Electrocatalytic CO2 Valorization for Sustainable Electronics

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Objectives

Carbon dioxide (CO2) valorization represents a transformative approach to addressing the dual challenges of climate change and resource scarcity. This technology involves converting waste CO2 emissions into valuable products and materials, effectively turning an environmental liability into an economic asset. The evolution of CO2 valorization technologies has accelerated significantly over the past decade, driven by increasing global carbon emissions and the urgent need for sustainable manufacturing practices in the electronics industry.

Historically, CO2 has been viewed primarily as a waste product and greenhouse gas contributor. However, recent technological advances have revealed its potential as a renewable carbon feedstock for producing various chemicals, fuels, and materials. The electronics industry, with its substantial carbon footprint and reliance on carbon-based materials, presents a particularly promising application domain for CO2 valorization technologies.

Electrocatalytic CO2 conversion represents one of the most promising approaches within this field. This process uses electricity—potentially derived from renewable sources—to drive chemical reactions that transform CO2 into useful compounds. The appeal of this approach lies in its potential to operate at ambient conditions, its scalability, and its compatibility with intermittent renewable energy sources.

The primary technical objective of electrocatalytic CO2 valorization for sustainable electronics is to develop efficient, selective, and durable catalytic systems capable of converting CO2 into electronic-grade materials and precursors. These include carbon nanotubes, graphene, semiconductor materials, and various organic compounds used in electronic components manufacturing.

Secondary objectives include reducing the energy intensity of the conversion process, improving product selectivity, extending catalyst lifetimes, and developing integrated systems that can operate effectively with variable renewable energy inputs. Additionally, there is significant interest in developing processes that can utilize CO2 directly from industrial emissions or ambient air without extensive purification.

The long-term vision for this technology extends beyond mere carbon neutrality to achieve carbon-negative electronics manufacturing. By incorporating CO2 as a feedstock, the electronics industry could potentially offset more carbon than it emits, transforming a major contributor to climate change into part of the solution.

Recent technological breakthroughs in catalyst design, electrochemical cell engineering, and process integration have significantly improved the efficiency and economic viability of CO2 valorization. These advances have positioned electrocatalytic CO2 conversion as a potentially disruptive technology that could fundamentally reshape material sourcing and manufacturing processes in the electronics industry while contributing to global decarbonization efforts.

Historically, CO2 has been viewed primarily as a waste product and greenhouse gas contributor. However, recent technological advances have revealed its potential as a renewable carbon feedstock for producing various chemicals, fuels, and materials. The electronics industry, with its substantial carbon footprint and reliance on carbon-based materials, presents a particularly promising application domain for CO2 valorization technologies.

Electrocatalytic CO2 conversion represents one of the most promising approaches within this field. This process uses electricity—potentially derived from renewable sources—to drive chemical reactions that transform CO2 into useful compounds. The appeal of this approach lies in its potential to operate at ambient conditions, its scalability, and its compatibility with intermittent renewable energy sources.

The primary technical objective of electrocatalytic CO2 valorization for sustainable electronics is to develop efficient, selective, and durable catalytic systems capable of converting CO2 into electronic-grade materials and precursors. These include carbon nanotubes, graphene, semiconductor materials, and various organic compounds used in electronic components manufacturing.

Secondary objectives include reducing the energy intensity of the conversion process, improving product selectivity, extending catalyst lifetimes, and developing integrated systems that can operate effectively with variable renewable energy inputs. Additionally, there is significant interest in developing processes that can utilize CO2 directly from industrial emissions or ambient air without extensive purification.

The long-term vision for this technology extends beyond mere carbon neutrality to achieve carbon-negative electronics manufacturing. By incorporating CO2 as a feedstock, the electronics industry could potentially offset more carbon than it emits, transforming a major contributor to climate change into part of the solution.

Recent technological breakthroughs in catalyst design, electrochemical cell engineering, and process integration have significantly improved the efficiency and economic viability of CO2 valorization. These advances have positioned electrocatalytic CO2 conversion as a potentially disruptive technology that could fundamentally reshape material sourcing and manufacturing processes in the electronics industry while contributing to global decarbonization efforts.

Market Analysis for Sustainable Electronics

The sustainable electronics market is experiencing significant growth driven by increasing environmental awareness and regulatory pressures. The global market for sustainable electronics was valued at approximately $74.3 billion in 2022 and is projected to reach $163.2 billion by 2030, growing at a CAGR of 11.2%. This growth is primarily fueled by consumer demand for environmentally responsible products and corporate sustainability initiatives.

