Electrocatalytic CO2 Valorization and Market Regulations

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Objectives

Carbon dioxide (CO2) valorization represents a transformative approach to addressing climate change by converting waste CO2 into valuable products. This technology has evolved significantly over the past decades, from theoretical concepts in the 1970s to practical applications in the 21st century. The electrocatalytic pathway for CO2 conversion has emerged as particularly promising due to its potential integration with renewable electricity sources, creating a sustainable carbon cycle.

The historical trajectory of CO2 valorization technology shows accelerated development since 2010, with breakthrough catalysts and reactor designs enabling higher conversion efficiencies. Early efforts focused primarily on methanol and formic acid production, while recent advances have expanded the product spectrum to include more complex hydrocarbons and oxygenates with higher market values.

Current global CO2 emissions exceed 35 billion tonnes annually, creating an urgent need for carbon mitigation technologies. Electrocatalytic CO2 valorization offers a dual benefit: reducing atmospheric CO2 while producing commercially viable chemicals and fuels. This approach aligns with circular economy principles and supports the transition toward carbon neutrality targets established in international agreements.

The primary technical objectives for advancing electrocatalytic CO2 valorization include improving energy efficiency, enhancing product selectivity, developing scalable reactor designs, and reducing catalyst costs. Current systems typically operate at 30-60% Faradaic efficiency, with significant room for improvement toward the theoretical maximum. Selectivity remains a critical challenge, as many catalysts produce multiple products simultaneously, complicating downstream separation.

Market regulations are increasingly favorable for CO2 valorization technologies. Carbon pricing mechanisms, including emissions trading systems and carbon taxes implemented in over 40 countries, create economic incentives for CO2 utilization. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are establishing regulatory frameworks that may accelerate adoption of these technologies.

Research trends indicate growing interest in integrating CO2 valorization with renewable energy systems, particularly addressing intermittency challenges through flexible electrocatalytic processes. The development of artificial photosynthesis systems represents another frontier, mimicking natural processes to convert CO2 using sunlight directly.

The ultimate goal of this field is to establish economically viable pathways for transforming CO2 from an environmental liability into a valuable feedstock for the chemical industry, creating a sustainable carbon economy while contributing to climate change mitigation efforts.

The historical trajectory of CO2 valorization technology shows accelerated development since 2010, with breakthrough catalysts and reactor designs enabling higher conversion efficiencies. Early efforts focused primarily on methanol and formic acid production, while recent advances have expanded the product spectrum to include more complex hydrocarbons and oxygenates with higher market values.

Current global CO2 emissions exceed 35 billion tonnes annually, creating an urgent need for carbon mitigation technologies. Electrocatalytic CO2 valorization offers a dual benefit: reducing atmospheric CO2 while producing commercially viable chemicals and fuels. This approach aligns with circular economy principles and supports the transition toward carbon neutrality targets established in international agreements.

The primary technical objectives for advancing electrocatalytic CO2 valorization include improving energy efficiency, enhancing product selectivity, developing scalable reactor designs, and reducing catalyst costs. Current systems typically operate at 30-60% Faradaic efficiency, with significant room for improvement toward the theoretical maximum. Selectivity remains a critical challenge, as many catalysts produce multiple products simultaneously, complicating downstream separation.

Market regulations are increasingly favorable for CO2 valorization technologies. Carbon pricing mechanisms, including emissions trading systems and carbon taxes implemented in over 40 countries, create economic incentives for CO2 utilization. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are establishing regulatory frameworks that may accelerate adoption of these technologies.

Research trends indicate growing interest in integrating CO2 valorization with renewable energy systems, particularly addressing intermittency challenges through flexible electrocatalytic processes. The development of artificial photosynthesis systems represents another frontier, mimicking natural processes to convert CO2 using sunlight directly.

The ultimate goal of this field is to establish economically viable pathways for transforming CO2 from an environmental liability into a valuable feedstock for the chemical industry, creating a sustainable carbon economy while contributing to climate change mitigation efforts.

Market Analysis for CO2 Conversion Products

The global market for CO2 conversion products is experiencing significant growth, driven by increasing environmental regulations and the push for sustainable industrial practices. Current market size for CO2-derived products is estimated at $6.0 billion in 2023, with projections indicating expansion to reach $9.5 billion by 2028, representing a compound annual growth rate of 9.6%. This growth trajectory is particularly notable in regions with stringent carbon pricing mechanisms, such as the European Union and parts of North America.

