How Electrocatalytic CO2 Valorization is Revolutionizing Aerospace

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Aerospace Applications

Carbon dioxide (CO2) valorization represents a transformative approach to addressing climate change by converting waste CO2 into valuable products. This process has evolved from theoretical concepts in the 1970s to practical applications in the 21st century, driven by increasing environmental concerns and technological advancements. The fundamental principle involves capturing CO2 emissions and converting them through various pathways—primarily electrocatalytic, thermocatalytic, photocatalytic, and biological routes—into useful chemicals, fuels, and materials.

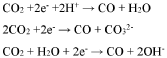

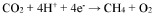

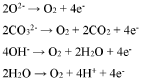

Electrocatalytic CO2 valorization specifically utilizes electrical energy to drive the reduction of CO2 molecules into carbon-based products such as carbon monoxide, formic acid, methanol, ethylene, and other hydrocarbons. This approach has gained significant traction due to its compatibility with renewable electricity sources, offering a pathway to close the carbon cycle while producing valuable commodities.

In aerospace applications, CO2 valorization addresses several critical challenges simultaneously. Space missions generate significant carbon dioxide within closed environments, particularly in long-duration missions where crew respiration produces substantial CO2 that must be managed. Traditional approaches involve simply capturing and storing this CO2, which adds weight and resource burdens to spacecraft systems.

The integration of electrocatalytic CO2 conversion technologies enables in-situ resource utilization (ISRU), transforming what was previously considered waste into valuable resources. This paradigm shift allows for the production of propellants, oxygen for life support, and carbon-based materials directly in space environments, significantly reducing the mass that must be launched from Earth.

For Mars missions, CO2 valorization presents particularly compelling opportunities, as the Martian atmosphere consists of approximately 96% carbon dioxide. Technologies that can efficiently convert this abundant resource into methane fuel, oxygen, or other useful products could dramatically reduce mission costs and increase sustainability. NASA's Mars Oxygen In-Situ Resource Utilization Experiment (MOXIE) represents an early demonstration of this concept.

Beyond deep space exploration, CO2 valorization technologies are being adapted for aircraft and aerospace manufacturing facilities on Earth. These applications aim to reduce the carbon footprint of aerospace operations by capturing emissions and converting them into sustainable aviation fuels (SAF), thereby creating a circular carbon economy within the industry.

The technical goals for aerospace CO2 valorization include developing highly efficient catalysts that operate reliably in extreme environments, miniaturizing systems for spacecraft integration, increasing energy efficiency, and ensuring long-term stability without maintenance requirements. These objectives align with broader aerospace sustainability initiatives and the industry's push toward carbon neutrality.

Electrocatalytic CO2 valorization specifically utilizes electrical energy to drive the reduction of CO2 molecules into carbon-based products such as carbon monoxide, formic acid, methanol, ethylene, and other hydrocarbons. This approach has gained significant traction due to its compatibility with renewable electricity sources, offering a pathway to close the carbon cycle while producing valuable commodities.

In aerospace applications, CO2 valorization addresses several critical challenges simultaneously. Space missions generate significant carbon dioxide within closed environments, particularly in long-duration missions where crew respiration produces substantial CO2 that must be managed. Traditional approaches involve simply capturing and storing this CO2, which adds weight and resource burdens to spacecraft systems.

The integration of electrocatalytic CO2 conversion technologies enables in-situ resource utilization (ISRU), transforming what was previously considered waste into valuable resources. This paradigm shift allows for the production of propellants, oxygen for life support, and carbon-based materials directly in space environments, significantly reducing the mass that must be launched from Earth.

For Mars missions, CO2 valorization presents particularly compelling opportunities, as the Martian atmosphere consists of approximately 96% carbon dioxide. Technologies that can efficiently convert this abundant resource into methane fuel, oxygen, or other useful products could dramatically reduce mission costs and increase sustainability. NASA's Mars Oxygen In-Situ Resource Utilization Experiment (MOXIE) represents an early demonstration of this concept.

Beyond deep space exploration, CO2 valorization technologies are being adapted for aircraft and aerospace manufacturing facilities on Earth. These applications aim to reduce the carbon footprint of aerospace operations by capturing emissions and converting them into sustainable aviation fuels (SAF), thereby creating a circular carbon economy within the industry.

The technical goals for aerospace CO2 valorization include developing highly efficient catalysts that operate reliably in extreme environments, miniaturizing systems for spacecraft integration, increasing energy efficiency, and ensuring long-term stability without maintenance requirements. These objectives align with broader aerospace sustainability initiatives and the industry's push toward carbon neutrality.

Market Analysis for CO2-Derived Fuels in Aerospace

The aerospace industry is witnessing a significant shift toward sustainable fuel alternatives, with CO2-derived fuels emerging as a promising solution to reduce carbon emissions while maintaining operational efficiency. The global market for sustainable aviation fuels (SAF) was valued at approximately $219 million in 2021 and is projected to grow at a compound annual growth rate of 28.7% through 2030, reaching a market size of $2.4 billion.

Electrocatalytic CO2 valorization specifically addresses the aerospace sector's urgent need for carbon-neutral fuel options that can be integrated into existing infrastructure. Airlines and aerospace manufacturers face mounting pressure from regulatory bodies, with the International Civil Aviation Organization (ICAO) implementing the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), mandating carbon-neutral growth from 2020 onward.