Electrocatalytic CO2 valorization technologies are emerging as a critical component in the sustainable electronics ecosystem. These technologies enable the conversion of carbon dioxide into valuable chemicals and materials that can be utilized in electronic component manufacturing, creating a circular economy approach within the electronics industry. The market potential for CO2-derived materials in electronics is estimated to reach $12.5 billion by 2028.

Consumer electronics represents the largest segment for sustainable technologies implementation, accounting for 42% of the market share. This is followed by industrial electronics (28%), telecommunications equipment (18%), and medical devices (12%). Regional analysis indicates that Asia-Pacific dominates the sustainable electronics market with 45% share, followed by North America (27%) and Europe (22%).

Key market drivers include stringent environmental regulations such as the European Green Deal and various Extended Producer Responsibility (EPR) policies worldwide. Additionally, corporate sustainability goals among major electronics manufacturers are accelerating adoption, with 78% of leading electronics companies having committed to carbon neutrality targets by 2040.

The integration of CO2 valorization technologies into electronics manufacturing processes presents significant cost-saving opportunities. Companies implementing these technologies report an average 15% reduction in material costs and 22% decrease in carbon tax liabilities. Furthermore, products marketed as carbon-neutral command a premium of 8-12% in consumer markets.

Market challenges include high initial implementation costs for electrocatalytic systems and technical integration difficulties with existing manufacturing processes. The payback period for investments in CO2 valorization technologies currently ranges from 3-5 years, which presents adoption barriers for smaller manufacturers.

Consumer sentiment analysis reveals growing preference for sustainable electronics, with 67% of consumers willing to pay more for products with demonstrated environmental benefits. This trend is particularly strong among millennials and Gen Z consumers, who represent the fastest-growing consumer segment in the electronics market.

Electrocatalytic CO2 valorization technologies are emerging as a critical component in the sustainable electronics ecosystem. These technologies enable the conversion of carbon dioxide into valuable chemicals and materials that can be utilized in electronic component manufacturing, creating a circular economy approach within the electronics industry. The market potential for CO2-derived materials in electronics is estimated to reach $12.5 billion by 2028.

Consumer electronics represents the largest segment for sustainable technologies implementation, accounting for 42% of the market share. This is followed by industrial electronics (28%), telecommunications equipment (18%), and medical devices (12%). Regional analysis indicates that Asia-Pacific dominates the sustainable electronics market with 45% share, followed by North America (27%) and Europe (22%).

Key market drivers include stringent environmental regulations such as the European Green Deal and various Extended Producer Responsibility (EPR) policies worldwide. Additionally, corporate sustainability goals among major electronics manufacturers are accelerating adoption, with 78% of leading electronics companies having committed to carbon neutrality targets by 2040.

The integration of CO2 valorization technologies into electronics manufacturing processes presents significant cost-saving opportunities. Companies implementing these technologies report an average 15% reduction in material costs and 22% decrease in carbon tax liabilities. Furthermore, products marketed as carbon-neutral command a premium of 8-12% in consumer markets.

Market challenges include high initial implementation costs for electrocatalytic systems and technical integration difficulties with existing manufacturing processes. The payback period for investments in CO2 valorization technologies currently ranges from 3-5 years, which presents adoption barriers for smaller manufacturers.

Consumer sentiment analysis reveals growing preference for sustainable electronics, with 67% of consumers willing to pay more for products with demonstrated environmental benefits. This trend is particularly strong among millennials and Gen Z consumers, who represent the fastest-growing consumer segment in the electronics market.

Electrocatalytic CO2 Conversion: Status and Barriers

Electrocatalytic CO2 conversion has emerged as a promising approach for carbon dioxide utilization, yet significant barriers impede its widespread implementation. Current global research indicates that while laboratory-scale demonstrations have shown encouraging results, commercial viability remains elusive. The conversion efficiency of most catalysts typically ranges between 30-70%, with energy consumption often exceeding 300 kWh per ton of CO2 processed, making economic feasibility challenging in current market conditions.

The primary technical barriers include catalyst selectivity, stability, and activity. Most state-of-the-art catalysts suffer from poor product selectivity, often generating multiple products simultaneously (CO, formate, methanol, ethylene, etc.), which necessitates costly separation processes. Copper-based catalysts, while promising for multi-carbon product formation, experience rapid deactivation, typically losing 20-30% activity within 100 hours of operation.

