What Design Modifications Minimize Battery Thermal Runaway

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway represents one of the most critical safety challenges in modern energy storage systems. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and the release of toxic gases. The evolution of battery technology has been marked by continuous improvements in energy density and performance, yet these advancements have often come at the cost of increased thermal instability risks.

The history of battery thermal runaway incidents dates back to the early commercialization of lithium-ion batteries in the 1990s. Notable incidents including consumer electronics fires, electric vehicle combustions, and grid storage system failures have highlighted the persistent nature of this challenge across multiple industries. These events have driven regulatory bodies worldwide to establish increasingly stringent safety standards, while simultaneously accelerating research into thermal management solutions.

From a technical perspective, thermal runaway typically initiates when internal cell temperature exceeds a critical threshold (approximately 130-150°C for most lithium-ion chemistries), triggering exothermic decomposition reactions between electrode materials and electrolyte. This process creates a dangerous feedback loop where heat generation exceeds dissipation capabilities, leading to cascading failure that can propagate through adjacent cells in a battery pack.

Current battery designs incorporate various passive and active safety mechanisms, including thermal fuses, pressure relief vents, and battery management systems. However, these solutions often represent compromises between safety, performance, cost, and manufacturing complexity. The fundamental challenge remains: how to maintain high energy density while effectively preventing or containing thermal runaway events.

The primary objective of this technical research is to identify and evaluate design modifications that can minimize battery thermal runaway risks without significantly compromising performance metrics. Specifically, we aim to explore innovations across multiple design elements: cell chemistry formulations, separator technologies, thermal interface materials, pack-level architecture, and advanced monitoring systems.

Secondary objectives include quantifying the effectiveness of various design approaches through standardized testing protocols, assessing manufacturing feasibility and cost implications of promising solutions, and developing implementation roadmaps aligned with industry adoption timelines. The research will prioritize solutions applicable to high-growth sectors including electric vehicles, consumer electronics, and grid-scale energy storage systems.

This investigation will establish a comprehensive framework for evaluating thermal runaway mitigation strategies, providing actionable insights for product development teams seeking to enhance battery safety while maintaining competitive performance characteristics.

The history of battery thermal runaway incidents dates back to the early commercialization of lithium-ion batteries in the 1990s. Notable incidents including consumer electronics fires, electric vehicle combustions, and grid storage system failures have highlighted the persistent nature of this challenge across multiple industries. These events have driven regulatory bodies worldwide to establish increasingly stringent safety standards, while simultaneously accelerating research into thermal management solutions.

From a technical perspective, thermal runaway typically initiates when internal cell temperature exceeds a critical threshold (approximately 130-150°C for most lithium-ion chemistries), triggering exothermic decomposition reactions between electrode materials and electrolyte. This process creates a dangerous feedback loop where heat generation exceeds dissipation capabilities, leading to cascading failure that can propagate through adjacent cells in a battery pack.

Current battery designs incorporate various passive and active safety mechanisms, including thermal fuses, pressure relief vents, and battery management systems. However, these solutions often represent compromises between safety, performance, cost, and manufacturing complexity. The fundamental challenge remains: how to maintain high energy density while effectively preventing or containing thermal runaway events.

The primary objective of this technical research is to identify and evaluate design modifications that can minimize battery thermal runaway risks without significantly compromising performance metrics. Specifically, we aim to explore innovations across multiple design elements: cell chemistry formulations, separator technologies, thermal interface materials, pack-level architecture, and advanced monitoring systems.

Secondary objectives include quantifying the effectiveness of various design approaches through standardized testing protocols, assessing manufacturing feasibility and cost implications of promising solutions, and developing implementation roadmaps aligned with industry adoption timelines. The research will prioritize solutions applicable to high-growth sectors including electric vehicles, consumer electronics, and grid-scale energy storage systems.

This investigation will establish a comprehensive framework for evaluating thermal runaway mitigation strategies, providing actionable insights for product development teams seeking to enhance battery safety while maintaining competitive performance characteristics.

