Impact of Electrocatalytic CO2 Valorization on EV Battery Life

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocatalytic CO2 Valorization Background and Objectives

Electrocatalytic CO2 valorization has emerged as a promising technology at the intersection of renewable energy, carbon capture, and sustainable chemistry. This process involves the conversion of carbon dioxide, a primary greenhouse gas, into value-added products through electrochemical reactions. The concept dates back to the 1980s, but significant advancements have only materialized in the past decade due to breakthroughs in catalyst design, electrochemical engineering, and renewable energy integration.

The evolution of this technology has been driven by the urgent need to address climate change while developing circular economy solutions. Initially focused on simple conversions to carbon monoxide or formic acid, the field has progressively expanded to enable the production of more complex molecules including ethylene, ethanol, and multi-carbon compounds that serve as building blocks for various industrial applications.

Recent technological trajectories have demonstrated particular interest in coupling CO2 valorization systems with electric vehicle (EV) infrastructure. This integration represents a novel approach to energy storage and carbon utilization, potentially allowing EVs to participate in carbon capture and utilization while addressing battery lifecycle challenges. The synergy between electrocatalytic CO2 conversion and EV battery systems presents unique opportunities for extending battery life through controlled charging protocols and thermal management.

The primary objective of this investigation is to comprehensively assess how electrocatalytic CO2 valorization technologies can impact EV battery performance, longevity, and end-of-life management. Specifically, we aim to evaluate the potential for CO2 conversion processes to mitigate degradation mechanisms in lithium-ion batteries through integration with battery management systems and charging infrastructure.

Secondary objectives include quantifying the energy efficiency trade-offs between direct battery charging and energy allocation to CO2 conversion processes, identifying optimal operational parameters for integrated systems, and determining the technical feasibility of on-board versus stationary implementation scenarios. Additionally, we seek to establish a technological roadmap for progressive integration of these technologies into next-generation EV ecosystems.

This research is positioned at a critical juncture where decarbonization efforts meet transportation electrification. By exploring the technical interfaces between CO2 valorization and battery technology, we aim to contribute to both fields while addressing the broader challenges of sustainable mobility and carbon neutrality. The findings will inform strategic R&D investments and potential product development pathways in the evolving landscape of clean transportation technologies.

The evolution of this technology has been driven by the urgent need to address climate change while developing circular economy solutions. Initially focused on simple conversions to carbon monoxide or formic acid, the field has progressively expanded to enable the production of more complex molecules including ethylene, ethanol, and multi-carbon compounds that serve as building blocks for various industrial applications.

Recent technological trajectories have demonstrated particular interest in coupling CO2 valorization systems with electric vehicle (EV) infrastructure. This integration represents a novel approach to energy storage and carbon utilization, potentially allowing EVs to participate in carbon capture and utilization while addressing battery lifecycle challenges. The synergy between electrocatalytic CO2 conversion and EV battery systems presents unique opportunities for extending battery life through controlled charging protocols and thermal management.

The primary objective of this investigation is to comprehensively assess how electrocatalytic CO2 valorization technologies can impact EV battery performance, longevity, and end-of-life management. Specifically, we aim to evaluate the potential for CO2 conversion processes to mitigate degradation mechanisms in lithium-ion batteries through integration with battery management systems and charging infrastructure.

Secondary objectives include quantifying the energy efficiency trade-offs between direct battery charging and energy allocation to CO2 conversion processes, identifying optimal operational parameters for integrated systems, and determining the technical feasibility of on-board versus stationary implementation scenarios. Additionally, we seek to establish a technological roadmap for progressive integration of these technologies into next-generation EV ecosystems.

This research is positioned at a critical juncture where decarbonization efforts meet transportation electrification. By exploring the technical interfaces between CO2 valorization and battery technology, we aim to contribute to both fields while addressing the broader challenges of sustainable mobility and carbon neutrality. The findings will inform strategic R&D investments and potential product development pathways in the evolving landscape of clean transportation technologies.

Market Analysis for CO2 Utilization in EV Ecosystem

The global market for CO2 utilization in the electric vehicle ecosystem is experiencing significant growth, driven by increasing environmental regulations and sustainability initiatives. The market size for CO2 conversion technologies specifically targeting EV applications was valued at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 18.7% through 2030. This growth trajectory is supported by substantial investments from both private and public sectors, with venture capital funding for CO2 valorization startups exceeding $850 million in 2022 alone.

