Electrocatalytic CO2 Valorization Challenges in Aerospace

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace CO2 Valorization Background and Objectives

Carbon dioxide (CO2) emissions represent one of the most significant challenges in aerospace operations, contributing substantially to the industry's environmental footprint. The concept of CO2 valorization—transforming waste carbon dioxide into valuable products—has emerged as a promising approach to mitigate these emissions while potentially creating new value streams for aerospace applications. This technological domain has evolved from theoretical concepts in the early 2000s to practical demonstrations in recent years, driven by increasing environmental regulations and sustainability commitments across the aerospace sector.

The evolution of electrocatalytic CO2 valorization technology has been marked by significant breakthroughs in catalyst design, reactor engineering, and system integration. Early approaches focused primarily on laboratory-scale demonstrations with limited efficiency and selectivity. However, recent advances in nanomaterials and computational modeling have accelerated development, enabling more efficient conversion processes with improved product selectivity and energy efficiency.

In the aerospace context, CO2 valorization presents unique opportunities and challenges. The closed environments of spacecraft and space stations create both necessity and opportunity for carbon recycling systems. Historical approaches to CO2 management in space have focused primarily on removal and storage, with limited attention to resource recovery. The International Space Station currently employs the Sabatier reaction to convert some CO2 to methane and water, but more comprehensive valorization systems remain underdeveloped.

The primary technical objectives for electrocatalytic CO2 valorization in aerospace applications include: developing lightweight, compact systems capable of operating in microgravity environments; achieving high conversion efficiency with minimal energy input; ensuring system reliability under extreme conditions; and producing useful products that can serve multiple purposes within aerospace operations, such as propellants, materials feedstocks, or life support consumables.

Market drivers for this technology include increasingly stringent emissions regulations for commercial aviation, growing interest in sustainable space operations, and the potential for in-situ resource utilization on long-duration space missions. The European Union's inclusion of aviation in its Emissions Trading System and NASA's commitment to sustainable space exploration have created regulatory and programmatic imperatives for CO2 management solutions.

The convergence of environmental imperatives, technological advancements, and commercial opportunities has positioned electrocatalytic CO2 valorization as a critical technology for aerospace sustainability. Success in this domain could transform waste management approaches across the industry while simultaneously addressing climate impact concerns and creating new resource streams for extended missions.

The evolution of electrocatalytic CO2 valorization technology has been marked by significant breakthroughs in catalyst design, reactor engineering, and system integration. Early approaches focused primarily on laboratory-scale demonstrations with limited efficiency and selectivity. However, recent advances in nanomaterials and computational modeling have accelerated development, enabling more efficient conversion processes with improved product selectivity and energy efficiency.

In the aerospace context, CO2 valorization presents unique opportunities and challenges. The closed environments of spacecraft and space stations create both necessity and opportunity for carbon recycling systems. Historical approaches to CO2 management in space have focused primarily on removal and storage, with limited attention to resource recovery. The International Space Station currently employs the Sabatier reaction to convert some CO2 to methane and water, but more comprehensive valorization systems remain underdeveloped.

The primary technical objectives for electrocatalytic CO2 valorization in aerospace applications include: developing lightweight, compact systems capable of operating in microgravity environments; achieving high conversion efficiency with minimal energy input; ensuring system reliability under extreme conditions; and producing useful products that can serve multiple purposes within aerospace operations, such as propellants, materials feedstocks, or life support consumables.

Market drivers for this technology include increasingly stringent emissions regulations for commercial aviation, growing interest in sustainable space operations, and the potential for in-situ resource utilization on long-duration space missions. The European Union's inclusion of aviation in its Emissions Trading System and NASA's commitment to sustainable space exploration have created regulatory and programmatic imperatives for CO2 management solutions.

The convergence of environmental imperatives, technological advancements, and commercial opportunities has positioned electrocatalytic CO2 valorization as a critical technology for aerospace sustainability. Success in this domain could transform waste management approaches across the industry while simultaneously addressing climate impact concerns and creating new resource streams for extended missions.