Market Analysis for Safer Battery Technologies

The global market for safer battery technologies is experiencing unprecedented growth, driven primarily by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. As of 2023, the market for advanced battery safety technologies is valued at approximately $8.7 billion, with projections indicating a compound annual growth rate of 15.3% through 2030. This growth trajectory is significantly influenced by stringent safety regulations and consumer demand for more reliable energy storage solutions.

Consumer electronics represents the largest application segment, accounting for 37% of the market share, followed closely by electric vehicles at 32%. The automotive sector, in particular, has become a critical driver for innovations in thermal runaway prevention technologies, as high-profile battery failure incidents have heightened awareness among manufacturers and consumers alike.

Geographically, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established significant production capacities. North America follows with 28% market share, while Europe accounts for 22%, with particularly strong growth in countries with aggressive electric mobility targets such as Germany, Norway, and the Netherlands.

The demand for safer battery technologies is further segmented by battery chemistry types. Lithium-ion batteries with enhanced safety features command the largest market segment at 68%, followed by solid-state batteries at 18%, which are gaining traction due to their inherent resistance to thermal runaway. Emerging technologies such as lithium-sulfur and sodium-ion batteries collectively represent about 14% of the market.

Key market drivers include increasingly stringent regulatory frameworks, such as the UN 38.3 safety testing requirements and region-specific standards like UL 1642 in North America and IEC 62133 in Europe. Additionally, insurance companies are beginning to offer premium reductions for systems incorporating advanced battery safety technologies, creating financial incentives beyond regulatory compliance.

Consumer awareness regarding battery safety has increased dramatically following widely publicized incidents involving thermal runaway in consumer electronics and electric vehicles. This has created a market environment where safety features have become significant differentiators for manufacturers, with 73% of consumers in recent surveys indicating willingness to pay premium prices for products with enhanced battery safety technologies.

The competitive landscape is characterized by both established battery manufacturers implementing incremental safety improvements and specialized startups developing disruptive technologies specifically targeting thermal runaway prevention. Venture capital investment in battery safety technologies has increased by 87% since 2020, indicating strong market confidence in the growth potential of this sector.

Consumer electronics represents the largest application segment, accounting for 37% of the market share, followed closely by electric vehicles at 32%. The automotive sector, in particular, has become a critical driver for innovations in thermal runaway prevention technologies, as high-profile battery failure incidents have heightened awareness among manufacturers and consumers alike.

Geographically, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established significant production capacities. North America follows with 28% market share, while Europe accounts for 22%, with particularly strong growth in countries with aggressive electric mobility targets such as Germany, Norway, and the Netherlands.

The demand for safer battery technologies is further segmented by battery chemistry types. Lithium-ion batteries with enhanced safety features command the largest market segment at 68%, followed by solid-state batteries at 18%, which are gaining traction due to their inherent resistance to thermal runaway. Emerging technologies such as lithium-sulfur and sodium-ion batteries collectively represent about 14% of the market.

Key market drivers include increasingly stringent regulatory frameworks, such as the UN 38.3 safety testing requirements and region-specific standards like UL 1642 in North America and IEC 62133 in Europe. Additionally, insurance companies are beginning to offer premium reductions for systems incorporating advanced battery safety technologies, creating financial incentives beyond regulatory compliance.

Consumer awareness regarding battery safety has increased dramatically following widely publicized incidents involving thermal runaway in consumer electronics and electric vehicles. This has created a market environment where safety features have become significant differentiators for manufacturers, with 73% of consumers in recent surveys indicating willingness to pay premium prices for products with enhanced battery safety technologies.

The competitive landscape is characterized by both established battery manufacturers implementing incremental safety improvements and specialized startups developing disruptive technologies specifically targeting thermal runaway prevention. Venture capital investment in battery safety technologies has increased by 87% since 2020, indicating strong market confidence in the growth potential of this sector.

Current Challenges in Battery Thermal Management

Despite significant advancements in battery technology, thermal management remains one of the most critical challenges in preventing thermal runaway incidents. Current lithium-ion battery systems face several persistent thermal management issues that compromise safety, performance, and longevity. The primary challenge lies in the inherent thermal instability of lithium-ion chemistry, where temperatures exceeding 80°C can trigger exothermic reactions that rapidly escalate to dangerous levels.

