Develop Atomic Force Microscopy Image Enhancement Techniques — Steps

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Technology Background and Objectives

Atomic Force Microscopy (AFM) emerged in the mid-1980s as a revolutionary imaging technique capable of visualizing surfaces at the nanoscale. Since its invention by Gerd Binnig, Calvin Quate, and Christoph Gerber in 1986, AFM has evolved from a basic surface profiling tool to a sophisticated multi-functional platform for nanoscale characterization across numerous scientific disciplines. The technology operates by detecting forces between a sharp probe and sample surface, generating topographical maps with resolution far exceeding optical diffraction limits.

The evolution of AFM technology has been marked by significant improvements in probe design, feedback systems, and operational modes. Early systems were limited to contact mode imaging, while modern instruments offer diverse modalities including tapping mode, non-contact mode, and specialized techniques for measuring electrical, magnetic, and mechanical properties. This progression has expanded AFM applications from basic materials science to advanced biological imaging, semiconductor quality control, and nanofabrication.

Despite these advances, AFM image quality remains a persistent challenge in the field. Raw AFM images frequently suffer from artifacts, noise, limited contrast, and resolution constraints that impede accurate data interpretation. These limitations stem from various sources including thermal drift, piezoelectric creep, probe-sample interactions, and environmental vibrations. As research demands increasingly precise nanoscale measurements, the need for sophisticated image enhancement techniques has become critical.

The primary objective of developing AFM image enhancement techniques is to overcome these inherent limitations and extract maximum information from raw scan data. This involves creating systematic approaches to identify and correct artifacts, reduce noise, enhance contrast, and improve resolution while preserving the integrity of the original topographical information. Effective enhancement methods must balance noise reduction with feature preservation, avoiding the introduction of artificial structures or data misinterpretation.

Current enhancement approaches range from traditional signal processing methods to advanced computational techniques. Basic filtering and statistical methods provide fundamental noise reduction, while more sophisticated wavelet transforms and machine learning algorithms offer powerful tools for feature extraction and pattern recognition. The integration of these techniques into coherent enhancement workflows represents a significant opportunity for advancing AFM capabilities.

The ultimate goal of this technological development is to establish standardized, reliable protocols for AFM image enhancement that can be widely adopted across research and industrial applications. Success in this domain would dramatically improve the accuracy and reproducibility of nanoscale measurements, enabling more precise characterization of materials, biological systems, and engineered nanostructures. Furthermore, enhanced imaging capabilities would expand the utility of AFM in emerging fields such as nanomedicine, quantum computing, and next-generation semiconductor development.

The evolution of AFM technology has been marked by significant improvements in probe design, feedback systems, and operational modes. Early systems were limited to contact mode imaging, while modern instruments offer diverse modalities including tapping mode, non-contact mode, and specialized techniques for measuring electrical, magnetic, and mechanical properties. This progression has expanded AFM applications from basic materials science to advanced biological imaging, semiconductor quality control, and nanofabrication.

Despite these advances, AFM image quality remains a persistent challenge in the field. Raw AFM images frequently suffer from artifacts, noise, limited contrast, and resolution constraints that impede accurate data interpretation. These limitations stem from various sources including thermal drift, piezoelectric creep, probe-sample interactions, and environmental vibrations. As research demands increasingly precise nanoscale measurements, the need for sophisticated image enhancement techniques has become critical.

The primary objective of developing AFM image enhancement techniques is to overcome these inherent limitations and extract maximum information from raw scan data. This involves creating systematic approaches to identify and correct artifacts, reduce noise, enhance contrast, and improve resolution while preserving the integrity of the original topographical information. Effective enhancement methods must balance noise reduction with feature preservation, avoiding the introduction of artificial structures or data misinterpretation.

Current enhancement approaches range from traditional signal processing methods to advanced computational techniques. Basic filtering and statistical methods provide fundamental noise reduction, while more sophisticated wavelet transforms and machine learning algorithms offer powerful tools for feature extraction and pattern recognition. The integration of these techniques into coherent enhancement workflows represents a significant opportunity for advancing AFM capabilities.