Market Analysis for Aerospace CO2 Utilization

The aerospace industry is witnessing a significant shift toward sustainability, creating a growing market for CO2 utilization technologies. Current market assessments indicate that aerospace CO2 valorization could reach substantial market value as regulatory pressures intensify and sustainability becomes a competitive advantage. The International Air Transport Association (IATA) has committed to reducing carbon emissions by 50% by 2050 compared to 2005 levels, driving investment in carbon capture and utilization technologies.

Market segmentation reveals multiple application areas for electrocatalytic CO2 valorization in aerospace. The primary segments include on-board carbon capture systems, ground-based processing facilities for captured CO2, and integrated life support systems for long-duration space missions. Each segment presents distinct market opportunities with varying growth trajectories and investment requirements.

Demand analysis shows that commercial aviation represents the largest potential market, with approximately 26,000 commercial aircraft currently in service globally. Space exploration constitutes a smaller but rapidly growing segment, particularly as plans for long-duration missions to Mars and lunar bases advance. Military aerospace applications form a third significant market segment, characterized by specialized requirements and higher tolerance for premium-priced solutions.

Regional market distribution indicates North America and Europe currently lead in aerospace CO2 utilization technology adoption, driven by stringent environmental regulations and substantial R&D investments. However, Asia-Pacific is experiencing the fastest growth rate, particularly in China and Japan, where government initiatives strongly support green aerospace technologies.

Economic factors significantly influence market development. The cost-benefit analysis of implementing electrocatalytic CO2 valorization systems must consider installation costs, operational expenses, and potential revenue from valuable carbon-based products. Current estimates suggest a payback period of 5-8 years for most systems, though this varies widely based on specific applications and scale.

Market barriers include high initial capital requirements, technological immaturity for aerospace-specific applications, and competition from alternative carbon reduction strategies. Additionally, the aerospace industry's stringent safety and reliability requirements create significant entry barriers for new technologies.

Growth projections indicate the market for aerospace CO2 utilization technologies could expand at a compound annual growth rate exceeding the broader aerospace sustainability sector. This growth is expected to accelerate as technology matures and regulatory pressures increase. Early adopters will likely include space agencies, premium commercial carriers, and military aerospace programs seeking to demonstrate environmental leadership and operational self-sufficiency.

Market segmentation reveals multiple application areas for electrocatalytic CO2 valorization in aerospace. The primary segments include on-board carbon capture systems, ground-based processing facilities for captured CO2, and integrated life support systems for long-duration space missions. Each segment presents distinct market opportunities with varying growth trajectories and investment requirements.

Demand analysis shows that commercial aviation represents the largest potential market, with approximately 26,000 commercial aircraft currently in service globally. Space exploration constitutes a smaller but rapidly growing segment, particularly as plans for long-duration missions to Mars and lunar bases advance. Military aerospace applications form a third significant market segment, characterized by specialized requirements and higher tolerance for premium-priced solutions.

Regional market distribution indicates North America and Europe currently lead in aerospace CO2 utilization technology adoption, driven by stringent environmental regulations and substantial R&D investments. However, Asia-Pacific is experiencing the fastest growth rate, particularly in China and Japan, where government initiatives strongly support green aerospace technologies.

Economic factors significantly influence market development. The cost-benefit analysis of implementing electrocatalytic CO2 valorization systems must consider installation costs, operational expenses, and potential revenue from valuable carbon-based products. Current estimates suggest a payback period of 5-8 years for most systems, though this varies widely based on specific applications and scale.

Market barriers include high initial capital requirements, technological immaturity for aerospace-specific applications, and competition from alternative carbon reduction strategies. Additionally, the aerospace industry's stringent safety and reliability requirements create significant entry barriers for new technologies.

