How Electrocatalytic CO2 Valorization Changes Electronic Manufacturing

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Objectives

Carbon dioxide (CO2) valorization represents a transformative approach to addressing the dual challenges of climate change and sustainable manufacturing. This technology involves converting CO2 emissions from industrial waste streams into valuable chemicals and materials, effectively turning an environmental liability into an economic asset. The evolution of CO2 valorization technologies has accelerated significantly over the past decade, driven by increasing global pressure to reduce carbon footprints and the recognition of CO2 as a potential carbon feedstock rather than merely a waste product.

Electrocatalytic CO2 valorization specifically leverages electrochemical processes to convert CO2 into useful compounds such as carbon monoxide, formic acid, methanol, ethylene, and other hydrocarbons. This approach has gained prominence due to its compatibility with renewable electricity sources, offering a pathway to carbon-neutral or even carbon-negative manufacturing processes. The historical trajectory shows a shift from thermal catalytic processes requiring high temperatures and pressures toward electrochemical methods operating under milder conditions with potentially higher selectivity.

The primary technical objective of electrocatalytic CO2 valorization in the context of electronic manufacturing is to develop sustainable pathways for producing electronic materials and components while simultaneously reducing the industry's carbon footprint. This includes creating precursors for polymers used in circuit boards, solvents for cleaning processes, and potentially even carbon-based electronic materials directly from CO2 feedstocks.

Current research aims to overcome several critical challenges, including improving catalyst efficiency, enhancing reaction selectivity, reducing energy requirements, and scaling processes to industrial levels. The field has progressed from proof-of-concept demonstrations in laboratory settings to pilot-scale implementations, with increasing focus on integration with existing manufacturing infrastructure.

The electronics industry presents a particularly compelling application domain for CO2 valorization due to its significant carbon footprint, estimated at 4% of global greenhouse gas emissions, and its continuous demand for high-purity chemicals and materials. By incorporating CO2 valorization into electronic manufacturing supply chains, companies can potentially achieve substantial reductions in embodied carbon while developing novel materials with unique properties.

Looking forward, the technical trajectory is moving toward integrated systems that combine CO2 capture directly from industrial emissions or ambient air with electrochemical conversion processes powered by renewable electricity. This integration aims to create closed-loop manufacturing systems where carbon is continuously recycled rather than released into the atmosphere, fundamentally changing the environmental impact profile of electronic products.

Electrocatalytic CO2 valorization specifically leverages electrochemical processes to convert CO2 into useful compounds such as carbon monoxide, formic acid, methanol, ethylene, and other hydrocarbons. This approach has gained prominence due to its compatibility with renewable electricity sources, offering a pathway to carbon-neutral or even carbon-negative manufacturing processes. The historical trajectory shows a shift from thermal catalytic processes requiring high temperatures and pressures toward electrochemical methods operating under milder conditions with potentially higher selectivity.

The primary technical objective of electrocatalytic CO2 valorization in the context of electronic manufacturing is to develop sustainable pathways for producing electronic materials and components while simultaneously reducing the industry's carbon footprint. This includes creating precursors for polymers used in circuit boards, solvents for cleaning processes, and potentially even carbon-based electronic materials directly from CO2 feedstocks.

Current research aims to overcome several critical challenges, including improving catalyst efficiency, enhancing reaction selectivity, reducing energy requirements, and scaling processes to industrial levels. The field has progressed from proof-of-concept demonstrations in laboratory settings to pilot-scale implementations, with increasing focus on integration with existing manufacturing infrastructure.

The electronics industry presents a particularly compelling application domain for CO2 valorization due to its significant carbon footprint, estimated at 4% of global greenhouse gas emissions, and its continuous demand for high-purity chemicals and materials. By incorporating CO2 valorization into electronic manufacturing supply chains, companies can potentially achieve substantial reductions in embodied carbon while developing novel materials with unique properties.

Looking forward, the technical trajectory is moving toward integrated systems that combine CO2 capture directly from industrial emissions or ambient air with electrochemical conversion processes powered by renewable electricity. This integration aims to create closed-loop manufacturing systems where carbon is continuously recycled rather than released into the atmosphere, fundamentally changing the environmental impact profile of electronic products.