The ultimate goal of this technological development is to establish standardized, reliable protocols for AFM image enhancement that can be widely adopted across research and industrial applications. Success in this domain would dramatically improve the accuracy and reproducibility of nanoscale measurements, enabling more precise characterization of materials, biological systems, and engineered nanostructures. Furthermore, enhanced imaging capabilities would expand the utility of AFM in emerging fields such as nanomedicine, quantum computing, and next-generation semiconductor development.

Market Analysis for Enhanced AFM Imaging

The global market for Atomic Force Microscopy (AFM) imaging enhancement technologies has been experiencing robust growth, driven primarily by increasing demand for high-resolution imaging in nanotechnology research and development. The current market size is estimated at approximately 500 million USD, with a compound annual growth rate of 8.3% projected over the next five years, potentially reaching 750 million USD by 2028.

Key market segments for enhanced AFM imaging include academic research institutions, semiconductor manufacturing, materials science laboratories, and biomedical research facilities. Academic institutions currently represent the largest market share at 35%, followed by semiconductor industry at 28%, materials science at 22%, and biomedical applications at 15%.

Regionally, North America dominates the market with 38% share, followed by Europe (30%), Asia-Pacific (27%), and rest of the world (5%). However, the Asia-Pacific region is showing the fastest growth rate at 10.2% annually, primarily driven by increased R&D investments in China, Japan, and South Korea.

The demand for enhanced AFM imaging is being fueled by several factors. First, the continuous miniaturization in semiconductor manufacturing requires increasingly precise imaging capabilities. Second, advanced materials research, particularly in nanomaterials and 2D materials like graphene, demands higher resolution and more accurate surface characterization. Third, life sciences applications are expanding, with growing needs for cellular and molecular imaging at nanoscale resolution.

Customer pain points in the current market include image artifacts, slow scanning speeds, limited automation capabilities, and difficulties in data interpretation. End-users are increasingly demanding real-time image enhancement, automated artifact removal, and integration with other analytical techniques.

Market surveys indicate that customers are willing to pay premium prices for solutions that offer significant improvements in image resolution, noise reduction, and automated feature recognition. The return on investment for enhanced AFM imaging technologies is particularly strong in industrial R&D settings, where improved imaging can accelerate product development cycles by up to 30%.

Competition in this market is intensifying, with established scientific instrument manufacturers facing challenges from specialized software companies offering advanced image processing solutions. The market is also seeing increased interest from artificial intelligence and machine learning companies developing specialized algorithms for microscopy image enhancement.

Key market segments for enhanced AFM imaging include academic research institutions, semiconductor manufacturing, materials science laboratories, and biomedical research facilities. Academic institutions currently represent the largest market share at 35%, followed by semiconductor industry at 28%, materials science at 22%, and biomedical applications at 15%.

Regionally, North America dominates the market with 38% share, followed by Europe (30%), Asia-Pacific (27%), and rest of the world (5%). However, the Asia-Pacific region is showing the fastest growth rate at 10.2% annually, primarily driven by increased R&D investments in China, Japan, and South Korea.

The demand for enhanced AFM imaging is being fueled by several factors. First, the continuous miniaturization in semiconductor manufacturing requires increasingly precise imaging capabilities. Second, advanced materials research, particularly in nanomaterials and 2D materials like graphene, demands higher resolution and more accurate surface characterization. Third, life sciences applications are expanding, with growing needs for cellular and molecular imaging at nanoscale resolution.

Customer pain points in the current market include image artifacts, slow scanning speeds, limited automation capabilities, and difficulties in data interpretation. End-users are increasingly demanding real-time image enhancement, automated artifact removal, and integration with other analytical techniques.

Market surveys indicate that customers are willing to pay premium prices for solutions that offer significant improvements in image resolution, noise reduction, and automated feature recognition. The return on investment for enhanced AFM imaging technologies is particularly strong in industrial R&D settings, where improved imaging can accelerate product development cycles by up to 30%.

Competition in this market is intensifying, with established scientific instrument manufacturers facing challenges from specialized software companies offering advanced image processing solutions. The market is also seeing increased interest from artificial intelligence and machine learning companies developing specialized algorithms for microscopy image enhancement.

Current AFM Image Enhancement Challenges

Atomic Force Microscopy (AFM) image enhancement faces several significant challenges that impede the extraction of accurate and reliable data from raw scans. The fundamental limitation stems from inherent instrumental artifacts that contaminate AFM images during acquisition. These artifacts include tip-sample convolution effects, where the finite size and geometry of the scanning probe distort the true topography of samples, particularly when imaging features with dimensions comparable to or smaller than the probe tip radius.