Growth projections indicate the market for aerospace CO2 utilization technologies could expand at a compound annual growth rate exceeding the broader aerospace sustainability sector. This growth is expected to accelerate as technology matures and regulatory pressures increase. Early adopters will likely include space agencies, premium commercial carriers, and military aerospace programs seeking to demonstrate environmental leadership and operational self-sufficiency.

Electrocatalytic CO2 Conversion: Current Status and Challenges

Electrocatalytic CO2 conversion has emerged as a promising approach for carbon dioxide utilization, offering potential solutions to both environmental challenges and resource limitations in aerospace applications. The technology leverages electrochemical processes to transform CO2 into value-added products such as carbon monoxide, formic acid, methanol, ethylene, and other hydrocarbons using renewable electricity as the energy input.

Current electrocatalytic CO2 conversion systems demonstrate varying levels of efficiency across different product pathways. Two-electron reduction products (CO and formate) have achieved industrial-relevant current densities exceeding 300 mA/cm² with Faradaic efficiencies above 90%. However, multi-carbon products still face significant performance limitations, with current densities typically below 100 mA/cm² and moderate selectivity.

The aerospace sector presents unique challenges for CO2 conversion technologies. Limited space, weight constraints, and the need for robust, reliable systems that can operate in extreme conditions significantly complicate implementation. Additionally, aerospace applications require systems capable of functioning in microgravity environments where conventional fluid dynamics principles may not apply, affecting catalyst-electrolyte interfaces and mass transport phenomena.

Energy efficiency remains a critical challenge, with most systems operating at energy efficiencies below 50%. This limitation is particularly problematic for aerospace applications where energy resources are strictly constrained. The high overpotentials required for CO2 reduction reactions contribute significantly to these efficiency losses, necessitating the development of more advanced catalysts with lower activation barriers.

Catalyst stability presents another major hurdle. Current electrocatalysts often experience deactivation through poisoning, structural degradation, or leaching during extended operation. For aerospace applications requiring long-duration missions with minimal maintenance, catalyst longevity becomes particularly crucial. Research indicates most catalysts maintain acceptable performance for only hundreds of hours, far below the thousands or tens of thousands of hours needed for practical aerospace implementation.

System integration challenges are equally significant. CO2 capture from cabin air or external sources must be efficiently coupled with conversion systems while managing heat generation, product separation, and overall system complexity. The integration must accommodate the strict safety protocols of aerospace environments, where flammable products and potential leaks pose serious risks.

Scale-up considerations further complicate implementation. Laboratory-scale demonstrations have shown promising results, but translating these to practical aerospace dimensions while maintaining performance metrics remains challenging. The trade-offs between system size, conversion efficiency, and product selectivity become more pronounced at scales relevant to aerospace applications.

Current electrocatalytic CO2 conversion systems demonstrate varying levels of efficiency across different product pathways. Two-electron reduction products (CO and formate) have achieved industrial-relevant current densities exceeding 300 mA/cm² with Faradaic efficiencies above 90%. However, multi-carbon products still face significant performance limitations, with current densities typically below 100 mA/cm² and moderate selectivity.

The aerospace sector presents unique challenges for CO2 conversion technologies. Limited space, weight constraints, and the need for robust, reliable systems that can operate in extreme conditions significantly complicate implementation. Additionally, aerospace applications require systems capable of functioning in microgravity environments where conventional fluid dynamics principles may not apply, affecting catalyst-electrolyte interfaces and mass transport phenomena.

Energy efficiency remains a critical challenge, with most systems operating at energy efficiencies below 50%. This limitation is particularly problematic for aerospace applications where energy resources are strictly constrained. The high overpotentials required for CO2 reduction reactions contribute significantly to these efficiency losses, necessitating the development of more advanced catalysts with lower activation barriers.

