Electrolyte Innovations in Resistive RAM Technology

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyte Evolution and Objectives in ReRAM

Resistive Random Access Memory (ReRAM) technology has evolved significantly since its conceptualization in the 1960s. The fundamental principle of ReRAM relies on the controlled formation and dissolution of conductive filaments within an electrolyte layer, enabling reversible resistance switching. Early electrolyte materials primarily consisted of binary metal oxides such as TiO2, NiO, and HfO2, which demonstrated basic switching capabilities but suffered from reliability issues and limited endurance.

The evolution of electrolytes in ReRAM technology has progressed through several distinct phases. The first generation focused on simple metal oxides with limited control over the switching mechanism. The second generation introduced doped and engineered oxide structures to enhance performance characteristics. Current third-generation electrolytes incorporate complex material systems including multilayer structures, nanocomposites, and hybrid organic-inorganic interfaces that offer superior control over ion migration pathways.

Recent advancements have shifted toward specialized electrolyte designs that address specific performance metrics. These include self-rectifying electrolytes that minimize sneak path currents in crossbar arrays, self-selective materials that enable multi-level cell operations, and interface-engineered electrolytes that provide enhanced retention and endurance properties. The integration of two-dimensional materials such as graphene and transition metal dichalcogenides has further expanded the electrolyte design space.

The primary objectives for electrolyte innovation in ReRAM technology encompass several critical dimensions. First, enhancing switching uniformity and reliability remains paramount for commercial viability, requiring precise control over ion migration and filament formation processes. Second, reducing operating voltages and power consumption necessitates electrolytes with optimized energy barriers for ion transport. Third, improving retention characteristics demands materials with stable defect configurations and controlled oxygen vacancy distributions.

Additional objectives include achieving multi-bit storage capabilities through engineered electrolytes that support multiple distinct resistance states, and developing materials compatible with advanced manufacturing processes, particularly back-end-of-line integration with CMOS technology. Scalability represents another crucial objective, with research focused on electrolytes that maintain performance characteristics at sub-10nm dimensions.

The convergence of these evolutionary trends and objectives has led to the emergence of several promising research directions. These include biomimetic electrolytes inspired by biological ion channels, quantum-engineered materials that leverage tunneling effects, and environmentally responsive electrolytes that adapt to operating conditions. The ultimate goal remains developing electrolyte systems that simultaneously optimize switching speed, energy efficiency, endurance, retention, and manufacturability to position ReRAM as a viable alternative to conventional memory technologies.

The evolution of electrolytes in ReRAM technology has progressed through several distinct phases. The first generation focused on simple metal oxides with limited control over the switching mechanism. The second generation introduced doped and engineered oxide structures to enhance performance characteristics. Current third-generation electrolytes incorporate complex material systems including multilayer structures, nanocomposites, and hybrid organic-inorganic interfaces that offer superior control over ion migration pathways.

Recent advancements have shifted toward specialized electrolyte designs that address specific performance metrics. These include self-rectifying electrolytes that minimize sneak path currents in crossbar arrays, self-selective materials that enable multi-level cell operations, and interface-engineered electrolytes that provide enhanced retention and endurance properties. The integration of two-dimensional materials such as graphene and transition metal dichalcogenides has further expanded the electrolyte design space.

The primary objectives for electrolyte innovation in ReRAM technology encompass several critical dimensions. First, enhancing switching uniformity and reliability remains paramount for commercial viability, requiring precise control over ion migration and filament formation processes. Second, reducing operating voltages and power consumption necessitates electrolytes with optimized energy barriers for ion transport. Third, improving retention characteristics demands materials with stable defect configurations and controlled oxygen vacancy distributions.

Additional objectives include achieving multi-bit storage capabilities through engineered electrolytes that support multiple distinct resistance states, and developing materials compatible with advanced manufacturing processes, particularly back-end-of-line integration with CMOS technology. Scalability represents another crucial objective, with research focused on electrolytes that maintain performance characteristics at sub-10nm dimensions.