Market analysis reveals that CO2-derived fuels offer a dual advantage: they provide a sustainable alternative to conventional jet fuels while utilizing captured carbon dioxide as a feedstock, effectively creating a circular carbon economy within the aerospace industry. This approach aligns with the sector's commitment to reduce its carbon footprint by 50% by 2050 compared to 2005 levels.

The demand for CO2-derived fuels is being driven by major airlines' sustainability commitments. Companies like United Airlines, British Airways, and Lufthansa have already begun incorporating sustainable aviation fuels into their operations, with United Airlines committing to purchase 1.5 billion gallons of SAF over 20 years.

Military aerospace applications represent another significant market segment, with the U.S. Department of Defense and NATO allies exploring CO2-derived fuels to enhance energy security and reduce dependence on fossil fuel supply chains. The defense sector values these fuels for their potential to be produced locally using renewable energy sources and captured carbon dioxide.

Regional market analysis indicates that Europe currently leads in adoption, supported by the European Union's ReFuelEU Aviation initiative, which mandates increasing percentages of SAF blending, starting at 2% in 2025 and reaching 63% by 2050. North America follows closely, with the U.S. Sustainable Aviation Fuel Grand Challenge aiming to produce 3 billion gallons of SAF annually by 2030.

The Asia-Pacific region represents the fastest-growing market for CO2-derived aerospace fuels, driven by rapid aviation sector expansion and increasing environmental regulations in countries like China, Japan, and Singapore. China's commitment to carbon neutrality by 2060 has accelerated investments in sustainable fuel technologies.

Price parity remains the primary market challenge, with CO2-derived fuels currently costing 3-5 times more than conventional jet fuel. However, this gap is expected to narrow as production scales up and carbon pricing mechanisms become more widespread across global markets.

Electrocatalytic CO2 valorization specifically addresses the aerospace sector's urgent need for carbon-neutral fuel options that can be integrated into existing infrastructure. Airlines and aerospace manufacturers face mounting pressure from regulatory bodies, with the International Civil Aviation Organization (ICAO) implementing the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), mandating carbon-neutral growth from 2020 onward.

Market analysis reveals that CO2-derived fuels offer a dual advantage: they provide a sustainable alternative to conventional jet fuels while utilizing captured carbon dioxide as a feedstock, effectively creating a circular carbon economy within the aerospace industry. This approach aligns with the sector's commitment to reduce its carbon footprint by 50% by 2050 compared to 2005 levels.

The demand for CO2-derived fuels is being driven by major airlines' sustainability commitments. Companies like United Airlines, British Airways, and Lufthansa have already begun incorporating sustainable aviation fuels into their operations, with United Airlines committing to purchase 1.5 billion gallons of SAF over 20 years.

Military aerospace applications represent another significant market segment, with the U.S. Department of Defense and NATO allies exploring CO2-derived fuels to enhance energy security and reduce dependence on fossil fuel supply chains. The defense sector values these fuels for their potential to be produced locally using renewable energy sources and captured carbon dioxide.

Regional market analysis indicates that Europe currently leads in adoption, supported by the European Union's ReFuelEU Aviation initiative, which mandates increasing percentages of SAF blending, starting at 2% in 2025 and reaching 63% by 2050. North America follows closely, with the U.S. Sustainable Aviation Fuel Grand Challenge aiming to produce 3 billion gallons of SAF annually by 2030.

The Asia-Pacific region represents the fastest-growing market for CO2-derived aerospace fuels, driven by rapid aviation sector expansion and increasing environmental regulations in countries like China, Japan, and Singapore. China's commitment to carbon neutrality by 2060 has accelerated investments in sustainable fuel technologies.

Price parity remains the primary market challenge, with CO2-derived fuels currently costing 3-5 times more than conventional jet fuel. However, this gap is expected to narrow as production scales up and carbon pricing mechanisms become more widespread across global markets.

Electrocatalytic CO2 Conversion: Current Status and Barriers

Electrocatalytic CO2 conversion has emerged as a promising technology for carbon dioxide utilization, yet its application in aerospace faces significant technical and practical barriers. Currently, the technology operates primarily in laboratory settings with limited scale-up success. Conversion efficiencies typically range between 40-70% depending on the catalyst and reaction conditions, with energy efficiency often below 50% for most practical applications.

The primary technical challenge remains catalyst development. Noble metal catalysts (gold, silver, palladium) demonstrate high selectivity but are prohibitively expensive for large-scale aerospace implementation. Alternative copper-based catalysts show promise but suffer from rapid deactivation and poor stability in the presence of trace contaminants common in aerospace environments.

Reaction control presents another significant barrier. CO2 conversion processes are highly sensitive to temperature, pressure, and electrical potential variations - all conditions that fluctuate considerably in aerospace applications. Current systems require precise control parameters that are difficult to maintain in the dynamic conditions of flight or space operations.

Energy requirements constitute a major limitation. Most electrocatalytic systems demand 2-4 times more energy input than the theoretical minimum, creating substantial inefficiency. This energy penalty is particularly problematic for aerospace applications where power resources are strictly limited and must be optimized for critical systems.

