How Electrocatalytic CO2 Valorization Affects Aerospace Efficiency

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Aerospace Goals

Electrocatalytic CO2 valorization represents a transformative approach to addressing both environmental challenges and resource utilization in aerospace applications. This technology has evolved from basic carbon capture concepts in the 1970s to sophisticated catalytic conversion systems capable of transforming carbon dioxide into valuable products. The progression has been marked by significant breakthroughs in catalyst design, electrochemical cell configurations, and integration with renewable energy sources.

The aerospace industry faces unique challenges regarding emissions, fuel efficiency, and sustainability in extreme operating environments. CO2 valorization offers a promising pathway to address these challenges by potentially creating a circular carbon economy within aerospace operations. Historical attempts to implement carbon management in aerospace have been limited by weight constraints, energy requirements, and the need for robust systems capable of functioning in variable conditions.

Current technological trajectories indicate convergence between electrocatalytic advances in materials science and the specific requirements of aerospace applications. The development of lightweight, high-efficiency catalysts based on transition metals rather than precious metals represents a critical evolution that aligns with aerospace weight constraints. Similarly, innovations in membrane technology and electrochemical cell design have reduced energy penalties associated with CO2 conversion processes.

The primary technical goals for CO2 valorization in aerospace applications include achieving conversion efficiencies exceeding 60% under variable pressure and temperature conditions, developing systems with power-to-weight ratios compatible with aircraft operations, and ensuring catalyst stability for extended operational periods without maintenance. Additionally, the technology aims to produce high-energy-density fuels or valuable chemical feedstocks that can be directly utilized within aerospace systems.

Global research initiatives have accelerated development in this field, with significant contributions from aerospace agencies, academic institutions, and private sector entities. The European Clean Sky initiative, NASA's sustainable aviation research, and JAXA's environmental technology programs have all incorporated aspects of CO2 valorization into their strategic roadmaps for future aerospace technologies.

The intersection of electrocatalytic CO2 valorization and aerospace efficiency represents not merely an incremental improvement but a paradigm shift in how aerospace systems manage carbon. By transforming what has traditionally been considered a waste product into a valuable resource, this technology offers the potential to simultaneously address environmental concerns while enhancing operational capabilities through in-situ resource utilization.

The aerospace industry faces unique challenges regarding emissions, fuel efficiency, and sustainability in extreme operating environments. CO2 valorization offers a promising pathway to address these challenges by potentially creating a circular carbon economy within aerospace operations. Historical attempts to implement carbon management in aerospace have been limited by weight constraints, energy requirements, and the need for robust systems capable of functioning in variable conditions.

Current technological trajectories indicate convergence between electrocatalytic advances in materials science and the specific requirements of aerospace applications. The development of lightweight, high-efficiency catalysts based on transition metals rather than precious metals represents a critical evolution that aligns with aerospace weight constraints. Similarly, innovations in membrane technology and electrochemical cell design have reduced energy penalties associated with CO2 conversion processes.

The primary technical goals for CO2 valorization in aerospace applications include achieving conversion efficiencies exceeding 60% under variable pressure and temperature conditions, developing systems with power-to-weight ratios compatible with aircraft operations, and ensuring catalyst stability for extended operational periods without maintenance. Additionally, the technology aims to produce high-energy-density fuels or valuable chemical feedstocks that can be directly utilized within aerospace systems.

Global research initiatives have accelerated development in this field, with significant contributions from aerospace agencies, academic institutions, and private sector entities. The European Clean Sky initiative, NASA's sustainable aviation research, and JAXA's environmental technology programs have all incorporated aspects of CO2 valorization into their strategic roadmaps for future aerospace technologies.

The intersection of electrocatalytic CO2 valorization and aerospace efficiency represents not merely an incremental improvement but a paradigm shift in how aerospace systems manage carbon. By transforming what has traditionally been considered a waste product into a valuable resource, this technology offers the potential to simultaneously address environmental concerns while enhancing operational capabilities through in-situ resource utilization.

