Design Innovations in Battery Pack Thermal Management

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple cooling mechanisms to sophisticated integrated systems. Initially developed for consumer electronics in the 1990s, battery thermal management systems (BTMS) gained critical importance with the rise of electric vehicles (EVs) in the early 2000s. The fundamental challenge has remained consistent: maintaining optimal battery temperature ranges to ensure safety, longevity, and performance while adapting to increasingly demanding applications.

The evolution of battery chemistries, particularly the shift from nickel-metal hydride to lithium-ion technologies, has necessitated more precise thermal control. Modern lithium-ion batteries typically require operating temperatures between 15°C and 35°C for optimal performance, with significant degradation occurring outside this range. This narrow window presents considerable engineering challenges, especially in extreme climate conditions or high-power applications.

Current technological trajectories indicate a move toward more integrated and predictive thermal management approaches. The industry is witnessing a convergence of passive and active cooling technologies, with increasing emphasis on system efficiency and reduced energy consumption. Computational fluid dynamics modeling and digital twin technologies are enabling more sophisticated design iterations before physical prototyping, accelerating innovation cycles.

The primary objectives of contemporary battery thermal management research focus on several key areas. First, achieving uniform temperature distribution across battery packs to prevent localized hotspots that accelerate degradation. Second, developing adaptive systems that can respond dynamically to changing operational conditions and battery states. Third, reducing the parasitic energy consumption of thermal management systems themselves, which can account for 5-15% of a battery's total energy in some applications.

Additionally, there is growing emphasis on sustainability considerations, including the use of environmentally friendly coolants and materials with lower carbon footprints. The recyclability of thermal management components is becoming increasingly important as the industry addresses end-of-life concerns for battery systems.

From a regulatory perspective, thermal management is gaining prominence in safety standards worldwide. Following several high-profile thermal runaway incidents, regulatory bodies have implemented stricter requirements for thermal safety in battery systems, particularly for transportation applications. These regulations are driving innovation in early detection systems and more effective containment strategies for thermal events.

The convergence of these factors has positioned battery thermal management as a critical enabling technology for the broader energy transition, with implications extending beyond electric vehicles to stationary storage, aerospace applications, and portable electronics. Future developments will likely focus on more integrated approaches that consider thermal management as an integral part of the battery system design rather than an add-on component.

The evolution of battery chemistries, particularly the shift from nickel-metal hydride to lithium-ion technologies, has necessitated more precise thermal control. Modern lithium-ion batteries typically require operating temperatures between 15°C and 35°C for optimal performance, with significant degradation occurring outside this range. This narrow window presents considerable engineering challenges, especially in extreme climate conditions or high-power applications.

Current technological trajectories indicate a move toward more integrated and predictive thermal management approaches. The industry is witnessing a convergence of passive and active cooling technologies, with increasing emphasis on system efficiency and reduced energy consumption. Computational fluid dynamics modeling and digital twin technologies are enabling more sophisticated design iterations before physical prototyping, accelerating innovation cycles.

The primary objectives of contemporary battery thermal management research focus on several key areas. First, achieving uniform temperature distribution across battery packs to prevent localized hotspots that accelerate degradation. Second, developing adaptive systems that can respond dynamically to changing operational conditions and battery states. Third, reducing the parasitic energy consumption of thermal management systems themselves, which can account for 5-15% of a battery's total energy in some applications.

Additionally, there is growing emphasis on sustainability considerations, including the use of environmentally friendly coolants and materials with lower carbon footprints. The recyclability of thermal management components is becoming increasingly important as the industry addresses end-of-life concerns for battery systems.

From a regulatory perspective, thermal management is gaining prominence in safety standards worldwide. Following several high-profile thermal runaway incidents, regulatory bodies have implemented stricter requirements for thermal safety in battery systems, particularly for transportation applications. These regulations are driving innovation in early detection systems and more effective containment strategies for thermal events.

The convergence of these factors has positioned battery thermal management as a critical enabling technology for the broader energy transition, with implications extending beyond electric vehicles to stationary storage, aerospace applications, and portable electronics. Future developments will likely focus on more integrated approaches that consider thermal management as an integral part of the battery system design rather than an add-on component.