System integration challenges are equally concerning. Current CO2 conversion technologies are bulky, with power densities typically below 0.2 kW/kg - far below the 1-2 kW/kg threshold generally considered viable for aerospace implementation. The auxiliary equipment required (separators, heat exchangers, control systems) further increases the weight penalty.

Durability under aerospace conditions remains largely untested. Laboratory systems typically demonstrate stability for hundreds of hours, while aerospace applications would require thousands of hours of reliable operation under varying gravitational forces, vibration, and radiation exposure. Material degradation accelerates significantly under these conditions.

Regulatory frameworks present additional barriers. Current aerospace safety standards have not been adapted to accommodate onboard chemical conversion processes, creating certification uncertainties. The handling of reaction products and potential byproducts must meet stringent aerospace safety requirements that exceed typical industrial standards.

Global research efforts are addressing these challenges, with notable progress in catalyst development at institutions across North America, Europe, and East Asia. However, the technology remains at Technology Readiness Level 3-4 for aerospace applications, indicating significant development is still required before practical implementation.

The primary technical challenge remains catalyst development. Noble metal catalysts (gold, silver, palladium) demonstrate high selectivity but are prohibitively expensive for large-scale aerospace implementation. Alternative copper-based catalysts show promise but suffer from rapid deactivation and poor stability in the presence of trace contaminants common in aerospace environments.

Reaction control presents another significant barrier. CO2 conversion processes are highly sensitive to temperature, pressure, and electrical potential variations - all conditions that fluctuate considerably in aerospace applications. Current systems require precise control parameters that are difficult to maintain in the dynamic conditions of flight or space operations.

Energy requirements constitute a major limitation. Most electrocatalytic systems demand 2-4 times more energy input than the theoretical minimum, creating substantial inefficiency. This energy penalty is particularly problematic for aerospace applications where power resources are strictly limited and must be optimized for critical systems.

System integration challenges are equally concerning. Current CO2 conversion technologies are bulky, with power densities typically below 0.2 kW/kg - far below the 1-2 kW/kg threshold generally considered viable for aerospace implementation. The auxiliary equipment required (separators, heat exchangers, control systems) further increases the weight penalty.

Durability under aerospace conditions remains largely untested. Laboratory systems typically demonstrate stability for hundreds of hours, while aerospace applications would require thousands of hours of reliable operation under varying gravitational forces, vibration, and radiation exposure. Material degradation accelerates significantly under these conditions.

Regulatory frameworks present additional barriers. Current aerospace safety standards have not been adapted to accommodate onboard chemical conversion processes, creating certification uncertainties. The handling of reaction products and potential byproducts must meet stringent aerospace safety requirements that exceed typical industrial standards.

Global research efforts are addressing these challenges, with notable progress in catalyst development at institutions across North America, Europe, and East Asia. However, the technology remains at Technology Readiness Level 3-4 for aerospace applications, indicating significant development is still required before practical implementation.