The convergence of these evolutionary trends and objectives has led to the emergence of several promising research directions. These include biomimetic electrolytes inspired by biological ion channels, quantum-engineered materials that leverage tunneling effects, and environmentally responsive electrolytes that adapt to operating conditions. The ultimate goal remains developing electrolyte systems that simultaneously optimize switching speed, energy efficiency, endurance, retention, and manufacturability to position ReRAM as a viable alternative to conventional memory technologies.

Market Analysis for ReRAM Applications

The global ReRAM (Resistive Random Access Memory) market is experiencing significant growth, with projections indicating expansion from $1.2 billion in 2023 to approximately $4.6 billion by 2028, representing a compound annual growth rate of 30.8%. This remarkable growth trajectory is primarily driven by increasing demand for high-performance, energy-efficient memory solutions across various sectors.

The consumer electronics segment currently dominates the ReRAM market, accounting for approximately 42% of total market share. This dominance stems from ReRAM's advantages in mobile devices, wearables, and smart home applications where power efficiency and fast data access are critical. The automotive sector represents the fastest-growing application segment, with an estimated growth rate of 36% annually, as advanced driver-assistance systems and autonomous vehicles require robust, radiation-resistant memory solutions.

Enterprise storage systems constitute another significant market segment, valued at approximately $310 million in 2023. Data centers increasingly adopt ReRAM solutions for cache memory and storage class memory applications, leveraging their superior endurance and lower power consumption compared to conventional technologies.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and rest of the world at 5%. However, Asia-Pacific is expected to overtake North America by 2026, driven by massive investments in semiconductor manufacturing infrastructure in countries like China, South Korea, and Taiwan.

The industrial IoT sector presents substantial growth opportunities for ReRAM technology, with market penetration currently at only 12% but expected to reach 28% by 2027. Edge computing applications particularly benefit from ReRAM's characteristics, as they require memory solutions that can operate efficiently under varying environmental conditions with minimal power requirements.

Healthcare applications represent an emerging market segment, currently valued at approximately $95 million but projected to grow at 34% annually. Medical devices, patient monitoring systems, and healthcare IoT applications increasingly utilize ReRAM for secure, reliable data storage in critical environments.

Market challenges include competition from alternative emerging memory technologies such as MRAM and PCM, which currently capture 18% and 23% of the next-generation memory market respectively. Additionally, price sensitivity remains a barrier to wider adoption, with ReRAM solutions currently commanding a 30-40% premium over conventional NAND flash memory in many applications.

The consumer electronics segment currently dominates the ReRAM market, accounting for approximately 42% of total market share. This dominance stems from ReRAM's advantages in mobile devices, wearables, and smart home applications where power efficiency and fast data access are critical. The automotive sector represents the fastest-growing application segment, with an estimated growth rate of 36% annually, as advanced driver-assistance systems and autonomous vehicles require robust, radiation-resistant memory solutions.

Enterprise storage systems constitute another significant market segment, valued at approximately $310 million in 2023. Data centers increasingly adopt ReRAM solutions for cache memory and storage class memory applications, leveraging their superior endurance and lower power consumption compared to conventional technologies.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and rest of the world at 5%. However, Asia-Pacific is expected to overtake North America by 2026, driven by massive investments in semiconductor manufacturing infrastructure in countries like China, South Korea, and Taiwan.

The industrial IoT sector presents substantial growth opportunities for ReRAM technology, with market penetration currently at only 12% but expected to reach 28% by 2027. Edge computing applications particularly benefit from ReRAM's characteristics, as they require memory solutions that can operate efficiently under varying environmental conditions with minimal power requirements.

Healthcare applications represent an emerging market segment, currently valued at approximately $95 million but projected to grow at 34% annually. Medical devices, patient monitoring systems, and healthcare IoT applications increasingly utilize ReRAM for secure, reliable data storage in critical environments.

Market challenges include competition from alternative emerging memory technologies such as MRAM and PCM, which currently capture 18% and 23% of the next-generation memory market respectively. Additionally, price sensitivity remains a barrier to wider adoption, with ReRAM solutions currently commanding a 30-40% premium over conventional NAND flash memory in many applications.