Market Demand Analysis for Advanced Thermal Solutions

The global market for advanced thermal management solutions in battery packs is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the battery thermal management system market is projected to reach $5.2 billion by 2025, growing at a CAGR of approximately 16.6% from 2020. This growth trajectory is significantly steeper than previously forecasted, reflecting the accelerating transition toward electrification across the automotive industry.

Consumer demand for EVs with extended range capabilities has emerged as a critical market driver. Range anxiety continues to be cited as a primary barrier to EV adoption in consumer surveys, with over 70% of potential buyers expressing concerns about battery performance in extreme temperature conditions. This has created substantial market pull for thermal management solutions that can maintain optimal battery operating temperatures between 20-40°C across diverse climate conditions.

Fast charging capabilities represent another significant market demand factor. As charging infrastructure expands globally, consumers increasingly expect rapid charging times comparable to traditional refueling experiences. Advanced thermal management systems that can efficiently dissipate heat during high-current charging scenarios are commanding premium pricing, with manufacturers willing to invest 15-20% more in thermal solutions that enable consistent fast-charging performance.

Safety considerations have become paramount following several high-profile battery thermal runaway incidents. Insurance data reveals that thermal-related battery failures account for approximately 28% of EV insurance claims, creating strong regulatory and consumer pressure for more robust thermal management solutions. This has expanded the market for advanced monitoring systems, phase-change materials, and intelligent cooling architectures.

The commercial vehicle segment represents an emerging high-value market for advanced thermal solutions. Fleet operators prioritize battery longevity and consistent performance metrics, with thermal management identified as a key factor in total cost of ownership calculations. Market analysis shows fleet operators are willing to pay up to 30% premium for thermal management systems that can demonstrably extend battery life by 20% or more.

Geographically, the most aggressive growth is occurring in regions with extreme climate conditions. Northern European markets, parts of North America, and rapidly developing EV markets in Southeast Asia are showing particularly strong demand for sophisticated thermal management solutions that can handle wide temperature variations. This regional variation is creating opportunities for specialized thermal management systems designed for specific climate challenges.

Consumer demand for EVs with extended range capabilities has emerged as a critical market driver. Range anxiety continues to be cited as a primary barrier to EV adoption in consumer surveys, with over 70% of potential buyers expressing concerns about battery performance in extreme temperature conditions. This has created substantial market pull for thermal management solutions that can maintain optimal battery operating temperatures between 20-40°C across diverse climate conditions.

Fast charging capabilities represent another significant market demand factor. As charging infrastructure expands globally, consumers increasingly expect rapid charging times comparable to traditional refueling experiences. Advanced thermal management systems that can efficiently dissipate heat during high-current charging scenarios are commanding premium pricing, with manufacturers willing to invest 15-20% more in thermal solutions that enable consistent fast-charging performance.

Safety considerations have become paramount following several high-profile battery thermal runaway incidents. Insurance data reveals that thermal-related battery failures account for approximately 28% of EV insurance claims, creating strong regulatory and consumer pressure for more robust thermal management solutions. This has expanded the market for advanced monitoring systems, phase-change materials, and intelligent cooling architectures.

The commercial vehicle segment represents an emerging high-value market for advanced thermal solutions. Fleet operators prioritize battery longevity and consistent performance metrics, with thermal management identified as a key factor in total cost of ownership calculations. Market analysis shows fleet operators are willing to pay up to 30% premium for thermal management systems that can demonstrably extend battery life by 20% or more.

Geographically, the most aggressive growth is occurring in regions with extreme climate conditions. Northern European markets, parts of North America, and rapidly developing EV markets in Southeast Asia are showing particularly strong demand for sophisticated thermal management solutions that can handle wide temperature variations. This regional variation is creating opportunities for specialized thermal management systems designed for specific climate challenges.

Current Challenges in Battery Pack Cooling Technologies

Battery thermal management systems (BTMS) face significant challenges in maintaining optimal operating temperatures across diverse conditions. Current cooling technologies struggle with heat distribution uniformity, as temperature gradients within battery packs can exceed 5-10°C, leading to accelerated degradation in hotter cells and overall performance inconsistency. This non-uniform cooling remains one of the most persistent technical barriers in large-scale battery applications.

