Electrocatalytic CO2 Valorization: Standards and Qualifications

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Valorization Background and Objectives

Carbon dioxide (CO2) valorization represents a transformative approach to addressing climate change by converting waste CO2 into valuable products. This technology has evolved significantly over the past decades, from theoretical concepts to practical applications across various industries. The electrocatalytic pathway for CO2 conversion has emerged as particularly promising due to its potential integration with renewable energy sources, creating a sustainable carbon cycle that reduces net emissions while producing commercially viable products.

The historical trajectory of CO2 valorization began in the 1970s with basic research into carbon dioxide reduction reactions. However, significant advancements only materialized in the early 2000s when climate change concerns intensified and technological capabilities improved. The field has since experienced accelerated development, with breakthrough catalysts and electrochemical systems emerging in the past decade that dramatically improve conversion efficiency and product selectivity.

Current technological trends indicate a shift toward more efficient multi-carbon product formation, improved catalyst stability, and integrated systems that combine capture and conversion processes. The integration of artificial intelligence for catalyst discovery and process optimization represents another significant trend that is reshaping research approaches in this domain.

The primary objective of electrocatalytic CO2 valorization is to develop economically viable and environmentally sustainable processes that can operate at industrial scales. Specific technical goals include achieving high Faradaic efficiency (>90%), substantial current densities (>200 mA/cm²), extended catalyst stability (>1000 hours), and selective production of targeted high-value chemicals.

Additionally, the field aims to establish standardized testing protocols and qualification criteria that enable meaningful comparison between different catalytic systems and technologies. This standardization is crucial for accelerating commercialization efforts and ensuring that laboratory successes translate to industrial implementation.

From an environmental perspective, the technology seeks to create a circular carbon economy where CO2 is viewed as a renewable feedstock rather than a waste product. The ultimate goal is to develop systems that can be powered by renewable electricity, thereby creating carbon-neutral or even carbon-negative production pathways for chemicals and fuels that are currently derived from fossil resources.

The interdisciplinary nature of this field necessitates collaboration between electrochemists, materials scientists, chemical engineers, and environmental scientists to overcome the complex challenges involved in scaling laboratory discoveries to commercial applications.

The historical trajectory of CO2 valorization began in the 1970s with basic research into carbon dioxide reduction reactions. However, significant advancements only materialized in the early 2000s when climate change concerns intensified and technological capabilities improved. The field has since experienced accelerated development, with breakthrough catalysts and electrochemical systems emerging in the past decade that dramatically improve conversion efficiency and product selectivity.

Current technological trends indicate a shift toward more efficient multi-carbon product formation, improved catalyst stability, and integrated systems that combine capture and conversion processes. The integration of artificial intelligence for catalyst discovery and process optimization represents another significant trend that is reshaping research approaches in this domain.

The primary objective of electrocatalytic CO2 valorization is to develop economically viable and environmentally sustainable processes that can operate at industrial scales. Specific technical goals include achieving high Faradaic efficiency (>90%), substantial current densities (>200 mA/cm²), extended catalyst stability (>1000 hours), and selective production of targeted high-value chemicals.

Additionally, the field aims to establish standardized testing protocols and qualification criteria that enable meaningful comparison between different catalytic systems and technologies. This standardization is crucial for accelerating commercialization efforts and ensuring that laboratory successes translate to industrial implementation.

From an environmental perspective, the technology seeks to create a circular carbon economy where CO2 is viewed as a renewable feedstock rather than a waste product. The ultimate goal is to develop systems that can be powered by renewable electricity, thereby creating carbon-neutral or even carbon-negative production pathways for chemicals and fuels that are currently derived from fossil resources.

The interdisciplinary nature of this field necessitates collaboration between electrochemists, materials scientists, chemical engineers, and environmental scientists to overcome the complex challenges involved in scaling laboratory discoveries to commercial applications.