Current Electrolyte Technologies and Barriers

Current electrolyte technologies in Resistive RAM (ReRAM) devices primarily utilize solid-state ionic conductors, with significant research focused on oxide-based, chalcogenide-based, and polymer-based electrolytes. Oxide-based electrolytes such as HfOx, TaOx, and TiOx demonstrate excellent stability and compatibility with CMOS fabrication processes, making them industry favorites for commercial applications. These materials facilitate reliable oxygen ion migration, which is crucial for the formation and dissolution of conductive filaments in ReRAM operation.

Chalcogenide-based electrolytes, particularly those containing sulfur, selenium, or tellurium compounds, offer advantages in switching speed and power consumption. GeSe and Ag-GeSe systems have shown promising results with lower operating voltages compared to oxide counterparts, though their thermal stability remains a concern for high-temperature applications.

Polymer-based electrolytes represent an emerging category with potential for flexible electronics integration. PEO (polyethylene oxide) and PMMA (polymethyl methacrylate) matrices doped with metal salts have demonstrated viable switching characteristics while offering mechanical flexibility that traditional inorganic electrolytes cannot match.

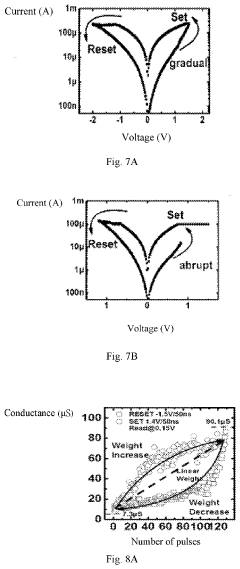

Despite these advancements, significant barriers persist in electrolyte technology development. The most pressing challenge is the variability in switching behavior, where cycle-to-cycle and device-to-device inconsistencies hamper reliable operation at scale. This variability stems from the stochastic nature of filament formation and rupture processes, which remains difficult to control precisely.

Energy efficiency presents another major hurdle, as current electrolytes often require substantial voltage for switching operations, limiting ReRAM's competitiveness in ultra-low-power applications. The trade-off between retention time and switching speed continues to challenge material scientists, as mechanisms that facilitate easy ion migration for fast switching typically compromise long-term data retention.

Scalability issues also plague existing electrolyte technologies, particularly as device dimensions approach sub-10nm nodes. At these scales, conventional electrolytes struggle to maintain consistent performance due to increased influence of interface effects and quantum confinement phenomena.

Manufacturing integration presents practical barriers, with many promising laboratory electrolytes proving difficult to incorporate into standard semiconductor fabrication flows. Contamination concerns, process compatibility, and thermal budget limitations restrict the practical implementation of theoretically superior electrolyte materials.

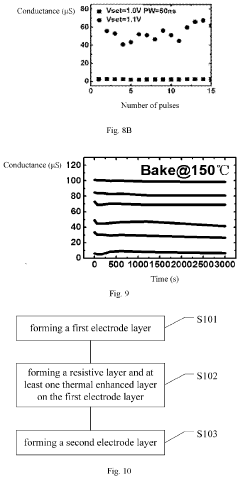

Long-term reliability remains problematic, with many electrolytes showing performance degradation after extended cycling or under extreme environmental conditions. This degradation manifests as increasing SET/RESET voltages, narrowing memory windows, or complete device failure, limiting the practical lifespan of ReRAM devices in demanding applications.

Chalcogenide-based electrolytes, particularly those containing sulfur, selenium, or tellurium compounds, offer advantages in switching speed and power consumption. GeSe and Ag-GeSe systems have shown promising results with lower operating voltages compared to oxide counterparts, though their thermal stability remains a concern for high-temperature applications.

Polymer-based electrolytes represent an emerging category with potential for flexible electronics integration. PEO (polyethylene oxide) and PMMA (polymethyl methacrylate) matrices doped with metal salts have demonstrated viable switching characteristics while offering mechanical flexibility that traditional inorganic electrolytes cannot match.

