost optimization. Weight reduction remains paramount as it directly impacts vehicle efficiency and range, with industry targets aiming for 15-20% weight reduction compared to current generation enclosures without compromising structural performance.

Thermal management has emerged as a critical objective, with enclosures now expected to actively participate in heat dissipation and temperature regulation rather than merely containing thermal systems. This shift reflects growing understanding of battery degradation mechanisms and the impact of thermal conditions on battery longevity and safety.

Safety requirements continue to evolve, with enclosures now designed to protect batteries from external threats while also containing potential thermal events. This dual-direction protection philosophy has driven innovation in materials and structural designs that can withstand impacts while managing internal thermal runaway scenarios.

Manufacturing scalability has become increasingly important as EV production volumes grow exponentially. Enclosure technologies must now be compatible with high-volume production techniques while maintaining precision and quality. This has led to exploration of novel joining methods, modular designs, and automated assembly processes specifically optimized for battery enclosure manufacturing.

The industry trajectory points toward integrated structural battery systems where the enclosure contributes to vehicle structural performance, potentially eliminating redundant structural elements and further improving vehicle-level efficiency. This represents the next frontier in enclosure technology evolution, with several major OEMs already demonstrating concept vehicles featuring structural battery systems.

The evolution accelerated around 2010-2015 when automotive manufacturers began dedicated EV platform development. This period marked a shift from adapted internal combustion engine (ICE) vehicle designs to purpose-built electric architectures, driving innovation in enclosure technologies. Material science advancements enabled the introduction of aluminum alloys and composite materials, reducing weight while maintaining structural integrity.

By 2018-2020, battery enclosure technology had progressed to incorporate multifunctional designs addressing thermal management, electromagnetic interference (EMI) shielding, and crash protection simultaneously. The integration of these functions into unified enclosure systems represented a significant technological leap, enabling improved energy density at the pack level.

Current technological objectives for battery enclosures center around five key areas: weight reduction, enhanced thermal management, improved crash safety, manufacturing scalability, and cost optimization. Weight reduction remains paramount as it directly impacts vehicle efficiency and range, with industry targets aiming for 15-20% weight reduction compared to current generation enclosures without compromising structural performance.

Thermal management has emerged as a critical objective, with enclosures now expected to actively participate in heat dissipation and temperature regulation rather than merely containing thermal systems. This shift reflects growing understanding of battery degradation mechanisms and the impact of thermal conditions on battery longevity and safety.

Safety requirements continue to evolve, with enclosures now designed to protect batteries from external threats while also containing potential thermal events. This dual-direction protection philosophy has driven innovation in materials and structural designs that can withstand impacts while managing internal thermal runaway scenarios.

Manufacturing scalability has become increasingly important as EV production volumes grow exponentially. Enclosure technologies must now be compatible with high-volume production techniques while maintaining precision and quality. This has led to exploration of novel joining methods, modular designs, and automated assembly processes specifically optimized for battery enclosure manufacturing.

The industry trajectory points toward integrated structural battery systems where the enclosure contributes to vehicle structural performance, potentially eliminating redundant structural elements and further improving vehicle-level efficiency. This represents the next frontier in enclosure technology evolution, with several major OEMs already demonstrating concept vehicles featuring structural battery systems.

Market Demand Analysis for Advanced Battery Enclosures

The global market for advanced battery enclosures is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the battery enclosure segment is projected to grow at a CAGR of 18.7% between 2023 and 2030, reaching a market value of 9.5 billion USD by the end of the forecast period. This growth trajectory is significantly steeper than previously anticipated, reflecting accelerated EV adoption rates across major automotive markets.

Consumer demands are increasingly shaping the evolution of battery enclosure technologies. Safety concerns remain paramount, with 87% of potential EV buyers citing battery safety as a critical purchasing factor. This has created substantial market pull for enclosure solutions that offer enhanced thermal management and crash protection capabilities. Additionally, range anxiety continues to influence consumer behavior, with lightweight enclosure materials becoming essential to maximize vehicle efficiency and driving range.