Existing cooling systems demonstrate significant limitations in high-power applications. Conventional air cooling methods prove inadequate for high-density battery packs, while liquid cooling systems, though more effective, introduce complexity, weight penalties, and potential leak risks. The trade-off between cooling efficiency and system simplicity continues to challenge engineers across the industry.

Temperature gradient management presents another substantial hurdle. Uneven temperature distribution within battery packs leads to differential aging, capacity imbalance, and localized hotspots that can initiate thermal runaway events. Current battery management systems (BMS) often lack the granularity needed for precise temperature monitoring at the cell level, particularly in large-format batteries used in electric vehicles and grid storage applications.

The integration of thermal management with other battery subsystems remains problematic. Cooling systems must operate harmoniously with electrical connections, structural components, and safety mechanisms, creating design conflicts that compromise overall system performance. Additionally, the thermal management requirements vary significantly across operating conditions, from extreme cold to high ambient temperatures, further complicating system design.

Material limitations constitute another significant barrier. Current thermal interface materials exhibit insufficient thermal conductivity or deteriorate over time, reducing heat transfer efficiency. Similarly, phase change materials show promise but face challenges in long-term stability and integration with existing battery architectures.

From a manufacturing perspective, the complexity of advanced thermal management systems increases production costs and complicates quality control processes. The industry struggles to develop cost-effective solutions that can be implemented at scale without compromising thermal performance or safety margins.

Regulatory frameworks and testing protocols for thermal management systems remain inconsistent across different markets and applications. This regulatory fragmentation complicates the development of standardized approaches to thermal runaway prevention and mitigation, forcing manufacturers to design multiple solutions for different compliance requirements.

Existing cooling systems demonstrate significant limitations in high-power applications. Conventional air cooling methods prove inadequate for high-density battery packs, while liquid cooling systems, though more effective, introduce complexity, weight penalties, and potential leak risks. The trade-off between cooling efficiency and system simplicity continues to challenge engineers across the industry.

Temperature gradient management presents another substantial hurdle. Uneven temperature distribution within battery packs leads to differential aging, capacity imbalance, and localized hotspots that can initiate thermal runaway events. Current battery management systems (BMS) often lack the granularity needed for precise temperature monitoring at the cell level, particularly in large-format batteries used in electric vehicles and grid storage applications.

The integration of thermal management with other battery subsystems remains problematic. Cooling systems must operate harmoniously with electrical connections, structural components, and safety mechanisms, creating design conflicts that compromise overall system performance. Additionally, the thermal management requirements vary significantly across operating conditions, from extreme cold to high ambient temperatures, further complicating system design.

Material limitations constitute another significant barrier. Current thermal interface materials exhibit insufficient thermal conductivity or deteriorate over time, reducing heat transfer efficiency. Similarly, phase change materials show promise but face challenges in long-term stability and integration with existing battery architectures.

From a manufacturing perspective, the complexity of advanced thermal management systems increases production costs and complicates quality control processes. The industry struggles to develop cost-effective solutions that can be implemented at scale without compromising thermal performance or safety margins.

Regulatory frameworks and testing protocols for thermal management systems remain inconsistent across different markets and applications. This regulatory fragmentation complicates the development of standardized approaches to thermal runaway prevention and mitigation, forcing manufacturers to design multiple solutions for different compliance requirements.

Existing Thermal Runaway Prevention Mechanisms

01 Thermal management systems for batteries

Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade effect that leads to thermal runaway.- Thermal management systems for batteries: Various thermal management systems are designed to prevent thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade of exothermic reactions that lead to thermal runaway.

- Battery cell design and materials to prevent thermal runaway: Innovative battery cell designs and materials are developed to inherently resist thermal runaway conditions. These include specialized electrode materials, separator technologies with thermal shutdown properties, and novel electrolyte formulations with flame-retardant additives. The cell architecture may incorporate safety features such as pressure relief mechanisms, internal current interruption devices, and thermally stable components that maintain structural integrity at elevated temperatures.