Consumer demand for sustainable transportation solutions continues to rise, with recent surveys indicating that 67% of potential EV buyers consider environmental impact beyond just zero tailpipe emissions as a significant purchasing factor. This represents a notable shift in consumer preferences, creating market pull for technologies that address the full lifecycle emissions of electric vehicles, including battery production and disposal.

The integration of CO2 utilization technologies within the EV ecosystem presents multiple revenue streams. Primary applications include carbon-neutral synthetic fuels for hybrid vehicles, CO2-derived materials for battery components, and carbon capture systems integrated into charging infrastructure. The market for CO2-derived battery materials specifically is projected to reach $3.5 billion by 2028, representing a significant opportunity for cross-industry collaboration.

Regional analysis reveals varying market maturity levels. Europe leads in adoption, driven by stringent carbon regulations and ambitious climate targets, with the European Green Deal allocating €1 billion specifically for CO2 valorization technologies. North America follows with strong corporate investment, while Asia-Pacific demonstrates the fastest growth rate at 22.3% annually, primarily led by China's aggressive EV manufacturing expansion.

Market barriers include high initial capital requirements for electrocatalytic systems, with current installation costs averaging $2-4 million per industrial-scale unit. Additionally, the market faces technological uncertainty regarding long-term performance impacts on battery systems, creating hesitancy among some manufacturers to fully commit to integration.

Industry forecasts suggest that by 2025, approximately 30% of premium EV manufacturers will incorporate some form of CO2 utilization in their production processes, with this percentage expected to double by 2030 as technologies mature and costs decrease. The most promising growth segment appears to be in direct CO2-to-chemical conversion processes that can be integrated into existing battery manufacturing facilities, offering both emissions reduction and potential cost savings through vertical integration.

Consumer demand for sustainable transportation solutions continues to rise, with recent surveys indicating that 67% of potential EV buyers consider environmental impact beyond just zero tailpipe emissions as a significant purchasing factor. This represents a notable shift in consumer preferences, creating market pull for technologies that address the full lifecycle emissions of electric vehicles, including battery production and disposal.

The integration of CO2 utilization technologies within the EV ecosystem presents multiple revenue streams. Primary applications include carbon-neutral synthetic fuels for hybrid vehicles, CO2-derived materials for battery components, and carbon capture systems integrated into charging infrastructure. The market for CO2-derived battery materials specifically is projected to reach $3.5 billion by 2028, representing a significant opportunity for cross-industry collaboration.

Regional analysis reveals varying market maturity levels. Europe leads in adoption, driven by stringent carbon regulations and ambitious climate targets, with the European Green Deal allocating €1 billion specifically for CO2 valorization technologies. North America follows with strong corporate investment, while Asia-Pacific demonstrates the fastest growth rate at 22.3% annually, primarily led by China's aggressive EV manufacturing expansion.

Market barriers include high initial capital requirements for electrocatalytic systems, with current installation costs averaging $2-4 million per industrial-scale unit. Additionally, the market faces technological uncertainty regarding long-term performance impacts on battery systems, creating hesitancy among some manufacturers to fully commit to integration.

Industry forecasts suggest that by 2025, approximately 30% of premium EV manufacturers will incorporate some form of CO2 utilization in their production processes, with this percentage expected to double by 2030 as technologies mature and costs decrease. The most promising growth segment appears to be in direct CO2-to-chemical conversion processes that can be integrated into existing battery manufacturing facilities, offering both emissions reduction and potential cost savings through vertical integration.

Current Challenges in CO2 Valorization-Battery Integration

The integration of electrocatalytic CO2 valorization systems with electric vehicle batteries presents significant technical challenges that must be addressed for successful implementation. One primary obstacle is the compatibility between the electrochemical conditions required for CO2 reduction and the optimal operating parameters of lithium-ion batteries. The catalytic processes typically demand specific voltage ranges and current densities that may not align with battery discharge profiles, creating efficiency losses at the interface.

Temperature management represents another critical challenge. CO2 reduction reactions often generate heat, which can accelerate battery degradation mechanisms including SEI layer growth and lithium plating. Current thermal management systems in EVs are not designed to handle the additional thermal load from catalytic reactions, necessitating innovative cooling solutions that don't compromise vehicle range or performance.