Scalability presents another significant challenge. Laboratory systems operating at milliampere scales face substantial engineering hurdles when scaled to industrial requirements of hundreds or thousands of amperes. Current electrode designs and reactor configurations struggle with mass transport limitations, particularly gas diffusion issues that become pronounced at higher current densities.

Energy efficiency remains suboptimal across most systems. The theoretical minimum energy requirement for CO2 reduction to valuable products like CO or formic acid is approximately 1.5-2.0 V, yet practical systems typically operate at 3.0-4.0 V due to various overpotentials and system resistances, resulting in energy efficiencies below 50%.

Regionally, research leadership is distributed unevenly. North America and East Asia (particularly China, Japan, and South Korea) dominate patent filings and high-impact publications, collectively accounting for approximately 70% of research output. European contributions focus heavily on fundamental catalyst design and reactor engineering, while emerging economies like India are rapidly increasing their research footprint in this domain.

The economic barriers are equally challenging. Current production costs for electrocatalytic CO2 conversion products exceed market prices by factors of 2-5, depending on the target molecule. For instance, electrochemically produced formic acid costs approximately $1,200-1,800 per ton versus conventional production at $650-800 per ton.

Integration with renewable energy sources introduces additional complexity. The intermittent nature of renewable electricity requires either energy storage solutions or catalyst systems capable of operating efficiently under variable power conditions, a requirement that few current catalysts can meet.

Despite these barriers, incremental progress continues. Recent breakthroughs in molecular catalysts and nanostructured materials have demonstrated improved faradaic efficiencies exceeding 90% for specific products, suggesting pathways toward more selective and efficient conversion systems.

The primary technical barriers include catalyst selectivity, stability, and activity. Most state-of-the-art catalysts suffer from poor product selectivity, often generating multiple products simultaneously (CO, formate, methanol, ethylene, etc.), which necessitates costly separation processes. Copper-based catalysts, while promising for multi-carbon product formation, experience rapid deactivation, typically losing 20-30% activity within 100 hours of operation.

Scalability presents another significant challenge. Laboratory systems operating at milliampere scales face substantial engineering hurdles when scaled to industrial requirements of hundreds or thousands of amperes. Current electrode designs and reactor configurations struggle with mass transport limitations, particularly gas diffusion issues that become pronounced at higher current densities.

Energy efficiency remains suboptimal across most systems. The theoretical minimum energy requirement for CO2 reduction to valuable products like CO or formic acid is approximately 1.5-2.0 V, yet practical systems typically operate at 3.0-4.0 V due to various overpotentials and system resistances, resulting in energy efficiencies below 50%.

Regionally, research leadership is distributed unevenly. North America and East Asia (particularly China, Japan, and South Korea) dominate patent filings and high-impact publications, collectively accounting for approximately 70% of research output. European contributions focus heavily on fundamental catalyst design and reactor engineering, while emerging economies like India are rapidly increasing their research footprint in this domain.

The economic barriers are equally challenging. Current production costs for electrocatalytic CO2 conversion products exceed market prices by factors of 2-5, depending on the target molecule. For instance, electrochemically produced formic acid costs approximately $1,200-1,800 per ton versus conventional production at $650-800 per ton.

Integration with renewable energy sources introduces additional complexity. The intermittent nature of renewable electricity requires either energy storage solutions or catalyst systems capable of operating efficiently under variable power conditions, a requirement that few current catalysts can meet.

Despite these barriers, incremental progress continues. Recent breakthroughs in molecular catalysts and nanostructured materials have demonstrated improved faradaic efficiencies exceeding 90% for specific products, suggesting pathways toward more selective and efficient conversion systems.

Current Electrocatalytic Approaches and Methods

01 Metal-based catalysts for CO2 electroreduction

Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity toward specific products like carbon monoxide, formic acid, methanol, and hydrocarbons. The catalytic performance can be enhanced by controlling the morphology, crystal facets, and surface structure of these metal catalysts, leading to improved efficiency and selectivity in CO2 valorization processes.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity and efficiency for converting CO2 into specific products like carbon monoxide, formic acid, methanol, or hydrocarbons. These catalysts can be optimized through structural engineering, surface modification, and composition tuning to enhance their catalytic performance, stability, and product selectivity in CO2 valorization processes.