- Detection and early warning systems: Advanced detection systems are implemented to identify early signs of thermal runaway before it escalates. These systems utilize sensors to monitor critical parameters such as temperature gradients, gas emissions, internal pressure, and voltage fluctuations. Machine learning algorithms analyze these parameters to recognize patterns indicative of impending thermal events, enabling preemptive safety measures. Early warning systems can trigger automated responses or alert operators to take corrective action before catastrophic failure occurs.

- Battery pack architecture and isolation strategies: Battery pack designs incorporate physical and thermal isolation strategies to prevent thermal runaway propagation between cells. These architectures include fire-resistant barriers, thermal fuses, and compartmentalization techniques that contain thermal events within affected modules. Strategic cell arrangement and spacing, combined with heat-resistant materials, create effective firebreaks within the battery system. Some designs implement active isolation mechanisms that can electrically or physically disconnect compromised cells from the rest of the pack.

- Emergency response and suppression systems: Integrated emergency response systems are designed to mitigate thermal runaway events once they occur. These systems include automatic fire suppression mechanisms that deploy fire-extinguishing agents directly to affected areas. Venting systems safely channel hot gases and potentially toxic emissions away from sensitive components and personnel. Some advanced designs incorporate sacrificial materials that absorb heat or neutralize hazardous byproducts during thermal events, minimizing collateral damage and preventing cascading failures.

02 Battery cell design and materials to prevent thermal runaway

Innovative battery cell designs and materials are developed to inherently resist thermal runaway conditions. These include specialized electrode materials, separator technologies with thermal shutdown properties, and novel electrolyte formulations with flame-retardant additives. The cell architecture may incorporate safety features such as pressure relief mechanisms, internal current interruption devices, and thermally stable components that maintain integrity at elevated temperatures.Expand Specific Solutions03 Detection and early warning systems

Advanced detection systems are implemented to identify early signs of thermal runaway before catastrophic failure occurs. These systems utilize sensors to monitor parameters such as temperature gradients, gas emissions, internal pressure, and voltage fluctuations. Machine learning algorithms analyze these parameters to predict potential thermal events, allowing for preventive measures to be activated. Early warning systems can trigger emergency protocols including power disconnection, enhanced cooling, or containment procedures.Expand Specific Solutions04 Battery pack isolation and containment strategies

Battery pack designs incorporate isolation and containment strategies to prevent thermal runaway from propagating between cells. These include physical barriers, thermal insulators, and fire-resistant materials placed between cells or modules. Compartmentalization techniques ensure that if one cell experiences thermal runaway, the heat and fire cannot easily spread to adjacent cells. Some designs also feature venting systems to safely direct hot gases away from other battery components.Expand Specific Solutions05 Battery management systems (BMS) for thermal runaway prevention

Sophisticated battery management systems are developed to actively prevent thermal runaway conditions. These systems continuously monitor cell parameters and control charging/discharging processes to avoid dangerous operating conditions. BMS implementations include algorithms for state-of-health estimation, adaptive charging protocols, and predictive maintenance capabilities. When abnormal conditions are detected, the BMS can implement protective measures such as current limitation, load disconnection, or emergency shutdown procedures.Expand Specific Solutions

Leading Battery Safety Technology Providers

The battery thermal runaway mitigation market is in a growth phase, driven by increasing electric vehicle adoption and stringent safety regulations. The market is projected to expand significantly as battery technologies evolve, with an estimated value exceeding $2 billion by 2025. Leading players include established battery manufacturers like CATL, LG Energy Solution, Samsung SDI, and Panasonic Energy, who are investing heavily in advanced thermal management systems. Automotive giants Tesla, BMW, and SAIC are integrating proprietary thermal runaway prevention technologies into their vehicle designs. The technology maturity varies, with companies like Tesla and CATL demonstrating more advanced solutions through multi-layer protection systems, while newer entrants like Automotive Cells Company are rapidly developing innovative approaches to compete in this critical safety domain.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive battery thermal management system called the Cell-to-Pack (CTP) technology with integrated thermal runaway prevention. Their design incorporates multiple layers of protection including: 1) Advanced separator materials with ceramic coatings that maintain structural integrity at high temperatures[1]; 2) Flame-retardant electrolytes that reduce combustibility during thermal events; 3) Novel cooling plate designs that distribute heat more efficiently across the battery pack; 4) Real-time temperature monitoring systems with predictive algorithms to detect potential thermal issues before they escalate[2]; and 5) Thermal propagation barriers between cells that prevent cascading failures. CATL's latest generation employs phase change materials embedded within the battery structure to absorb excess heat during operation or potential thermal events.