Among CO2 conversion products, methanol represents the largest market segment, accounting for approximately 45% of the total market value. This dominance stems from methanol's versatility as both a fuel additive and chemical feedstock. Following methanol, formic acid and carbon monoxide hold significant market shares of 18% and 15% respectively, with emerging applications in pharmaceutical synthesis and metallurgical processes driving demand.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, particularly China and South Korea, where government initiatives strongly support carbon capture and utilization technologies. The European market demonstrates the highest growth rate at 11.2% annually, propelled by the EU's Green Deal and circular economy initiatives that incentivize carbon recycling.

Market penetration of CO2-derived products varies significantly across industries. The chemical manufacturing sector remains the primary consumer, absorbing 52% of production, followed by the fuel industry at 27%. Emerging applications in construction materials, particularly CO2-cured concrete, represent the fastest-growing segment with 14.8% annual growth.

Price competitiveness remains a critical market factor, with CO2-derived products typically commanding a 15-30% premium over conventional alternatives. This premium has been gradually decreasing as production scales and technology improves, with the gap narrowing by approximately 3-4% annually over the past five years.

Consumer and industrial acceptance of these products shows positive trends, with 68% of surveyed industrial buyers expressing willingness to incorporate CO2-derived materials into their supply chains when price differentials remain below 20%. This acceptance is highest in consumer-facing industries where sustainability credentials offer marketing advantages.

Market regulations significantly impact growth trajectories, with carbon pricing mechanisms being the most influential factor. Jurisdictions with carbon prices exceeding $40 per ton consistently show higher adoption rates of CO2 conversion technologies, creating regional market disparities that influence global trade patterns and technology deployment.

Among CO2 conversion products, methanol represents the largest market segment, accounting for approximately 45% of the total market value. This dominance stems from methanol's versatility as both a fuel additive and chemical feedstock. Following methanol, formic acid and carbon monoxide hold significant market shares of 18% and 15% respectively, with emerging applications in pharmaceutical synthesis and metallurgical processes driving demand.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, particularly China and South Korea, where government initiatives strongly support carbon capture and utilization technologies. The European market demonstrates the highest growth rate at 11.2% annually, propelled by the EU's Green Deal and circular economy initiatives that incentivize carbon recycling.

Market penetration of CO2-derived products varies significantly across industries. The chemical manufacturing sector remains the primary consumer, absorbing 52% of production, followed by the fuel industry at 27%. Emerging applications in construction materials, particularly CO2-cured concrete, represent the fastest-growing segment with 14.8% annual growth.

Price competitiveness remains a critical market factor, with CO2-derived products typically commanding a 15-30% premium over conventional alternatives. This premium has been gradually decreasing as production scales and technology improves, with the gap narrowing by approximately 3-4% annually over the past five years.

Consumer and industrial acceptance of these products shows positive trends, with 68% of surveyed industrial buyers expressing willingness to incorporate CO2-derived materials into their supply chains when price differentials remain below 20%. This acceptance is highest in consumer-facing industries where sustainability credentials offer marketing advantages.

Market regulations significantly impact growth trajectories, with carbon pricing mechanisms being the most influential factor. Jurisdictions with carbon prices exceeding $40 per ton consistently show higher adoption rates of CO2 conversion technologies, creating regional market disparities that influence global trade patterns and technology deployment.

Electrocatalytic CO2 Reduction: Status and Barriers

Electrocatalytic CO2 reduction (ECR) has emerged as a promising technology for converting carbon dioxide into value-added chemicals and fuels. Currently, the field has achieved significant milestones in catalyst development, with copper-based catalysts showing particular promise for multi-carbon product formation. Research groups worldwide have demonstrated faradaic efficiencies exceeding 90% for certain products like carbon monoxide and formate, while efficiencies for more complex products like ethylene and ethanol have reached 60-70% in optimized systems.

Despite these advances, several critical barriers impede widespread implementation. Catalyst selectivity remains a fundamental challenge, as most systems produce a mixture of products rather than a single target compound, complicating downstream separation processes and reducing economic viability. The stability of catalysts presents another significant hurdle, with many high-performing materials showing performance degradation within hours or days of operation, far below the thousands of hours required for industrial applications.