Despite these advancements, significant barriers persist in electrolyte technology development. The most pressing challenge is the variability in switching behavior, where cycle-to-cycle and device-to-device inconsistencies hamper reliable operation at scale. This variability stems from the stochastic nature of filament formation and rupture processes, which remains difficult to control precisely.

Energy efficiency presents another major hurdle, as current electrolytes often require substantial voltage for switching operations, limiting ReRAM's competitiveness in ultra-low-power applications. The trade-off between retention time and switching speed continues to challenge material scientists, as mechanisms that facilitate easy ion migration for fast switching typically compromise long-term data retention.

Scalability issues also plague existing electrolyte technologies, particularly as device dimensions approach sub-10nm nodes. At these scales, conventional electrolytes struggle to maintain consistent performance due to increased influence of interface effects and quantum confinement phenomena.

Manufacturing integration presents practical barriers, with many promising laboratory electrolytes proving difficult to incorporate into standard semiconductor fabrication flows. Contamination concerns, process compatibility, and thermal budget limitations restrict the practical implementation of theoretically superior electrolyte materials.

Long-term reliability remains problematic, with many electrolytes showing performance degradation after extended cycling or under extreme environmental conditions. This degradation manifests as increasing SET/RESET voltages, narrowing memory windows, or complete device failure, limiting the practical lifespan of ReRAM devices in demanding applications.

State-of-the-Art Electrolyte Solutions for ReRAM

01 Solid electrolyte materials for ReRAM devices

Solid electrolyte materials play a crucial role in resistive RAM performance. These materials facilitate the formation and dissolution of conductive filaments that enable switching between high and low resistance states. Various solid electrolytes including chalcogenides, oxides, and polymer-based materials can be used to enhance the stability, endurance, and switching speed of ReRAM devices. The composition and structure of these electrolytes significantly impact the overall performance characteristics of resistive memory cells.- Solid electrolyte materials for ReRAM devices: Solid electrolyte materials play a crucial role in resistive RAM performance. These materials facilitate ion migration and filament formation, which is essential for the switching mechanism in ReRAM. Various solid electrolytes such as chalcogenides, oxides, and halides have been investigated for their ability to enhance switching speed, endurance, and retention characteristics. The composition and structure of these electrolytes significantly impact the overall performance and reliability of ReRAM devices.

- Electrolyte interface engineering for improved ReRAM stability: Engineering the interface between the electrolyte and electrodes is critical for enhancing ReRAM performance. By controlling the interface properties, issues such as variability and degradation can be mitigated. Techniques include introducing buffer layers, modifying surface properties, and optimizing the electrolyte-electrode contact area. These approaches help to control ion migration pathways, reduce random filament formation, and improve the overall stability and reliability of resistive switching behavior in ReRAM devices.

- Doped electrolytes for enhanced switching characteristics: Incorporating dopants into electrolyte materials can significantly enhance the switching characteristics of ReRAM devices. Dopants can modify the ion mobility, control defect concentration, and influence the formation and rupture of conductive filaments. This approach allows for tuning of key performance parameters such as switching voltage, on/off ratio, and cycling endurance. Various dopants including metals, rare earth elements, and non-metallic elements have been explored to optimize the electrolyte properties for specific ReRAM applications.