Regulatory frameworks are also creating strong market incentives for advanced enclosure solutions. The European Union's battery regulation proposal includes specific requirements for battery durability, carbon footprint, and end-of-life management that directly impact enclosure design. Similarly, China's dual-credit policy system and the United States' Inflation Reduction Act have established financial incentives that favor sophisticated battery protection systems.

From an industry perspective, automotive OEMs are increasingly viewing battery enclosures as critical differentiators rather than commodity components. This shift has expanded the market for premium enclosure solutions that offer multifunctional benefits beyond basic protection, including structural integration with vehicle platforms and enhanced thermal management capabilities.

Regional market analysis reveals significant variations in demand patterns. The European market shows strong preference for lightweight composite solutions that support longer range capabilities, while the North American market emphasizes ruggedness and crash protection. The Asia-Pacific region, led by China, demonstrates the highest volume demand with particular focus on cost-effective solutions that can be scaled rapidly.

The commercial vehicle segment represents an emerging high-growth market for specialized battery enclosures, with unique requirements for durability, serviceability, and integration with existing vehicle architectures. Market forecasts suggest this segment will grow at 22.3% annually through 2030, outpacing the passenger vehicle segment.

Overall, market signals indicate a clear shift toward integrated enclosure systems that address multiple performance parameters simultaneously, creating opportunities for suppliers who can deliver holistic solutions rather than single-attribute improvements.

Consumer demands are increasingly shaping the evolution of battery enclosure technologies. Safety concerns remain paramount, with 87% of potential EV buyers citing battery safety as a critical purchasing factor. This has created substantial market pull for enclosure solutions that offer enhanced thermal management and crash protection capabilities. Additionally, range anxiety continues to influence consumer behavior, with lightweight enclosure materials becoming essential to maximize vehicle efficiency and driving range.

Regulatory frameworks are also creating strong market incentives for advanced enclosure solutions. The European Union's battery regulation proposal includes specific requirements for battery durability, carbon footprint, and end-of-life management that directly impact enclosure design. Similarly, China's dual-credit policy system and the United States' Inflation Reduction Act have established financial incentives that favor sophisticated battery protection systems.

From an industry perspective, automotive OEMs are increasingly viewing battery enclosures as critical differentiators rather than commodity components. This shift has expanded the market for premium enclosure solutions that offer multifunctional benefits beyond basic protection, including structural integration with vehicle platforms and enhanced thermal management capabilities.

Regional market analysis reveals significant variations in demand patterns. The European market shows strong preference for lightweight composite solutions that support longer range capabilities, while the North American market emphasizes ruggedness and crash protection. The Asia-Pacific region, led by China, demonstrates the highest volume demand with particular focus on cost-effective solutions that can be scaled rapidly.

The commercial vehicle segment represents an emerging high-growth market for specialized battery enclosures, with unique requirements for durability, serviceability, and integration with existing vehicle architectures. Market forecasts suggest this segment will grow at 22.3% annually through 2030, outpacing the passenger vehicle segment.

Overall, market signals indicate a clear shift toward integrated enclosure systems that address multiple performance parameters simultaneously, creating opportunities for suppliers who can deliver holistic solutions rather than single-attribute improvements.

Current Enclosure Technologies and Challenges

Battery pack enclosure technologies have evolved significantly over the past decade, with several distinct approaches currently dominating the market. Metal enclosures, particularly those made from aluminum and steel, represent the traditional solution with widespread adoption across automotive and energy storage applications. These enclosures offer excellent structural integrity, thermal conductivity, and electromagnetic shielding properties. Aluminum enclosures provide superior weight advantages compared to steel variants, though at higher material costs.

Composite enclosures have gained significant traction in recent years, utilizing carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and hybrid materials. These solutions deliver exceptional strength-to-weight ratios, with some advanced composites achieving weight reductions of 40-50% compared to equivalent metal designs while maintaining comparable structural performance.

Polymer-based enclosures, including engineering thermoplastics and thermosets, represent an emerging category with growing market share. These materials offer excellent electrical insulation properties, corrosion resistance, and design flexibility through injection molding processes. High-performance polymers such as polyamide (PA), polyphenylene sulfide (PPS), and polyetheretherketone (PEEK) are increasingly utilized in battery enclosure applications.