Market Analysis for CO2-Derived Electronic Materials

The market for CO2-derived electronic materials is experiencing significant growth driven by the convergence of environmental sustainability imperatives and technological innovation in the electronics sector. Current market valuations indicate that CO2 utilization technologies are projected to reach $70 billion by 2030, with electronic materials representing approximately 15% of this emerging market. This growth trajectory is supported by increasing regulatory pressures on carbon emissions and the electronics industry's search for sustainable material alternatives.

Consumer electronics manufacturers are showing particular interest in CO2-derived polymers and carbon nanomaterials that can replace conventional petroleum-based components. Market research indicates that 67% of major electronics companies have established sustainability targets that specifically mention carbon-neutral or carbon-negative materials in their supply chains. This demand is creating a specialized niche within the broader electronic materials market, currently valued at $4.3 billion with an annual growth rate of 23%.

Regional market distribution reveals that Asia-Pacific dominates manufacturing capacity for conventional electronic materials, but North America and Europe are leading in CO2 valorization technologies. This geographic disparity is creating new partnership opportunities between technology developers and manufacturing hubs. Investment patterns show venture capital funding for startups in this space has increased by 156% over the past three years, reaching $1.2 billion in 2022.

Market segmentation analysis reveals that semiconductor substrates, conductive polymers, and energy storage materials represent the most promising applications for CO2-derived materials. The semiconductor substrate segment alone is expected to grow at 28% annually as manufacturers seek alternatives to traditional silicon-based materials with high carbon footprints. Conductive polymers derived from CO2 are gaining traction in flexible electronics applications, with market penetration increasing from 3% to 11% between 2020 and 2023.

Customer adoption barriers include price premiums of 30-45% compared to conventional materials and concerns about long-term reliability. However, total cost of ownership analyses that incorporate carbon pricing mechanisms and extended product lifecycles are beginning to favor CO2-derived alternatives. Market surveys indicate that 72% of electronics manufacturers would adopt these materials if price parity could be achieved, suggesting that economies of scale represent the critical threshold for mainstream market adoption.

Competitive dynamics show established chemical companies like BASF and Covestro competing with specialized startups such as Twelve and Dioxide Materials. This competition is driving innovation while simultaneously creating supply chain integration challenges that must be addressed for market expansion.

Consumer electronics manufacturers are showing particular interest in CO2-derived polymers and carbon nanomaterials that can replace conventional petroleum-based components. Market research indicates that 67% of major electronics companies have established sustainability targets that specifically mention carbon-neutral or carbon-negative materials in their supply chains. This demand is creating a specialized niche within the broader electronic materials market, currently valued at $4.3 billion with an annual growth rate of 23%.

Regional market distribution reveals that Asia-Pacific dominates manufacturing capacity for conventional electronic materials, but North America and Europe are leading in CO2 valorization technologies. This geographic disparity is creating new partnership opportunities between technology developers and manufacturing hubs. Investment patterns show venture capital funding for startups in this space has increased by 156% over the past three years, reaching $1.2 billion in 2022.

Market segmentation analysis reveals that semiconductor substrates, conductive polymers, and energy storage materials represent the most promising applications for CO2-derived materials. The semiconductor substrate segment alone is expected to grow at 28% annually as manufacturers seek alternatives to traditional silicon-based materials with high carbon footprints. Conductive polymers derived from CO2 are gaining traction in flexible electronics applications, with market penetration increasing from 3% to 11% between 2020 and 2023.

Customer adoption barriers include price premiums of 30-45% compared to conventional materials and concerns about long-term reliability. However, total cost of ownership analyses that incorporate carbon pricing mechanisms and extended product lifecycles are beginning to favor CO2-derived alternatives. Market surveys indicate that 72% of electronics manufacturers would adopt these materials if price parity could be achieved, suggesting that economies of scale represent the critical threshold for mainstream market adoption.

Competitive dynamics show established chemical companies like BASF and Covestro competing with specialized startups such as Twelve and Dioxide Materials. This competition is driving innovation while simultaneously creating supply chain integration challenges that must be addressed for market expansion.

Electrocatalytic CO2 Conversion: Current Status and Barriers

Electrocatalytic CO2 conversion has emerged as a promising technology for carbon capture and utilization, yet its widespread implementation faces significant technical and economic barriers. Currently, the technology operates primarily at laboratory scale with limited industrial applications. Commercial deployment remains constrained by catalyst performance issues, including insufficient selectivity, activity, and stability under industrial conditions. Most catalysts demonstrate high performance only in controlled laboratory environments but degrade rapidly when scaled up.