Energy efficiency constitutes a major limitation, with current systems typically requiring overpotentials of 0.5-1V beyond thermodynamic requirements, substantially reducing overall process efficiency. This challenge is compounded by mass transport limitations, particularly in gas-diffusion electrode configurations where reactant delivery and product removal become rate-limiting steps at industrially relevant current densities above 200 mA/cm².

Scale-up challenges represent perhaps the most significant barrier to commercialization. Laboratory demonstrations typically operate at electrode areas of 1-10 cm², while industrial implementation would require several orders of magnitude larger systems. This scale-up introduces new challenges in heat management, electrolyte distribution, and maintaining uniform reaction conditions across large electrode surfaces.

The economic landscape presents additional obstacles. Current capital costs for ECR systems range from $1,000-2,000/kW, significantly higher than the $300-500/kW target needed for commercial viability. Operating costs are similarly challenged by expensive catalyst materials, limited catalyst lifetimes, and energy inefficiencies. Market analyses suggest that without significant technological breakthroughs, ECR products cannot compete with conventional petrochemical routes except in niche applications or regions with exceptionally low electricity costs.

Regulatory frameworks worldwide remain inconsistent regarding carbon pricing and incentives for CO2 utilization technologies. While the EU has established a carbon pricing mechanism through its Emissions Trading System, many other regions lack similar structures, creating an uneven playing field for technology deployment. This regulatory uncertainty complicates investment decisions and technology development pathways.

Despite these advances, several critical barriers impede widespread implementation. Catalyst selectivity remains a fundamental challenge, as most systems produce a mixture of products rather than a single target compound, complicating downstream separation processes and reducing economic viability. The stability of catalysts presents another significant hurdle, with many high-performing materials showing performance degradation within hours or days of operation, far below the thousands of hours required for industrial applications.

Energy efficiency constitutes a major limitation, with current systems typically requiring overpotentials of 0.5-1V beyond thermodynamic requirements, substantially reducing overall process efficiency. This challenge is compounded by mass transport limitations, particularly in gas-diffusion electrode configurations where reactant delivery and product removal become rate-limiting steps at industrially relevant current densities above 200 mA/cm².

Scale-up challenges represent perhaps the most significant barrier to commercialization. Laboratory demonstrations typically operate at electrode areas of 1-10 cm², while industrial implementation would require several orders of magnitude larger systems. This scale-up introduces new challenges in heat management, electrolyte distribution, and maintaining uniform reaction conditions across large electrode surfaces.

The economic landscape presents additional obstacles. Current capital costs for ECR systems range from $1,000-2,000/kW, significantly higher than the $300-500/kW target needed for commercial viability. Operating costs are similarly challenged by expensive catalyst materials, limited catalyst lifetimes, and energy inefficiencies. Market analyses suggest that without significant technological breakthroughs, ECR products cannot compete with conventional petrochemical routes except in niche applications or regions with exceptionally low electricity costs.

Regulatory frameworks worldwide remain inconsistent regarding carbon pricing and incentives for CO2 utilization technologies. While the EU has established a carbon pricing mechanism through its Emissions Trading System, many other regions lack similar structures, creating an uneven playing field for technology deployment. This regulatory uncertainty complicates investment decisions and technology development pathways.

Current Electrocatalytic Approaches and Methods

01 Metal-based catalysts for CO2 electroreduction

Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity toward specific products like carbon monoxide, formate, or hydrocarbons. The catalyst structure, morphology, and composition significantly influence the reaction pathways and efficiency of CO2 conversion. These catalysts can be optimized through nanostructuring, alloying, or surface modification to enhance their catalytic performance and stability during the electrocatalytic CO2 valorization process.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity toward specific products like carbon monoxide, formate, or hydrocarbons. The catalytic performance can be enhanced by controlling the morphology, particle size, and surface structure of these metal catalysts, leading to improved efficiency and selectivity in CO2 valorization processes.

- Carbon-based electrocatalysts for CO2 conversion: Carbon-based materials serve as effective electrocatalysts for CO2 reduction. These include carbon nanotubes, graphene, and nitrogen-doped carbon materials that offer high surface area, good electrical conductivity, and tunable surface properties. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks can create active sites that enhance catalytic activity and selectivity toward specific CO2 reduction products, making them promising alternatives to metal-based catalysts.