Aerospace Market Demand for CO2 Conversion Technologies

The aerospace industry is experiencing a significant shift towards sustainability, creating a growing market demand for CO2 conversion technologies. This demand is primarily driven by increasingly stringent environmental regulations and the industry's commitment to reduce its carbon footprint. The International Air Transport Association (IATA) has set ambitious targets to cut net aviation carbon emissions to half of 2005 levels by 2050, creating immediate market opportunities for carbon capture and utilization technologies.

Market analysis indicates that aerospace companies are actively seeking solutions that can convert CO2 into sustainable aviation fuels (SAF) and other valuable products. The global SAF market is projected to grow substantially over the next decade, with electrocatalytic CO2 conversion technologies positioned as key enablers for this growth. Airlines and aircraft manufacturers are particularly interested in on-site CO2 conversion systems that can be integrated into airport infrastructure or even aircraft systems themselves.

The defense sector represents another significant market segment, with military aerospace organizations exploring CO2 conversion technologies for remote operations and fuel security. The ability to produce fuels from captured CO2 in isolated locations offers strategic advantages, reducing dependency on traditional supply chains and enhancing operational resilience.

Space exploration agencies and private space companies constitute an emerging market with unique requirements. Long-duration missions and potential extraterrestrial habitats will require closed-loop life support systems where CO2 conversion is essential. NASA and other space agencies have expressed interest in compact, efficient electrocatalytic systems that can operate in microgravity environments.

Market research reveals that aerospace customers prioritize specific performance metrics for CO2 conversion technologies: energy efficiency, system weight, reliability, and integration capability with existing aerospace infrastructure. Weight considerations are particularly critical, as every additional kilogram impacts fuel consumption and operational costs.

The geographical distribution of market demand shows concentration in regions with advanced aerospace industries, including North America, Europe, and increasingly Asia-Pacific. Countries with strong environmental policies, such as those in the European Union with its Emissions Trading System, demonstrate accelerated adoption rates for these technologies.

Investment trends indicate growing venture capital interest in startups developing aerospace-specific CO2 conversion solutions, with funding rounds increasing by approximately 30% annually over the past three years. Major aerospace corporations are also establishing dedicated sustainability innovation funds, signaling long-term commitment to this technology space.

Market analysis indicates that aerospace companies are actively seeking solutions that can convert CO2 into sustainable aviation fuels (SAF) and other valuable products. The global SAF market is projected to grow substantially over the next decade, with electrocatalytic CO2 conversion technologies positioned as key enablers for this growth. Airlines and aircraft manufacturers are particularly interested in on-site CO2 conversion systems that can be integrated into airport infrastructure or even aircraft systems themselves.

The defense sector represents another significant market segment, with military aerospace organizations exploring CO2 conversion technologies for remote operations and fuel security. The ability to produce fuels from captured CO2 in isolated locations offers strategic advantages, reducing dependency on traditional supply chains and enhancing operational resilience.

Space exploration agencies and private space companies constitute an emerging market with unique requirements. Long-duration missions and potential extraterrestrial habitats will require closed-loop life support systems where CO2 conversion is essential. NASA and other space agencies have expressed interest in compact, efficient electrocatalytic systems that can operate in microgravity environments.

Market research reveals that aerospace customers prioritize specific performance metrics for CO2 conversion technologies: energy efficiency, system weight, reliability, and integration capability with existing aerospace infrastructure. Weight considerations are particularly critical, as every additional kilogram impacts fuel consumption and operational costs.

The geographical distribution of market demand shows concentration in regions with advanced aerospace industries, including North America, Europe, and increasingly Asia-Pacific. Countries with strong environmental policies, such as those in the European Union with its Emissions Trading System, demonstrate accelerated adoption rates for these technologies.