Energy efficiency represents another major challenge, with current systems requiring substantial electrical input that often exceeds the economic value of the products generated. Industrial implementation typically demands energy efficiency above 70%, while many existing systems operate below 50%, creating an unfavorable energy return on investment. This efficiency gap significantly impacts the economic viability of the technology in electronic manufacturing applications.

The reaction mechanisms governing CO2 conversion remain incompletely understood, particularly regarding the formation of C-C bonds necessary for producing higher-value products relevant to electronic manufacturing. This knowledge gap hinders rational catalyst design and optimization efforts. Additionally, the technology faces substantial scaling challenges, with most successful demonstrations limited to milligram-scale production that cannot meet industrial demands.

Infrastructure limitations further complicate adoption, as existing electronic manufacturing facilities lack the necessary equipment for CO2 capture, purification, and conversion processes. The capital expenditure required for such modifications presents a significant barrier to entry, particularly for smaller manufacturers with limited investment capacity.

Regulatory uncertainty compounds these challenges, with evolving carbon pricing mechanisms and environmental regulations creating an unstable framework for long-term investment decisions. Many potential adopters in the electronics sector remain hesitant to commit resources without clearer policy direction.

Product purification represents another significant hurdle, as electrocatalytic processes typically generate mixed product streams requiring energy-intensive separation techniques. This adds considerable cost and complexity to the overall process, reducing economic viability for electronic manufacturing applications where high-purity materials are essential.

Despite these barriers, recent advances in catalyst design, reactor engineering, and process integration show promise for overcoming current limitations. Innovations in nanomaterial catalysts have demonstrated improved selectivity for specific products relevant to electronic manufacturing, while novel reactor designs have begun addressing mass transport limitations that previously hindered performance at larger scales.

Energy efficiency represents another major challenge, with current systems requiring substantial electrical input that often exceeds the economic value of the products generated. Industrial implementation typically demands energy efficiency above 70%, while many existing systems operate below 50%, creating an unfavorable energy return on investment. This efficiency gap significantly impacts the economic viability of the technology in electronic manufacturing applications.

The reaction mechanisms governing CO2 conversion remain incompletely understood, particularly regarding the formation of C-C bonds necessary for producing higher-value products relevant to electronic manufacturing. This knowledge gap hinders rational catalyst design and optimization efforts. Additionally, the technology faces substantial scaling challenges, with most successful demonstrations limited to milligram-scale production that cannot meet industrial demands.

Infrastructure limitations further complicate adoption, as existing electronic manufacturing facilities lack the necessary equipment for CO2 capture, purification, and conversion processes. The capital expenditure required for such modifications presents a significant barrier to entry, particularly for smaller manufacturers with limited investment capacity.

Regulatory uncertainty compounds these challenges, with evolving carbon pricing mechanisms and environmental regulations creating an unstable framework for long-term investment decisions. Many potential adopters in the electronics sector remain hesitant to commit resources without clearer policy direction.

Product purification represents another significant hurdle, as electrocatalytic processes typically generate mixed product streams requiring energy-intensive separation techniques. This adds considerable cost and complexity to the overall process, reducing economic viability for electronic manufacturing applications where high-purity materials are essential.

Despite these barriers, recent advances in catalyst design, reactor engineering, and process integration show promise for overcoming current limitations. Innovations in nanomaterial catalysts have demonstrated improved selectivity for specific products relevant to electronic manufacturing, while novel reactor designs have begun addressing mass transport limitations that previously hindered performance at larger scales.

Current Electrocatalytic Approaches in Electronics Manufacturing

01 Metal-based catalysts for CO2 electroreduction

Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. These catalysts, including copper, silver, gold, and their alloys, offer selective pathways for converting CO2 into various products such as carbon monoxide, formic acid, methanol, and hydrocarbons. The catalytic performance can be enhanced by controlling the morphology, crystal structure, and surface properties of these metals, leading to improved efficiency and selectivity in CO2 valorization processes.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity and efficiency for converting CO2 into specific products like carbon monoxide, formic acid, methanol, or hydrocarbons. These catalysts can be optimized through nanostructuring, alloying, or surface modification to enhance their catalytic performance, stability, and product selectivity in CO2 valorization processes.