Market Analysis for CO2 Conversion Products

The global market for CO2 conversion products is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The market size for CO2-derived products was valued at approximately $2.5 billion in 2022 and is projected to reach $8.6 billion by 2030, representing a compound annual growth rate (CAGR) of 16.7%. This growth trajectory reflects the expanding industrial interest in carbon capture and utilization (CCU) technologies as viable pathways toward carbon neutrality.

Among CO2 conversion products, methanol currently dominates the market share, accounting for roughly 40% of the total market value. This is primarily due to its versatility as a chemical feedstock and potential as a clean fuel alternative. Formic acid and carbon monoxide follow with market shares of 25% and 15% respectively, while emerging products such as ethylene and syngas collectively represent the remaining 20%.

Geographically, Europe leads the market with approximately 35% share, driven by stringent carbon regulations and substantial government investments in green technologies. North America follows at 30%, with Asia-Pacific rapidly gaining ground at 25% and expected to demonstrate the fastest growth rate over the next decade due to increasing industrialization coupled with growing environmental awareness.

Key market drivers include tightening carbon emission regulations worldwide, rising carbon pricing mechanisms, and growing corporate commitments to carbon neutrality. The European Union's Carbon Border Adjustment Mechanism (CBAM) and similar policies are creating economic incentives for CO2 utilization technologies. Additionally, consumer preference for sustainable products is pushing industries toward greener production methods, including CO2-derived materials.

Despite promising growth prospects, the market faces significant challenges. Production costs for CO2-derived products remain substantially higher than conventional alternatives, with price premiums ranging from 30% to 200% depending on the product category. Market penetration is further hindered by technological limitations in conversion efficiency and scalability issues that prevent widespread industrial adoption.

Industry analysts identify several high-potential market segments for CO2 conversion products. The construction materials sector shows particular promise, with CO2-cured concrete gaining commercial traction. The polymer industry represents another growth opportunity, with CO2-derived polycarbonates and polyurethanes increasingly finding applications in packaging and insulation materials. The fuel sector, while currently limited by cost barriers, holds substantial long-term potential as renewable energy integration advances and enables more cost-effective electrocatalytic conversion processes.

Among CO2 conversion products, methanol currently dominates the market share, accounting for roughly 40% of the total market value. This is primarily due to its versatility as a chemical feedstock and potential as a clean fuel alternative. Formic acid and carbon monoxide follow with market shares of 25% and 15% respectively, while emerging products such as ethylene and syngas collectively represent the remaining 20%.

Geographically, Europe leads the market with approximately 35% share, driven by stringent carbon regulations and substantial government investments in green technologies. North America follows at 30%, with Asia-Pacific rapidly gaining ground at 25% and expected to demonstrate the fastest growth rate over the next decade due to increasing industrialization coupled with growing environmental awareness.

Key market drivers include tightening carbon emission regulations worldwide, rising carbon pricing mechanisms, and growing corporate commitments to carbon neutrality. The European Union's Carbon Border Adjustment Mechanism (CBAM) and similar policies are creating economic incentives for CO2 utilization technologies. Additionally, consumer preference for sustainable products is pushing industries toward greener production methods, including CO2-derived materials.

Despite promising growth prospects, the market faces significant challenges. Production costs for CO2-derived products remain substantially higher than conventional alternatives, with price premiums ranging from 30% to 200% depending on the product category. Market penetration is further hindered by technological limitations in conversion efficiency and scalability issues that prevent widespread industrial adoption.

Industry analysts identify several high-potential market segments for CO2 conversion products. The construction materials sector shows particular promise, with CO2-cured concrete gaining commercial traction. The polymer industry represents another growth opportunity, with CO2-derived polycarbonates and polyurethanes increasingly finding applications in packaging and insulation materials. The fuel sector, while currently limited by cost barriers, holds substantial long-term potential as renewable energy integration advances and enables more cost-effective electrocatalytic conversion processes.