Scanner nonlinearities represent another persistent challenge, manifesting as hysteresis, creep, and cross-coupling between axes. These nonlinearities introduce systematic distortions that vary with scan direction, speed, and size, making reproducible measurements difficult without sophisticated correction algorithms. Environmental factors further complicate image quality, with thermal drift causing progressive displacement of features during scanning, and mechanical vibrations introducing random noise patterns that obscure fine structural details.

Sample-specific challenges also exist, particularly when imaging soft or biological materials. These samples may deform under probe pressure, leading to inconsistent height measurements and artificial topographical features. Additionally, charging effects in non-conductive samples can generate long-range electrostatic forces that interfere with accurate topographical mapping, creating phantom features or masking real structural elements.

Current image processing workflows suffer from significant limitations, including operator dependency and subjective parameter selection. The lack of standardized enhancement protocols leads to inconsistent results across different laboratories and operators, hampering reproducibility and comparative analysis. Many enhancement algorithms also struggle with the trade-off between noise reduction and preservation of genuine structural details, often sacrificing one for the other.

Resolution limitations persist despite technological advances, with current systems struggling to achieve true atomic resolution consistently across diverse sample types. This challenge is particularly acute when attempting to resolve closely spaced features or subtle height variations in the sub-nanometer range. The signal-to-noise ratio deteriorates dramatically at these scales, necessitating sophisticated noise filtering techniques that risk removing genuine structural information.

Data interpretation challenges compound these technical issues, as distinguishing between true sample features and artifacts introduced during scanning or processing remains difficult. This uncertainty is especially problematic in emerging applications like nanomedicine and semiconductor metrology, where precise dimensional measurements are critical for functional understanding and quality control.

The integration of AFM with complementary techniques presents additional challenges in image registration and correlation, as different imaging modalities often operate at different scales and resolutions, complicating the fusion of multi-modal data into coherent analytical frameworks.

Scanner nonlinearities represent another persistent challenge, manifesting as hysteresis, creep, and cross-coupling between axes. These nonlinearities introduce systematic distortions that vary with scan direction, speed, and size, making reproducible measurements difficult without sophisticated correction algorithms. Environmental factors further complicate image quality, with thermal drift causing progressive displacement of features during scanning, and mechanical vibrations introducing random noise patterns that obscure fine structural details.

Sample-specific challenges also exist, particularly when imaging soft or biological materials. These samples may deform under probe pressure, leading to inconsistent height measurements and artificial topographical features. Additionally, charging effects in non-conductive samples can generate long-range electrostatic forces that interfere with accurate topographical mapping, creating phantom features or masking real structural elements.

Current image processing workflows suffer from significant limitations, including operator dependency and subjective parameter selection. The lack of standardized enhancement protocols leads to inconsistent results across different laboratories and operators, hampering reproducibility and comparative analysis. Many enhancement algorithms also struggle with the trade-off between noise reduction and preservation of genuine structural details, often sacrificing one for the other.

Resolution limitations persist despite technological advances, with current systems struggling to achieve true atomic resolution consistently across diverse sample types. This challenge is particularly acute when attempting to resolve closely spaced features or subtle height variations in the sub-nanometer range. The signal-to-noise ratio deteriorates dramatically at these scales, necessitating sophisticated noise filtering techniques that risk removing genuine structural information.

Data interpretation challenges compound these technical issues, as distinguishing between true sample features and artifacts introduced during scanning or processing remains difficult. This uncertainty is especially problematic in emerging applications like nanomedicine and semiconductor metrology, where precise dimensional measurements are critical for functional understanding and quality control.

The integration of AFM with complementary techniques presents additional challenges in image registration and correlation, as different imaging modalities often operate at different scales and resolutions, complicating the fusion of multi-modal data into coherent analytical frameworks.

Current AFM Image Enhancement Solutions

01 Image processing algorithms for AFM enhancement

Various image processing algorithms can be applied to enhance the quality of atomic force microscopy images. These techniques include noise reduction filters, contrast enhancement, and advanced signal processing methods that improve the clarity and resolution of AFM scans. These computational approaches help to extract more meaningful information from raw AFM data by removing artifacts and enhancing the visibility of nanoscale features.- Image processing algorithms for AFM enhancement: Various image processing algorithms can be applied to enhance Atomic Force Microscopy images. These include noise reduction techniques, contrast enhancement, filtering methods, and advanced computational approaches that improve image clarity and resolution. These algorithms help in extracting more accurate topographical information from raw AFM data and enable better visualization of nanoscale features.