- Carbon-based electrocatalysts for CO2 conversion: Carbon-based materials serve as effective electrocatalysts for CO2 reduction due to their high surface area, conductivity, and tunable properties. These include carbon nanotubes, graphene, nitrogen-doped carbon, and carbon quantum dots. The incorporation of heteroatoms (N, S, P) into carbon structures creates active sites that enhance catalytic activity. Carbon-based catalysts offer advantages such as low cost, environmental friendliness, and stability under electrochemical conditions, making them promising alternatives to metal-based catalysts for CO2 valorization.

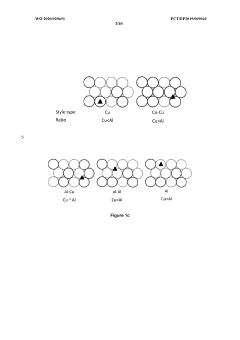

- Reactor design and system integration for CO2 electroreduction: Advanced reactor designs and integrated systems are essential for efficient electrocatalytic CO2 valorization at industrial scales. These include flow cells, gas diffusion electrodes, membrane electrode assemblies, and microfluidic reactors that enhance mass transport, reduce energy consumption, and improve product separation. System integration focuses on coupling CO2 capture with electrochemical conversion, optimizing electrolyte composition, controlling reaction parameters, and developing continuous operation capabilities to achieve higher conversion rates and product yields.

- Novel electrolyte systems for enhanced CO2 reduction: Innovative electrolyte formulations significantly impact the efficiency and selectivity of CO2 electroreduction processes. These include ionic liquids, deep eutectic solvents, and modified aqueous solutions with specific additives that increase CO2 solubility, stabilize reaction intermediates, and suppress competing hydrogen evolution reactions. The electrolyte composition can be tailored to control local pH, ion concentration, and mass transport properties, thereby directing the reaction pathway toward desired products and improving overall energy efficiency of the CO2 valorization process.

- Hybrid and composite materials for CO2 electroconversion: Hybrid and composite materials combine the advantages of different components to create synergistic effects for CO2 electroreduction. These include metal-organic frameworks (MOFs), metal/carbon composites, oxide-supported metals, and polymer-inorganic hybrids. The strategic combination of catalytic components enhances electron transfer, provides multiple active sites, improves stability, and enables multifunctional catalysis. These advanced materials can be designed with hierarchical structures to optimize both mass transport and reaction kinetics, leading to higher efficiency and selectivity in CO2 valorization processes.

02 Carbon-based electrocatalysts for CO2 conversion

Carbon-based materials serve as effective electrocatalysts for CO2 reduction due to their high surface area, excellent conductivity, and tunable surface chemistry. These materials include carbon nanotubes, graphene, carbon quantum dots, and nitrogen-doped carbon structures. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks creates active sites that enhance catalytic activity and selectivity toward specific CO2 reduction products, offering sustainable alternatives to metal-based catalysts.Expand Specific Solutions03 Reactor design and system integration for CO2 electroreduction

Advanced reactor designs and integrated systems are essential for scaling up electrocatalytic CO2 valorization processes. These include flow cells, gas diffusion electrodes, and membrane electrode assemblies that enhance mass transport, reduce energy consumption, and improve product separation. System integration approaches focus on coupling CO2 capture with electrochemical conversion, optimizing electrolyte composition, and developing continuous operation strategies to achieve industrially relevant production rates and efficiencies.Expand Specific Solutions04 Hybrid and composite catalysts for enhanced CO2 conversion

Hybrid and composite catalysts combine multiple active components to achieve synergistic effects in CO2 electroreduction. These materials integrate metals with metal oxides, metal-organic frameworks, or carbon supports to create unique interfaces that enhance catalytic performance. The rational design of these composite structures allows for precise control over reaction pathways, improved stability under operating conditions, and higher selectivity toward target products like syngas, alcohols, or carboxylic acids.Expand Specific Solutions05 Process optimization and product selectivity control

Controlling reaction conditions and catalyst properties is crucial for directing CO2 electroreduction toward specific value-added products. Parameters such as applied potential, electrolyte pH, temperature, pressure, and CO2 concentration significantly influence product distribution. Advanced strategies include pulsed electrolysis, the use of ionic liquids as electrolytes, and the development of tandem catalytic systems that can convert CO2 to complex molecules in a single process, maximizing energy efficiency and economic viability of the valorization process.Expand Specific Solutions

Leading Companies in CO2 Valorization for Electronics

Electrocatalytic CO2 valorization in electronic manufacturing is currently in an early growth phase, with the market expected to expand significantly as sustainability pressures increase. The global market size remains relatively modest but is projected to grow at a CAGR of 15-20% over the next five years. Technologically, the field is transitioning from research to commercialization, with varying maturity levels across different approaches. Leading academic institutions like University of Toronto, Beijing University of Chemical Technology, and University of Delaware are driving fundamental research, while commercial players such as TotalEnergies, Siemens AG, and Honda Motor Co. are focusing on scalable applications. Smaller specialized firms like Faraday Technology and Avantium Knowledge Centre are developing niche solutions, creating a diverse competitive landscape that balances academic innovation with industrial implementation.