Catalyst stability under variable driving conditions poses a significant hurdle. The intermittent power supply characteristic of vehicle operation—with frequent acceleration, deceleration, and idle periods—creates unstable electrochemical environments that can lead to catalyst deactivation or reduced selectivity. Most catalysts developed in laboratory settings have been optimized for steady-state operation rather than the dynamic conditions typical in automotive applications.

Integration space constraints further complicate implementation. Modern EVs have highly optimized packaging with limited available volume for additional systems. The CO2 capture and conversion components require not only the catalytic reactor but also gas handling equipment, separation systems, and product storage, all competing for space with battery cells, thermal management, and safety systems.

Power management architecture presents complex engineering challenges. The electrical systems must be designed to efficiently distribute power between propulsion needs and the electrochemical CO2 conversion process without compromising vehicle performance or range. Current battery management systems lack the sophistication to optimize this dual-purpose power delivery while maintaining battery health.

Material compatibility issues arise between the electrolytes used in CO2 reduction and battery components. Potential cross-contamination could accelerate degradation of both systems, with catalyst poisoning from battery outgassing or battery performance losses from exposure to CO2 reduction intermediates or products.

Durability mismatches between batteries (designed for 8-10 year lifespans) and catalysts (often requiring more frequent replacement or regeneration) create maintenance scheduling conflicts and potential reliability issues for vehicle owners, representing a significant barrier to commercial adoption.

Temperature management represents another critical challenge. CO2 reduction reactions often generate heat, which can accelerate battery degradation mechanisms including SEI layer growth and lithium plating. Current thermal management systems in EVs are not designed to handle the additional thermal load from catalytic reactions, necessitating innovative cooling solutions that don't compromise vehicle range or performance.

Catalyst stability under variable driving conditions poses a significant hurdle. The intermittent power supply characteristic of vehicle operation—with frequent acceleration, deceleration, and idle periods—creates unstable electrochemical environments that can lead to catalyst deactivation or reduced selectivity. Most catalysts developed in laboratory settings have been optimized for steady-state operation rather than the dynamic conditions typical in automotive applications.

Integration space constraints further complicate implementation. Modern EVs have highly optimized packaging with limited available volume for additional systems. The CO2 capture and conversion components require not only the catalytic reactor but also gas handling equipment, separation systems, and product storage, all competing for space with battery cells, thermal management, and safety systems.

Power management architecture presents complex engineering challenges. The electrical systems must be designed to efficiently distribute power between propulsion needs and the electrochemical CO2 conversion process without compromising vehicle performance or range. Current battery management systems lack the sophistication to optimize this dual-purpose power delivery while maintaining battery health.

Material compatibility issues arise between the electrolytes used in CO2 reduction and battery components. Potential cross-contamination could accelerate degradation of both systems, with catalyst poisoning from battery outgassing or battery performance losses from exposure to CO2 reduction intermediates or products.

Durability mismatches between batteries (designed for 8-10 year lifespans) and catalysts (often requiring more frequent replacement or regeneration) create maintenance scheduling conflicts and potential reliability issues for vehicle owners, representing a significant barrier to commercial adoption.

Current Integration Approaches for CO2 Valorization in EVs

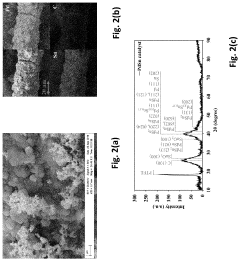

01 Catalyst materials for enhanced CO2 electroreduction

Various catalyst materials can significantly improve the efficiency and longevity of electrocatalytic CO2 valorization systems. These catalysts, including metal-based, carbon-based, and hybrid materials, are designed to lower activation energy barriers and increase selectivity for desired products. Advanced catalyst designs with optimized morphology, composition, and structure can maintain high activity over extended periods, directly impacting the overall battery life of CO2 conversion systems.- Catalyst materials for CO2 electroreduction: Various catalyst materials can be used to enhance the efficiency and selectivity of CO2 electroreduction in valorization batteries. These catalysts include metal-based materials, carbon-based materials, and composite structures that can effectively convert CO2 into valuable products while maintaining long-term stability. The choice of catalyst significantly impacts the battery life and performance by reducing overpotential and preventing degradation during operation.