Investment trends indicate growing venture capital interest in startups developing aerospace-specific CO2 conversion solutions, with funding rounds increasing by approximately 30% annually over the past three years. Major aerospace corporations are also establishing dedicated sustainability innovation funds, signaling long-term commitment to this technology space.

Electrocatalytic CO2 Valorization: Current Status and Challenges

Electrocatalytic CO2 valorization has emerged as a promising technology for addressing both climate change and resource utilization challenges. Currently, this field has advanced significantly with various catalytic systems demonstrating the ability to convert CO2 into value-added products such as carbon monoxide, formic acid, methanol, ethanol, and higher hydrocarbons. The most mature systems utilize copper-based catalysts, which show unique capabilities for C-C coupling reactions necessary for producing multi-carbon products.

Despite these advancements, several critical challenges remain unresolved. Catalyst selectivity continues to be a major hurdle, with most systems producing a mixture of products rather than a single desired compound. This lack of selectivity significantly increases downstream separation costs and reduces overall process efficiency. Additionally, current catalytic systems typically require high overpotentials, resulting in substantial energy inefficiency that limits commercial viability.

Stability presents another significant challenge, as many promising catalysts suffer from deactivation under industrial operating conditions. Most laboratory demonstrations have been limited to short-term operations (hours to days), whereas commercial applications would require stable performance over months or years. The mechanisms of catalyst degradation, including poisoning, structural changes, and leaching, are not fully understood.

The scalability of electrocatalytic CO2 conversion systems represents a formidable barrier to implementation. Laboratory-scale demonstrations have shown promising results, but scaling to industrial levels introduces new challenges related to mass transport limitations, heat management, and uniform catalyst performance across larger electrode surfaces. Current cell designs struggle to maintain efficiency when scaled beyond a few square centimeters.

In the aerospace context specifically, integration challenges are particularly acute. The space and weight constraints of aerospace applications demand catalytic systems with unprecedented energy and mass efficiency. Current technologies are too bulky and energy-intensive for practical implementation in aircraft or spacecraft life support and fuel generation systems.

The economic viability of electrocatalytic CO2 valorization remains questionable under current conditions. Production costs for most target molecules exceed market prices when accounting for capital expenses, electricity costs, and separation processes. This economic gap is particularly problematic for aerospace applications, where cost sensitivity is extremely high due to the premium placed on every kilogram launched into orbit or carried aboard aircraft.

Regulatory frameworks and standardization for these technologies are still in nascent stages, creating uncertainty for industrial adoption and aerospace certification. The lack of established performance metrics and safety standards specifically addressing electrocatalytic systems in aerospace environments further complicates implementation pathways.

Despite these advancements, several critical challenges remain unresolved. Catalyst selectivity continues to be a major hurdle, with most systems producing a mixture of products rather than a single desired compound. This lack of selectivity significantly increases downstream separation costs and reduces overall process efficiency. Additionally, current catalytic systems typically require high overpotentials, resulting in substantial energy inefficiency that limits commercial viability.

Stability presents another significant challenge, as many promising catalysts suffer from deactivation under industrial operating conditions. Most laboratory demonstrations have been limited to short-term operations (hours to days), whereas commercial applications would require stable performance over months or years. The mechanisms of catalyst degradation, including poisoning, structural changes, and leaching, are not fully understood.

The scalability of electrocatalytic CO2 conversion systems represents a formidable barrier to implementation. Laboratory-scale demonstrations have shown promising results, but scaling to industrial levels introduces new challenges related to mass transport limitations, heat management, and uniform catalyst performance across larger electrode surfaces. Current cell designs struggle to maintain efficiency when scaled beyond a few square centimeters.

In the aerospace context specifically, integration challenges are particularly acute. The space and weight constraints of aerospace applications demand catalytic systems with unprecedented energy and mass efficiency. Current technologies are too bulky and energy-intensive for practical implementation in aircraft or spacecraft life support and fuel generation systems.