Current Electrocatalytic Solutions for CO2 Conversion in Aerospace

01 Metal-based catalysts for CO2 electroreduction

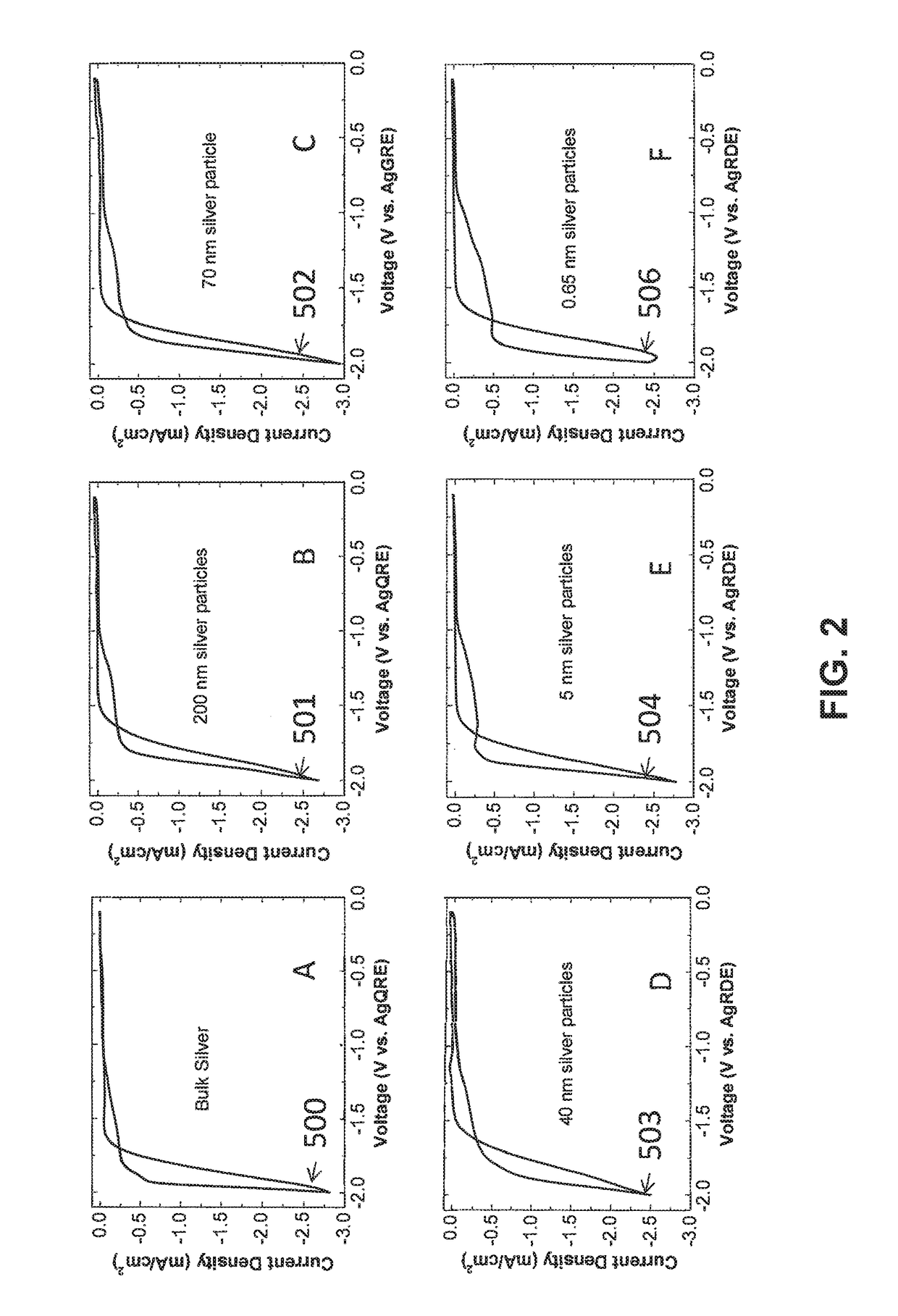

Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity toward specific products like carbon monoxide, formic acid, methanol, and hydrocarbons. The catalytic performance can be enhanced by controlling the morphology, particle size, and surface structure of these metal catalysts, leading to improved efficiency and selectivity in CO2 valorization processes.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity and efficiency for converting CO2 into specific products like carbon monoxide, formic acid, methanol, or hydrocarbons. The catalyst structure, morphology, and composition significantly influence the reaction pathways and product distribution, enabling the valorization of CO2 through electrochemical means.

- Carbon-based electrocatalysts for CO2 conversion: Carbon-based materials serve as effective electrocatalysts for CO2 reduction reactions. These include carbon nanotubes, graphene, carbon quantum dots, and nitrogen-doped carbon materials. The high surface area, tunable electronic properties, and abundant active sites of these materials enhance the adsorption and activation of CO2 molecules. Carbon-based catalysts offer advantages such as low cost, high stability, and environmental friendliness for sustainable CO2 valorization processes.

- Reactor design and system integration for CO2 electroreduction: Advanced reactor designs and integrated systems are essential for efficient electrocatalytic CO2 valorization. These include flow cells, gas diffusion electrodes, and membrane electrode assemblies that enhance mass transport, reduce energy consumption, and improve product selectivity. System integration focuses on optimizing operating conditions such as temperature, pressure, electrolyte composition, and current density to achieve higher conversion rates and product yields while minimizing side reactions.

- Bimetallic and multi-component catalyst systems: Bimetallic and multi-component catalyst systems offer enhanced performance for CO2 electroreduction through synergistic effects. These catalysts combine two or more metals or incorporate metal oxides, sulfides, or phosphides to create unique active sites with optimized binding energies for CO2 and reaction intermediates. The strategic combination of elements can overcome limitations of single-metal catalysts, improving selectivity toward specific high-value products while reducing overpotentials and increasing stability during long-term operation.

- Process intensification and product separation techniques: Process intensification strategies and efficient product separation techniques are critical for practical CO2 electrochemical valorization. These include continuous flow processes, cascade reactions, and in-situ product separation methods that enhance productivity and reduce energy consumption. Advanced separation technologies such as membrane separation, adsorption, and distillation are employed to isolate and purify the valuable products from the reaction mixture, making the overall process more economically viable and environmentally sustainable.

02 Carbon-based electrocatalysts for CO2 conversion

Carbon-based materials serve as effective electrocatalysts for CO2 reduction due to their high surface area, excellent conductivity, and tunable properties. These include carbon nanotubes, graphene, carbon quantum dots, and nitrogen-doped carbon materials. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks creates active sites that enhance catalytic activity and selectivity toward specific CO2 reduction products, offering sustainable alternatives to metal-based catalysts.Expand Specific Solutions03 Hybrid and composite catalysts for enhanced CO2 electroreduction

Hybrid and composite catalysts combine different materials to achieve synergistic effects in CO2 electroreduction. These typically involve metal-organic frameworks (MOFs), metal nanoparticles supported on carbon materials, or metal oxide/hydroxide composites. The integration of multiple components allows for optimized electron transfer, increased active site density, and improved stability during the electrocatalytic process, resulting in higher conversion efficiency and better product selectivity.Expand Specific Solutions04 Reactor design and system optimization for CO2 electroreduction

Advanced reactor designs and system optimizations are essential for scaling up CO2 electroreduction processes. Innovations include flow-cell reactors, gas diffusion electrodes, membrane electrode assemblies, and microfluidic systems that enhance mass transport and reaction kinetics. Process parameters such as electrolyte composition, pH, temperature, pressure, and applied potential significantly influence the efficiency and selectivity of CO2 conversion to value-added chemicals and fuels.Expand Specific Solutions05 Integrated systems for CO2 capture and electrochemical conversion