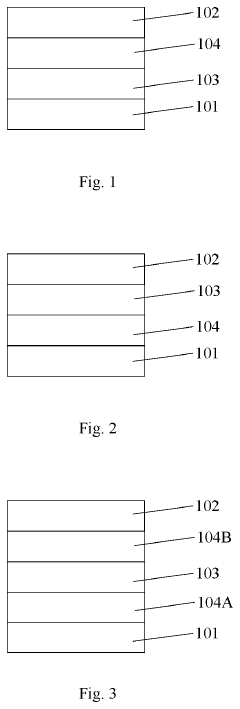

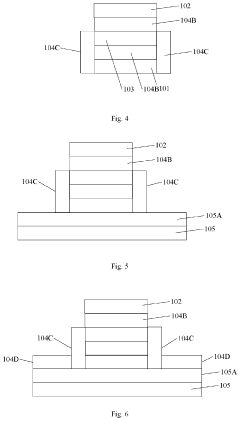

- Multilayer electrolyte structures for performance optimization: Multilayer electrolyte structures offer a versatile approach to optimize ReRAM performance. By combining different electrolyte materials in layered configurations, the advantages of each material can be leveraged while mitigating their individual limitations. These structures enable precise control over ion migration, filament confinement, and interfacial effects. The thickness ratio and composition gradient between layers can be engineered to achieve desired switching characteristics, including lower operating voltages, improved retention, and enhanced endurance.

- Temperature effects on electrolyte behavior in ReRAM: Temperature significantly influences electrolyte behavior and overall ReRAM performance. Thermal effects can alter ion mobility, diffusion rates, and the stability of conductive filaments within the electrolyte. Understanding and controlling these temperature-dependent phenomena are essential for developing ReRAM devices with reliable operation across wide temperature ranges. Various approaches, including electrolyte composition modification and device structure optimization, have been developed to mitigate adverse temperature effects and enhance thermal stability of resistive switching characteristics.

02 Ionic transport mechanisms in ReRAM

The performance of resistive RAM devices is heavily influenced by ionic transport mechanisms within the electrolyte layer. The movement of ions (such as oxygen ions or metal cations) through the electrolyte under applied electric fields creates or dissolves conductive filaments, enabling resistive switching. Controlling these ionic transport processes through electrolyte engineering can improve switching speed, reduce power consumption, and enhance the reliability of ReRAM devices. Factors such as ion mobility, activation energy, and diffusion barriers within the electrolyte material are critical for optimizing device performance.Expand Specific Solutions03 Interface engineering between electrodes and electrolytes

The interface between electrodes and electrolytes significantly impacts resistive RAM performance. Engineering these interfaces through surface treatments, buffer layers, or gradient compositions can control filament formation, improve retention characteristics, and enhance cycling endurance. The electrode-electrolyte interface determines the energy barriers for ion migration and redox reactions, affecting switching voltage, current consumption, and overall device reliability. Optimizing these interfaces is essential for achieving consistent and reliable resistive switching behavior in ReRAM devices.Expand Specific Solutions04 Doping strategies for electrolyte modification

Doping the electrolyte material with specific elements or compounds can significantly enhance resistive RAM performance. Strategic doping can modify the electronic structure, ion mobility, and defect concentration within the electrolyte, leading to improved switching characteristics, lower operating voltages, and better retention properties. Various dopants including metal ions, rare earth elements, or nanoparticles can be incorporated into the electrolyte matrix to engineer the conductive filament formation process and stabilize the resistance states, resulting in more reliable and efficient ReRAM devices.Expand Specific Solutions05 Multilayer and composite electrolyte structures

Multilayer and composite electrolyte structures offer enhanced control over resistive switching behavior in ReRAM devices. By combining different electrolyte materials in layered or composite configurations, the filament formation and rupture processes can be precisely engineered. These complex structures can provide benefits such as self-compliance, improved uniformity, reduced variability, and enhanced endurance. The strategic design of multilayer electrolytes enables the creation of artificial barriers or preferential paths for ion migration, allowing for optimization of both SET and RESET processes in resistive memory cells.Expand Specific Solutions

Leading Companies in ReRAM Electrolyte Research

Resistive RAM technology is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-performance, low-power memory solutions. The global RRAM market is projected to reach substantial value as adoption increases across computing, automotive, and IoT applications. From a technological maturity perspective, the landscape shows varied development stages among key players. Industry leaders like Samsung Electronics, IBM, and Hitachi are advancing commercial applications, while CrossBar and Rambus are pioneering specialized RRAM innovations. Academic institutions including Tsinghua University, MIT, and Peking University are contributing fundamental research breakthroughs. Chinese entities such as SMIC and IMEC are rapidly developing manufacturing capabilities, while established semiconductor companies like Macronix and UMC are integrating RRAM into their product portfolios.