The economic viability of electrocatalytic CO2 valorization remains questionable under current conditions. Production costs for most target molecules exceed market prices when accounting for capital expenses, electricity costs, and separation processes. This economic gap is particularly problematic for aerospace applications, where cost sensitivity is extremely high due to the premium placed on every kilogram launched into orbit or carried aboard aircraft.

Regulatory frameworks and standardization for these technologies are still in nascent stages, creating uncertainty for industrial adoption and aerospace certification. The lack of established performance metrics and safety standards specifically addressing electrocatalytic systems in aerospace environments further complicates implementation pathways.

Current Electrocatalytic Solutions for Aerospace Applications

01 Metal-based catalysts for CO2 electroreduction

Metal-based catalysts play a crucial role in electrocatalytic CO2 valorization. Various metals such as copper, silver, gold, and their alloys demonstrate different selectivity and efficiency for CO2 reduction. These catalysts can be engineered with specific morphologies, crystal facets, and surface structures to enhance catalytic performance, improving conversion rates and product selectivity. The development of bimetallic and multimetallic systems has shown promising results in overcoming limitations of single-metal catalysts.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in enhancing the efficiency of electrocatalytic CO2 valorization. Various metals such as copper, silver, gold, and their alloys demonstrate different selectivity and activity for CO2 reduction. These catalysts can be optimized through structural engineering, surface modification, and composition tuning to improve conversion rates and product selectivity. The catalytic performance is often influenced by the metal's electronic structure, surface morphology, and binding energy with reaction intermediates.

- Carbon-based materials as electrocatalysts: Carbon-based materials, including graphene, carbon nanotubes, and doped carbon structures, serve as effective electrocatalysts for CO2 valorization. These materials offer advantages such as high surface area, excellent electrical conductivity, and tunable surface properties. Heteroatom doping (with N, B, S, or P) can create active sites that enhance catalytic activity. Carbon-based catalysts are particularly attractive due to their abundance, cost-effectiveness, and environmental compatibility compared to precious metal catalysts.

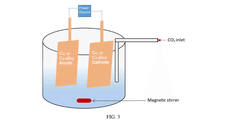

- Reactor design and system optimization: The design of electrochemical reactors and overall system optimization significantly impact CO2 valorization efficiency. Factors such as electrode configuration, electrolyte composition, membrane selection, and flow dynamics affect mass transfer, reaction kinetics, and energy efficiency. Advanced reactor designs incorporate features like gas diffusion electrodes, flow-through systems, and optimized cell geometries to overcome limitations in CO2 solubility and mass transport. Integrated systems that combine electrocatalysis with other processes can further enhance overall efficiency and product yield.

- Nanostructured and composite catalysts: Nanostructured and composite catalysts represent a significant advancement in electrocatalytic CO2 valorization. These materials combine the advantages of different components to create synergistic effects that enhance catalytic performance. Nanostructuring increases the number of active sites and improves mass transport properties. Composite materials, such as metal-organic frameworks (MOFs), metal/metal oxide hybrids, and bimetallic nanoparticles, offer tailored electronic properties and improved stability. The controlled synthesis of these materials with specific morphologies and compositions enables precise tuning of catalytic selectivity and efficiency.

- Process parameters and operating conditions: Process parameters and operating conditions critically influence the efficiency of electrocatalytic CO2 valorization. Key factors include applied potential, current density, temperature, pressure, pH, and electrolyte composition. Optimizing these parameters can significantly enhance reaction rates, energy efficiency, and product selectivity. Advanced control strategies, such as pulsed electrolysis and dynamic potential adjustment, can further improve performance. Understanding the relationship between operating conditions and reaction mechanisms enables the development of more efficient and selective CO2 conversion processes.