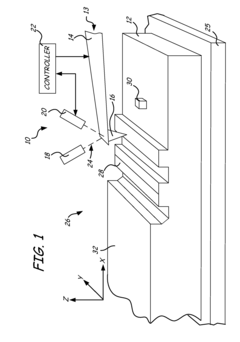

- Hardware modifications for improved AFM imaging: Hardware-based enhancements to AFM systems can significantly improve image quality. These include modifications to cantilever design, probe tip optimization, vibration isolation systems, and improved feedback control mechanisms. Such hardware improvements reduce artifacts, increase sensitivity, and enable more precise measurements of surface topography at the nanoscale.

- Real-time AFM image enhancement techniques: Real-time enhancement techniques allow for immediate improvement of AFM images during the scanning process. These methods incorporate adaptive scanning parameters, dynamic feedback adjustments, and on-the-fly data processing. Real-time enhancement enables researchers to optimize imaging conditions while scanning, reducing the need for post-processing and allowing for more efficient data collection.

- Multi-dimensional and multi-modal AFM imaging: Advanced AFM techniques combine multiple imaging modes or dimensions to enhance the information content of microscopy data. These approaches include combining topographical data with other physical properties (electrical, magnetic, mechanical), 3D reconstruction methods, and correlation with other microscopy techniques. Multi-dimensional imaging provides more comprehensive characterization of samples at the nanoscale.

- Machine learning and AI for AFM image enhancement: Artificial intelligence and machine learning algorithms are increasingly applied to enhance AFM images. These computational approaches can automatically identify and remove artifacts, improve resolution through super-resolution techniques, and extract features that might be difficult to detect with conventional methods. Neural networks and deep learning models can be trained to recognize patterns in AFM data and enhance image quality beyond traditional processing methods.

02 Hardware modifications for improved AFM imaging

Physical modifications to AFM hardware components can significantly enhance image quality. These include improvements to cantilever design, tip fabrication techniques, and vibration isolation systems. Advanced feedback control mechanisms and specialized probe technologies help to minimize distortions and increase the sensitivity of measurements, resulting in higher resolution images with better accuracy at the nanoscale.Expand Specific Solutions03 Multi-parameter and multi-modal AFM techniques

Combining multiple measurement parameters or imaging modes enables enhanced characterization of samples. These approaches simultaneously capture different physical properties of the specimen, such as topography, mechanical properties, and electrical characteristics. By correlating these different data streams, researchers can generate more comprehensive and informative images that reveal complex surface properties not visible through conventional single-parameter AFM.Expand Specific Solutions04 Real-time image correction and enhancement

Real-time processing systems can enhance AFM images during acquisition rather than in post-processing. These systems incorporate adaptive scanning parameters, dynamic feedback adjustments, and on-the-fly artifact correction algorithms. This approach allows researchers to optimize imaging conditions while scanning, resulting in higher quality raw data and reducing the need for extensive post-processing of images.Expand Specific Solutions05 Machine learning and AI for AFM image enhancement

Artificial intelligence and machine learning techniques are increasingly being applied to enhance AFM images. These approaches use neural networks and other advanced algorithms to recognize patterns, remove noise, and reconstruct high-resolution features from lower quality scans. AI-based systems can be trained to identify and correct specific types of artifacts common in AFM imaging, leading to automated enhancement processes that produce more consistent and reliable results.Expand Specific Solutions

Leading AFM Technology Providers

Atomic Force Microscopy (AFM) image enhancement is currently in a growth phase, with increasing market adoption across research and industrial applications. The global AFM market is expanding at approximately 6-8% annually, reaching about $500 million, driven by demand for nanoscale imaging solutions. Technologically, the field is moderately mature but continues to evolve rapidly. Leading players include established instrumentation companies like Bruker Nano and Leica Microsystems who offer commercial solutions, alongside research powerhouses such as CSIC, University of California, and Tsinghua University advancing algorithmic innovations. Major electronics manufacturers including Samsung Electronics and FUJIFILM are integrating enhanced AFM techniques into quality control processes, while specialized entities like FEI Co. and ASML focus on semiconductor applications, indicating the technology's growing industrial relevance beyond academic research.