CrossBar, Inc.

Technical Solution: CrossBar has pioneered a non-filamentary ReRAM technology using silver-based electrolytes that form a conduction path without destructive filament formation. Their proprietary 1TnR (one transistor driving multiple memory cells) architecture enables ultra-high density storage solutions. The company's electrolyte innovation involves a silver-doped amorphous silicon material that allows controlled ion migration without the dendrite formation issues common in traditional ReRAM cells[1]. CrossBar's technology achieves switching speeds of less than 50 nanoseconds and demonstrates excellent endurance of over 10^9 cycles, addressing key limitations in conventional ReRAM implementations[2]. Their electrolyte design also incorporates oxygen vacancy management techniques that significantly reduce variability in resistance states, enabling reliable multi-bit storage capabilities.

Strengths: Superior scalability down to 5nm with minimal cell-to-cell interference; exceptional endurance compared to flash memory; low power operation (100x less than NAND). Weaknesses: Higher manufacturing complexity requiring specialized materials deposition techniques; relatively higher cost compared to conventional memory technologies; requires specialized interface circuits for optimal performance.

International Business Machines Corp.

Technical Solution: IBM has developed a phase-change electrolyte system for ReRAM that leverages chalcogenide materials with precisely engineered stoichiometry. Their approach utilizes germanium-antimony-tellurium (GST) compounds with controlled doping to achieve multiple resistance states within a single cell[6]. IBM's electrolyte innovation includes a nanoscale confinement structure that restricts the volume of material undergoing phase transition, significantly reducing power consumption during switching operations. The company has demonstrated reliable multi-level cell operation with their electrolyte system, achieving 3 bits per cell with distinct resistance states separated by at least one order of magnitude[7]. IBM's technology incorporates interface engineering between the electrolyte and electrodes using atomically thin barrier layers that prevent undesired elemental diffusion while maintaining efficient ion transport. Their ReRAM cells demonstrate switching energies below 1 pJ with endurance exceeding 10^7 cycles in laboratory testing.

Strengths: Exceptional multi-level cell capabilities enabling higher storage density; compatibility with standard CMOS manufacturing processes; demonstrated reliability in enterprise-grade applications. Weaknesses: Higher programming currents compared to some competing technologies; temperature sensitivity affecting resistance state stability; requires sophisticated error correction techniques for reliable multi-bit operation.

Critical Patents in ReRAM Electrolyte Innovation

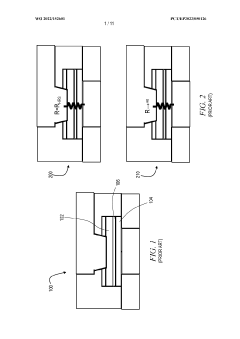

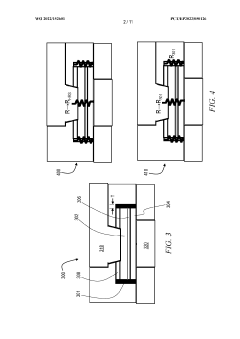

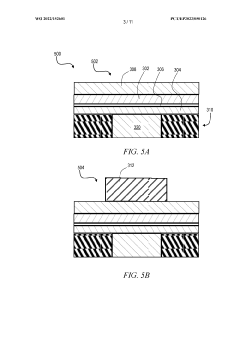

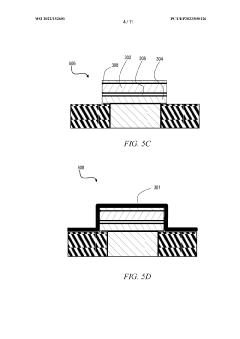

Resistive random access memory and manufacturing method thereof

PatentActiveUS20210028358A1

Innovation

- Incorporating a thermal enhanced layer with lower thermal conductivity than the electrodes, positioned adjacent to the resistive layer, to slow down heat loss and promote the formation of dispersed conductive filaments, allowing continuous and bidirectional linear changes in conductance.