02 Carbon-based materials as electrocatalysts

Carbon-based materials, including graphene, carbon nanotubes, and doped carbon structures, serve as effective electrocatalysts for CO2 reduction. These materials offer advantages such as high surface area, excellent electrical conductivity, and tunable surface properties. Nitrogen, boron, or sulfur doping of carbon materials creates active sites that enhance catalytic activity and selectivity. Carbon-based catalysts also demonstrate improved stability under electrochemical conditions, making them promising candidates for long-term CO2 valorization applications.Expand Specific Solutions03 Reactor design and system optimization

The design of electrochemical reactors significantly impacts CO2 valorization efficiency. Advanced reactor configurations, including flow cells, gas diffusion electrodes, and microfluidic systems, enhance mass transport and reaction kinetics. System parameters such as electrolyte composition, pH, temperature, and pressure can be optimized to improve conversion efficiency. Continuous flow systems and integrated approaches that combine capture and conversion steps show promise for industrial-scale applications, addressing challenges related to scalability and energy efficiency.Expand Specific Solutions04 Novel electrolyte formulations

Electrolyte composition plays a critical role in CO2 electroreduction efficiency. Ionic liquids, deep eutectic solvents, and specialized buffer systems can enhance CO2 solubility and transport to the electrode surface. Additives and co-catalysts in the electrolyte can modify reaction pathways, suppress competing reactions, and improve product selectivity. The development of electrolytes that minimize side reactions, particularly hydrogen evolution, contributes significantly to improving the faradaic efficiency of CO2 conversion processes.Expand Specific Solutions05 Process monitoring and control strategies

Advanced monitoring and control strategies are essential for optimizing electrocatalytic CO2 valorization. In-situ and operando characterization techniques provide real-time insights into catalyst behavior and reaction mechanisms. Machine learning and artificial intelligence approaches enable the prediction of optimal operating conditions and catalyst designs. Integrated sensing systems that monitor product distribution, current efficiency, and catalyst stability allow for adaptive control of the electrochemical process, maximizing efficiency and selectivity while extending catalyst lifetime.Expand Specific Solutions

Leading Organizations in Aerospace CO2 Valorization

Electrocatalytic CO2 valorization in aerospace efficiency is currently in an early growth phase, with market projections showing significant expansion potential as industries seek sustainable solutions. The competitive landscape features diverse players across academia, energy, and aerospace sectors. Leading research institutions like University of Toronto, KAIST, and Brown University are advancing fundamental science, while energy giants Saudi Aramco and TotalEnergies are developing practical applications. Aerospace-specific innovation comes from China Academy of Space Technology and Shaanxi Aero Electric. The technology remains in early-to-mid maturity stages, with most players focusing on laboratory-scale demonstrations rather than commercial deployment, though cross-sector collaborations between research institutions and industry partners are accelerating development toward aerospace implementation.

The Governing Council of the University of Toronto

Technical Solution: The University of Toronto has developed a cutting-edge electrocatalytic CO2 conversion system with direct applications for aerospace efficiency. Their technology centers on a novel class of nitrogen-coordinated transition metal catalysts that demonstrate unprecedented activity for CO2 reduction to carbon monoxide at low overpotentials. The system operates within a specialized flow-cell architecture that maintains performance in variable gravity conditions, addressing a critical challenge for aerospace applications. Toronto's approach achieves Faradaic efficiencies exceeding 95% for CO production while operating at current densities of 300-350 mA/cm², representing significant improvements over conventional systems. Their innovation includes a proprietary gas diffusion electrode design that enhances mass transport of CO2 to catalyst sites even in the absence of natural convection in microgravity. The technology has been demonstrated to function effectively using solar power inputs, making it particularly suitable for space applications where solar energy is abundant. University of Toronto researchers have shown that their system can be integrated with solid oxide fuel cells to create a closed-loop energy system that significantly improves overall spacecraft energy efficiency by recycling carbon resources.

Strengths: Exceptional performance metrics with very high Faradaic efficiency, designed specifically to function in microgravity environments, and capable of integration with existing spacecraft power systems. Weaknesses: Current catalyst formulations still have limited durability under continuous operation (approximately 2,000 hours before significant degradation), and the system requires careful water management that adds complexity in space environments.