Electrocatalytic CO2 Reduction: Status and Barriers

Electrocatalytic CO2 reduction (ECR) has emerged as a promising technology for converting carbon dioxide into value-added chemicals and fuels. Currently, the field has advanced significantly with laboratory-scale demonstrations achieving faradaic efficiencies exceeding 90% for certain products like carbon monoxide and formate. However, industrial implementation faces substantial barriers related to catalyst performance, system design, and economic viability.

The state-of-the-art catalysts predominantly include metals such as copper, silver, gold, and zinc, each showing selectivity toward different products. Copper catalysts demonstrate unique capabilities for producing multi-carbon products but suffer from stability issues and product selectivity challenges. Noble metal catalysts like gold and silver show excellent performance for CO production but remain cost-prohibitive for large-scale applications.

A significant technical barrier is the limited understanding of reaction mechanisms at the molecular level. The complex multi-electron transfer processes involved in CO2 reduction pathways create difficulties in rational catalyst design. Additionally, competing hydrogen evolution reactions often diminish faradaic efficiency toward desired carbon products, particularly at industrially relevant current densities.

Stability represents another critical challenge, with most catalysts showing performance degradation within hours or days of operation. This degradation stems from multiple factors including catalyst poisoning, structural changes, and electrolyte degradation. Long-term stability testing protocols remain inconsistent across research groups, complicating comparative analysis.

Mass transport limitations constitute a substantial barrier to scaling ECR technology. The low solubility of CO2 in aqueous electrolytes (approximately 33 mM at ambient conditions) creates concentration gradients that limit reaction rates. Gas diffusion electrode configurations have partially addressed this issue but introduce additional complexity regarding water management and electrode flooding.

Energy efficiency remains suboptimal, with most systems requiring overpotentials exceeding 1V for meaningful product formation rates. This translates to energy efficiencies typically below 50%, challenging economic viability when compared to conventional production methods for target chemicals.

The field also faces standardization challenges. Varying testing protocols, reporting metrics, and reactor configurations make direct comparison between research results difficult. Recent efforts by organizations like NIST and the electrocatalysis community have begun addressing this through proposed benchmarking protocols, but widespread adoption remains limited.

Technoeconomic analyses indicate that current ECR technologies require significant improvements in current density (>200 mA/cm²), selectivity (>90%), and stability (>10,000 hours) to become commercially competitive. The pathway toward overcoming these barriers likely requires interdisciplinary approaches combining advanced materials science, electrochemical engineering, and process optimization.

The state-of-the-art catalysts predominantly include metals such as copper, silver, gold, and zinc, each showing selectivity toward different products. Copper catalysts demonstrate unique capabilities for producing multi-carbon products but suffer from stability issues and product selectivity challenges. Noble metal catalysts like gold and silver show excellent performance for CO production but remain cost-prohibitive for large-scale applications.

A significant technical barrier is the limited understanding of reaction mechanisms at the molecular level. The complex multi-electron transfer processes involved in CO2 reduction pathways create difficulties in rational catalyst design. Additionally, competing hydrogen evolution reactions often diminish faradaic efficiency toward desired carbon products, particularly at industrially relevant current densities.

Stability represents another critical challenge, with most catalysts showing performance degradation within hours or days of operation. This degradation stems from multiple factors including catalyst poisoning, structural changes, and electrolyte degradation. Long-term stability testing protocols remain inconsistent across research groups, complicating comparative analysis.

Mass transport limitations constitute a substantial barrier to scaling ECR technology. The low solubility of CO2 in aqueous electrolytes (approximately 33 mM at ambient conditions) creates concentration gradients that limit reaction rates. Gas diffusion electrode configurations have partially addressed this issue but introduce additional complexity regarding water management and electrode flooding.

Energy efficiency remains suboptimal, with most systems requiring overpotentials exceeding 1V for meaningful product formation rates. This translates to energy efficiencies typically below 50%, challenging economic viability when compared to conventional production methods for target chemicals.