Strengths: Industry-leading energy density while maintaining thermal safety; extensive manufacturing capacity allows for rapid implementation of safety innovations; proprietary materials science expertise. Weaknesses: Higher production costs compared to conventional designs; added thermal management components increase overall weight; system complexity requires sophisticated battery management systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a multi-faceted approach to battery thermal runaway mitigation through their "Safety Reinforced Separator" (SRS) technology. This proprietary design incorporates ceramic-coated separators with higher thermal stability (maintaining integrity up to 180°C compared to conventional separators' 130°C)[3]. Their battery cells feature a unique internal structure with thermal fuses that physically disconnect cells when temperature thresholds are exceeded. Samsung has also developed specialized electrolyte additives that polymerize at elevated temperatures, creating a protective barrier that prevents further exothermic reactions. Their module design incorporates aerogel-based insulation materials between cells that can withstand temperatures exceeding 1000°C while providing minimal thermal conductivity, effectively isolating thermal events to individual cells[4]. Additionally, Samsung employs a liquid cooling system with redundant circulation paths to ensure cooling capability even if primary channels are compromised.

Strengths: Exceptional thermal isolation between cells prevents propagation; advanced materials science capabilities; extensive testing facilities for thermal event simulation. Weaknesses: Higher manufacturing complexity increases production costs; thermal protection systems add weight and volume to battery packs; requires sophisticated thermal monitoring systems.

Critical Patents in Battery Thermal Protection

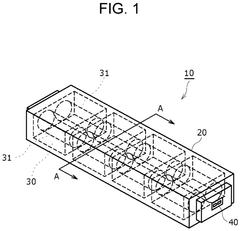

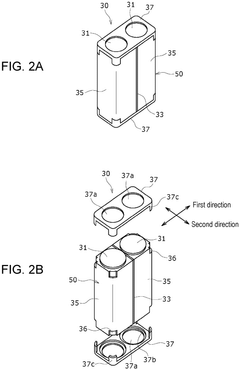

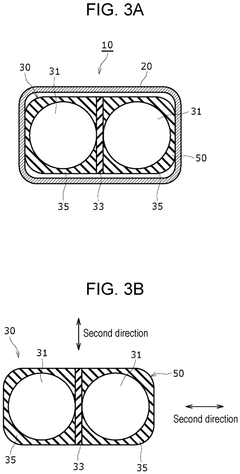

Battery pack

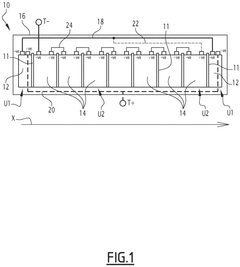

PatentPendingEP4456263A1

Innovation

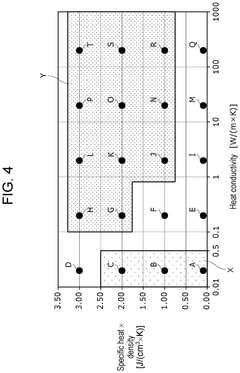

- A battery pack design incorporating a heat insulating member with lower thermal conductivity and a side surface member with higher thermal conductivity, specifically chosen for their thermal properties, is used between adjacent cells to reduce heat transfer and enhance thermal runaway suppression without increasing the pack's size.