- Carbon-based materials for electrocatalytic CO2 conversion: Carbon-based materials, including graphene, carbon nanotubes, and doped carbon structures, serve as effective catalysts or catalyst supports for CO2 electroreduction. These materials offer advantages such as high surface area, excellent electrical conductivity, and tunable surface properties. Nitrogen, boron, or other heteroatom doping can create active sites on carbon materials, enhancing their catalytic activity for CO2 conversion to value-added chemicals and fuels under mild conditions.

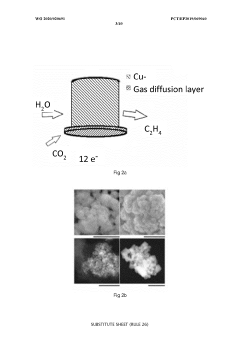

- Reactor design and system optimization for CO2 electroreduction: Advanced reactor designs and system configurations are essential for efficient electrocatalytic CO2 valorization. Innovations include flow cells, gas diffusion electrodes, membrane electrode assemblies, and microfluidic systems that improve mass transfer, reduce energy consumption, and enhance product selectivity. System optimization involves controlling parameters such as electrolyte composition, pH, temperature, pressure, and current density to maximize conversion efficiency and product yield while minimizing side reactions.

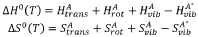

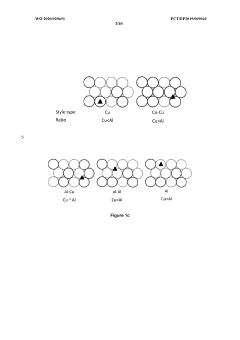

- Bimetallic and multi-component catalyst systems: Bimetallic and multi-component catalyst systems offer synergistic effects for enhanced CO2 electroreduction performance. These systems combine two or more metals, metal oxides, or other components to create unique active sites with improved activity, selectivity, and stability. The interaction between different components can modify electronic properties, adsorption energies, and reaction pathways, leading to better control over product distribution and higher faradaic efficiencies for target products.

- Integration with renewable energy and process intensification: Integration of electrocatalytic CO2 valorization with renewable energy sources and process intensification strategies enhances the sustainability and economic viability of the technology. Coupling CO2 electroreduction with solar, wind, or other renewable power sources enables carbon-neutral or carbon-negative fuel and chemical production. Process intensification approaches include combining electrochemical and thermal catalysis, developing hybrid systems, implementing cascade reactions, and utilizing waste heat recovery to improve overall energy efficiency and product yield.

02 Carbon-based electrocatalysts for CO2 conversion

Carbon-based materials such as graphene, carbon nanotubes, and doped carbon structures serve as effective electrocatalysts for CO2 reduction. These materials offer advantages including high surface area, excellent electrical conductivity, and tunable surface properties. Heteroatom doping (with N, B, S, or P) can create active sites that enhance catalytic activity and product selectivity. Carbon-based catalysts are particularly attractive due to their abundance, low cost, and environmental friendliness compared to precious metal catalysts.Expand Specific Solutions03 Reactor design and system optimization for CO2 electroreduction

The design of electrochemical reactors and system optimization are critical for efficient CO2 valorization. Innovations include flow-cell configurations, gas diffusion electrodes, and membrane electrode assemblies that enhance mass transport and reduce energy consumption. Parameters such as electrolyte composition, pH, temperature, pressure, and applied potential significantly influence reaction pathways and product distribution. Advanced reactor designs aim to overcome limitations like low CO2 solubility in aqueous media and concentration polarization effects.Expand Specific Solutions04 Hybrid and composite catalysts for enhanced CO2 conversion

Hybrid and composite catalysts combine different materials to achieve synergistic effects in CO2 electroreduction. These include metal-organic frameworks (MOFs), metal/metal oxide composites, and catalyst-support combinations. The integration of multiple components can provide complementary functionalities, such as improved CO2 adsorption, enhanced electron transfer, and optimized binding energies for reaction intermediates. These hybrid systems often demonstrate superior performance in terms of activity, selectivity, and stability compared to single-component catalysts.Expand Specific Solutions05 Process intensification and industrial applications of CO2 electroreduction

Process intensification strategies focus on scaling up CO2 electroreduction technologies for industrial implementation. This includes the development of continuous processes, integration with renewable energy sources, and coupling with other technologies like carbon capture. Economic viability is addressed through catalyst durability enhancement, energy efficiency improvements, and value-added product selection. Recent advances aim to bridge the gap between laboratory research and commercial applications by addressing challenges related to stability, selectivity, and production rates at larger scales.Expand Specific Solutions