The field also faces standardization challenges. Varying testing protocols, reporting metrics, and reactor configurations make direct comparison between research results difficult. Recent efforts by organizations like NIST and the electrocatalysis community have begun addressing this through proposed benchmarking protocols, but widespread adoption remains limited.

Technoeconomic analyses indicate that current ECR technologies require significant improvements in current density (>200 mA/cm²), selectivity (>90%), and stability (>10,000 hours) to become commercially competitive. The pathway toward overcoming these barriers likely requires interdisciplinary approaches combining advanced materials science, electrochemical engineering, and process optimization.

Current Electrocatalytic Approaches and Methods

01 Standardized methods for CO2 electrocatalytic conversion

Standardized protocols and methods for the electrocatalytic conversion of CO2 are essential for consistent and comparable results across different research and industrial applications. These standards include specific parameters for catalyst performance evaluation, reaction conditions, and analytical techniques to measure conversion efficiency and product selectivity. Standardized methods ensure reliability and reproducibility in CO2 valorization processes, facilitating technology advancement and commercialization.- Standardized methods for CO2 electroreduction performance evaluation: Standardized protocols and methods for evaluating the performance of electrocatalysts in CO2 reduction reactions are essential for consistent and comparable results across different research groups. These standards include specific parameters for measuring catalytic activity, selectivity, stability, and efficiency. The methods typically involve controlled experimental conditions, standardized electrochemical cells, and precise analytical techniques to quantify the products formed during CO2 electroreduction.

- Qualification criteria for electrocatalyst materials: Qualification criteria for electrocatalyst materials used in CO2 valorization include specific requirements for material composition, structure, surface properties, and performance metrics. These criteria help ensure that catalysts meet minimum standards for activity, selectivity toward valuable products, durability under operating conditions, and cost-effectiveness. Materials must undergo rigorous testing to verify their suitability for industrial applications and compliance with environmental regulations.

- Quality control systems for CO2 conversion products: Quality control systems are implemented to ensure that products derived from electrocatalytic CO2 conversion meet specific purity and composition standards. These systems include analytical methods for product characterization, contaminant detection, and verification of chemical properties. Quality assurance protocols establish acceptance criteria for products such as carbon monoxide, formic acid, ethylene, and other value-added chemicals produced through CO2 electroreduction, ensuring they meet industry requirements for downstream applications.

- Certification frameworks for CO2 valorization technologies: Certification frameworks provide a structured approach to validating the performance, safety, and environmental impact of CO2 valorization technologies. These frameworks include technical specifications, testing procedures, and documentation requirements that must be met before technologies can be certified for commercial deployment. Certification may cover aspects such as energy efficiency, carbon footprint reduction, product quality, and compliance with relevant regulations, offering assurance to stakeholders about the technology's capabilities and benefits.

- Regulatory standards for industrial implementation: Regulatory standards govern the industrial implementation of electrocatalytic CO2 valorization processes, addressing safety, environmental impact, and operational requirements. These standards include specifications for equipment design, process controls, emissions monitoring, and waste management. Compliance with these regulations is mandatory for commercial operations and may involve periodic audits, reporting requirements, and adherence to specific operational protocols designed to minimize risks and ensure sustainable operation of CO2 conversion facilities.

02 Catalyst qualification and certification frameworks

Qualification frameworks for electrocatalysts used in CO2 valorization establish criteria for catalyst certification, including performance benchmarks, stability requirements, and environmental impact assessments. These frameworks define the necessary qualifications for catalysts to be considered viable for commercial applications, ensuring they meet specific standards for efficiency, durability, and sustainability. Certification processes validate catalyst properties and performance under standardized testing conditions.Expand Specific Solutions03 Quality control systems for CO2 conversion products