Catalyst stability presents another major hurdle. Current electrocatalysts often experience deactivation through poisoning, structural degradation, or leaching during extended operation. For aerospace applications requiring long-duration missions with minimal maintenance, catalyst longevity becomes particularly crucial. Research indicates most catalysts maintain acceptable performance for only hundreds of hours, far below the thousands or tens of thousands of hours needed for practical aerospace implementation.

System integration challenges are equally significant. CO2 capture from cabin air or external sources must be efficiently coupled with conversion systems while managing heat generation, product separation, and overall system complexity. The integration must accommodate the strict safety protocols of aerospace environments, where flammable products and potential leaks pose serious risks.

Scale-up considerations further complicate implementation. Laboratory-scale demonstrations have shown promising results, but translating these to practical aerospace dimensions while maintaining performance metrics remains challenging. The trade-offs between system size, conversion efficiency, and product selectivity become more pronounced at scales relevant to aerospace applications.

Current Electrocatalytic Solutions for CO2 Conversion

01 Metal-based catalysts for CO2 electroreduction

Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity toward specific products like carbon monoxide, formic acid, or hydrocarbons. The catalyst structure, morphology, and composition significantly influence the efficiency and selectivity of the CO2 reduction reaction. Nanostructured metal catalysts with high surface area and optimized binding energies can enhance the conversion rates and product selectivity.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts play a crucial role in the electrochemical reduction of CO2 to valuable products. Various metals such as copper, silver, gold, and their alloys exhibit different selectivity and efficiency for converting CO2 into specific products like carbon monoxide, formic acid, methanol, or hydrocarbons. The catalyst structure, morphology, and composition significantly influence the reaction pathways and product distribution, allowing for tailored approaches to CO2 valorization.

- Carbon-based electrocatalysts for CO2 conversion: Carbon-based materials serve as effective electrocatalysts for CO2 reduction due to their high surface area, tunable porosity, and modifiable surface chemistry. These materials include carbon nanotubes, graphene, carbon fibers, and nitrogen-doped carbon structures. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks creates active sites that enhance catalytic activity and selectivity, offering cost-effective alternatives to precious metal catalysts for CO2 valorization.

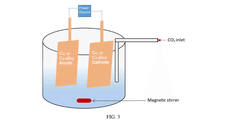

- Reactor design and system integration for CO2 electroreduction: Advanced reactor designs and integrated systems are essential for scaling up electrocatalytic CO2 conversion processes. These include flow cells, gas diffusion electrodes, and membrane electrode assemblies that enhance mass transport and reaction efficiency. System integration focuses on optimizing electrolyte composition, controlling reaction parameters, and coupling with renewable energy sources to achieve sustainable CO2 valorization. Novel reactor configurations also address challenges related to product separation and process intensification.

- Bimetallic and multi-component catalysts for selective CO2 conversion: Bimetallic and multi-component catalysts offer enhanced performance for CO2 electroreduction through synergistic effects between different elements. These catalysts can be designed as alloys, core-shell structures, or supported nanoparticles to optimize electronic properties and active site distribution. The combination of metals with complementary properties allows for tuning product selectivity and lowering overpotentials, addressing key challenges in CO2 valorization such as competing hydrogen evolution reactions and catalyst stability.

- Process optimization and product selectivity control: Controlling reaction conditions and catalyst surface properties is crucial for directing CO2 electroreduction toward specific high-value products. Parameters such as applied potential, electrolyte pH, temperature, and pressure significantly influence reaction pathways and product distribution. Advanced techniques including pulsed electrolysis, in-situ spectroscopy for mechanistic studies, and machine learning approaches for catalyst design help optimize the process efficiency and selectivity, enabling economically viable CO2 valorization technologies.