- Reactor design and system integration for CO2 electroreduction: Advanced reactor designs and integrated systems are essential for scaling up electrocatalytic CO2 valorization. These include flow cells, gas diffusion electrodes, and membrane electrode assemblies that enhance mass transport and reaction kinetics. System integration approaches focus on optimizing electrolyte composition, controlling reaction conditions, and coupling with renewable energy sources to achieve sustainable CO2 conversion processes with improved energy efficiency and product yield.

- Bimetallic and multi-component catalyst systems: Bimetallic and multi-component catalyst systems offer synergistic effects that enhance CO2 electroreduction performance. By combining two or more metals or incorporating metal oxides and other components, these catalysts can overcome limitations of single-metal catalysts. The interface between different components creates unique active sites that can lower energy barriers, improve selectivity, and increase conversion efficiency for producing value-added chemicals from CO2.

- Process optimization and product selectivity control: Controlling reaction parameters and catalyst properties to optimize product selectivity is crucial in CO2 electroreduction. Factors such as applied potential, electrolyte pH, temperature, and pressure significantly influence the distribution of products. Advanced techniques for in-situ characterization and real-time monitoring help understand reaction mechanisms and catalyst behavior under operating conditions, enabling the development of strategies to direct the reaction pathway toward desired high-value products.

02 Carbon-based materials as electrocatalysts

Carbon-based materials serve as effective electrocatalysts or catalyst supports for CO2 reduction reactions. These materials include graphene, carbon nanotubes, carbon fibers, and nitrogen-doped carbon structures. The high surface area, excellent electrical conductivity, and tunable surface properties make carbon-based materials attractive for CO2 electroreduction. Functionalization with heteroatoms or metal nanoparticles can further enhance their catalytic activity and selectivity toward specific products, offering sustainable alternatives to precious metal catalysts for CO2 valorization.Expand Specific Solutions03 Reactor design and system integration

The design of electrochemical reactors and their integration into complete systems is critical for efficient CO2 valorization. Various reactor configurations, including flow cells, membrane electrode assemblies, and microfluidic devices, have been developed to optimize mass transfer, reduce energy consumption, and enhance product selectivity. System integration aspects involve coupling CO2 capture with electroreduction, managing heat and mass transfer, controlling reaction conditions, and developing efficient product separation methods. Advanced reactor designs can significantly improve the overall efficiency and economic viability of electrocatalytic CO2 conversion processes.Expand Specific Solutions04 Process optimization and operating conditions

Optimizing operating conditions is essential for efficient electrocatalytic CO2 valorization. Key parameters include electrolyte composition, pH, temperature, pressure, applied potential, and current density. The selection of appropriate electrolytes can significantly influence reaction pathways and product distribution. Continuous or pulsed operation modes can affect catalyst stability and product selectivity. Process optimization strategies often involve systematic studies of these parameters to maximize conversion efficiency, product selectivity, and energy efficiency while minimizing degradation of catalysts and other system components.Expand Specific Solutions05 Value-added products from CO2 electroreduction

Electrocatalytic CO2 reduction can yield various value-added products depending on the catalyst and reaction conditions. These products include carbon monoxide, formic acid, methanol, ethanol, ethylene, and other hydrocarbons or oxygenates. Each product has different market values and applications in chemical manufacturing, fuel production, or pharmaceutical synthesis. The selective production of higher-value chemicals through CO2 electroreduction represents a promising approach for carbon utilization and circular economy. Research focuses on developing catalysts and processes that can selectively produce specific high-value products with high faradaic efficiency and current density.Expand Specific Solutions

Leading Organizations in CO2 Valorization Research

Electrocatalytic CO2 valorization is currently in an early growth phase, with the market expanding due to increasing environmental regulations and carbon neutrality goals. The global market size is projected to reach significant scale as industries seek sustainable carbon utilization technologies. Technologically, the field shows varying maturity levels across players. Academic institutions like University of Toronto, Brown University, and Zhejiang University are advancing fundamental research, while companies such as Dioxide Materials, TotalEnergies, and Carbon Energy Technology are moving toward commercialization. PetroChina and Honda are investing in industrial-scale applications, though widespread deployment remains limited. The competitive landscape features collaboration between research institutions and industry partners, with increasing patent activity signaling growing commercial interest in this emerging clean technology sector.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has pioneered advanced electrocatalytic systems for CO2 reduction through their Materials and Systems Engineering Research (MASER) program. Their technology utilizes atomically dispersed metal catalysts (particularly Ni, Fe, and Cu) on nitrogen-doped carbon supports that demonstrate exceptional selectivity toward specific products[5]. Their most advanced system employs a flow-cell design with gas diffusion electrodes that achieve current densities exceeding 400 mA/cm² while maintaining product selectivity above 85% for CO and formate production[6]. Argonne has developed computational models that predict catalyst behavior and guide rational design, resulting in catalysts with significantly reduced precious metal content while maintaining performance. Their technology also incorporates innovative bipolar membrane configurations that allow for different pH environments at cathode and anode, optimizing reaction conditions while minimizing energy losses.