Energy efficiency presents another major challenge, with conventional cooling systems consuming 3-8% of the battery's total energy capacity. This parasitic loss directly impacts vehicle range and operational efficiency, creating a technical paradox where cooling systems designed to protect batteries simultaneously reduce their effective capacity. The trade-off between cooling effectiveness and energy consumption continues to challenge engineers.

Space and weight constraints severely limit cooling system design options, particularly in electric vehicles where every millimeter and gram affects performance. Current liquid cooling systems, while effective, add approximately 15-25% to battery pack weight and occupy valuable space that could otherwise be used for additional energy storage. Air cooling systems, though lighter, struggle to provide sufficient cooling capacity for high-performance applications.

Thermal response time represents another significant hurdle, as most existing systems cannot react quickly enough to sudden temperature spikes during fast charging or high-power discharge events. The thermal lag between heat generation and cooling response can allow temperatures to temporarily exceed safe operating ranges, potentially triggering protective throttling mechanisms that limit performance.

Cost considerations further complicate cooling technology implementation, with advanced thermal management systems adding $10-20 per kWh to battery pack costs. This represents a significant portion of overall pack cost, creating market pressure to develop more cost-effective solutions without compromising thermal performance.

Material compatibility issues also plague current cooling technologies, as coolants must remain chemically stable with battery components over the pack's entire lifecycle. Several promising cooling fluids have been abandoned due to long-term degradation concerns or potential reactivity with battery materials in failure scenarios.

Finally, the industry faces substantial challenges in developing cooling systems that perform consistently across extreme temperature environments. Most current technologies operate optimally within a narrow temperature band, struggling to maintain performance in sub-zero conditions or extreme heat, limiting the practical deployment of battery systems in many global regions.

Energy efficiency presents another major challenge, with conventional cooling systems consuming 3-8% of the battery's total energy capacity. This parasitic loss directly impacts vehicle range and operational efficiency, creating a technical paradox where cooling systems designed to protect batteries simultaneously reduce their effective capacity. The trade-off between cooling effectiveness and energy consumption continues to challenge engineers.

Space and weight constraints severely limit cooling system design options, particularly in electric vehicles where every millimeter and gram affects performance. Current liquid cooling systems, while effective, add approximately 15-25% to battery pack weight and occupy valuable space that could otherwise be used for additional energy storage. Air cooling systems, though lighter, struggle to provide sufficient cooling capacity for high-performance applications.

Thermal response time represents another significant hurdle, as most existing systems cannot react quickly enough to sudden temperature spikes during fast charging or high-power discharge events. The thermal lag between heat generation and cooling response can allow temperatures to temporarily exceed safe operating ranges, potentially triggering protective throttling mechanisms that limit performance.

Cost considerations further complicate cooling technology implementation, with advanced thermal management systems adding $10-20 per kWh to battery pack costs. This represents a significant portion of overall pack cost, creating market pressure to develop more cost-effective solutions without compromising thermal performance.

Material compatibility issues also plague current cooling technologies, as coolants must remain chemically stable with battery components over the pack's entire lifecycle. Several promising cooling fluids have been abandoned due to long-term degradation concerns or potential reactivity with battery materials in failure scenarios.

Finally, the industry faces substantial challenges in developing cooling systems that perform consistently across extreme temperature environments. Most current technologies operate optimally within a narrow temperature band, struggling to maintain performance in sub-zero conditions or extreme heat, limiting the practical deployment of battery systems in many global regions.

Current Thermal Management System Architectures

01 Liquid cooling systems for battery packs

Liquid cooling systems utilize coolant circulation through channels or plates in direct contact with battery cells to efficiently manage thermal conditions. These systems can include pumps, heat exchangers, and temperature sensors to maintain optimal operating temperatures. The liquid medium provides superior heat transfer capabilities compared to air cooling, allowing for more precise temperature control and better performance in high-power applications.- Liquid cooling systems for battery packs: Liquid cooling systems are used in battery packs to efficiently manage thermal conditions. These systems typically include cooling plates, channels, or jackets that allow coolant to circulate through or around battery cells. The liquid absorbs heat from the cells and transfers it away from the battery pack, maintaining optimal operating temperatures and preventing thermal runaway. Advanced designs incorporate flow optimization and temperature sensors for precise thermal control.