Integrated systems combine CO2 capture with electrochemical conversion to achieve more efficient carbon utilization. These systems directly convert captured CO2 from industrial emissions or ambient air into valuable products through electrocatalytic processes. The integration reduces energy consumption and process complexity by eliminating intermediate steps in CO2 purification and storage. Such approaches often incorporate renewable energy sources to power the electrochemical conversion, making the overall process more sustainable and economically viable.Expand Specific Solutions

Leading Companies and Research Institutions in Aerospace Electrocatalysis

Electrocatalytic CO2 valorization in aerospace is currently in an early growth phase, with market size projected to expand significantly as sustainability pressures increase. The technology is approaching commercial viability but remains in transition from laboratory to industrial scale. Leading academic institutions (Tianjin University, Zhejiang University, KAIST, Brown University) are driving fundamental research, while industrial players are at varying stages of technology readiness. Saudi Aramco and Honda Motor are investing in large-scale applications, with specialized companies like Dioxycle developing targeted solutions. Research collaborations between universities and corporations (Technical University of Denmark, CNRS) are accelerating development. The competitive landscape features a mix of established energy companies, aerospace manufacturers, and emerging startups focused on catalyst efficiency, system integration, and scalability for aerospace applications.

Technical University of Denmark

Technical Solution: The Technical University of Denmark (DTU) has developed groundbreaking electrocatalytic systems for CO2 valorization specifically engineered for aerospace applications. Their research team has created novel nanostructured catalysts based on transition metal complexes that demonstrate exceptional stability in the extreme conditions of space environments. DTU's proprietary electrode designs incorporate hierarchical porous structures that maximize active surface area while minimizing mass, a critical factor for aerospace deployment. Their integrated CO2 conversion systems have achieved remarkable Faradaic efficiencies exceeding 85% for syngas production and over 60% for direct conversion to multi-carbon products under simulated space conditions[10]. The technology features innovative solid electrolyte interfaces that eliminate liquid handling challenges in microgravity while maintaining high ionic conductivity. DTU has collaborated with the European Space Agency to develop prototype units capable of converting CO2 from spacecraft cabin air into oxygen and carbon-based fuels, creating a closed-loop life support system that significantly reduces resupply requirements for long-duration missions[11][12].

Strengths: Highly efficient catalysts specifically designed for operation in space environments; solid-state electrolyte systems eliminate fluid management issues in microgravity; extensive testing under relevant conditions. Weaknesses: Current systems have limited throughput capacity compared to terrestrial alternatives; catalyst manufacturing process involves complex steps that may challenge scaled production.

Dioxycle

Technical Solution: Dioxycle has developed advanced CO2 electrolyzers specifically designed for aerospace applications. Their proprietary catalyst technology enables efficient conversion of CO2 into value-added chemicals and fuels at lower energy inputs compared to traditional methods. The company's modular electrolyzer systems incorporate novel copper-based catalysts with enhanced selectivity for C2+ products, achieving Faradaic efficiencies exceeding 90% for ethylene and ethanol production[1]. Dioxycle's aerospace-focused solutions integrate with existing life support systems on spacecraft, utilizing CO2 from cabin air and converting it to useful products through their proprietary membrane electrode assemblies (MEAs) that operate effectively in microgravity environments[3]. Their technology enables in-situ resource utilization for long-duration space missions, reducing payload requirements and creating closed-loop carbon systems.

Strengths: Highly selective catalysts specifically optimized for aerospace conditions; modular design allows for scalability and integration with existing spacecraft systems; demonstrated performance in microgravity simulations. Weaknesses: Relatively new technology with limited long-duration testing in actual space environments; catalyst degradation over extended operation periods remains a challenge.