Despite technological advancements, significant challenges persist across all enclosure technologies. Thermal management remains a critical concern, as enclosures must effectively dissipate heat during charging and discharging cycles while preventing thermal runaway propagation. Current solutions often require complex cooling systems that add weight, cost, and complexity to the overall battery system.

Safety compliance presents another major challenge, with enclosures needing to meet stringent regulatory standards for crash protection, fire resistance, and environmental sealing. These requirements often create design constraints that limit material selection and geometric optimization.

Manufacturing scalability continues to impede widespread adoption of advanced enclosure technologies. While composite materials offer superior performance characteristics, their production processes remain labor-intensive and difficult to scale compared to established metal forming techniques. High-volume manufacturing of complex composite structures presents particular challenges in maintaining consistent quality and reducing cycle times.

Cost considerations represent perhaps the most significant barrier to innovation in this space. Premium enclosure technologies utilizing advanced composites or specialized polymers can increase overall battery pack costs by 15-25%, creating adoption barriers in price-sensitive market segments. This cost premium must be balanced against performance benefits and potential lifecycle advantages.

Composite enclosures have gained significant traction in recent years, utilizing carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and hybrid materials. These solutions deliver exceptional strength-to-weight ratios, with some advanced composites achieving weight reductions of 40-50% compared to equivalent metal designs while maintaining comparable structural performance.

Polymer-based enclosures, including engineering thermoplastics and thermosets, represent an emerging category with growing market share. These materials offer excellent electrical insulation properties, corrosion resistance, and design flexibility through injection molding processes. High-performance polymers such as polyamide (PA), polyphenylene sulfide (PPS), and polyetheretherketone (PEEK) are increasingly utilized in battery enclosure applications.

Despite technological advancements, significant challenges persist across all enclosure technologies. Thermal management remains a critical concern, as enclosures must effectively dissipate heat during charging and discharging cycles while preventing thermal runaway propagation. Current solutions often require complex cooling systems that add weight, cost, and complexity to the overall battery system.

Safety compliance presents another major challenge, with enclosures needing to meet stringent regulatory standards for crash protection, fire resistance, and environmental sealing. These requirements often create design constraints that limit material selection and geometric optimization.

Manufacturing scalability continues to impede widespread adoption of advanced enclosure technologies. While composite materials offer superior performance characteristics, their production processes remain labor-intensive and difficult to scale compared to established metal forming techniques. High-volume manufacturing of complex composite structures presents particular challenges in maintaining consistent quality and reducing cycle times.

Cost considerations represent perhaps the most significant barrier to innovation in this space. Premium enclosure technologies utilizing advanced composites or specialized polymers can increase overall battery pack costs by 15-25%, creating adoption barriers in price-sensitive market segments. This cost premium must be balanced against performance benefits and potential lifecycle advantages.

Comparative Analysis of Enclosure Solutions

01 Thermal management systems for battery enclosures

Battery pack enclosures incorporate advanced thermal management systems to regulate temperature and prevent overheating. These systems include cooling channels, heat sinks, and thermal interface materials that efficiently dissipate heat generated during battery operation. Some designs feature active cooling mechanisms using liquid coolants or air circulation, while others employ passive cooling strategies with thermally conductive materials. Effective thermal management extends battery life, maintains optimal performance, and enhances safety by preventing thermal runaway events.- Thermal management systems for battery enclosures: Battery pack enclosures incorporate advanced thermal management systems to regulate temperature and prevent overheating. These systems may include cooling channels, heat sinks, or thermal interface materials that efficiently dissipate heat generated during battery operation. Proper thermal management is crucial for maintaining battery performance, extending lifespan, and ensuring safety by preventing thermal runaway conditions.

- Structural materials and designs for impact resistance: Battery enclosures utilize specialized structural materials and designs to provide impact resistance and protect battery cells from physical damage. These may include reinforced composites, high-strength alloys, or multi-layer structures that can absorb and distribute impact forces. Strategic design elements such as crumple zones and reinforced corners further enhance the protective capabilities of the enclosure during collision events.