- Phase change materials for thermal management: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb excess heat during operation. These materials change from solid to liquid state when heated, absorbing large amounts of energy during the phase transition. This helps maintain consistent battery temperatures during high-load operations and prevents overheating. PCMs can be integrated into battery modules as dedicated layers or components, providing passive thermal regulation without requiring active cooling systems.

- Air cooling and ventilation systems: Air cooling systems utilize forced or natural convection to remove heat from battery packs. These systems incorporate strategically placed air channels, fans, and heat sinks to direct airflow across battery cells. The design focuses on optimizing air distribution to ensure uniform cooling across all cells, preventing hot spots and temperature gradients. Air cooling solutions are often preferred for their simplicity, lower weight, and reduced complexity compared to liquid cooling systems, though they typically offer lower cooling capacity.

- Thermal insulation and heat dissipation structures: Specialized thermal insulation and heat dissipation structures are designed to manage heat flow within battery packs. These include heat shields, thermal barriers, and thermally conductive materials strategically placed to direct heat away from sensitive components. Advanced designs incorporate composite materials with tailored thermal properties to optimize heat transfer in specific directions. These structures help maintain temperature uniformity across battery cells and protect surrounding vehicle components from excessive heat.

- Intelligent thermal management control systems: Intelligent control systems monitor and regulate battery pack temperatures using sensors, algorithms, and predictive models. These systems collect real-time temperature data from multiple points within the battery pack and adjust cooling or heating parameters accordingly. Advanced implementations incorporate machine learning to predict thermal behavior based on usage patterns and environmental conditions. The control systems can activate different cooling mechanisms, adjust coolant flow rates, or modify battery usage to maintain optimal thermal conditions and extend battery life.

02 Phase change materials for thermal management

Phase change materials (PCMs) absorb and release thermal energy during phase transitions, providing passive thermal regulation for battery packs. These materials can be integrated into battery modules to absorb excess heat during operation and discharge it when temperatures drop. PCMs help maintain consistent battery temperatures, extend battery life, and improve safety by preventing thermal runaway conditions without requiring active cooling systems.Expand Specific Solutions03 Air cooling and ventilation systems

Air cooling systems utilize forced or natural convection to remove heat from battery packs. These systems may include fans, ducts, heat sinks, and thermal insulation to direct airflow efficiently across battery cells. Air cooling solutions are often lighter and less complex than liquid systems, making them suitable for applications where weight and simplicity are priorities, though they typically offer lower cooling capacity for high-power applications.Expand Specific Solutions04 Integrated thermal management control systems

Integrated control systems coordinate multiple thermal management components based on real-time temperature monitoring. These systems use sensors, controllers, and algorithms to optimize cooling or heating strategies according to operating conditions, battery state of charge, and ambient environment. Advanced systems may incorporate predictive models to anticipate thermal needs, balance cell temperatures, and implement protective measures during extreme conditions to maximize efficiency and battery longevity.Expand Specific Solutions05 Structural thermal management solutions