The Regents of the University of California

Technical Solution: The University of California has pioneered several innovative approaches to AFM image enhancement through their network of nanoscience research centers. Their methodology begins with fundamental signal processing techniques including adaptive Wiener filtering and principal component analysis to separate noise from true topographical features. UC researchers have developed open-source software packages that implement advanced flattening algorithms capable of preserving complex surface features while removing background artifacts. Their enhancement pipeline incorporates blind tip reconstruction methods that mathematically account for tip-sample convolution effects, significantly improving lateral resolution. UC's approach also includes specialized enhancement techniques for biological samples, utilizing gentle force control algorithms that minimize sample deformation while maximizing resolution. Recent innovations from UC laboratories include physics-informed neural networks that enhance AFM images by incorporating known physical constraints of the imaging process. Their collaborative research has also yielded multi-modal enhancement techniques that combine AFM data with complementary imaging modalities such as Raman spectroscopy and fluorescence microscopy to improve feature identification and characterization.

Strengths: Cutting-edge research approaches often surpass commercial solutions for specific applications. Open-source nature of many UC-developed tools promotes accessibility and customization. Weaknesses: Less integrated workflow compared to commercial solutions requires more technical expertise to implement effectively. Some advanced techniques remain in research phase without robust user interfaces for routine application.

Leica Microsystems CMS GmbH

Technical Solution: Leica Microsystems has developed a comprehensive AFM image enhancement pipeline specifically designed for biological and materials science applications. Their approach begins with hardware-level optimization using advanced piezoelectric scanners with closed-loop feedback systems to minimize initial imaging artifacts. The enhancement process continues with their proprietary deconvolution algorithms that account for tip-sample convolution effects, significantly improving lateral resolution. Leica's software suite incorporates adaptive noise filtering techniques that selectively preserve high-frequency information while removing background noise. Their enhancement workflow includes automated detection and correction of common AFM artifacts such as bow, tilt, and scanner nonlinearities. For biological samples, Leica has developed specialized enhancement protocols that maintain structural integrity while improving contrast of nanoscale features. Their latest innovation incorporates deep learning models trained on extensive AFM image datasets to restore details below conventional resolution limits.

Strengths: Exceptional performance on biological samples with specialized algorithms for soft matter imaging. Intuitive user interface makes advanced enhancement techniques accessible to non-specialists. Weaknesses: Some enhancement algorithms are computationally intensive and may require high-performance computing resources. Less effective for certain specialized industrial applications compared to purpose-built systems.

Key Patents in AFM Image Processing

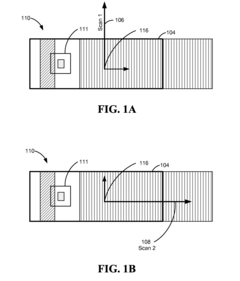

Advanced atomic force microscopy scanning for obtaining a true shape

PatentInactiveUS20130081159A1

Innovation

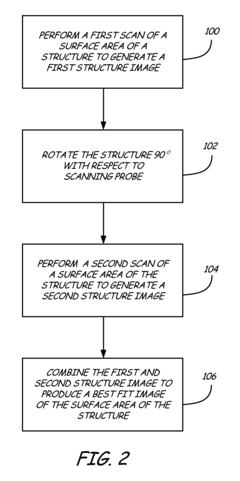

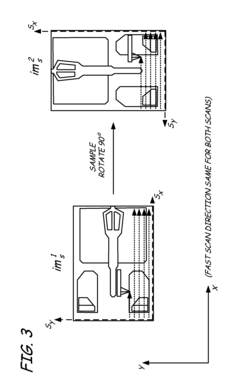

- The Advanced Pole tip recession and Perpendicular writer protrusion (APP) method involves performing multiple scans at different angles and positions, using image correction techniques such as true 3D image flattening and image subtraction to correct for scanner bow, system drift, and localized feature shape errors, ensuring accurate topography measurement.