02 Carbon-based electrocatalysts for CO2 conversion

Carbon-based materials serve as effective electrocatalysts for CO2 valorization. These include carbon nanotubes, graphene, nitrogen-doped carbon, and carbon quantum dots. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks creates active sites that facilitate CO2 adsorption and activation. Carbon-based catalysts offer advantages such as high conductivity, large surface area, tunable porosity, and excellent stability under electrochemical conditions, making them promising alternatives to metal-based catalysts for sustainable CO2 conversion.Expand Specific Solutions03 Reactor design and system integration for CO2 electroreduction

The design of electrochemical reactors and their integration into complete systems significantly impacts the efficiency of CO2 valorization processes. Advanced reactor configurations such as flow cells, gas diffusion electrodes, and microfluidic systems can enhance mass transport, reduce energy consumption, and improve product selectivity. System integration aspects include electrolyte management, product separation, heat recovery, and coupling with renewable energy sources. Optimized reactor designs address challenges like CO2 solubility limitations, bubble formation, and pH gradients to achieve higher conversion rates and energy efficiency.Expand Specific Solutions04 Electrolyte composition and optimization for CO2 reduction

Electrolyte composition significantly influences the performance of CO2 electroreduction processes. Parameters such as pH, ionic strength, buffer capacity, and the presence of specific ions can alter reaction pathways and product distributions. Ionic liquids, deep eutectic solvents, and specialized additives can enhance CO2 solubility and stabilize reaction intermediates. Optimizing electrolyte composition helps overcome challenges like competing hydrogen evolution reactions and product crossover, leading to improved faradaic efficiency and selectivity toward desired products.Expand Specific Solutions05 Process intensification and scale-up strategies

Process intensification and scale-up strategies are essential for transitioning CO2 electroreduction technologies from laboratory to industrial applications. These include the development of high-pressure systems, continuous flow processes, and modular designs that can be easily scaled. Advanced approaches involve coupling electrochemical CO2 reduction with other processes like photocatalysis or thermocatalysis in hybrid systems. Techno-economic analysis and life cycle assessment guide the optimization of operating parameters and system configurations to maximize economic viability and environmental benefits while addressing challenges related to catalyst stability, product separation, and energy efficiency at larger scales.Expand Specific Solutions

Leading Organizations in Aerospace Electrocatalysis

Electrocatalytic CO2 valorization in aerospace faces significant challenges at the early development stage, with market potential estimated to grow substantially as sustainability pressures increase. The technology remains in early maturity, with academic institutions leading research efforts. Key players include University of Science & Technology of China and Zhejiang University advancing fundamental catalysis research, while Palo Alto Research Center and Agora Energy Technologies focus on practical applications. Honda Motor and B. Braun Surgical represent industrial interest in scaling solutions. The competitive landscape is characterized by cross-sector collaboration between aerospace specialists, chemical engineering experts, and materials science researchers, with significant opportunities for breakthrough innovations in catalyst efficiency, selectivity, and durability under aerospace-specific conditions.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has pioneered a comprehensive electrocatalytic CO2 valorization platform specifically engineered for aerospace applications. Their system employs hierarchically structured catalysts combining transition metals with nitrogen-doped carbon supports that demonstrate exceptional activity for CO2 reduction at low overpotentials. The technology utilizes a flow-cell configuration optimized for microgravity environments, with specialized electrode architectures that maintain three-phase boundaries regardless of orientation. Argonne's approach incorporates in-situ spectroscopic monitoring capabilities that enable real-time analysis of catalyst surface chemistry and reaction intermediates, allowing for adaptive control of reaction conditions to maintain optimal performance. Their system achieves over 90% CO2 conversion with tunable product distribution between syngas, formate, and C2+ products depending on mission requirements. The technology has undergone extensive testing in simulated space environments, demonstrating resilience to radiation exposure and temperature fluctuations typical of aerospace applications. Argonne has also developed specialized electrolyte formulations that minimize volatility concerns in reduced-pressure environments.