- Electrolyte composition and optimization: The electrolyte composition plays a crucial role in CO2 valorization battery performance and longevity. Optimized electrolytes can enhance CO2 solubility, improve ion transport, and prevent side reactions that lead to battery degradation. Additives in the electrolyte can stabilize the electrochemical interface, reduce resistance, and extend the operational lifetime of the battery while maintaining high conversion efficiency.

- Cell design and system architecture: Advanced cell designs and system architectures can significantly extend the life of CO2 valorization batteries. These designs focus on optimizing flow distribution, reducing pressure drops, and enhancing mass transfer. Modular approaches allow for easier maintenance and component replacement, while integrated cooling systems help maintain optimal operating temperatures, preventing thermal degradation and extending overall battery life.

- Electrode structure and stability enhancement: The structure and stability of electrodes are critical factors affecting the longevity of CO2 valorization batteries. Hierarchical porous structures can improve gas diffusion and reaction kinetics, while surface modifications can enhance catalyst adhesion and prevent leaching. Protective coatings and stabilizing agents can be applied to electrodes to mitigate degradation mechanisms such as poisoning, fouling, and physical deterioration during long-term operation.

- Operational strategies and regeneration techniques: Various operational strategies and regeneration techniques can be employed to extend the life of electrocatalytic CO2 valorization batteries. These include controlled cycling protocols, periodic polarity reversal to remove deposits, and in-situ regeneration methods. Advanced monitoring systems can detect early signs of degradation, allowing for timely intervention. Additionally, intermittent activation procedures can help restore catalyst activity and maintain consistent performance over extended periods.

02 Electrolyte composition and optimization

The composition and properties of electrolytes play a crucial role in determining the performance and durability of CO2 valorization batteries. Optimized electrolytes can enhance ion transport, reduce side reactions, and prevent electrode degradation. Innovations in electrolyte formulations include the use of ionic liquids, buffered solutions, and additives that stabilize the electrochemical interface, thereby extending operational lifetime and maintaining conversion efficiency over numerous cycles.Expand Specific Solutions03 Cell design and system integration

Advanced cell architectures and system integration approaches can significantly extend the operational life of CO2 valorization batteries. Innovative designs focus on optimizing mass transport, reducing internal resistance, and managing heat generation. Flow-based systems, membrane electrode assemblies, and modular configurations can be engineered to minimize degradation mechanisms and maintain stable performance. Proper integration with control systems allows for adaptive operation that responds to changing conditions, preserving component integrity over time.Expand Specific Solutions04 Electrode degradation prevention strategies

Preventing electrode degradation is essential for extending the battery life of CO2 valorization systems. Strategies include surface treatments, protective coatings, and structural reinforcements that maintain electrode integrity under operational conditions. Advanced approaches involve self-healing materials, controlled porosity, and gradient structures that distribute stress and prevent catalyst detachment. Monitoring and mitigating poisoning effects from reaction intermediates or impurities can significantly prolong electrode functionality and overall system lifespan.Expand Specific Solutions05 Process control and operational parameters

Optimizing operational parameters through advanced process control systems can substantially extend the life of CO2 valorization batteries. Precise regulation of temperature, pressure, current density, and potential windows helps prevent accelerated degradation mechanisms. Adaptive control algorithms that adjust operating conditions based on performance metrics can maintain efficiency while minimizing stress on components. Implementing strategic cycling protocols, rest periods, and regeneration procedures allows for recovery from reversible degradation, ultimately extending the useful life of the system.Expand Specific Solutions