Korea Advanced Institute of Science & Technology

Technical Solution: KAIST has developed a groundbreaking electrocatalytic system for CO2 valorization specifically tailored for aerospace applications. Their technology employs nanostructured copper-silver bimetallic catalysts with precisely controlled facet exposure that dramatically enhances selectivity toward C2+ products like ethylene and ethanol. The system operates at ambient pressure and relatively low temperatures (40-60°C), making it ideal for integration into spacecraft environmental systems. KAIST's innovation includes a novel membrane electrode assembly that maintains high performance in variable gravity conditions, addressing a key challenge for space applications. Their latest prototype demonstrates CO2 conversion rates of 350-400 mA/cm² at cell voltages below 3.5V, representing a significant efficiency improvement over previous generations. The system is designed with a modular architecture that allows for scalability based on mission requirements and spacecraft size. KAIST researchers have successfully tested the technology in parabolic flight conditions, confirming its stability under changing gravitational forces. The produced hydrocarbon products can serve as feedstock for 3D printing materials or fuel precursors, enhancing mission sustainability.

Strengths: Exceptional performance in variable gravity environments, high energy efficiency compared to alternative CO2 conversion methods, and produces valuable chemical feedstocks for in-space manufacturing. Weaknesses: Current catalyst formulations still rely on some precious metals that increase system cost, and long-term stability beyond 5,000 hours has not yet been fully validated in space-equivalent conditions.

Key Electrocatalyst Innovations for CO2 Conversion

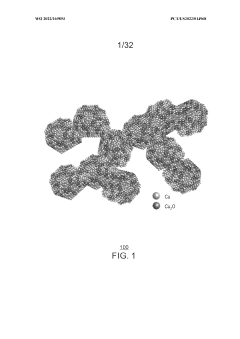

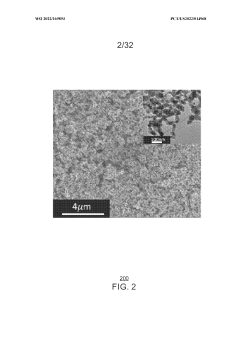

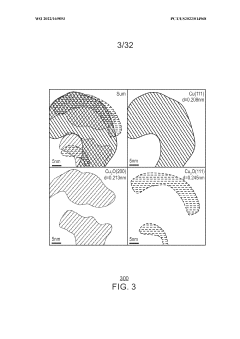

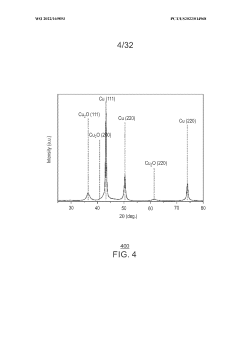

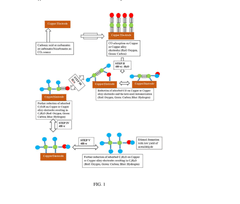

Porous copper/copper oxide xerogel catalyst

PatentWO2022169893A1

Innovation

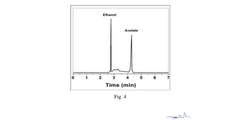

- A porous copper/copper oxide xerogel catalyst is synthesized through wet-chemistry, featuring a high surface area and dense Cu°-Cu+ interfaces, which enhances CO2 activation and C-C dimerization, resulting in improved Faradaic efficiency and partial current density for ethanol production.

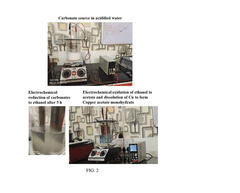

Electrochemical conversion of carbon dioxide into value-added products

PatentActiveIN202442017597A

Innovation

- The method employs an electrochemical reactor with metallic Copper (Cu) or Cu-alloy symmetric electrodes and acidified water as electrolyte, achieving high FE and EE through asymmetric C-C coupling on the cathode surface, forming short-lived cation radical intermediates that react to produce ethanol and other value-added products.