Battery module with reduced risk of thermal runaway

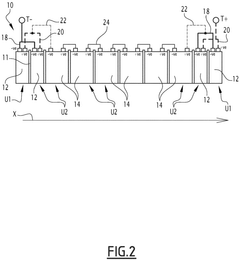

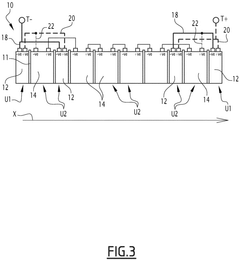

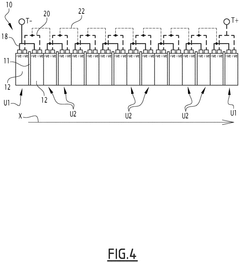

PatentPendingEP4579876A1

Innovation

- The battery module design incorporates smaller capacity cells at the ends, connected in parallel and series with larger capacity cells in the center, utilizing thermal walls to isolate units and manage heat transfer, thereby reducing the energy release during thermal runaway.

Regulatory Standards for Battery Safety Compliance

The regulatory landscape for battery safety has evolved significantly in response to increasing incidents of thermal runaway. Key international standards include IEC 62133, which establishes requirements for portable sealed secondary cells and batteries, and UN 38.3, which outlines transportation testing requirements for lithium batteries. These standards mandate specific tests for thermal abuse, short circuit protection, overcharging, and mechanical integrity.

In the United States, UL 1642 for lithium batteries and UL 2054 for household and commercial batteries provide comprehensive safety requirements. The National Fire Protection Association (NFPA) has also developed standards specifically addressing energy storage systems, including NFPA 855, which provides installation requirements for stationary energy storage systems.

European regulations are governed by EN 62619 for industrial applications and the Battery Directive 2006/66/EC, which has been updated to address emerging safety concerns. These standards are increasingly focusing on thermal management systems as a critical component of battery safety design.

Automotive applications face particularly stringent requirements under ISO 6469-1 and SAE J2464, which specify safety requirements for rechargeable energy storage systems. These standards require extensive testing for thermal propagation and mandate design features that can prevent cell-to-cell thermal runaway propagation.

Compliance testing protocols typically include nail penetration tests, crush tests, thermal shock tests, and overcharge tests. Recent regulatory updates have introduced more rigorous thermal propagation requirements, reflecting growing concerns about cascading failures in battery packs.

Emerging regulatory trends include the development of specific standards for different battery chemistries, recognizing that thermal runaway mechanisms vary significantly between lithium-ion, solid-state, and other battery technologies. Regulators are also moving toward performance-based standards rather than prescriptive requirements, allowing manufacturers greater flexibility in design approaches while maintaining safety outcomes.

Manufacturers must implement design verification testing (DVT) programs that align with these regulatory requirements. Documentation requirements have become increasingly comprehensive, with detailed thermal management strategies now expected as part of safety compliance submissions. Failure to meet these standards can result in product recalls, market access restrictions, and significant liability exposure.

In the United States, UL 1642 for lithium batteries and UL 2054 for household and commercial batteries provide comprehensive safety requirements. The National Fire Protection Association (NFPA) has also developed standards specifically addressing energy storage systems, including NFPA 855, which provides installation requirements for stationary energy storage systems.

European regulations are governed by EN 62619 for industrial applications and the Battery Directive 2006/66/EC, which has been updated to address emerging safety concerns. These standards are increasingly focusing on thermal management systems as a critical component of battery safety design.

Automotive applications face particularly stringent requirements under ISO 6469-1 and SAE J2464, which specify safety requirements for rechargeable energy storage systems. These standards require extensive testing for thermal propagation and mandate design features that can prevent cell-to-cell thermal runaway propagation.

Compliance testing protocols typically include nail penetration tests, crush tests, thermal shock tests, and overcharge tests. Recent regulatory updates have introduced more rigorous thermal propagation requirements, reflecting growing concerns about cascading failures in battery packs.

Emerging regulatory trends include the development of specific standards for different battery chemistries, recognizing that thermal runaway mechanisms vary significantly between lithium-ion, solid-state, and other battery technologies. Regulators are also moving toward performance-based standards rather than prescriptive requirements, allowing manufacturers greater flexibility in design approaches while maintaining safety outcomes.

Manufacturers must implement design verification testing (DVT) programs that align with these regulatory requirements. Documentation requirements have become increasingly comprehensive, with detailed thermal management strategies now expected as part of safety compliance submissions. Failure to meet these standards can result in product recalls, market access restrictions, and significant liability exposure.