Quality control systems for products derived from electrocatalytic CO2 conversion ensure consistency and purity of the output chemicals or fuels. These systems include specifications for product composition, contamination limits, and physical properties. Standards for quality assurance in CO2 valorization products are crucial for market acceptance and regulatory compliance, particularly when the products are intended for use as chemical feedstocks or fuels.Expand Specific Solutions04 Performance metrics and benchmarking standards

Performance metrics and benchmarking standards provide quantitative measures to evaluate electrocatalytic CO2 conversion processes. These include energy efficiency indicators, conversion rates, product selectivity, and economic viability metrics. Standardized performance benchmarks allow for objective comparison between different catalysts, reactor designs, and process configurations, guiding research priorities and investment decisions in CO2 valorization technologies.Expand Specific Solutions05 Regulatory compliance and certification procedures

Regulatory frameworks and certification procedures govern the implementation of electrocatalytic CO2 valorization technologies in industrial settings. These include safety standards, environmental impact assessments, and compliance with carbon accounting protocols. Certification procedures validate that CO2 conversion processes meet established regulatory requirements and industry standards, addressing aspects such as emissions reduction claims, process safety, and sustainable operation practices.Expand Specific Solutions

Leading Entities in CO2 Valorization Research

Electrocatalytic CO2 valorization is currently in an early growth phase, with the market expanding rapidly due to increasing focus on carbon neutrality technologies. The global market size is projected to reach significant scale by 2030, driven by environmental regulations and sustainability initiatives. Technologically, the field shows varying maturity levels across different approaches. Leading research institutions like Dalian Institute of Chemical Physics, CNRS, and Zhejiang University are advancing fundamental catalysis research, while companies such as TotalEnergies, Saudi Aramco, and Faraday Technology are focusing on industrial applications and scaling. Academic-industrial partnerships between entities like Brown University, KAIST, and commercial players are accelerating technology transfer, though standardization and qualification frameworks remain underdeveloped, presenting both challenges and opportunities for market participants.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced electrocatalysts for CO2 reduction featuring atomically dispersed metal sites on nitrogen-doped carbon supports. Their technology employs single-atom catalysts (SACs) with precisely controlled active sites that enable selective conversion of CO2 to valuable products like carbon monoxide, formate, and hydrocarbons. DICP's approach includes innovative synthesis methods such as pyrolysis of metal-organic frameworks and wet chemistry techniques to create highly efficient catalysts with near 100% Faradaic efficiency for specific products. They've established comprehensive standards for catalyst characterization including in-situ spectroscopic techniques and advanced microscopy methods to verify atomic dispersion and oxidation states. Their qualification protocols include stability testing under industrial conditions, demonstrating thousands of hours of operation with minimal performance degradation.

Strengths: Superior selectivity through atomic-level catalyst design; comprehensive characterization protocols; demonstrated long-term stability. Weaknesses: Higher production costs compared to traditional catalysts; potential challenges in scaling up single-atom catalyst synthesis to industrial levels; requires specialized equipment for proper implementation.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has pioneered molecular-level design of electrocatalysts for CO2 valorization, focusing on bimetallic and metal-organic framework (MOF) derived catalysts. Their approach involves precise control of the electronic structure of catalytic sites through atomic engineering, creating synergistic effects between different metal centers. They've developed novel copper-zinc catalysts that achieve over 90% Faradaic efficiency for ethanol production at industrially relevant current densities. Their qualification standards include rigorous protocols for measuring intrinsic activity through normalization by electrochemically active surface area and mass activity metrics. The institute has established benchmarking procedures that account for mass transport limitations and local pH effects during CO2 reduction, enabling more accurate comparison between different catalyst systems. Their technology also incorporates in-situ/operando characterization techniques to monitor catalyst structural evolution during reaction conditions.

Strengths: Exceptional product selectivity through molecular engineering; comprehensive activity normalization protocols; advanced in-situ characterization capabilities. Weaknesses: Complex synthesis procedures may limit large-scale production; higher costs associated with specialized characterization equipment; potential challenges in maintaining performance under varied industrial conditions.