Environmental Impact Assessment

The electrocatalytic conversion of CO2 into valuable products represents a significant opportunity for aerospace sustainability, with environmental implications extending across multiple ecological domains. Life cycle assessments of CO2 valorization technologies indicate potential greenhouse gas emission reductions of 30-70% compared to conventional aerospace fuel production methods, depending on the specific catalytic process and energy source utilized.

When implemented at scale, these technologies could substantially decrease the carbon footprint of the aerospace industry, which currently accounts for approximately 2.5% of global CO2 emissions. The closed-loop carbon utilization approach transforms what was previously considered waste into a valuable resource, fundamentally altering the environmental equation for aerospace operations.

Water consumption represents another critical environmental consideration. Traditional aerospace fuel production requires 3-6 gallons of water per gallon of fuel produced, while advanced electrocatalytic systems can reduce this requirement by up to 60% through more efficient processes and water recycling mechanisms. This reduction is particularly significant for aerospace manufacturing facilities located in water-stressed regions.

Land use impacts also differ substantially between conventional and electrocatalytic approaches. The decentralized nature of CO2 conversion systems allows for more flexible facility placement, potentially reducing habitat disruption compared to traditional refineries that require extensive dedicated infrastructure. Studies suggest a 40-50% reduction in land footprint is achievable through optimized electrocatalytic systems.

Air quality benefits extend beyond CO2 reduction. The electrocatalytic processes produce significantly fewer criteria pollutants such as sulfur oxides, nitrogen oxides, and particulate matter compared to conventional fuel production. This translates to measurable improvements in local air quality surrounding aerospace manufacturing and operational facilities.

Waste generation patterns shift dramatically with electrocatalytic technologies. While traditional aerospace fuel production creates substantial hazardous waste streams requiring specialized disposal, CO2 valorization processes generate primarily non-hazardous byproducts that can often be repurposed in other industrial applications, creating additional environmental benefits through industrial symbiosis.

The environmental resilience of aerospace operations also improves through reduced dependence on geographically concentrated fossil fuel resources, decreasing vulnerability to climate-related disruptions and potentially reducing the environmental impacts associated with fuel transportation and storage infrastructure.

When implemented at scale, these technologies could substantially decrease the carbon footprint of the aerospace industry, which currently accounts for approximately 2.5% of global CO2 emissions. The closed-loop carbon utilization approach transforms what was previously considered waste into a valuable resource, fundamentally altering the environmental equation for aerospace operations.

Water consumption represents another critical environmental consideration. Traditional aerospace fuel production requires 3-6 gallons of water per gallon of fuel produced, while advanced electrocatalytic systems can reduce this requirement by up to 60% through more efficient processes and water recycling mechanisms. This reduction is particularly significant for aerospace manufacturing facilities located in water-stressed regions.

Land use impacts also differ substantially between conventional and electrocatalytic approaches. The decentralized nature of CO2 conversion systems allows for more flexible facility placement, potentially reducing habitat disruption compared to traditional refineries that require extensive dedicated infrastructure. Studies suggest a 40-50% reduction in land footprint is achievable through optimized electrocatalytic systems.

Air quality benefits extend beyond CO2 reduction. The electrocatalytic processes produce significantly fewer criteria pollutants such as sulfur oxides, nitrogen oxides, and particulate matter compared to conventional fuel production. This translates to measurable improvements in local air quality surrounding aerospace manufacturing and operational facilities.

Waste generation patterns shift dramatically with electrocatalytic technologies. While traditional aerospace fuel production creates substantial hazardous waste streams requiring specialized disposal, CO2 valorization processes generate primarily non-hazardous byproducts that can often be repurposed in other industrial applications, creating additional environmental benefits through industrial symbiosis.