- Sealing and environmental protection technologies: Advanced sealing technologies are implemented in battery pack enclosures to protect against environmental factors such as moisture, dust, and corrosive substances. These may include specialized gaskets, sealants, and waterproofing membranes that maintain the integrity of the enclosure under various conditions. Environmental protection features help prevent electrical shorts, corrosion of components, and degradation of battery performance over time.

- Lightweight and high-strength composite materials: Battery enclosures increasingly utilize lightweight yet high-strength composite materials to reduce overall vehicle weight while maintaining structural integrity. These materials may include carbon fiber reinforced polymers, aluminum alloys, or hybrid metal-composite structures. The use of advanced materials helps optimize the weight-to-strength ratio, improving vehicle efficiency and range while ensuring adequate protection for battery cells.

- Modular and scalable enclosure designs: Modular and scalable enclosure designs allow for flexible battery configurations to suit different vehicle platforms or energy storage requirements. These designs feature standardized components that can be assembled in various arrangements to accommodate different battery sizes and capacities. Modular approaches simplify manufacturing, maintenance, and potential battery upgrades or replacements, while ensuring consistent safety and performance standards across different configurations.

02 Structural materials and manufacturing techniques

Battery enclosures utilize various structural materials and manufacturing techniques to balance strength, weight, and cost requirements. Advanced materials include lightweight aluminum alloys, high-strength steel, composite materials, and engineered polymers. Manufacturing methods range from traditional stamping and welding to innovative techniques like die casting, extrusion, and additive manufacturing. These approaches enable the creation of complex geometries with integrated features while maintaining structural integrity and meeting crash safety standards.Expand Specific Solutions03 Sealing and protection systems

Battery pack enclosures incorporate sophisticated sealing and protection systems to shield sensitive components from environmental factors. These include water-resistant gaskets, IP-rated seals, and specialized coatings that prevent moisture ingress and corrosion. Some designs feature multi-layer protection with redundant sealing mechanisms and drainage channels to direct away any liquid that might penetrate the outer barriers. These systems ensure long-term reliability in various operating conditions while maintaining electrical isolation and safety.Expand Specific Solutions04 Modular and scalable enclosure designs

Modern battery enclosures feature modular and scalable designs that accommodate different battery configurations and vehicle platforms. These systems allow for efficient manufacturing, simplified assembly, and easier maintenance or battery replacement. Modular approaches include standardized cell housings, expandable frame structures, and reconfigurable cooling systems. This flexibility enables manufacturers to adapt to evolving battery technologies and varying energy storage requirements across different vehicle models while optimizing production costs.Expand Specific Solutions05 Integrated safety features

Battery enclosures incorporate multiple integrated safety features to mitigate risks associated with battery failures. These include reinforced crash structures, flame-retardant materials, and pressure relief mechanisms that prevent catastrophic failures. Some designs feature isolation systems that can disconnect electrical connections during collision events or detected faults. Advanced enclosures also include sensors for monitoring temperature, pressure, and gas emissions, enabling early detection of potential issues before they escalate into safety hazards.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The battery pack enclosure technology market is in a growth phase, with increasing demand driven by electric vehicle adoption and energy storage applications. The market size is expanding rapidly, expected to reach significant value by 2030. Technologically, the field shows varying maturity levels across different solutions. Leading players like Tesla, BYD, and LG Energy Solution have developed advanced enclosure technologies focusing on thermal management, structural integrity, and weight reduction. Traditional automotive manufacturers such as Ford are investing heavily to catch up, while specialized battery manufacturers including Samsung SDI, CALB, and SK On are developing proprietary enclosure solutions. Chinese companies are gaining market share through cost-effective innovations, while established players differentiate through safety features and integration capabilities.

BYD Co., Ltd.