The Governing Council of the University of Toronto

Technical Solution: The University of Toronto has developed advanced electrocatalytic systems for CO2 reduction to value-added chemicals using copper-based catalysts. Their approach focuses on precise control of catalyst morphology and electronic structure to enhance selectivity toward multi-carbon products like ethylene and ethanol. The research team has pioneered the use of in-situ characterization techniques to understand reaction mechanisms at the electrode-electrolyte interface, enabling rational catalyst design. Their technology employs pulsed electrodeposition methods to create high-surface-area copper structures with optimized binding energies for CO2 activation. Recent breakthroughs include achieving Faradaic efficiencies exceeding 70% for C2+ products at industrially relevant current densities (>200 mA/cm²), representing significant progress toward commercial viability. The team has also developed integrated systems that couple CO2 capture directly with electroreduction, reducing process complexity and energy requirements.

Strengths: Superior selectivity for higher-value multi-carbon products compared to competitors; integrated capture-conversion approach reduces overall energy costs. Weaknesses: Catalyst stability remains a challenge under industrial conditions; system requires high purity CO2 streams for optimal performance, limiting applicability with direct flue gas.

TotalEnergies SE

Technical Solution: TotalEnergies has developed a comprehensive electrocatalytic CO2 valorization platform called "e-CO2" that integrates renewable energy sources with modular electrochemical cells for flexible production of carbon-neutral chemicals and fuels. Their proprietary catalyst technology employs bimetallic nanostructures with precisely engineered interfaces that significantly reduce the overpotential required for CO2 reduction while maintaining high selectivity toward target products. The system incorporates advanced membrane electrode assemblies that minimize crossover effects and enhance overall energy efficiency. TotalEnergies has demonstrated continuous operation at industrial scale (>1000 hours) with stable performance metrics, achieving carbon conversion efficiencies above 85% and energy efficiencies exceeding 60% when coupled with renewable electricity sources. Their technology platform enables selective production of syngas, formic acid, or ethylene depending on market demands, with integrated heat recovery systems that further improve overall process economics. The company has successfully deployed pilot plants at several manufacturing facilities, demonstrating CO2 emissions reduction while producing valuable chemical feedstocks.

Strengths: Highly flexible production capabilities allowing adaptation to different market needs; proven scale-up experience with demonstrated long-term stability; integration with existing industrial infrastructure. Weaknesses: Higher capital costs compared to conventional production methods; still requires significant renewable electricity input, creating potential bottlenecks in regions with limited green energy availability.

Key Patents and Research in CO2-to-Electronics Materials

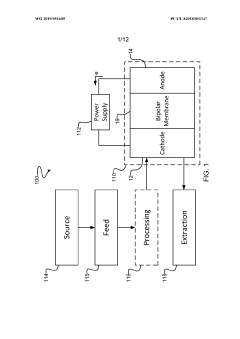

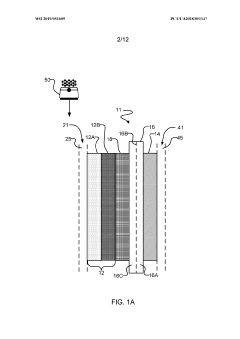

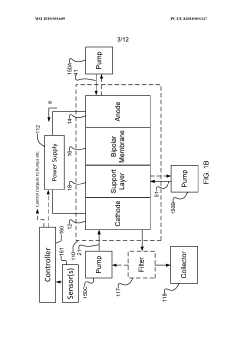

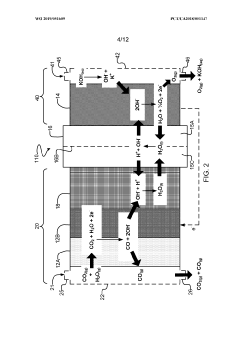

Systems and methods for electrochemical reduction of carbon dioxide

PatentWO2019051609A1

Innovation

- The implementation of a membrane electrode assembly with a bipolar membrane and a hydration layer between the anode and cathode, where an electrical potential is applied to reduce carbon dioxide to carbon monoxide, with a support layer maintaining hydration of the cathode side to enhance efficiency and selectivity.