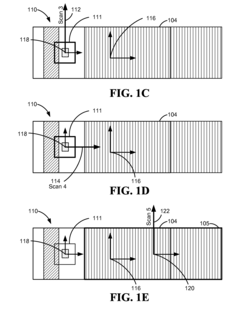

Atomic force microscopy true shape measurement method

PatentInactiveUS8296860B2

Innovation

- The method involves scanning a structure and a flat standard surface twice, each time rotated 90°, and combining the images to produce best fit images. These best fit images are then subtracted to eliminate thermal drift and Zrr errors, allowing for the generation of a true topographical image.

Nanoscale Metrology Standards

Nanoscale metrology standards are critical for the advancement of atomic force microscopy (AFM) image enhancement techniques. The development of reliable, reproducible standards at the nanoscale presents unique challenges due to the extremely small dimensions involved and the sensitivity of measurements to environmental factors.

Current nanoscale metrology standards for AFM include silicon gratings with precisely defined pitch values, typically ranging from 100 nm to several micrometers. These standards enable calibration of the x, y, and z axes of AFM instruments, ensuring measurement accuracy across different instruments and laboratories. The National Institute of Standards and Technology (NIST) and similar international organizations have developed certified reference materials specifically for AFM calibration.

Step height standards, typically fabricated from silicon or quartz, provide known vertical dimensions ranging from a few nanometers to several hundred nanometers. These are essential for validating the vertical measurement capabilities of AFM systems and for calibrating the z-axis response. Complementing these are lateral standards with precisely defined patterns that allow for the assessment of tip convolution effects and lateral resolution.

Nanoparticle standards, consisting of monodisperse spherical particles with tightly controlled diameters, serve as three-dimensional calibration references. Gold nanoparticles and polystyrene latex spheres are commonly used due to their stability and uniform shape characteristics. These standards are particularly valuable for evaluating AFM image enhancement algorithms, as they provide known geometries against which processed images can be compared.

Recent advances include the development of DNA origami structures as biological nanoscale standards. These programmable self-assembled structures offer precise control over nanoscale features and can be designed to incorporate specific patterns or dimensions, providing versatile calibration standards for biological AFM applications.

The traceability of nanoscale measurements to the International System of Units (SI) remains a significant challenge. Efforts are underway to establish quantum-based standards that link nanoscale measurements directly to fundamental physical constants, potentially offering improved accuracy and reproducibility.

For AFM image enhancement techniques, these metrology standards serve as ground truth references against which the performance of various algorithms can be evaluated. They enable quantitative assessment of enhancement outcomes, including improvements in resolution, noise reduction, and feature preservation. The development of standardized test samples with known characteristics is essential for benchmarking different enhancement approaches and ensuring that processing techniques do not introduce artifacts or distortions.

Current nanoscale metrology standards for AFM include silicon gratings with precisely defined pitch values, typically ranging from 100 nm to several micrometers. These standards enable calibration of the x, y, and z axes of AFM instruments, ensuring measurement accuracy across different instruments and laboratories. The National Institute of Standards and Technology (NIST) and similar international organizations have developed certified reference materials specifically for AFM calibration.

Step height standards, typically fabricated from silicon or quartz, provide known vertical dimensions ranging from a few nanometers to several hundred nanometers. These are essential for validating the vertical measurement capabilities of AFM systems and for calibrating the z-axis response. Complementing these are lateral standards with precisely defined patterns that allow for the assessment of tip convolution effects and lateral resolution.

Nanoparticle standards, consisting of monodisperse spherical particles with tightly controlled diameters, serve as three-dimensional calibration references. Gold nanoparticles and polystyrene latex spheres are commonly used due to their stability and uniform shape characteristics. These standards are particularly valuable for evaluating AFM image enhancement algorithms, as they provide known geometries against which processed images can be compared.

Recent advances include the development of DNA origami structures as biological nanoscale standards. These programmable self-assembled structures offer precise control over nanoscale features and can be designed to incorporate specific patterns or dimensions, providing versatile calibration standards for biological AFM applications.

The traceability of nanoscale measurements to the International System of Units (SI) remains a significant challenge. Efforts are underway to establish quantum-based standards that link nanoscale measurements directly to fundamental physical constants, potentially offering improved accuracy and reproducibility.

For AFM image enhancement techniques, these metrology standards serve as ground truth references against which the performance of various algorithms can be evaluated. They enable quantitative assessment of enhancement outcomes, including improvements in resolution, noise reduction, and feature preservation. The development of standardized test samples with known characteristics is essential for benchmarking different enhancement approaches and ensuring that processing techniques do not introduce artifacts or distortions.