Technical Solution: BYD has developed the revolutionary Blade Battery technology with a corresponding enclosure system designed specifically for enhanced safety and space efficiency. The enclosure features a unique cell-to-pack (CTP) design that eliminates the traditional module level, allowing for 50% higher energy density within the same space. BYD's enclosure utilizes high-strength aluminum alloys combined with composite materials that provide excellent thermal conductivity while maintaining structural integrity. Their enclosures incorporate specialized fire-resistant materials and thermal barriers between cells to prevent thermal runaway propagation. BYD's battery enclosures also feature an integrated liquid cooling system with multiple redundant circuits to ensure consistent temperature control across the entire pack, even in extreme operating conditions.

Strengths: Superior safety performance with proven nail penetration test results; excellent thermal management capabilities; high volumetric efficiency with CTP design. Weaknesses: Relatively heavier than some competing solutions; limited flexibility for different vehicle platforms; higher manufacturing complexity requiring specialized production equipment.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced battery pack enclosure technologies focusing on prismatic and pouch cell configurations. Their "Z-Fold" enclosure design incorporates specialized aluminum extrusions with internal reinforcement structures that provide superior crash protection while minimizing weight. Samsung's enclosures feature a dual-layer approach with an inner protective shell made from fire-resistant composites and an outer shell optimized for structural integrity. Their thermal management system utilizes a combination of phase-change materials and liquid cooling channels integrated directly into the enclosure walls, providing efficient heat dissipation without additional components. Samsung SDI has also pioneered the use of specialized coatings that provide both electrical insulation and enhanced thermal conductivity, allowing for better heat distribution across the pack.

Strengths: Excellent thermal efficiency with innovative cooling solutions; high crash safety ratings; modular design allowing for flexible vehicle integration. Weaknesses: Higher production costs compared to simpler designs; more complex assembly process; slightly lower volumetric efficiency compared to cell-to-pack designs.

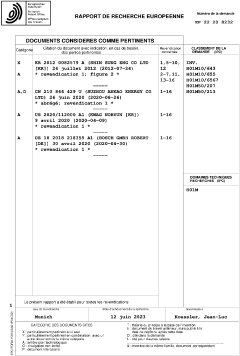

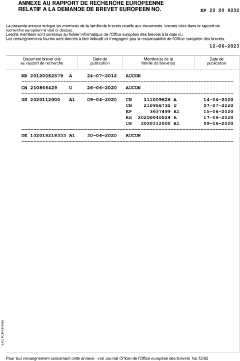

Key Patents and Innovations in Enclosure Design

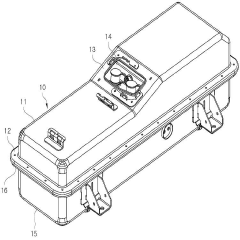

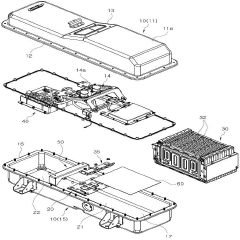

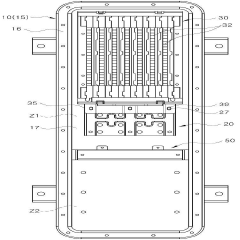

Enclosure of battery pack, battery pack and automobileusing the same

PatentActiveKR1020190101263A

Innovation

- A modular enclosure design that allows for mounting one or multiple battery modules, featuring a lower case with a middle panel and symmetrical structure, along with an upper case with stepped surfaces, enabling flexible configuration and installation of battery modules and electrical components based on vehicle needs.

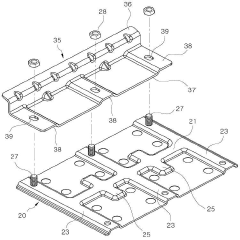

Enclosure for a battery module or battery pack, with a sealed membrane for allowing a circulation of a heat transfer fluid therein for optimal cooling of the module or pack batteries.

PatentPendingEP4199190A3

Innovation

- Sealed membrane design that allows circulation of heat transfer fluid in close proximity to each accumulator while leaving output terminals unobstructed.

- Flexible sealing lips that provide both positioning/holding function for accumulators and ensure sealing around the case while exposing necessary terminals.

- Adaptable enclosure design suitable for various applications including electric/hybrid transport and storage systems with both flexible and rigid packaging options.