Environmental Impact of Battery Safety Technologies

Battery safety technologies, while primarily designed to protect users and equipment, have significant environmental implications that must be considered in a comprehensive assessment. The materials used in thermal management systems, fire suppression mechanisms, and containment structures all contribute to the environmental footprint of battery systems throughout their lifecycle.

Flame retardants and thermal management materials commonly employed in battery safety systems often contain compounds that may persist in the environment. Halogenated flame retardants, while effective at preventing fire spread, can bioaccumulate in ecosystems when improperly disposed of. Advanced ceramic insulators and phase change materials present more environmentally friendly alternatives, though their production may still involve energy-intensive processes.

Cooling systems designed to prevent thermal runaway events typically require additional resources and energy consumption during operation. Liquid cooling solutions necessitate pumps and circulation systems that increase overall energy usage, potentially offsetting some of the environmental benefits of battery-powered applications. Passive cooling designs, while less resource-intensive during operation, may require specialized materials with their own extraction and manufacturing impacts.

The environmental consequences of battery failure events are particularly concerning. Thermal runaway incidents can release toxic gases, heavy metals, and other contaminants into surrounding ecosystems. Safety technologies that effectively contain these emissions during failure events provide significant environmental protection beyond their primary safety function, highlighting the dual benefit of robust containment systems.

End-of-life considerations reveal another dimension of environmental impact. Battery safety components often complicate recycling processes, requiring specialized handling and separation techniques. However, innovations in design for disassembly are creating safety systems that can be more easily separated from cells during recycling, improving resource recovery rates and reducing waste.

Carbon footprint analyses of various safety technologies demonstrate that preventative measures generally have lower environmental impacts than the consequences of catastrophic failures. The emissions associated with manufacturing additional safety components are typically offset by extended battery lifespans and reduced replacement frequency, creating a net positive environmental effect when assessed from a lifecycle perspective.

Regulatory frameworks increasingly recognize this environmental dimension, with emerging standards beginning to address both the safety performance and environmental impact of battery protection systems. This dual focus is driving innovation toward bio-based flame retardants, recyclable thermal management materials, and safety designs that facilitate rather than hinder end-of-life processing.

Flame retardants and thermal management materials commonly employed in battery safety systems often contain compounds that may persist in the environment. Halogenated flame retardants, while effective at preventing fire spread, can bioaccumulate in ecosystems when improperly disposed of. Advanced ceramic insulators and phase change materials present more environmentally friendly alternatives, though their production may still involve energy-intensive processes.

Cooling systems designed to prevent thermal runaway events typically require additional resources and energy consumption during operation. Liquid cooling solutions necessitate pumps and circulation systems that increase overall energy usage, potentially offsetting some of the environmental benefits of battery-powered applications. Passive cooling designs, while less resource-intensive during operation, may require specialized materials with their own extraction and manufacturing impacts.

The environmental consequences of battery failure events are particularly concerning. Thermal runaway incidents can release toxic gases, heavy metals, and other contaminants into surrounding ecosystems. Safety technologies that effectively contain these emissions during failure events provide significant environmental protection beyond their primary safety function, highlighting the dual benefit of robust containment systems.

End-of-life considerations reveal another dimension of environmental impact. Battery safety components often complicate recycling processes, requiring specialized handling and separation techniques. However, innovations in design for disassembly are creating safety systems that can be more easily separated from cells during recycling, improving resource recovery rates and reducing waste.

Carbon footprint analyses of various safety technologies demonstrate that preventative measures generally have lower environmental impacts than the consequences of catastrophic failures. The emissions associated with manufacturing additional safety components are typically offset by extended battery lifespans and reduced replacement frequency, creating a net positive environmental effect when assessed from a lifecycle perspective.

Regulatory frameworks increasingly recognize this environmental dimension, with emerging standards beginning to address both the safety performance and environmental impact of battery protection systems. This dual focus is driving innovation toward bio-based flame retardants, recyclable thermal management materials, and safety designs that facilitate rather than hinder end-of-life processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!