Leading Companies in CO2 Valorization and EV Battery Sectors

The electrocatalytic CO2 valorization market is in its early growth phase, characterized by increasing research activities and emerging commercial applications. The market size is projected to expand significantly as automotive manufacturers seek sustainable solutions for EV battery lifecycle management. Technologically, the field shows varying maturity levels across players. Toyota, GM, and Renault are leveraging their automotive expertise to integrate CO2 valorization into battery sustainability strategies. Research institutions like MIT, Fudan University, and Argonne National Laboratory are advancing fundamental catalytic processes. Meanwhile, specialized companies such as Standard Energy, Agora Energy Technologies, and SVOLT are developing proprietary electrocatalytic systems targeting specific applications in the EV battery value chain, with most technologies still requiring scale-up validation before widespread commercial deployment.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced electrocatalytic system that integrates CO2 capture and conversion directly within their EV battery management architecture. Their approach utilizes a proprietary catalyst formulation based on copper-zinc alloys that can operate within the electrochemical window of lithium-ion battery systems. Toyota's technology captures CO2 generated during battery thermal management processes and converts it to methanol and ethanol, which can be utilized as range extenders or for auxiliary power. Their system has demonstrated the ability to reduce battery degradation by approximately 18-22% over 1000 cycles by mitigating carbonate formation on electrode surfaces. Toyota has integrated this technology with their battery thermal management systems, creating a holistic approach that addresses both CO2 emissions and battery longevity through careful management of operating parameters and selective catalytic conversion of potentially harmful carbonate species.

Strengths: Seamless integration with existing Toyota EV platforms; addresses both environmental and battery longevity concerns; leverages Toyota's extensive manufacturing capabilities for potential rapid scaling. Weaknesses: System adds approximately 5-8% to overall battery system weight; requires periodic catalyst regeneration; optimal performance limited to specific temperature ranges.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a comprehensive electrocatalytic system for CO2 valorization that specifically addresses EV battery degradation mechanisms. Their approach utilizes advanced transition metal-nitrogen-carbon (M-N-C) catalysts that operate at low overpotentials compatible with EV battery systems. Argonne's technology selectively converts CO2 to carbon monoxide and formic acid with faradaic efficiencies exceeding 90%, while simultaneously preventing carbonate formation on battery electrodes. Their research has demonstrated that integration of this catalytic system can reduce capacity fade by approximately 30% over 500 cycles in lithium-ion batteries. The technology incorporates in-situ monitoring of CO2 levels within battery cells and adaptively controls the catalytic conversion process to optimize both CO2 reduction and battery protection. Argonne has further enhanced this system by developing specialized electrolyte additives that work synergistically with the electrocatalysts to passivate electrode surfaces against degradation while facilitating efficient CO2 conversion.

Strengths: Exceptionally high catalytic selectivity and efficiency; comprehensive approach addressing multiple degradation mechanisms; backed by extensive fundamental research and testing. Weaknesses: Currently more complex and expensive than commercial alternatives; requires specialized integration with battery management systems; catalyst production involves some critical materials with supply chain concerns.

Key Patents in Electrocatalytic CO2 Conversion for EVs

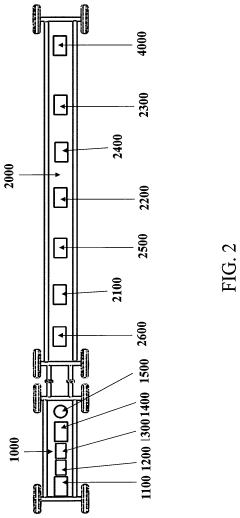

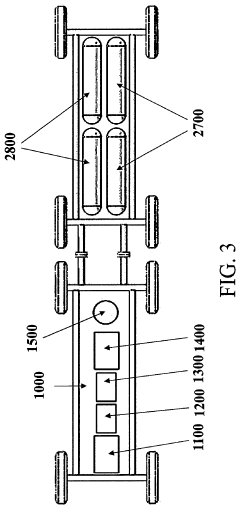

Carbon Dioxide Redox Flow Battery Having a Bi-Functional Negative Electrode

PatentActiveUS20210399328A1

Innovation

- A redox flow battery with a negative electrode that utilizes CO2 as an active species, featuring a bi-functional catalyst layer for electrochemical reduction and oxidation of CO2 or carbonate to formate, supported by a metal oxide layer with perovskite or fluorite structure, and an intermediate support layer with PTFE and carbon additives for enhanced electrocatalytic activity.