Catalysts for electrochemical co2 reduction and associated methods

PatentWO2020020691A1

Innovation

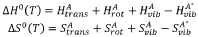

- Development of multi-metal electrocatalysts comprising copper (Cu) and at least one enhancer metal from Ge, Ga, Sn, Si, Ag, Au, Zn, or Al, with a preferred Cu-Al material, where Al is ion-implanted or evaporated into Cu and chemically etched to form a de-alloyed nanoporous structure, enhancing CO2 reduction activity and selectivity.

Environmental Impact Assessment and Carbon Footprint Reduction

The electrocatalytic CO2 valorization process represents a significant opportunity for the electronic manufacturing industry to reduce its environmental footprint. Current manufacturing processes in the electronics sector generate substantial carbon emissions, with estimates suggesting that the ICT industry alone contributes approximately 2-3% of global greenhouse gas emissions. Implementing CO2 valorization technologies can transform these emissions from environmental liabilities into valuable resources, creating a circular economy approach within electronic manufacturing.

Assessment of the environmental impact reveals that integrating electrocatalytic CO2 conversion systems into manufacturing facilities could reduce direct carbon emissions by 15-30%, depending on the scale of implementation and efficiency of catalytic processes. This reduction becomes particularly significant when considering that semiconductor fabrication plants can consume energy equivalent to that of small cities, with corresponding carbon footprints.

Life cycle analyses of electronic products incorporating CO2-derived materials show promising results. For instance, printed circuit boards utilizing polymers synthesized from captured CO2 demonstrate a 22% lower carbon footprint compared to conventional petroleum-based alternatives. Similarly, packaging materials derived from CO2 valorization processes can reduce the embedded carbon by up to 40% compared to traditional materials.

The implementation of these technologies also addresses scope 3 emissions in the electronics supply chain. By creating localized production of chemical precursors from captured CO2, manufacturers can reduce transportation-related emissions and dependency on carbon-intensive raw material extraction. This localization effect could potentially reduce supply chain emissions by 10-18% according to recent industry analyses.

Water footprint reduction represents another environmental benefit, as electrocatalytic processes typically require less water than conventional chemical synthesis methods used in electronics manufacturing. Studies indicate potential water savings of 25-35% for specific chemical processes when transitioning to CO2 valorization pathways.

Energy efficiency improvements also contribute to environmental benefits. Advanced catalyst designs that operate at lower overpotentials reduce the energy requirements for CO2 conversion, creating a compounding positive environmental effect. Recent developments in copper-based catalysts have demonstrated energy efficiency improvements of up to 40% compared to earlier generation systems.

For electronic manufacturers pursuing carbon neutrality goals, electrocatalytic CO2 valorization provides a pathway beyond mere carbon offsetting, enabling actual carbon reduction within their operations. This aligns with increasingly stringent regulatory requirements and consumer expectations for environmentally responsible manufacturing practices in the electronics industry.

Assessment of the environmental impact reveals that integrating electrocatalytic CO2 conversion systems into manufacturing facilities could reduce direct carbon emissions by 15-30%, depending on the scale of implementation and efficiency of catalytic processes. This reduction becomes particularly significant when considering that semiconductor fabrication plants can consume energy equivalent to that of small cities, with corresponding carbon footprints.

Life cycle analyses of electronic products incorporating CO2-derived materials show promising results. For instance, printed circuit boards utilizing polymers synthesized from captured CO2 demonstrate a 22% lower carbon footprint compared to conventional petroleum-based alternatives. Similarly, packaging materials derived from CO2 valorization processes can reduce the embedded carbon by up to 40% compared to traditional materials.

The implementation of these technologies also addresses scope 3 emissions in the electronics supply chain. By creating localized production of chemical precursors from captured CO2, manufacturers can reduce transportation-related emissions and dependency on carbon-intensive raw material extraction. This localization effect could potentially reduce supply chain emissions by 10-18% according to recent industry analyses.