Structural approaches to thermal management incorporate thermal considerations into the physical design of battery packs. These solutions include thermally conductive materials, strategic cell arrangement, thermal barriers, and heat-dissipating structures. By optimizing the physical layout and material selection, these designs can passively improve heat distribution, reduce hotspots, and enhance overall thermal stability without relying solely on active cooling systems.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Battery Pack Thermal Management is evolving rapidly in a maturing market estimated at $3.5 billion, with projected growth to $7 billion by 2028. The industry is transitioning from early development to commercial scale, with varying levels of technological maturity. Leading players like Tesla, CATL, and LG Energy Solution have established advanced liquid cooling systems, while BYD and Samsung SDI focus on innovative air and phase-change cooling technologies. GM and Volvo are integrating thermal management into vehicle design architecture. Emerging companies like EVE Energy and Canoo are developing next-generation solutions combining multiple cooling methods. The competitive landscape shows a clear division between established automotive manufacturers, specialized battery producers, and technology startups, with Asian companies currently dominating production scale and European and American firms focusing on technological innovation.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced battery thermal management system featuring a multi-layered approach to temperature control. Their design incorporates a network of cooling plates with optimized microchannel structures that maximize contact with cell surfaces while minimizing coolant volume. LG's system employs a proprietary coolant formulation with enhanced thermal conductivity properties, improving heat transfer efficiency by approximately 25% compared to standard glycol solutions. The company has pioneered a variable-flow cooling system that dynamically adjusts coolant circulation based on real-time temperature monitoring and predictive thermal modeling. For their pouch cell configurations, LG has developed specialized cooling fins that insert between cells, creating direct thermal pathways that reduce temperature gradients across the pack. Their latest innovation includes integrated heating elements within the cooling structure that can rapidly bring batteries to optimal operating temperature in cold conditions, improving charging performance and extending cycle life in extreme climates.

Strengths: Highly adaptable system that can be configured for various cell types and pack geometries. Excellent temperature uniformity across cells with minimal parasitic energy consumption. Weaknesses: Relatively complex manufacturing process with multiple components requiring precise assembly. Higher cost compared to simpler air-cooled or indirect cooling systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a cell-to-pack (CTP) technology with integrated thermal management that eliminates the need for traditional module structures. Their latest innovation includes a liquid cooling plate design with micro-channels that increases cooling efficiency by up to 50% compared to conventional designs. CATL's system features intelligent thermal management algorithms that predict heat generation patterns based on driving conditions and battery state, proactively adjusting cooling intensity. The company has also pioneered phase change materials (PCMs) integrated within battery packs that absorb excess heat during rapid charging and high-load operations, then gradually release it when temperatures normalize. Their newest generation employs a multi-layer cooling structure where coolant flows through specially designed plates between cell layers, ensuring uniform temperature distribution across the entire pack while minimizing the thermal management system's weight and volume.

Strengths: Highly efficient cooling with minimal space requirements, enabling higher energy density at the pack level. The intelligent predictive cooling reduces energy consumption. Weaknesses: Complex manufacturing process requiring precise assembly tolerances. Higher initial cost compared to conventional cooling systems, though potentially offset by improved battery longevity.

Critical Patents and Innovations in Battery Cooling

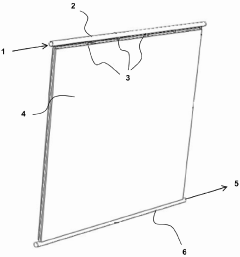

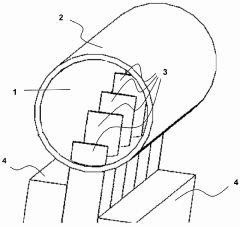

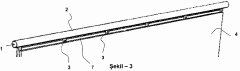

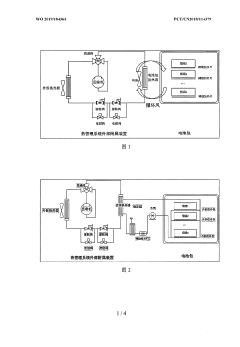

A HYBRID BATTERY PACK THERMAL MANAGEMENT SYSTEM

PatentActiveTR202112320A1

Innovation

- Hybrid thermal management system utilizing refrigerant/fluids to achieve homogeneous temperature distribution across battery cells in a pack.

- Specialized design optimized for pouch and prismatic type battery packs, addressing their unique thermal characteristics.

- Uniform temperature control throughout each individual battery cell (8), minimizing thermal gradients that can lead to performance degradation and reduced lifespan.