Strengths: Highly adaptable product distribution to meet different mission needs; extensive testing under space-relevant conditions; integrated monitoring capabilities for autonomous operation. Weaknesses: Complex system architecture may present integration challenges with existing spacecraft systems; higher power requirements compared to some competing technologies.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking electrocatalytic system for CO2 valorization in aerospace applications, focusing on resource utilization for long-duration missions. Their technology employs a novel class of bimetallic catalysts with precisely controlled atomic arrangements that significantly reduce the energy barriers for C-C coupling reactions. The system achieves remarkable selectivity (>85%) toward higher-value C2+ products such as ethylene and ethanol at moderate potentials (-0.7 to -1.0V vs. RHE). UC researchers have engineered a specialized gas diffusion electrode architecture that maintains optimal three-phase interfaces even under variable gravity conditions, addressing a critical challenge for space applications. The technology incorporates a unique electrolyte management system that minimizes water loss through evaporation while maintaining ionic conductivity, crucial for closed-loop operation in spacecraft environments. Their system has demonstrated stable operation for over 1,000 hours with minimal performance degradation, utilizing advanced catalyst anchoring strategies that prevent nanoparticle agglomeration. The UC approach also features integrated product separation membranes that facilitate direct utilization of generated chemicals for life support or propellant applications.

Strengths: Exceptional selectivity toward higher-value multi-carbon products; innovative electrolyte management system designed specifically for space constraints; demonstrated long-term stability. Weaknesses: Current system prototypes still require further miniaturization for practical spacecraft integration; catalyst materials include some rare elements that may present supply chain challenges.

Key Patents and Research in Aerospace CO2 Valorization

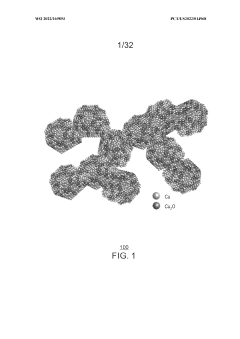

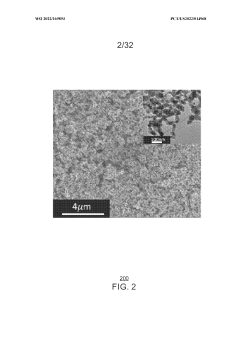

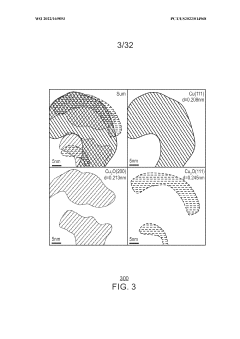

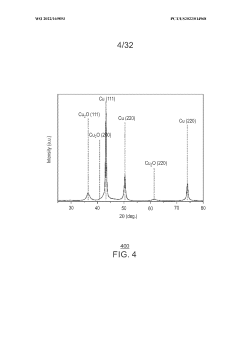

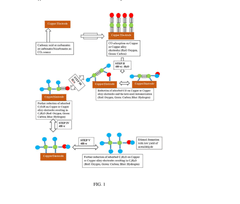

Porous copper/copper oxide xerogel catalyst

PatentWO2022169893A1

Innovation

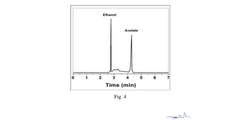

- A porous copper/copper oxide xerogel catalyst is synthesized through wet-chemistry, featuring a high surface area and dense Cu°-Cu+ interfaces, which enhances CO2 activation and C-C dimerization, resulting in improved Faradaic efficiency and partial current density for ethanol production.

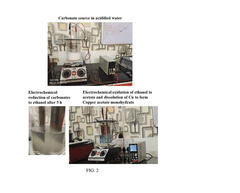

Electrochemical conversion of carbon dioxide into value-added products

PatentActiveIN202442017597A

Innovation

- The method employs an electrochemical reactor with metallic Copper (Cu) or Cu-alloy symmetric electrodes and acidified water as electrolyte, achieving high FE and EE through asymmetric C-C coupling on the cathode surface, forming short-lived cation radical intermediates that react to produce ethanol and other value-added products.