Thermal Management Integration Strategies

Thermal management integration represents a critical aspect of battery pack enclosure design, directly impacting performance, safety, and longevity of electric vehicle battery systems. Current integration strategies can be categorized into three primary approaches: passive, active, and hybrid thermal management systems, each with distinct implementation methodologies within enclosure designs.

Passive thermal management strategies utilize the enclosure structure itself as a heat dissipation medium. Aluminum enclosures excel in this regard, offering thermal conductivity values of 150-235 W/m·K, significantly outperforming steel (50-60 W/m·K) and composite materials (typically 0.5-5 W/m·K). Advanced designs incorporate heat-dissipating fins and thermal pathways directly into the enclosure structure, creating efficient passive cooling without additional energy consumption.

Active thermal management integration involves dedicated cooling or heating systems embedded within the enclosure design. Liquid cooling channels integrated directly into the enclosure walls represent the most efficient approach, with implementation varying by material. Aluminum enclosures allow for extruded cooling channels, while composite enclosures typically require inserted metal cooling plates or tubes. Recent innovations include phase-change material (PCM) integration within double-walled enclosure designs, providing temperature buffering during high-load operations.

Hybrid approaches combine multiple thermal management strategies, optimizing for specific operational conditions. A notable example is the integration of liquid cooling systems for high-load operation with passive thermal pathways for normal conditions, controlled by intelligent thermal management systems that adapt to driving patterns and environmental conditions.

Material selection significantly impacts thermal management integration capabilities. While aluminum offers superior thermal conductivity, composite materials present challenges requiring innovative solutions such as embedded metal heat spreaders or thermally conductive additives. Steel enclosures typically require more extensive active cooling systems to compensate for lower thermal conductivity.

Manufacturing considerations also influence thermal management integration. Aluminum enclosures allow for complex cooling channel designs through extrusion or casting processes, while composite enclosures may require additional assembly steps to incorporate thermal management components. This manufacturing complexity directly impacts production costs and scalability.

Recent technological advancements include direct cell-to-enclosure thermal interfaces that bypass traditional intermediate thermal management layers, reducing thermal resistance by up to 30%. Additionally, smart thermal management systems utilizing embedded temperature sensors throughout the enclosure structure enable predictive cooling/heating activation based on anticipated load conditions, improving overall efficiency by 15-20% compared to reactive systems.

Passive thermal management strategies utilize the enclosure structure itself as a heat dissipation medium. Aluminum enclosures excel in this regard, offering thermal conductivity values of 150-235 W/m·K, significantly outperforming steel (50-60 W/m·K) and composite materials (typically 0.5-5 W/m·K). Advanced designs incorporate heat-dissipating fins and thermal pathways directly into the enclosure structure, creating efficient passive cooling without additional energy consumption.

Active thermal management integration involves dedicated cooling or heating systems embedded within the enclosure design. Liquid cooling channels integrated directly into the enclosure walls represent the most efficient approach, with implementation varying by material. Aluminum enclosures allow for extruded cooling channels, while composite enclosures typically require inserted metal cooling plates or tubes. Recent innovations include phase-change material (PCM) integration within double-walled enclosure designs, providing temperature buffering during high-load operations.

Hybrid approaches combine multiple thermal management strategies, optimizing for specific operational conditions. A notable example is the integration of liquid cooling systems for high-load operation with passive thermal pathways for normal conditions, controlled by intelligent thermal management systems that adapt to driving patterns and environmental conditions.

Material selection significantly impacts thermal management integration capabilities. While aluminum offers superior thermal conductivity, composite materials present challenges requiring innovative solutions such as embedded metal heat spreaders or thermally conductive additives. Steel enclosures typically require more extensive active cooling systems to compensate for lower thermal conductivity.

Manufacturing considerations also influence thermal management integration. Aluminum enclosures allow for complex cooling channel designs through extrusion or casting processes, while composite enclosures may require additional assembly steps to incorporate thermal management components. This manufacturing complexity directly impacts production costs and scalability.