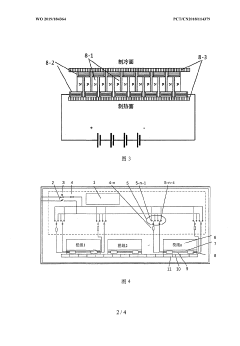

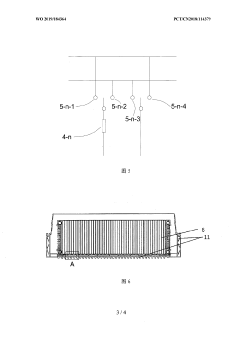

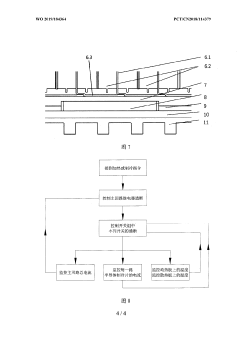

Thermal management assembly for power battery pack

PatentWO2019184364A1

Innovation

- Semiconductor refrigeration chips are used to directly heat and cool the battery, and rapid switching is achieved by controlling the direction of the current. There is no need for heat transfer from the refrigerant medium, and the control circuit and intelligent management module are integrated for precise control.

Safety Standards and Regulatory Requirements

The regulatory landscape for battery thermal management systems has evolved significantly in response to high-profile safety incidents in the electric vehicle and energy storage sectors. International standards such as IEC 62619 and UL 1642 establish comprehensive requirements for lithium-ion battery safety, with specific provisions addressing thermal runaway prevention and management. These standards mandate rigorous testing protocols including thermal abuse tests, overcharge protection verification, and short circuit response evaluation to ensure battery packs can withstand extreme thermal conditions without catastrophic failure.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The UN Transportation of Dangerous Goods regulations impose strict thermal stability requirements for batteries during shipping, while the European Union's Battery Directive and China's GB/T standards implement region-specific thermal safety parameters. These divergent requirements necessitate sophisticated thermal management solutions that can satisfy multiple regulatory regimes simultaneously.

Safety certification processes increasingly focus on thermal management as a critical component. Certification bodies require manufacturers to demonstrate robust thermal monitoring capabilities, effective heat dissipation mechanisms, and fail-safe thermal protection systems. Documentation requirements have expanded to include detailed thermal modeling data, temperature distribution analyses, and thermal runaway propagation prevention strategies.

Emerging regulations are placing greater emphasis on battery thermal management throughout the product lifecycle. New standards under development by ISO and SAE specifically address thermal management during charging, operation, and end-of-life handling. These standards are moving toward performance-based approaches that evaluate a thermal management system's ability to maintain optimal temperature ranges under various operating conditions rather than prescribing specific technical solutions.

Compliance with evolving safety standards is driving innovation in thermal management design. Advanced features such as thermal isolation between cells, intelligent thermal monitoring systems with predictive capabilities, and multi-layered thermal protection mechanisms are becoming standard requirements rather than optional enhancements. The regulatory trend toward more stringent thermal safety requirements is accelerating the development of novel cooling technologies and thermal materials that can provide superior performance while meeting increasingly demanding safety standards.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The UN Transportation of Dangerous Goods regulations impose strict thermal stability requirements for batteries during shipping, while the European Union's Battery Directive and China's GB/T standards implement region-specific thermal safety parameters. These divergent requirements necessitate sophisticated thermal management solutions that can satisfy multiple regulatory regimes simultaneously.

Safety certification processes increasingly focus on thermal management as a critical component. Certification bodies require manufacturers to demonstrate robust thermal monitoring capabilities, effective heat dissipation mechanisms, and fail-safe thermal protection systems. Documentation requirements have expanded to include detailed thermal modeling data, temperature distribution analyses, and thermal runaway propagation prevention strategies.

Emerging regulations are placing greater emphasis on battery thermal management throughout the product lifecycle. New standards under development by ISO and SAE specifically address thermal management during charging, operation, and end-of-life handling. These standards are moving toward performance-based approaches that evaluate a thermal management system's ability to maintain optimal temperature ranges under various operating conditions rather than prescribing specific technical solutions.

Compliance with evolving safety standards is driving innovation in thermal management design. Advanced features such as thermal isolation between cells, intelligent thermal monitoring systems with predictive capabilities, and multi-layered thermal protection mechanisms are becoming standard requirements rather than optional enhancements. The regulatory trend toward more stringent thermal safety requirements is accelerating the development of novel cooling technologies and thermal materials that can provide superior performance while meeting increasingly demanding safety standards.