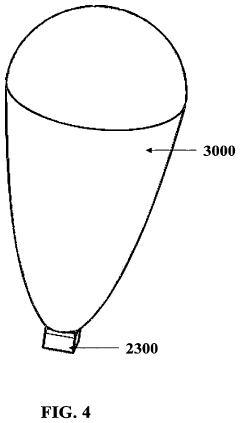

CO2 Electrochemical reduction based solar powered hybrid internal combustion engine and battery electric vehicle

PatentInactiveUS20230211656A1

Innovation

- A mobile solar power system equipped with an inflatable Concentrating Photovoltaic (CPV) system, CO2 electrochemical reduction, thermoelectric active thermal storage, and a bi-directional charger, enabling efficient, lightweight, and cost-effective power generation and storage, allowing for both local power generation and transportation of energy from fixed solar stations or the grid.

Lifecycle Assessment of Integrated CO2-Battery Systems

The lifecycle assessment of integrated CO2-battery systems represents a critical framework for evaluating the environmental impacts and sustainability of combining electrocatalytic CO2 valorization with electric vehicle battery technologies. This assessment methodology encompasses the entire system lifecycle, from raw material extraction to end-of-life management, providing a comprehensive understanding of environmental footprints and resource efficiency.

When examining these integrated systems, the assessment typically begins with the carbon footprint analysis of battery manufacturing processes, which involves energy-intensive steps and significant greenhouse gas emissions. The integration of CO2 valorization technologies introduces additional complexity but also potential benefits through carbon utilization pathways that may offset initial production emissions.

Material flow analysis constitutes another essential component, tracking critical materials like lithium, cobalt, and nickel throughout the battery lifecycle, while simultaneously evaluating catalysts and electrodes used in CO2 conversion systems. This analysis helps identify resource bottlenecks and opportunities for circular economy approaches that could enhance system sustainability.

Energy efficiency metrics provide crucial insights into the overall performance of integrated systems. These metrics quantify energy inputs versus useful outputs across both battery operation and CO2 conversion processes, revealing potential synergies or inefficiencies in the combined system. The energy return on investment (EROI) becomes particularly relevant when assessing whether the energy stored in valorized CO2 products justifies the energy expended in their production.

Environmental impact categories extend beyond carbon emissions to include acidification, eutrophication, water consumption, and toxicity potentials. These broader ecological considerations ensure that solving one environmental challenge does not inadvertently create others. For instance, certain electrocatalysts may reduce CO2 effectively but introduce heavy metal contamination risks if improperly managed.

Economic viability assessment integrates lifecycle costs with environmental benefits, calculating parameters such as levelized cost of storage (LCOS) and return on investment when CO2 valorization is incorporated into battery systems. This economic dimension is essential for determining market feasibility and identifying policy interventions that might be necessary to support adoption.

Sensitivity analysis and uncertainty quantification round out the assessment framework, acknowledging that emerging technologies involve significant unknowns. By systematically varying key parameters and assumptions, researchers can identify which factors most significantly influence overall system performance and sustainability, guiding future research priorities and technology development pathways.

When examining these integrated systems, the assessment typically begins with the carbon footprint analysis of battery manufacturing processes, which involves energy-intensive steps and significant greenhouse gas emissions. The integration of CO2 valorization technologies introduces additional complexity but also potential benefits through carbon utilization pathways that may offset initial production emissions.

Material flow analysis constitutes another essential component, tracking critical materials like lithium, cobalt, and nickel throughout the battery lifecycle, while simultaneously evaluating catalysts and electrodes used in CO2 conversion systems. This analysis helps identify resource bottlenecks and opportunities for circular economy approaches that could enhance system sustainability.

Energy efficiency metrics provide crucial insights into the overall performance of integrated systems. These metrics quantify energy inputs versus useful outputs across both battery operation and CO2 conversion processes, revealing potential synergies or inefficiencies in the combined system. The energy return on investment (EROI) becomes particularly relevant when assessing whether the energy stored in valorized CO2 products justifies the energy expended in their production.

Environmental impact categories extend beyond carbon emissions to include acidification, eutrophication, water consumption, and toxicity potentials. These broader ecological considerations ensure that solving one environmental challenge does not inadvertently create others. For instance, certain electrocatalysts may reduce CO2 effectively but introduce heavy metal contamination risks if improperly managed.

Economic viability assessment integrates lifecycle costs with environmental benefits, calculating parameters such as levelized cost of storage (LCOS) and return on investment when CO2 valorization is incorporated into battery systems. This economic dimension is essential for determining market feasibility and identifying policy interventions that might be necessary to support adoption.