Recent technological advancements include direct cell-to-enclosure thermal interfaces that bypass traditional intermediate thermal management layers, reducing thermal resistance by up to 30%. Additionally, smart thermal management systems utilizing embedded temperature sensors throughout the enclosure structure enable predictive cooling/heating activation based on anticipated load conditions, improving overall efficiency by 15-20% compared to reactive systems.

Safety Standards and Certification Requirements

Battery pack enclosure safety standards and certification requirements have evolved significantly in response to the growing adoption of electric vehicles and energy storage systems. The primary regulatory frameworks governing battery enclosures include UN ECE R100, which specifically addresses the safety requirements for battery electric vehicles in Europe, and the Federal Motor Vehicle Safety Standards (FMVSS) in the United States. These standards establish comprehensive guidelines for mechanical integrity, thermal management, and electrical isolation of battery enclosures.

International standards such as ISO 6469-1 and IEC 62660 provide detailed specifications for safety performance under various conditions, including crash scenarios, thermal events, and electrical failures. These standards mandate rigorous testing protocols, including crush tests, penetration resistance, fire resistance, and immersion tests to ensure enclosures can withstand extreme conditions while maintaining structural integrity.

Certification processes typically involve multiple stages of validation testing conducted by accredited third-party laboratories. For automotive applications, battery enclosures must demonstrate compliance with regional type approval requirements, which vary significantly between markets. The Chinese market follows GB/T 31467 standards, while Japanese manufacturers adhere to JARI standards, creating a complex global certification landscape.

Thermal runaway containment has emerged as a critical safety requirement, with standards increasingly focusing on the enclosure's ability to prevent propagation between cells and modules. UL 2580 and SAE J2929 specifically address these concerns, requiring enclosures to demonstrate effective thermal management during failure events. These standards have driven innovation in fire-resistant materials and thermal barrier technologies.

Environmental protection ratings, particularly IP67 and IP69K, have become standard requirements for battery enclosures, ensuring protection against dust ingress and water immersion. Additionally, electromagnetic compatibility (EMC) standards such as IEC 61000 series require enclosures to provide adequate shielding against electromagnetic interference, which has implications for enclosure material selection and design.

Recent regulatory developments have placed increased emphasis on end-of-life considerations, with standards like EU Directive 2006/66/EC mandating recyclability requirements for battery systems, including their enclosures. This has influenced material selection strategies, favoring designs that facilitate disassembly and material recovery. Manufacturers must now document compliance with these sustainability requirements as part of their certification process.

International standards such as ISO 6469-1 and IEC 62660 provide detailed specifications for safety performance under various conditions, including crash scenarios, thermal events, and electrical failures. These standards mandate rigorous testing protocols, including crush tests, penetration resistance, fire resistance, and immersion tests to ensure enclosures can withstand extreme conditions while maintaining structural integrity.

Certification processes typically involve multiple stages of validation testing conducted by accredited third-party laboratories. For automotive applications, battery enclosures must demonstrate compliance with regional type approval requirements, which vary significantly between markets. The Chinese market follows GB/T 31467 standards, while Japanese manufacturers adhere to JARI standards, creating a complex global certification landscape.

Thermal runaway containment has emerged as a critical safety requirement, with standards increasingly focusing on the enclosure's ability to prevent propagation between cells and modules. UL 2580 and SAE J2929 specifically address these concerns, requiring enclosures to demonstrate effective thermal management during failure events. These standards have driven innovation in fire-resistant materials and thermal barrier technologies.

Environmental protection ratings, particularly IP67 and IP69K, have become standard requirements for battery enclosures, ensuring protection against dust ingress and water immersion. Additionally, electromagnetic compatibility (EMC) standards such as IEC 61000 series require enclosures to provide adequate shielding against electromagnetic interference, which has implications for enclosure material selection and design.

Recent regulatory developments have placed increased emphasis on end-of-life considerations, with standards like EU Directive 2006/66/EC mandating recyclability requirements for battery systems, including their enclosures. This has influenced material selection strategies, favoring designs that facilitate disassembly and material recovery. Manufacturers must now document compliance with these sustainability requirements as part of their certification process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!