Key Patents and Breakthroughs in CO2 Conversion

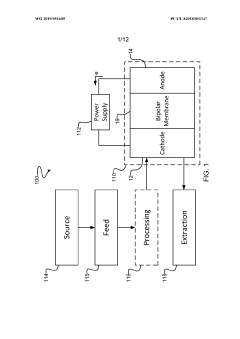

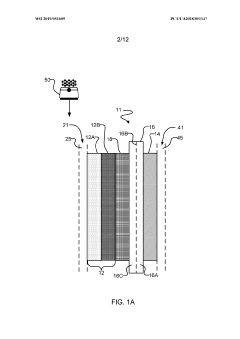

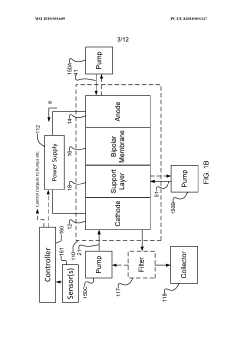

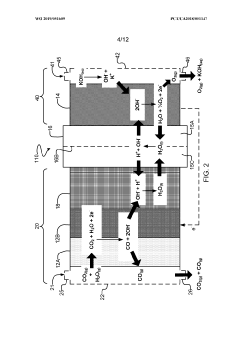

Systems and methods for electrochemical reduction of carbon dioxide

PatentWO2019051609A1

Innovation

- The implementation of a membrane electrode assembly with a bipolar membrane and a hydration layer between the anode and cathode, where an electrical potential is applied to reduce carbon dioxide to carbon monoxide, with a support layer maintaining hydration of the cathode side to enhance efficiency and selectivity.

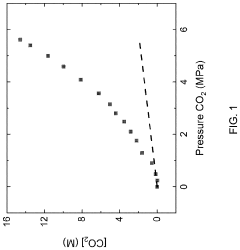

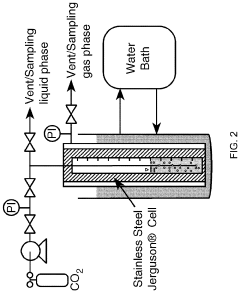

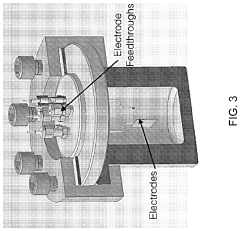

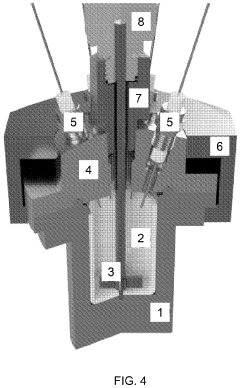

Electrocatalytic conversion of carbon dioxide in liquids expanded by carbon dioxide

PatentInactiveUS20210262103A1

Innovation

- The use of CO2 expanded liquid media at elevated pressures, which increases CO2 solubility and enables high CO2 concentrations and fast electron transfer, allowing for sustainable and commercially viable pathways to convert CO2 into fuels and chemicals, by optimizing the combination of organic liquid solvents and electrolytes to maintain a single phase and facilitate pressure-tunable CO2 conversion.

Standardization Framework for CO2 Valorization

The standardization framework for CO2 valorization represents a critical infrastructure for advancing electrocatalytic CO2 conversion technologies from laboratory research to commercial implementation. Currently, the field lacks comprehensive standardization, creating barriers to technology validation, market acceptance, and regulatory compliance. A robust framework must address multiple dimensions including performance metrics, safety protocols, and environmental impact assessments.

Performance standardization should establish uniform methods for measuring conversion efficiency, selectivity, stability, and energy consumption across different electrocatalytic systems. These metrics must be reproducible across laboratories and scalable to industrial applications. The framework should define standard testing conditions, reference materials, and analytical procedures to ensure comparable results regardless of testing location or equipment specifications.