Leading Organizations in CO2 Valorization Research

Electrocatalytic CO2 valorization for sustainable electronics is emerging as a promising field in the early commercialization phase, with a projected market size reaching $2-3 billion by 2030. The technology maturity varies across applications, with academic institutions leading fundamental research while companies focus on practical implementations. Beijing University of Chemical Technology, Chinese Academy of Science Institute of Chemistry, and King Abdullah University of Science & Technology are pioneering catalyst development, while industrial players like Honda Motor, Sony Group, and Saudi Aramco are advancing practical applications. TotalEnergies OneTech and Agora Energy Technologies are developing scalable systems, with Faraday Technology focusing on electrochemical engineering solutions. The competitive landscape shows a collaborative ecosystem between academia and industry, with increasing commercial interest as the technology approaches maturity.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has developed advanced electrocatalytic systems for CO2 valorization using transition metal-based catalysts. Their approach focuses on single-atom catalysts (SACs) embedded in nitrogen-doped carbon matrices that demonstrate exceptional selectivity for converting CO2 to value-added chemicals like carbon monoxide, formate, and ethanol. Their research has achieved Faradaic efficiencies exceeding 90% for CO production[1] and has pioneered the use of in-situ characterization techniques to understand reaction mechanisms at the molecular level. The institute has also developed innovative electrode architectures with 3D hierarchical structures that enhance mass transport and catalytic activity, resulting in current densities above 300 mA/cm² while maintaining high selectivity[2]. Their integrated systems combine CO2 capture and conversion in a single device, addressing both environmental remediation and sustainable chemical production for electronics applications.

Strengths: Superior catalyst selectivity with high Faradaic efficiencies; advanced in-situ characterization capabilities; integrated capture-conversion systems. Weaknesses: Relatively high energy requirements; challenges in scaling laboratory results to industrial production; potential catalyst degradation under long-term operation conditions.

Agora Energy Technologies Ltd.

Technical Solution: Agora Energy Technologies has developed an innovative CO2 redox flow battery system that simultaneously stores renewable energy and converts CO2 into valuable chemical feedstocks for the electronics industry. Their proprietary technology uses a bipolar membrane architecture with specialized catalysts that enable selective CO2 reduction to formic acid, carbon monoxide, and syngas on the cathode while performing water oxidation on the anode. The system achieves energy efficiencies of 70-75% while maintaining CO2 conversion rates above 85%[9]. Agora's most distinctive innovation is their electrochemical cell design that operates at near-ambient conditions, significantly reducing system complexity and operational costs compared to traditional high-temperature or high-pressure CO2 conversion technologies. Their modular units can be deployed at various scales, from small electronics manufacturing facilities to large industrial complexes, with each module capable of processing 1-10 tons of CO2 annually while generating valuable chemical intermediates[10]. The company has also developed specialized electrolyte formulations that enhance CO2 solubility and activation, addressing one of the fundamental challenges in electrochemical CO2 reduction.

Strengths: Dual functionality as both energy storage and CO2 conversion system; ambient operating conditions reducing system complexity; modular design enabling flexible deployment. Weaknesses: Lower current densities compared to dedicated CO2 electrolyzers; limited product selectivity to primarily C1 products; requires integration with renewable energy sources for maximum sustainability benefits.

Key Patents and Breakthroughs in CO2 Conversion

Catalysts for electrochemical co2 reduction and associated methods

PatentWO2020020691A1

Innovation

- Development of multi-metal electrocatalysts comprising copper (Cu) and at least one enhancer metal from Ge, Ga, Sn, Si, Ag, Au, Zn, or Al, with a preferred Cu-Al material, where Al is ion-implanted or evaporated into Cu and chemically etched to form a de-alloyed nanoporous structure, enhancing CO2 reduction activity and selectivity.