Strengths: World-class research facilities and multidisciplinary expertise; strong computational capabilities for catalyst design; established partnerships with industry for technology transfer. Weaknesses: As a national laboratory, faces challenges in direct commercialization; technology optimization has focused more on scientific understanding than industrial implementation; dependent on external partners for market deployment.

TotalEnergies SE

Technical Solution: TotalEnergies has developed an integrated approach to electrocatalytic CO2 valorization that combines renewable energy generation with advanced CO2 capture and conversion technologies. Their system employs copper-based nanostructured catalysts modified with nitrogen-doped carbon supports to enhance selectivity toward multi-carbon products like ethylene and ethanol[3]. The company has invested in pilot facilities that integrate direct air capture technology with their electrocatalytic conversion units, creating a closed-loop carbon utilization system. Their process operates at moderate temperatures (25-50°C) and pressures (1-10 bar), achieving current densities of 150-300 mA/cm² with energy efficiencies approaching 60% for certain product streams[4]. TotalEnergies has also developed proprietary membrane electrode assemblies that minimize crossover effects and extend catalyst lifetime to thousands of operating hours.

Strengths: Vertically integrated approach combining renewable energy, CO2 capture, and conversion; strong financial resources to scale technology; established distribution channels for end products. Weaknesses: Technology still faces challenges in catalyst stability under industrial conditions; economic viability heavily dependent on electricity costs and carbon pricing; competing internal investments in traditional hydrocarbon technologies.

Key Catalyst Innovations and Mechanisms

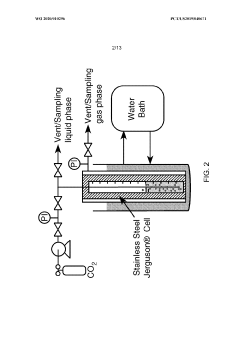

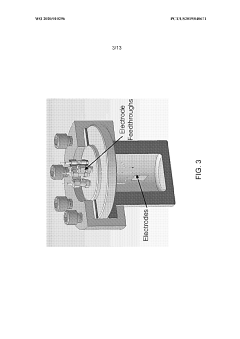

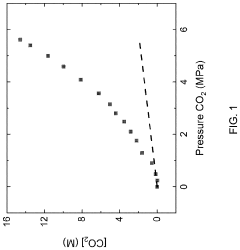

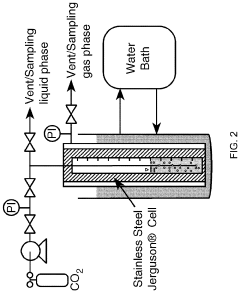

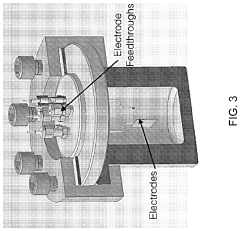

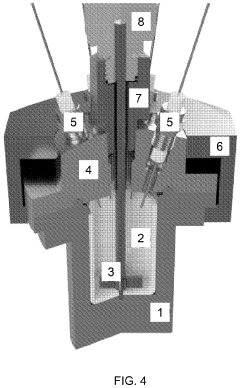

Electrocatalytic conversion of carbon dioxide in liquids expanded by carbon dioxide

PatentWO2020010296A1

Innovation

- The use of a CO2 expanded liquid medium at elevated pressures, which increases CO2 solubility and enables higher CO2 concentrations and transfer rates to catalytic surfaces, facilitating electrochemical reduction with organic liquid solvents and electrolytes that maintain a single phase and support fast electron transfer.

Electrocatalytic conversion of carbon dioxide in liquids expanded by carbon dioxide

PatentInactiveUS20210262103A1

Innovation

- The use of CO2 expanded liquid media at elevated pressures, which increases CO2 solubility and enables high CO2 concentrations and fast electron transfer, allowing for sustainable and commercially viable pathways to convert CO2 into fuels and chemicals, by optimizing the combination of organic liquid solvents and electrolytes to maintain a single phase and facilitate pressure-tunable CO2 conversion.