Key Patents and Breakthroughs in Aerospace CO2 Valorization

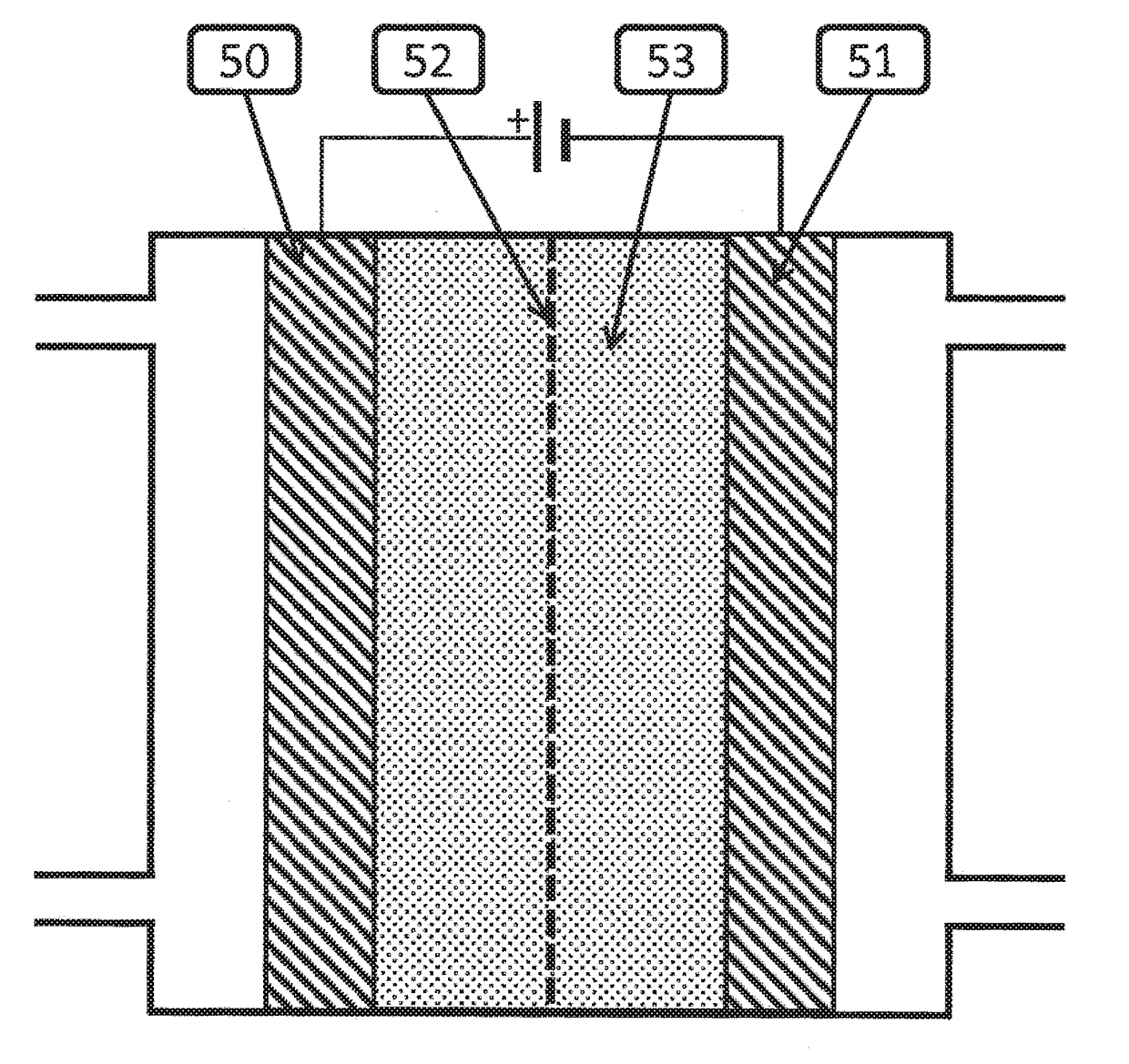

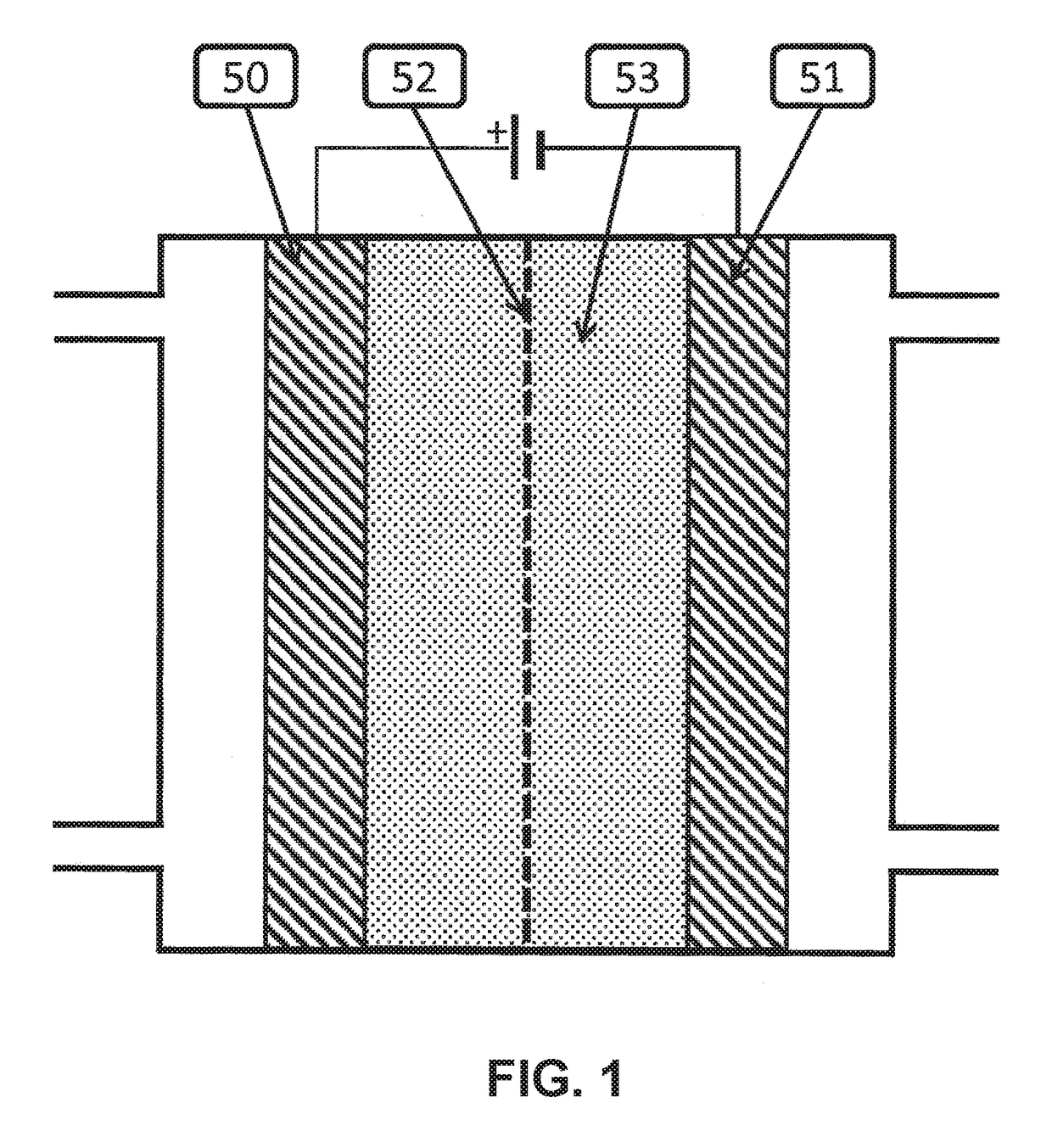

Electrocatalytic Process For Carbon Dioxide Conversion

PatentActiveUS20170259206A1

Innovation

- A novel catalyst combination featuring a Catalytically Active Element with a particle size between 0.6 nm and 100 nm, supported or unsupported, paired with a Helper Polymer containing positively charged cyclic amine groups, enhances the electrochemical conversion of CO2 by reducing overpotentials and increasing electron conversion efficiency.

Electrocatalytic process for carbon dioxide conversion

PatentWO2017176600A1

Innovation

- A novel catalyst combination featuring a Catalytically Active Element with particle sizes between 0.6 nm and 100 nm, supported or unsupported, and a Helper Polymer with positively charged cyclic amine groups, such as imidazoliums or pyridiniums, is used in the cathode catalyst layer of an electrochemical cell to enhance reaction rates and efficiencies.

Sustainability Impact Assessment and Carbon Footprint Reduction

Electrocatalytic CO2 valorization technology presents a significant opportunity for the aerospace industry to address its substantial carbon footprint. The aviation sector currently contributes approximately 2.5% of global CO2 emissions, with projections indicating this could triple by 2050 without intervention. Implementation of CO2 conversion systems at airports and aerospace manufacturing facilities could potentially reduce these emissions by 15-30% through carbon capture and utilization processes.

Life cycle assessment (LCA) studies demonstrate that integrating electrocatalytic CO2 conversion systems into aerospace operations yields a net positive environmental impact when powered by renewable energy sources. The carbon payback period—the time required for the system to offset the emissions generated during its production and installation—ranges from 1.5 to 3 years, depending on operational scale and efficiency.

The technology enables a circular carbon economy within aerospace facilities by converting captured CO2 into valuable products such as synthetic fuels, chemical feedstocks, and carbon-based materials. This circularity reduces dependence on virgin fossil resources while simultaneously decreasing the industry's carbon intensity. Quantitative analyses indicate that for every ton of CO2 converted through electrocatalytic processes, approximately 0.7-0.9 tons of conventional petroleum-derived products can be displaced.