Safety standards for CO2 valorization technologies need to address both operational risks and product quality assurance. This includes protocols for handling pressurized CO2, managing potentially flammable products like carbon monoxide or hydrocarbons, and ensuring the purity of chemical products for downstream applications. The framework should align with existing chemical process safety standards while addressing the unique challenges of electrochemical CO2 conversion.

Environmental impact standardization is particularly important given that CO2 valorization aims to provide sustainability benefits. Life cycle assessment methodologies specific to electrocatalytic processes must be standardized to accurately quantify net carbon reduction, energy balance, and potential environmental trade-offs. These standards should enable fair comparison between different CO2 utilization approaches and against conventional production methods.

Regulatory compliance standards must bridge the gap between technical performance and market requirements. This includes product certification pathways, quality assurance protocols, and documentation requirements for various jurisdictions. The framework should facilitate regulatory approval processes by providing clear guidelines on how to demonstrate compliance with environmental, safety, and product quality regulations.

International harmonization of these standards is essential for global technology deployment. Organizations such as ISO, ASTM International, and IEC should coordinate efforts to develop consensus-based standards that can be adopted across different regions. The framework should be flexible enough to accommodate technological evolution while providing sufficient structure for meaningful benchmarking and certification.

Industry-academia collaboration will be crucial for developing practical yet scientifically rigorous standards. Pilot programs for standard implementation can help refine methodologies and identify potential challenges before widespread adoption. The standardization framework should ultimately serve as an enabler for market growth by reducing uncertainty, building trust, and facilitating investment in CO2 valorization technologies.

Performance standardization should establish uniform methods for measuring conversion efficiency, selectivity, stability, and energy consumption across different electrocatalytic systems. These metrics must be reproducible across laboratories and scalable to industrial applications. The framework should define standard testing conditions, reference materials, and analytical procedures to ensure comparable results regardless of testing location or equipment specifications.

Safety standards for CO2 valorization technologies need to address both operational risks and product quality assurance. This includes protocols for handling pressurized CO2, managing potentially flammable products like carbon monoxide or hydrocarbons, and ensuring the purity of chemical products for downstream applications. The framework should align with existing chemical process safety standards while addressing the unique challenges of electrochemical CO2 conversion.

Environmental impact standardization is particularly important given that CO2 valorization aims to provide sustainability benefits. Life cycle assessment methodologies specific to electrocatalytic processes must be standardized to accurately quantify net carbon reduction, energy balance, and potential environmental trade-offs. These standards should enable fair comparison between different CO2 utilization approaches and against conventional production methods.

Regulatory compliance standards must bridge the gap between technical performance and market requirements. This includes product certification pathways, quality assurance protocols, and documentation requirements for various jurisdictions. The framework should facilitate regulatory approval processes by providing clear guidelines on how to demonstrate compliance with environmental, safety, and product quality regulations.

International harmonization of these standards is essential for global technology deployment. Organizations such as ISO, ASTM International, and IEC should coordinate efforts to develop consensus-based standards that can be adopted across different regions. The framework should be flexible enough to accommodate technological evolution while providing sufficient structure for meaningful benchmarking and certification.

Industry-academia collaboration will be crucial for developing practical yet scientifically rigorous standards. Pilot programs for standard implementation can help refine methodologies and identify potential challenges before widespread adoption. The standardization framework should ultimately serve as an enabler for market growth by reducing uncertainty, building trust, and facilitating investment in CO2 valorization technologies.

Environmental Impact Assessment and Carbon Accounting

The environmental impact assessment of electrocatalytic CO2 valorization processes requires comprehensive carbon accounting methodologies to accurately evaluate their sustainability credentials. These technologies aim to convert carbon dioxide into valuable products, potentially offering a dual benefit of reducing atmospheric CO2 while producing useful chemicals. However, rigorous assessment frameworks are essential to verify these environmental claims.