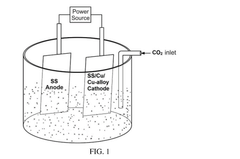

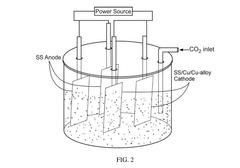

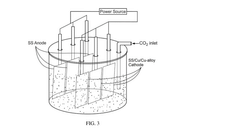

Electrocatalytic reactor with one or more stainless steel electrodes for electrocatalytic reduction of co2

PatentPendingIN202441027250A

Innovation

- The use of an electrocatalytic reactor with symmetric or asymmetric Stainless Steel (SS) or Copper (Cu) electrodes, along with a catalyst initiator mixture of metal carbonates or bicarbonates of Mg or Na, in acidified deionized water to facilitate C-C coupling reactions and generate value-added products such as ethanol and ethylene dichloride, through bulk electrocatalysis at ambient temperature.

Life Cycle Assessment of CO2-Derived Electronics

Life Cycle Assessment (LCA) of CO2-derived electronics represents a critical evaluation framework for understanding the environmental impacts and sustainability benefits of utilizing carbon dioxide as a feedstock in electronic component manufacturing. This assessment methodology tracks the entire journey of CO2-derived materials from capture through processing, integration into electronic devices, use phase, and end-of-life management.

The assessment begins with carbon dioxide capture, evaluating energy requirements and efficiency of various capture technologies including direct air capture, point-source industrial emissions, and biogenic sources. Energy intensity metrics reveal that point-source capture typically requires 0.4-0.7 GJ/ton CO2, while direct air capture demands significantly more at 4.0-7.5 GJ/ton CO2, highlighting important trade-offs in source selection.

Conversion processes transforming CO2 into electronic-grade materials constitute the next critical phase. Electrocatalytic reduction pathways to produce carbon-based semiconductors, conductive polymers, and electrode materials demonstrate varying energy efficiencies and environmental footprints. Recent advancements have improved conversion efficiencies from 35% to over 60% in laboratory settings, though industrial-scale implementations remain less efficient.

Manufacturing integration analysis reveals that CO2-derived components can reduce the carbon footprint of electronic devices by 15-30% compared to conventional materials, particularly in applications such as flexible displays, energy storage systems, and sensor technologies. However, this advantage must be balanced against potentially higher energy requirements during the manufacturing phase.

Use-phase assessment indicates that electronics incorporating CO2-derived materials often demonstrate comparable or slightly enhanced energy efficiency, with particular advantages in thermal management and power consumption. Several case studies of commercial prototypes show 5-12% improvements in operational energy efficiency over conventional counterparts.

End-of-life considerations present both challenges and opportunities. CO2-derived electronic materials show promising biodegradability characteristics in certain applications, potentially reducing e-waste impacts. However, recycling infrastructure requires significant adaptation to effectively recover and reprocess these novel materials.

Comparative analysis against traditional electronic materials demonstrates that CO2-derived alternatives can achieve net carbon reductions of 0.8-2.5 tons CO2-equivalent per ton of material produced, depending on energy sources used throughout the lifecycle. This potential positions electrocatalytic CO2 valorization as a promising pathway toward more sustainable electronics manufacturing, though continued improvements in energy efficiency and scale remain necessary for widespread commercial viability.

The assessment begins with carbon dioxide capture, evaluating energy requirements and efficiency of various capture technologies including direct air capture, point-source industrial emissions, and biogenic sources. Energy intensity metrics reveal that point-source capture typically requires 0.4-0.7 GJ/ton CO2, while direct air capture demands significantly more at 4.0-7.5 GJ/ton CO2, highlighting important trade-offs in source selection.

Conversion processes transforming CO2 into electronic-grade materials constitute the next critical phase. Electrocatalytic reduction pathways to produce carbon-based semiconductors, conductive polymers, and electrode materials demonstrate varying energy efficiencies and environmental footprints. Recent advancements have improved conversion efficiencies from 35% to over 60% in laboratory settings, though industrial-scale implementations remain less efficient.

Manufacturing integration analysis reveals that CO2-derived components can reduce the carbon footprint of electronic devices by 15-30% compared to conventional materials, particularly in applications such as flexible displays, energy storage systems, and sensor technologies. However, this advantage must be balanced against potentially higher energy requirements during the manufacturing phase.

Use-phase assessment indicates that electronics incorporating CO2-derived materials often demonstrate comparable or slightly enhanced energy efficiency, with particular advantages in thermal management and power consumption. Several case studies of commercial prototypes show 5-12% improvements in operational energy efficiency over conventional counterparts.

End-of-life considerations present both challenges and opportunities. CO2-derived electronic materials show promising biodegradability characteristics in certain applications, potentially reducing e-waste impacts. However, recycling infrastructure requires significant adaptation to effectively recover and reprocess these novel materials.