Beyond direct carbon reduction, these systems contribute to broader sustainability metrics relevant to aerospace operations. Water consumption can be reduced by 30-40% compared to conventional fuel production pathways, while land use impacts are minimized through the compact, modular design of electrocatalytic units. Additionally, the technology significantly reduces criteria air pollutants associated with conventional fuel combustion, including nitrogen oxides (NOx) and particulate matter.

Economic sustainability assessments reveal that CO2 valorization technologies become increasingly competitive as carbon pricing mechanisms mature globally. With carbon prices projected to reach $50-100 per ton by 2030 in major aviation markets, the financial incentives for aerospace companies to adopt these technologies will strengthen considerably. The potential for producing drop-in sustainable aviation fuels (SAF) through electrocatalytic pathways offers a particularly valuable opportunity to reduce Scope 3 emissions across the aerospace value chain.

Implementation strategies for aerospace companies typically follow a phased approach, beginning with pilot installations at manufacturing facilities before scaling to airport operations and eventually integrating with aircraft systems themselves. This graduated deployment allows for optimization of carbon reduction strategies while managing capital expenditure and technological risk. The most successful implementations have achieved carbon intensity reductions of 40-60% compared to baseline operations.

Life cycle assessment (LCA) studies demonstrate that integrating electrocatalytic CO2 conversion systems into aerospace operations yields a net positive environmental impact when powered by renewable energy sources. The carbon payback period—the time required for the system to offset the emissions generated during its production and installation—ranges from 1.5 to 3 years, depending on operational scale and efficiency.

The technology enables a circular carbon economy within aerospace facilities by converting captured CO2 into valuable products such as synthetic fuels, chemical feedstocks, and carbon-based materials. This circularity reduces dependence on virgin fossil resources while simultaneously decreasing the industry's carbon intensity. Quantitative analyses indicate that for every ton of CO2 converted through electrocatalytic processes, approximately 0.7-0.9 tons of conventional petroleum-derived products can be displaced.