Carbon Pricing and Regulatory Frameworks

Carbon pricing mechanisms and regulatory frameworks represent critical policy instruments that significantly influence the development and deployment of electrocatalytic CO2 valorization technologies. The European Union's Emissions Trading System (EU ETS), established in 2005, stands as the world's largest carbon market, covering approximately 40% of EU greenhouse gas emissions. This cap-and-trade system has evolved through multiple phases, with carbon prices reaching record levels of over €90 per tonne in 2022, creating substantial economic incentives for carbon capture and utilization technologies.

Beyond the EU, various carbon pricing initiatives have emerged globally, including carbon taxes in Scandinavian countries, Canada's federal carbon pricing backstop, and regional markets like California's cap-and-trade program. These mechanisms differ significantly in their design, coverage, and price levels, creating a complex global landscape for technology developers and investors in the CO2 valorization space.

Regulatory frameworks supporting electrocatalytic CO2 valorization extend beyond carbon pricing to include renewable energy mandates, low-carbon fuel standards, and product certification schemes. The EU's Renewable Energy Directive II (RED II) and the proposed Carbon Border Adjustment Mechanism (CBAM) represent significant policy developments that will shape market conditions for CO2-derived products. Similarly, California's Low Carbon Fuel Standard (LCFS) has created premium markets for fuels with lower carbon intensities, including those produced via CO2 conversion.

Policy stability and long-term predictability remain crucial challenges for the sector. The capital-intensive nature of electrocatalytic CO2 valorization facilities requires investment horizons spanning decades, while policy frameworks often operate on shorter political cycles. This temporal mismatch creates significant investment uncertainty, potentially slowing technology deployment despite technical readiness.

Harmonization of standards and regulations across jurisdictions represents another key challenge. The lack of internationally recognized methodologies for carbon accounting in CO2 valorization processes complicates cross-border trade and technology transfer. Efforts by organizations such as the International Organization for Standardization (ISO) and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) aim to address these challenges through the development of standardized frameworks.

Recent policy innovations, including carbon contracts for difference (CCfDs) in Germany and the Netherlands, demonstrate evolving approaches to de-risking investments in novel carbon reduction technologies. These instruments guarantee minimum carbon prices for project developers, effectively bridging the gap between current carbon prices and the levels needed to make electrocatalytic CO2 valorization economically viable in the near term.

Beyond the EU, various carbon pricing initiatives have emerged globally, including carbon taxes in Scandinavian countries, Canada's federal carbon pricing backstop, and regional markets like California's cap-and-trade program. These mechanisms differ significantly in their design, coverage, and price levels, creating a complex global landscape for technology developers and investors in the CO2 valorization space.

Regulatory frameworks supporting electrocatalytic CO2 valorization extend beyond carbon pricing to include renewable energy mandates, low-carbon fuel standards, and product certification schemes. The EU's Renewable Energy Directive II (RED II) and the proposed Carbon Border Adjustment Mechanism (CBAM) represent significant policy developments that will shape market conditions for CO2-derived products. Similarly, California's Low Carbon Fuel Standard (LCFS) has created premium markets for fuels with lower carbon intensities, including those produced via CO2 conversion.

Policy stability and long-term predictability remain crucial challenges for the sector. The capital-intensive nature of electrocatalytic CO2 valorization facilities requires investment horizons spanning decades, while policy frameworks often operate on shorter political cycles. This temporal mismatch creates significant investment uncertainty, potentially slowing technology deployment despite technical readiness.

Harmonization of standards and regulations across jurisdictions represents another key challenge. The lack of internationally recognized methodologies for carbon accounting in CO2 valorization processes complicates cross-border trade and technology transfer. Efforts by organizations such as the International Organization for Standardization (ISO) and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) aim to address these challenges through the development of standardized frameworks.

Recent policy innovations, including carbon contracts for difference (CCfDs) in Germany and the Netherlands, demonstrate evolving approaches to de-risking investments in novel carbon reduction technologies. These instruments guarantee minimum carbon prices for project developers, effectively bridging the gap between current carbon prices and the levels needed to make electrocatalytic CO2 valorization economically viable in the near term.