Cross-Industry Applications of Enhanced AFM Imaging

Enhanced Atomic Force Microscopy (AFM) imaging techniques have transcended their traditional boundaries in materials science and nanotechnology to find valuable applications across diverse industries. In the semiconductor industry, advanced AFM imaging enables precise characterization of nanoscale features on integrated circuits, critical for quality control and failure analysis. The enhanced resolution and contrast provided by modern AFM techniques allow manufacturers to detect defects as small as a few nanometers, significantly improving yield rates and device performance.

The pharmaceutical and biotechnology sectors have embraced enhanced AFM imaging for drug development and formulation studies. These techniques provide crucial insights into drug-carrier interactions, protein folding mechanisms, and cellular membrane structures. The non-destructive nature of AFM makes it particularly valuable for examining delicate biological samples under near-physiological conditions, offering advantages over electron microscopy techniques that require vacuum environments.

In the energy sector, enhanced AFM imaging facilitates the development of next-generation battery technologies by enabling researchers to visualize electrochemical processes at the nanoscale. This capability has proven instrumental in understanding degradation mechanisms in lithium-ion batteries and optimizing electrode materials for improved performance and longevity. Similarly, solar cell manufacturers utilize advanced AFM techniques to characterize thin-film morphology and interface properties, directly correlating these features with device efficiency.

The aerospace and automotive industries apply enhanced AFM imaging for analyzing surface coatings and composite materials. The ability to quantitatively measure mechanical properties while simultaneously capturing topographical information allows engineers to develop materials with superior wear resistance, thermal stability, and structural integrity. These improvements translate directly to enhanced product performance and extended operational lifetimes.

Medical device manufacturers leverage enhanced AFM imaging for quality assurance of implantable devices and precision components. The technique's capability to characterize surface roughness at the nanoscale is particularly valuable for optimizing biocompatibility and reducing friction in moving parts. Additionally, forensic science has adopted enhanced AFM imaging for analyzing trace evidence, including fingerprints, fibers, and document authenticity, providing complementary information to traditional analytical methods.

Environmental monitoring and remediation efforts benefit from enhanced AFM techniques through the characterization of nanoparticles in air and water samples. This application has become increasingly important as concerns about nanomaterial pollution grow, offering researchers tools to understand how engineered nanoparticles interact with environmental systems and biological organisms.

The pharmaceutical and biotechnology sectors have embraced enhanced AFM imaging for drug development and formulation studies. These techniques provide crucial insights into drug-carrier interactions, protein folding mechanisms, and cellular membrane structures. The non-destructive nature of AFM makes it particularly valuable for examining delicate biological samples under near-physiological conditions, offering advantages over electron microscopy techniques that require vacuum environments.

In the energy sector, enhanced AFM imaging facilitates the development of next-generation battery technologies by enabling researchers to visualize electrochemical processes at the nanoscale. This capability has proven instrumental in understanding degradation mechanisms in lithium-ion batteries and optimizing electrode materials for improved performance and longevity. Similarly, solar cell manufacturers utilize advanced AFM techniques to characterize thin-film morphology and interface properties, directly correlating these features with device efficiency.

The aerospace and automotive industries apply enhanced AFM imaging for analyzing surface coatings and composite materials. The ability to quantitatively measure mechanical properties while simultaneously capturing topographical information allows engineers to develop materials with superior wear resistance, thermal stability, and structural integrity. These improvements translate directly to enhanced product performance and extended operational lifetimes.

Medical device manufacturers leverage enhanced AFM imaging for quality assurance of implantable devices and precision components. The technique's capability to characterize surface roughness at the nanoscale is particularly valuable for optimizing biocompatibility and reducing friction in moving parts. Additionally, forensic science has adopted enhanced AFM imaging for analyzing trace evidence, including fingerprints, fibers, and document authenticity, providing complementary information to traditional analytical methods.

Environmental monitoring and remediation efforts benefit from enhanced AFM techniques through the characterization of nanoparticles in air and water samples. This application has become increasingly important as concerns about nanomaterial pollution grow, offering researchers tools to understand how engineered nanoparticles interact with environmental systems and biological organisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!