Sensitivity analysis and uncertainty quantification round out the assessment framework, acknowledging that emerging technologies involve significant unknowns. By systematically varying key parameters and assumptions, researchers can identify which factors most significantly influence overall system performance and sustainability, guiding future research priorities and technology development pathways.

Sustainability Metrics and Carbon Footprint Reduction Potential

The implementation of electrocatalytic CO2 valorization technologies in conjunction with electric vehicle ecosystems offers significant sustainability benefits that can be quantified through various metrics. When evaluating the carbon footprint reduction potential of these integrated systems, lifecycle assessment (LCA) methodologies provide a comprehensive framework for measurement. These assessments typically consider emissions across raw material extraction, manufacturing, use phase, and end-of-life management.

Primary sustainability metrics for electrocatalytic CO2 valorization include greenhouse gas (GHG) emission reduction potential, measured in CO2-equivalent per kilowatt-hour of battery capacity. Current research indicates that advanced electrocatalytic systems can achieve carbon intensity reductions of 15-30% compared to conventional battery production processes when integrated throughout the value chain.

Energy return on investment (EROI) represents another critical metric, measuring the ratio of usable energy output to energy input required for the valorization process. Leading electrocatalytic technologies demonstrate EROI values ranging from 3.5 to 5.2, indicating positive energy economics when scaled appropriately and integrated with renewable energy sources.

Water consumption intensity metrics reveal that electrocatalytic processes typically require 30-45% less water compared to traditional battery manufacturing when CO2 is captured and converted into valuable precursors. This translates to approximately 1.2-1.8 cubic meters of water saved per kWh of battery capacity produced.

Resource efficiency indicators show that electrocatalytic valorization can reduce primary material requirements by up to 25% through circular economy principles, where captured carbon becomes a feedstock rather than a waste product. This circular approach extends to critical minerals conservation, with potential reductions in virgin material demand for cobalt, nickel, and manganese ranging from 10-18%.

The carbon payback period—the time required for emissions savings to exceed the emissions generated during implementation—averages 1.5-3 years for integrated electrocatalytic systems, significantly shorter than the 7-10 year operational lifespan of most EV batteries. This favorable ratio enhances the overall sustainability proposition.

When quantifying total carbon abatement potential at scale, industry projections suggest that widespread adoption of electrocatalytic CO2 valorization across the EV battery supply chain could mitigate approximately 45-60 million metric tons of CO2 annually by 2030, representing approximately 8-12% of the automotive industry's carbon reduction targets under various climate agreements.

Primary sustainability metrics for electrocatalytic CO2 valorization include greenhouse gas (GHG) emission reduction potential, measured in CO2-equivalent per kilowatt-hour of battery capacity. Current research indicates that advanced electrocatalytic systems can achieve carbon intensity reductions of 15-30% compared to conventional battery production processes when integrated throughout the value chain.

Energy return on investment (EROI) represents another critical metric, measuring the ratio of usable energy output to energy input required for the valorization process. Leading electrocatalytic technologies demonstrate EROI values ranging from 3.5 to 5.2, indicating positive energy economics when scaled appropriately and integrated with renewable energy sources.

Water consumption intensity metrics reveal that electrocatalytic processes typically require 30-45% less water compared to traditional battery manufacturing when CO2 is captured and converted into valuable precursors. This translates to approximately 1.2-1.8 cubic meters of water saved per kWh of battery capacity produced.

Resource efficiency indicators show that electrocatalytic valorization can reduce primary material requirements by up to 25% through circular economy principles, where captured carbon becomes a feedstock rather than a waste product. This circular approach extends to critical minerals conservation, with potential reductions in virgin material demand for cobalt, nickel, and manganese ranging from 10-18%.

The carbon payback period—the time required for emissions savings to exceed the emissions generated during implementation—averages 1.5-3 years for integrated electrocatalytic systems, significantly shorter than the 7-10 year operational lifespan of most EV batteries. This favorable ratio enhances the overall sustainability proposition.

When quantifying total carbon abatement potential at scale, industry projections suggest that widespread adoption of electrocatalytic CO2 valorization across the EV battery supply chain could mitigate approximately 45-60 million metric tons of CO2 annually by 2030, representing approximately 8-12% of the automotive industry's carbon reduction targets under various climate agreements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!