Sustainability Metrics and Life Cycle Assessment

Sustainability metrics and life cycle assessment (LCA) are critical frameworks for evaluating the environmental impact and long-term viability of electrocatalytic CO2 valorization technologies. These methodologies provide quantitative measures to assess whether CO2 conversion processes deliver genuine environmental benefits compared to conventional production routes.

The carbon footprint analysis of electrocatalytic CO2 valorization must account for direct and indirect emissions across the entire technology lifecycle. Current assessments indicate that the electricity source powering these processes is the dominant factor determining overall sustainability. Systems powered by renewable energy sources can achieve carbon reduction potentials of 40-90% compared to fossil-based production routes, while those relying on coal-powered electricity may actually increase net carbon emissions.

Energy return on investment (EROI) metrics reveal significant challenges for many CO2 valorization pathways. Most current technologies require 2-5 times more energy input than contained in the final products. This energy penalty necessitates careful optimization of catalyst performance, reactor design, and system integration to improve overall efficiency. Leading research groups have demonstrated pathways to reduce this gap through advanced catalyst materials that lower overpotentials and increase faradaic efficiencies.

Water consumption represents another critical sustainability metric, particularly for hydrogen-involving CO2 reduction processes. Recent LCA studies indicate water requirements ranging from 10-50 liters per kilogram of product, depending on the specific pathway and cooling system design. This water footprint must be factored into deployment decisions, especially in water-stressed regions.

Resource depletion potential assessments highlight concerns regarding catalyst materials, particularly those utilizing precious metals or rare earth elements. Sustainable design approaches increasingly focus on earth-abundant alternatives and recovery/recycling strategies to minimize resource constraints. Several promising catalysts based on transition metal compounds have demonstrated comparable activity while reducing dependence on critical materials.

Comprehensive LCA frameworks must also consider additional environmental impact categories including acidification potential, eutrophication, and human toxicity. Standardized methodologies such as ISO 14040/14044 provide structured approaches for these assessments, though application-specific adaptations are often necessary for emerging technologies like CO2 valorization.

The temporal dimension of sustainability metrics presents particular challenges for CO2 valorization technologies. Short-term carbon accounting may not fully capture long-term benefits, necessitating dynamic LCA approaches that account for technology learning curves and evolving energy systems. Recent methodological advances incorporate these temporal considerations through scenario-based assessments and sensitivity analyses.

The carbon footprint analysis of electrocatalytic CO2 valorization must account for direct and indirect emissions across the entire technology lifecycle. Current assessments indicate that the electricity source powering these processes is the dominant factor determining overall sustainability. Systems powered by renewable energy sources can achieve carbon reduction potentials of 40-90% compared to fossil-based production routes, while those relying on coal-powered electricity may actually increase net carbon emissions.

Energy return on investment (EROI) metrics reveal significant challenges for many CO2 valorization pathways. Most current technologies require 2-5 times more energy input than contained in the final products. This energy penalty necessitates careful optimization of catalyst performance, reactor design, and system integration to improve overall efficiency. Leading research groups have demonstrated pathways to reduce this gap through advanced catalyst materials that lower overpotentials and increase faradaic efficiencies.

Water consumption represents another critical sustainability metric, particularly for hydrogen-involving CO2 reduction processes. Recent LCA studies indicate water requirements ranging from 10-50 liters per kilogram of product, depending on the specific pathway and cooling system design. This water footprint must be factored into deployment decisions, especially in water-stressed regions.

Resource depletion potential assessments highlight concerns regarding catalyst materials, particularly those utilizing precious metals or rare earth elements. Sustainable design approaches increasingly focus on earth-abundant alternatives and recovery/recycling strategies to minimize resource constraints. Several promising catalysts based on transition metal compounds have demonstrated comparable activity while reducing dependence on critical materials.

Comprehensive LCA frameworks must also consider additional environmental impact categories including acidification potential, eutrophication, and human toxicity. Standardized methodologies such as ISO 14040/14044 provide structured approaches for these assessments, though application-specific adaptations are often necessary for emerging technologies like CO2 valorization.

The temporal dimension of sustainability metrics presents particular challenges for CO2 valorization technologies. Short-term carbon accounting may not fully capture long-term benefits, necessitating dynamic LCA approaches that account for technology learning curves and evolving energy systems. Recent methodological advances incorporate these temporal considerations through scenario-based assessments and sensitivity analyses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!