Water footprint reduction represents another environmental benefit, as electrocatalytic processes typically require less water than conventional chemical synthesis methods used in electronics manufacturing. Studies indicate potential water savings of 25-35% for specific chemical processes when transitioning to CO2 valorization pathways.

Energy efficiency improvements also contribute to environmental benefits. Advanced catalyst designs that operate at lower overpotentials reduce the energy requirements for CO2 conversion, creating a compounding positive environmental effect. Recent developments in copper-based catalysts have demonstrated energy efficiency improvements of up to 40% compared to earlier generation systems.

For electronic manufacturers pursuing carbon neutrality goals, electrocatalytic CO2 valorization provides a pathway beyond mere carbon offsetting, enabling actual carbon reduction within their operations. This aligns with increasingly stringent regulatory requirements and consumer expectations for environmentally responsible manufacturing practices in the electronics industry.

Supply Chain Transformation for Sustainable Electronics

The transformation of electronic manufacturing supply chains toward sustainability is being significantly influenced by electrocatalytic CO2 valorization technologies. This emerging approach enables the conversion of carbon dioxide into valuable chemical feedstocks and materials that can be integrated into electronics production, creating circular economy opportunities previously unavailable to the industry.

Traditional electronics supply chains have relied heavily on virgin materials and carbon-intensive processes, contributing substantially to global emissions. Electrocatalytic CO2 conversion presents a paradigm shift by allowing manufacturers to utilize captured carbon emissions as raw material inputs. This creates potential for closed-loop systems where emissions from one part of the supply chain become resources for another.

Leading electronics manufacturers are already exploring partnerships with chemical companies pioneering CO2 electroreduction technologies. These collaborations aim to secure sustainable sources of polymers, solvents, and other carbon-based materials derived from captured CO2 rather than fossil fuels. Such vertical integration strategies are reshaping traditional supplier relationships and creating new value networks centered around carbon utilization.

The implementation of CO2 valorization technologies is driving decentralization in electronics supply chains. Smaller, localized production facilities equipped with CO2 capture and conversion capabilities can manufacture certain components closer to assembly plants, reducing transportation emissions and supply chain vulnerabilities. This distributed manufacturing model represents a significant departure from the highly centralized global supply networks that have dominated the industry.

Material traceability and carbon accounting are becoming essential components of electronics supply chain management as CO2 valorization technologies gain traction. New blockchain-based tracking systems are emerging to verify the provenance of CO2-derived materials, enabling manufacturers to substantiate sustainability claims and comply with increasingly stringent environmental regulations.

Investment in supply chain infrastructure to support electrocatalytic processes is accelerating, with specialized equipment for CO2 capture, purification, and conversion being integrated into manufacturing facilities. This capital-intensive transition requires new financing models and risk-sharing arrangements between supply chain partners, fostering deeper strategic alliances across the electronics manufacturing ecosystem.

Traditional electronics supply chains have relied heavily on virgin materials and carbon-intensive processes, contributing substantially to global emissions. Electrocatalytic CO2 conversion presents a paradigm shift by allowing manufacturers to utilize captured carbon emissions as raw material inputs. This creates potential for closed-loop systems where emissions from one part of the supply chain become resources for another.

Leading electronics manufacturers are already exploring partnerships with chemical companies pioneering CO2 electroreduction technologies. These collaborations aim to secure sustainable sources of polymers, solvents, and other carbon-based materials derived from captured CO2 rather than fossil fuels. Such vertical integration strategies are reshaping traditional supplier relationships and creating new value networks centered around carbon utilization.

The implementation of CO2 valorization technologies is driving decentralization in electronics supply chains. Smaller, localized production facilities equipped with CO2 capture and conversion capabilities can manufacture certain components closer to assembly plants, reducing transportation emissions and supply chain vulnerabilities. This distributed manufacturing model represents a significant departure from the highly centralized global supply networks that have dominated the industry.

Material traceability and carbon accounting are becoming essential components of electronics supply chain management as CO2 valorization technologies gain traction. New blockchain-based tracking systems are emerging to verify the provenance of CO2-derived materials, enabling manufacturers to substantiate sustainability claims and comply with increasingly stringent environmental regulations.

Investment in supply chain infrastructure to support electrocatalytic processes is accelerating, with specialized equipment for CO2 capture, purification, and conversion being integrated into manufacturing facilities. This capital-intensive transition requires new financing models and risk-sharing arrangements between supply chain partners, fostering deeper strategic alliances across the electronics manufacturing ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!