Life Cycle Assessment (LCA) serves as the primary tool for quantifying the environmental footprint of CO2 valorization processes. When applied to electrocatalytic systems, LCA must account for electricity sources, catalyst production, system operation, and end-of-life considerations. Research indicates that electricity source remains the dominant factor, with renewable energy integration potentially reducing carbon footprints by 60-85% compared to fossil fuel-powered operations.

Carbon accounting for these technologies must distinguish between avoided emissions, captured emissions, and process emissions. The net carbon impact calculation should include CO2 utilized, energy inputs, fugitive emissions, and product lifetime considerations. Current standards such as ISO 14067 and the Greenhouse Gas Protocol provide general frameworks, but specialized protocols for electrocatalytic CO2 valorization are still emerging.

Temporal considerations present significant challenges in carbon accounting for these technologies. The durability of products derived from CO2 valorization determines whether carbon is sequestered long-term or quickly re-released to the atmosphere. For instance, CO2-derived fuels release carbon upon combustion, while materials like polymers or carbonates may sequester carbon for decades or centuries.

Boundary setting for environmental assessments remains contentious, with varying approaches to upstream and downstream emissions accounting. Comprehensive assessments should include catalyst mining impacts, manufacturing energy requirements, operational emissions, and end-of-life scenarios. Recent studies suggest that neglecting any of these phases can underestimate total environmental impacts by 15-40%.

Standardization efforts are advancing through organizations like the International CO2 Capture and Conversion Association (ICCCA) and the Global CO2 Initiative, which are developing Product Category Rules (PCRs) specifically for CO2 utilization technologies. These emerging standards aim to establish consistent methodologies for quantifying environmental benefits, enabling fair comparisons between different valorization approaches and conventional production methods.

The development of digital carbon accounting tools specifically designed for electrocatalytic processes represents a promising frontier. These tools integrate real-time monitoring data with life cycle inventory databases to provide dynamic environmental performance metrics, potentially enabling optimization of operational parameters to minimize carbon footprints while maintaining production efficiency.

Life Cycle Assessment (LCA) serves as the primary tool for quantifying the environmental footprint of CO2 valorization processes. When applied to electrocatalytic systems, LCA must account for electricity sources, catalyst production, system operation, and end-of-life considerations. Research indicates that electricity source remains the dominant factor, with renewable energy integration potentially reducing carbon footprints by 60-85% compared to fossil fuel-powered operations.

Carbon accounting for these technologies must distinguish between avoided emissions, captured emissions, and process emissions. The net carbon impact calculation should include CO2 utilized, energy inputs, fugitive emissions, and product lifetime considerations. Current standards such as ISO 14067 and the Greenhouse Gas Protocol provide general frameworks, but specialized protocols for electrocatalytic CO2 valorization are still emerging.

Temporal considerations present significant challenges in carbon accounting for these technologies. The durability of products derived from CO2 valorization determines whether carbon is sequestered long-term or quickly re-released to the atmosphere. For instance, CO2-derived fuels release carbon upon combustion, while materials like polymers or carbonates may sequester carbon for decades or centuries.

Boundary setting for environmental assessments remains contentious, with varying approaches to upstream and downstream emissions accounting. Comprehensive assessments should include catalyst mining impacts, manufacturing energy requirements, operational emissions, and end-of-life scenarios. Recent studies suggest that neglecting any of these phases can underestimate total environmental impacts by 15-40%.

Standardization efforts are advancing through organizations like the International CO2 Capture and Conversion Association (ICCCA) and the Global CO2 Initiative, which are developing Product Category Rules (PCRs) specifically for CO2 utilization technologies. These emerging standards aim to establish consistent methodologies for quantifying environmental benefits, enabling fair comparisons between different valorization approaches and conventional production methods.

The development of digital carbon accounting tools specifically designed for electrocatalytic processes represents a promising frontier. These tools integrate real-time monitoring data with life cycle inventory databases to provide dynamic environmental performance metrics, potentially enabling optimization of operational parameters to minimize carbon footprints while maintaining production efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!