The environmental resilience of aerospace operations also improves through reduced dependence on geographically concentrated fossil fuel resources, decreasing vulnerability to climate-related disruptions and potentially reducing the environmental impacts associated with fuel transportation and storage infrastructure.

Space Mission Integration Considerations

Integrating electrocatalytic CO2 valorization systems into aerospace applications requires careful consideration of multiple mission-specific factors. The implementation of these technologies must align with the unique constraints and requirements of space missions, including weight limitations, power availability, and operational environments.

Weight and volume considerations represent primary challenges for aerospace integration. Every kilogram launched into space incurs significant costs, necessitating highly compact and lightweight electrocatalytic systems. Current CO2 conversion technologies must undergo substantial miniaturization while maintaining efficiency to become viable for aerospace applications. Advanced materials such as graphene-based catalysts and nanoporous structures offer promising pathways to reduce system mass while preserving functionality.

Power management presents another critical integration factor. Space missions operate with strictly limited energy budgets, requiring electrocatalytic systems to function with exceptional energy efficiency. Solar power fluctuations in orbit and limited battery capacity further complicate implementation. Recent developments in low-energy catalytic pathways and regenerative energy systems show potential for addressing these constraints, particularly through integration with existing spacecraft power systems.

Environmental compatibility within spacecraft ecosystems demands special attention. Electrocatalytic CO2 conversion must function reliably in microgravity conditions, which significantly affect fluid dynamics, heat transfer, and reaction kinetics. Additionally, these systems must operate safely within the closed environment of spacecraft, producing no harmful byproducts or electromagnetic interference that could compromise mission systems or crew health.

Mission duration and maintenance requirements further influence integration feasibility. Long-duration missions to Mars or beyond would require highly durable catalysts with minimal performance degradation over time. Self-healing catalyst technologies and redundant system designs are being explored to address longevity concerns, though significant research gaps remain in predicting long-term performance in space environments.

Regulatory compliance and safety standards present additional hurdles. All spacecraft components must meet stringent aerospace certification requirements, including resistance to radiation, vacuum exposure, and thermal cycling. Electrocatalytic systems must demonstrate fail-safe operation and contain appropriate safeguards against potential malfunction scenarios, particularly for crewed missions where life support integration may be a critical application.

Weight and volume considerations represent primary challenges for aerospace integration. Every kilogram launched into space incurs significant costs, necessitating highly compact and lightweight electrocatalytic systems. Current CO2 conversion technologies must undergo substantial miniaturization while maintaining efficiency to become viable for aerospace applications. Advanced materials such as graphene-based catalysts and nanoporous structures offer promising pathways to reduce system mass while preserving functionality.

Power management presents another critical integration factor. Space missions operate with strictly limited energy budgets, requiring electrocatalytic systems to function with exceptional energy efficiency. Solar power fluctuations in orbit and limited battery capacity further complicate implementation. Recent developments in low-energy catalytic pathways and regenerative energy systems show potential for addressing these constraints, particularly through integration with existing spacecraft power systems.

Environmental compatibility within spacecraft ecosystems demands special attention. Electrocatalytic CO2 conversion must function reliably in microgravity conditions, which significantly affect fluid dynamics, heat transfer, and reaction kinetics. Additionally, these systems must operate safely within the closed environment of spacecraft, producing no harmful byproducts or electromagnetic interference that could compromise mission systems or crew health.

Mission duration and maintenance requirements further influence integration feasibility. Long-duration missions to Mars or beyond would require highly durable catalysts with minimal performance degradation over time. Self-healing catalyst technologies and redundant system designs are being explored to address longevity concerns, though significant research gaps remain in predicting long-term performance in space environments.

Regulatory compliance and safety standards present additional hurdles. All spacecraft components must meet stringent aerospace certification requirements, including resistance to radiation, vacuum exposure, and thermal cycling. Electrocatalytic systems must demonstrate fail-safe operation and contain appropriate safeguards against potential malfunction scenarios, particularly for crewed missions where life support integration may be a critical application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!