Space Environment Constraints on Catalytic Processes

The space environment presents unique and extreme conditions that significantly impact catalytic processes, particularly for electrocatalytic CO2 valorization systems. Microgravity conditions fundamentally alter fluid dynamics and mass transport phenomena, disrupting conventional convection mechanisms that terrestrial catalytic systems rely upon. This results in diffusion-dominated transport regimes that can lead to concentration polarization near catalyst surfaces, potentially reducing reaction efficiency and selectivity in CO2 conversion processes.

Radiation exposure in space presents another critical challenge, as high-energy cosmic rays and solar radiation can degrade catalyst structures and alter electronic properties of catalytic materials. This radiation-induced damage may accelerate catalyst deactivation through mechanisms such as sintering, poisoning, or structural reorganization, necessitating more robust catalyst designs or frequent replacement strategies for long-duration missions.

Temperature extremes and thermal cycling in space environments further complicate catalytic process stability. Spacecraft experience temperature variations from -150°C to +150°C depending on sun exposure, requiring catalysts that maintain activity across wide temperature ranges or sophisticated thermal management systems that consume precious energy resources.

The vacuum conditions of space introduce additional complications for electrocatalytic systems, particularly regarding electrolyte stability. Conventional liquid electrolytes face risks of evaporation or freezing, while gas-phase reactants behave differently under reduced pressure conditions, affecting reaction kinetics and thermodynamics of CO2 reduction pathways.

Resource constraints represent perhaps the most significant limitation for space-based catalytic processes. The high mass-to-orbit costs necessitate catalysts with exceptional atom efficiency, minimal rare earth elements, and extended operational lifetimes. Additionally, regeneration or recycling capabilities become essential as resupply missions are infrequent and extremely costly.

Power limitations aboard spacecraft further restrict electrocatalytic processes, which typically require significant energy input. This necessitates catalysts operating at lower overpotentials and systems designed for maximum energy efficiency, potentially leveraging solar power fluctuations rather than requiring constant power supply.

Finally, the integration challenges within closed-loop life support systems add complexity, as CO2 valorization catalysts must function harmoniously with other spacecraft systems while avoiding cross-contamination or interference with sensitive equipment. The catalytic processes must also be designed with exceptional safety parameters, as any failure could have catastrophic consequences in the isolated environment of space.

Radiation exposure in space presents another critical challenge, as high-energy cosmic rays and solar radiation can degrade catalyst structures and alter electronic properties of catalytic materials. This radiation-induced damage may accelerate catalyst deactivation through mechanisms such as sintering, poisoning, or structural reorganization, necessitating more robust catalyst designs or frequent replacement strategies for long-duration missions.

Temperature extremes and thermal cycling in space environments further complicate catalytic process stability. Spacecraft experience temperature variations from -150°C to +150°C depending on sun exposure, requiring catalysts that maintain activity across wide temperature ranges or sophisticated thermal management systems that consume precious energy resources.

The vacuum conditions of space introduce additional complications for electrocatalytic systems, particularly regarding electrolyte stability. Conventional liquid electrolytes face risks of evaporation or freezing, while gas-phase reactants behave differently under reduced pressure conditions, affecting reaction kinetics and thermodynamics of CO2 reduction pathways.

Resource constraints represent perhaps the most significant limitation for space-based catalytic processes. The high mass-to-orbit costs necessitate catalysts with exceptional atom efficiency, minimal rare earth elements, and extended operational lifetimes. Additionally, regeneration or recycling capabilities become essential as resupply missions are infrequent and extremely costly.

Power limitations aboard spacecraft further restrict electrocatalytic processes, which typically require significant energy input. This necessitates catalysts operating at lower overpotentials and systems designed for maximum energy efficiency, potentially leveraging solar power fluctuations rather than requiring constant power supply.

Finally, the integration challenges within closed-loop life support systems add complexity, as CO2 valorization catalysts must function harmoniously with other spacecraft systems while avoiding cross-contamination or interference with sensitive equipment. The catalytic processes must also be designed with exceptional safety parameters, as any failure could have catastrophic consequences in the isolated environment of space.