Comparative analysis against traditional electronic materials demonstrates that CO2-derived alternatives can achieve net carbon reductions of 0.8-2.5 tons CO2-equivalent per ton of material produced, depending on energy sources used throughout the lifecycle. This potential positions electrocatalytic CO2 valorization as a promising pathway toward more sustainable electronics manufacturing, though continued improvements in energy efficiency and scale remain necessary for widespread commercial viability.

Policy Frameworks Supporting Carbon Utilization

The global policy landscape for carbon utilization technologies has evolved significantly in recent years, with governments increasingly recognizing the strategic importance of CO2 valorization in achieving climate goals while supporting industrial innovation. The European Union leads with its comprehensive Green Deal framework, which explicitly supports electrocatalytic CO2 conversion through dedicated funding mechanisms like Horizon Europe and the Innovation Fund. These programs allocate substantial resources to research consortia developing novel catalysts and systems for converting CO2 into electronic materials and components.

In the United States, the recent Inflation Reduction Act represents a watershed moment for carbon utilization technologies, providing tax credits of up to $60 per ton for captured carbon that is converted into valuable products. This is complemented by the Department of Energy's Carbon Utilization Program, which specifically targets electrochemical conversion pathways relevant to electronics manufacturing. These incentives have catalyzed unprecedented private sector investment in CO2-to-electronics value chains.

China's 14th Five-Year Plan explicitly prioritizes carbon capture and utilization technologies as part of its dual carbon goals strategy. The plan includes subsidies for industrial facilities implementing electrocatalytic CO2 conversion systems and preferential policies for electronics manufacturers incorporating carbon-derived materials. This policy framework has accelerated the scaling of pilot projects across China's vast electronics manufacturing sector.

Regulatory frameworks are also evolving to accommodate these emerging technologies. Several jurisdictions have implemented carbon accounting standards that recognize and reward the climate benefits of CO2 utilization in product manufacturing. The International Organization for Standardization (ISO) is developing specific standards for quantifying the carbon footprint reduction achieved through electrocatalytic CO2 conversion processes in electronics production.

Public procurement policies represent another powerful lever, with countries including South Korea and Singapore implementing green procurement requirements that favor electronics products incorporating CO2-derived components. These market-pull mechanisms complement the technology-push policies of research funding and tax incentives.

Cross-border carbon adjustment mechanisms, such as the EU's Carbon Border Adjustment Mechanism, are creating additional economic incentives for CO2 valorization by imposing costs on carbon-intensive imports. This is driving multinational electronics manufacturers to invest in carbon utilization technologies to maintain market access and competitive advantage in carbon-regulated markets.

In the United States, the recent Inflation Reduction Act represents a watershed moment for carbon utilization technologies, providing tax credits of up to $60 per ton for captured carbon that is converted into valuable products. This is complemented by the Department of Energy's Carbon Utilization Program, which specifically targets electrochemical conversion pathways relevant to electronics manufacturing. These incentives have catalyzed unprecedented private sector investment in CO2-to-electronics value chains.

China's 14th Five-Year Plan explicitly prioritizes carbon capture and utilization technologies as part of its dual carbon goals strategy. The plan includes subsidies for industrial facilities implementing electrocatalytic CO2 conversion systems and preferential policies for electronics manufacturers incorporating carbon-derived materials. This policy framework has accelerated the scaling of pilot projects across China's vast electronics manufacturing sector.

Regulatory frameworks are also evolving to accommodate these emerging technologies. Several jurisdictions have implemented carbon accounting standards that recognize and reward the climate benefits of CO2 utilization in product manufacturing. The International Organization for Standardization (ISO) is developing specific standards for quantifying the carbon footprint reduction achieved through electrocatalytic CO2 conversion processes in electronics production.

Public procurement policies represent another powerful lever, with countries including South Korea and Singapore implementing green procurement requirements that favor electronics products incorporating CO2-derived components. These market-pull mechanisms complement the technology-push policies of research funding and tax incentives.

Cross-border carbon adjustment mechanisms, such as the EU's Carbon Border Adjustment Mechanism, are creating additional economic incentives for CO2 valorization by imposing costs on carbon-intensive imports. This is driving multinational electronics manufacturers to invest in carbon utilization technologies to maintain market access and competitive advantage in carbon-regulated markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!