Environmental Impact and Sustainability Considerations

The environmental impact of battery thermal management systems (BTMS) extends far beyond operational efficiency, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. Traditional cooling systems often rely on refrigerants with high global warming potential (GWP), contributing significantly to greenhouse gas emissions. Recent innovations have focused on transitioning to natural refrigerants and low-GWP alternatives, reducing the climate impact by up to 90% compared to conventional systems.

Material selection represents another critical environmental consideration. The shift from metal-based heat exchangers to advanced polymer composites has reduced the embodied carbon footprint of BTMS components by approximately 30-45%. These materials not only require less energy-intensive manufacturing processes but also facilitate easier recycling at end-of-life. Additionally, the integration of bio-based phase change materials (PCMs) derived from renewable resources offers a sustainable alternative to petroleum-based thermal management solutions.

Energy consumption during operation constitutes a significant environmental factor. Passive thermal management systems that utilize PCMs or thermosiphon technology can reduce parasitic energy losses by 15-20% compared to active cooling systems, extending vehicle range while minimizing environmental impact. Smart thermal management algorithms that optimize cooling based on driving conditions and battery state further reduce unnecessary energy expenditure, with field tests demonstrating energy savings of up to 25%.

Water usage presents an emerging concern, particularly for direct liquid cooling systems. Closed-loop designs that minimize water consumption and prevent contamination have become industry standard, with some manufacturers implementing water recovery systems that reduce freshwater requirements by over 80%. This approach is particularly valuable in water-stressed regions where automotive manufacturing and battery production facilities operate.

End-of-life considerations have gained prominence as battery volumes increase globally. Design for disassembly principles are being incorporated into modern BTMS, allowing for more efficient recovery of valuable materials. Modular designs facilitate the replacement of individual components rather than entire systems, extending useful life and reducing waste. Some manufacturers have implemented take-back programs specifically for thermal management components, achieving recycling rates exceeding 85% for certain materials.

Regulatory frameworks increasingly influence BTMS design, with policies like the European Union's F-Gas Regulation driving innovation in refrigerant selection and system efficiency. Forward-thinking manufacturers are anticipating stricter environmental regulations by developing thermal management solutions that exceed current requirements, providing competitive advantage while reducing environmental impact throughout the battery lifecycle.

Material selection represents another critical environmental consideration. The shift from metal-based heat exchangers to advanced polymer composites has reduced the embodied carbon footprint of BTMS components by approximately 30-45%. These materials not only require less energy-intensive manufacturing processes but also facilitate easier recycling at end-of-life. Additionally, the integration of bio-based phase change materials (PCMs) derived from renewable resources offers a sustainable alternative to petroleum-based thermal management solutions.

Energy consumption during operation constitutes a significant environmental factor. Passive thermal management systems that utilize PCMs or thermosiphon technology can reduce parasitic energy losses by 15-20% compared to active cooling systems, extending vehicle range while minimizing environmental impact. Smart thermal management algorithms that optimize cooling based on driving conditions and battery state further reduce unnecessary energy expenditure, with field tests demonstrating energy savings of up to 25%.

Water usage presents an emerging concern, particularly for direct liquid cooling systems. Closed-loop designs that minimize water consumption and prevent contamination have become industry standard, with some manufacturers implementing water recovery systems that reduce freshwater requirements by over 80%. This approach is particularly valuable in water-stressed regions where automotive manufacturing and battery production facilities operate.

End-of-life considerations have gained prominence as battery volumes increase globally. Design for disassembly principles are being incorporated into modern BTMS, allowing for more efficient recovery of valuable materials. Modular designs facilitate the replacement of individual components rather than entire systems, extending useful life and reducing waste. Some manufacturers have implemented take-back programs specifically for thermal management components, achieving recycling rates exceeding 85% for certain materials.

Regulatory frameworks increasingly influence BTMS design, with policies like the European Union's F-Gas Regulation driving innovation in refrigerant selection and system efficiency. Forward-thinking manufacturers are anticipating stricter environmental regulations by developing thermal management solutions that exceed current requirements, providing competitive advantage while reducing environmental impact throughout the battery lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!