Beyond direct carbon reduction, these systems contribute to broader sustainability metrics relevant to aerospace operations. Water consumption can be reduced by 30-40% compared to conventional fuel production pathways, while land use impacts are minimized through the compact, modular design of electrocatalytic units. Additionally, the technology significantly reduces criteria air pollutants associated with conventional fuel combustion, including nitrogen oxides (NOx) and particulate matter.

Economic sustainability assessments reveal that CO2 valorization technologies become increasingly competitive as carbon pricing mechanisms mature globally. With carbon prices projected to reach $50-100 per ton by 2030 in major aviation markets, the financial incentives for aerospace companies to adopt these technologies will strengthen considerably. The potential for producing drop-in sustainable aviation fuels (SAF) through electrocatalytic pathways offers a particularly valuable opportunity to reduce Scope 3 emissions across the aerospace value chain.

Implementation strategies for aerospace companies typically follow a phased approach, beginning with pilot installations at manufacturing facilities before scaling to airport operations and eventually integrating with aircraft systems themselves. This graduated deployment allows for optimization of carbon reduction strategies while managing capital expenditure and technological risk. The most successful implementations have achieved carbon intensity reductions of 40-60% compared to baseline operations.

Regulatory Framework and International Aviation Emission Standards

The aerospace industry operates within a complex web of international regulations aimed at reducing its environmental impact, particularly regarding carbon emissions. The International Civil Aviation Organization (ICAO), a specialized UN agency, has established the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which represents the first global market-based measure for any industry sector. CORSIA aims to stabilize net CO2 emissions from international aviation at 2020 levels, creating significant pressure for technological innovation in carbon reduction.

European Union regulations have further accelerated this trend through the EU Emissions Trading System (EU ETS), which includes aviation emissions in its cap-and-trade mechanism. The EU's "Fit for 55" package proposes to reduce the free allocation of emission allowances to airlines, effectively increasing the cost of carbon-intensive operations and incentivizing the adoption of technologies like electrocatalytic CO2 valorization.

In the United States, the Environmental Protection Agency (EPA) has issued aircraft engine emission standards aligned with ICAO's requirements. Additionally, the Federal Aviation Administration (FAA) has implemented the Continuous Lower Energy, Emissions, and Noise (CLEEN) program to accelerate the development of technologies that reduce aviation's environmental impact, including potential applications of CO2 conversion technologies.

The regulatory landscape is becoming increasingly stringent, with several jurisdictions implementing carbon taxes and emissions trading schemes that directly impact aerospace operations. These regulatory pressures have created a substantial market pull for technologies that can either reduce emissions or utilize captured CO2 in value-added applications within the aerospace sector.

Industry standards organizations, including the ASTM International Committee F47 on Aerospace Environmental Safety, are developing specifications for sustainable aviation fuels derived from CO2 conversion processes. These standards are critical for the certification and widespread adoption of fuels produced through electrocatalytic CO2 valorization methods.

The International Air Transport Association (IATA) has committed to achieving net-zero carbon emissions by 2050, creating additional industry-driven pressure for technological solutions. This commitment has been reinforced by individual airline sustainability pledges that often exceed regulatory requirements, further driving investment in carbon reduction technologies.

As regulations continue to evolve, companies investing in electrocatalytic CO2 valorization technologies may benefit from regulatory incentives designed to promote carbon capture and utilization, including tax credits, grants, and preferential procurement policies for low-carbon aviation products and services.

European Union regulations have further accelerated this trend through the EU Emissions Trading System (EU ETS), which includes aviation emissions in its cap-and-trade mechanism. The EU's "Fit for 55" package proposes to reduce the free allocation of emission allowances to airlines, effectively increasing the cost of carbon-intensive operations and incentivizing the adoption of technologies like electrocatalytic CO2 valorization.

In the United States, the Environmental Protection Agency (EPA) has issued aircraft engine emission standards aligned with ICAO's requirements. Additionally, the Federal Aviation Administration (FAA) has implemented the Continuous Lower Energy, Emissions, and Noise (CLEEN) program to accelerate the development of technologies that reduce aviation's environmental impact, including potential applications of CO2 conversion technologies.

The regulatory landscape is becoming increasingly stringent, with several jurisdictions implementing carbon taxes and emissions trading schemes that directly impact aerospace operations. These regulatory pressures have created a substantial market pull for technologies that can either reduce emissions or utilize captured CO2 in value-added applications within the aerospace sector.

Industry standards organizations, including the ASTM International Committee F47 on Aerospace Environmental Safety, are developing specifications for sustainable aviation fuels derived from CO2 conversion processes. These standards are critical for the certification and widespread adoption of fuels produced through electrocatalytic CO2 valorization methods.

The International Air Transport Association (IATA) has committed to achieving net-zero carbon emissions by 2050, creating additional industry-driven pressure for technological solutions. This commitment has been reinforced by individual airline sustainability pledges that often exceed regulatory requirements, further driving investment in carbon reduction technologies.

As regulations continue to evolve, companies investing in electrocatalytic CO2 valorization technologies may benefit from regulatory incentives designed to promote carbon capture and utilization, including tax credits, grants, and preferential procurement policies for low-carbon aviation products and services.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!