Sustainability Impact of In-Situ Resource Utilization

The implementation of in-situ resource utilization (ISRU) technologies, particularly electrocatalytic CO2 valorization systems, represents a significant advancement in sustainable aerospace operations. By converting waste CO2 into valuable resources during space missions, these technologies directly contribute to reducing the environmental footprint of aerospace activities while simultaneously addressing resource constraints in extraterrestrial environments.

The sustainability impact of ISRU extends beyond immediate operational benefits. Earth-based launch operations typically generate substantial carbon emissions, with each rocket launch producing significant quantities of CO2. By enabling the production of propellants, life support consumables, and construction materials in space using locally available resources, ISRU technologies can dramatically reduce the mass requirements for Earth launches, thereby decreasing the associated carbon footprint of space missions.

Electrocatalytic CO2 conversion systems specifically offer a closed-loop approach to resource management in space. These systems can transform exhaled CO2 from crew members into oxygen for life support and carbon-based compounds for various applications. This recycling capability extends mission durations without requiring additional supply launches, representing a fundamental shift toward sustainable space exploration paradigms.

From a broader environmental perspective, the development of efficient electrocatalysts for CO2 valorization has significant terrestrial applications. Technologies initially designed for aerospace applications often find their way into Earth-based industries, potentially contributing to carbon capture and utilization strategies in sectors responsible for high greenhouse gas emissions. This technology transfer effect multiplies the sustainability impact of aerospace-focused research.

Economic sustainability also benefits from ISRU implementation. The prohibitive costs of transporting materials to space (estimated at $10,000-$20,000 per kilogram to low Earth orbit) can be substantially reduced through local resource utilization. This cost reduction makes long-duration missions and permanent extraterrestrial settlements more economically viable, opening new frontiers for sustainable human presence beyond Earth.

The long-term sustainability impact extends to the concept of planetary protection. By reducing dependence on Earth's resources and minimizing waste generation in space, ISRU technologies help preserve both Earth's environment and the pristine nature of other celestial bodies. This aligns with international space policy objectives that emphasize responsible exploration and utilization of space resources.

The sustainability impact of ISRU extends beyond immediate operational benefits. Earth-based launch operations typically generate substantial carbon emissions, with each rocket launch producing significant quantities of CO2. By enabling the production of propellants, life support consumables, and construction materials in space using locally available resources, ISRU technologies can dramatically reduce the mass requirements for Earth launches, thereby decreasing the associated carbon footprint of space missions.

Electrocatalytic CO2 conversion systems specifically offer a closed-loop approach to resource management in space. These systems can transform exhaled CO2 from crew members into oxygen for life support and carbon-based compounds for various applications. This recycling capability extends mission durations without requiring additional supply launches, representing a fundamental shift toward sustainable space exploration paradigms.

From a broader environmental perspective, the development of efficient electrocatalysts for CO2 valorization has significant terrestrial applications. Technologies initially designed for aerospace applications often find their way into Earth-based industries, potentially contributing to carbon capture and utilization strategies in sectors responsible for high greenhouse gas emissions. This technology transfer effect multiplies the sustainability impact of aerospace-focused research.

Economic sustainability also benefits from ISRU implementation. The prohibitive costs of transporting materials to space (estimated at $10,000-$20,000 per kilogram to low Earth orbit) can be substantially reduced through local resource utilization. This cost reduction makes long-duration missions and permanent extraterrestrial settlements more economically viable, opening new frontiers for sustainable human presence beyond Earth.

The long-term sustainability impact extends to the concept of planetary protection. By reducing dependence on Earth's resources and minimizing waste generation in space, ISRU technologies help preserve both Earth's environment and the pristine nature of other celestial bodies. This aligns with international space policy objectives that emphasize responsible exploration and utilization of space resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!