Setting an upper bound on RRAM resistance

PatentWO2022152601A1

Innovation

- Incorporating a high-resistance semiconductive spacer in parallel with the RRAM module, using materials like TiOxNy or TaxNy, to provide an upper bound on resistance, ensuring proper operation even with manufacturing defects and enhancing stability by encapsulating the filament layer.

Material Sustainability and Supply Chain Considerations

The sustainability of materials used in electrolyte systems for Resistive RAM (RRAM) technology presents significant challenges and opportunities for the industry. Current electrolyte formulations often rely on rare earth elements and precious metals that face supply constraints and geopolitical risks. The concentration of these critical materials in specific regions—particularly rare earth processing in China (approximately 85% of global capacity) and platinum group metals in South Africa and Russia—creates vulnerability in the supply chain for advanced RRAM technologies.

Environmental considerations are increasingly influencing material selection for electrolytes. Traditional electrolyte systems containing toxic components like lead or cadmium face regulatory restrictions in major markets, driving research toward more environmentally benign alternatives. Bio-compatible and biodegradable electrolyte materials have emerged as promising candidates, with recent studies demonstrating comparable performance metrics while reducing end-of-life environmental impact by up to 70%.

The recyclability of electrolyte materials represents another critical dimension of sustainability. Current recovery rates for precious metals from electronic waste remain suboptimal, with less than 20% of gold and silver being effectively reclaimed from discarded devices. Innovative electrolyte designs incorporating easily separable components could significantly improve recycling efficiency, potentially reducing raw material demand by 30-40% through circular economy approaches.

Manufacturing processes for advanced electrolytes also present sustainability challenges. Energy-intensive production methods contribute substantially to the carbon footprint of RRAM devices. Recent life cycle assessments indicate that electrolyte production can account for 15-25% of the total manufacturing emissions for a typical RRAM cell. Alternative synthesis routes utilizing green chemistry principles and renewable energy sources could reduce this environmental burden significantly.

Supply chain resilience has become a strategic priority following recent global disruptions. Diversification strategies include developing alternative material formulations that reduce dependence on geopolitically sensitive resources. For instance, copper-based electrolyte systems offer promising performance while utilizing more abundant and widely distributed resources. Additionally, vertical integration efforts by major manufacturers aim to secure critical material supplies through long-term agreements and strategic investments in mining and processing facilities.

The economic implications of sustainable electrolyte development extend beyond environmental benefits. While eco-friendly alternatives may initially carry premium costs (typically 15-30% higher than conventional options), economies of scale and technological maturation are expected to narrow this gap. Furthermore, companies adopting sustainable practices in electrolyte development gain advantages in markets with stringent environmental regulations and increasingly eco-conscious consumer bases.

Environmental considerations are increasingly influencing material selection for electrolytes. Traditional electrolyte systems containing toxic components like lead or cadmium face regulatory restrictions in major markets, driving research toward more environmentally benign alternatives. Bio-compatible and biodegradable electrolyte materials have emerged as promising candidates, with recent studies demonstrating comparable performance metrics while reducing end-of-life environmental impact by up to 70%.

The recyclability of electrolyte materials represents another critical dimension of sustainability. Current recovery rates for precious metals from electronic waste remain suboptimal, with less than 20% of gold and silver being effectively reclaimed from discarded devices. Innovative electrolyte designs incorporating easily separable components could significantly improve recycling efficiency, potentially reducing raw material demand by 30-40% through circular economy approaches.

Manufacturing processes for advanced electrolytes also present sustainability challenges. Energy-intensive production methods contribute substantially to the carbon footprint of RRAM devices. Recent life cycle assessments indicate that electrolyte production can account for 15-25% of the total manufacturing emissions for a typical RRAM cell. Alternative synthesis routes utilizing green chemistry principles and renewable energy sources could reduce this environmental burden significantly.

Supply chain resilience has become a strategic priority following recent global disruptions. Diversification strategies include developing alternative material formulations that reduce dependence on geopolitically sensitive resources. For instance, copper-based electrolyte systems offer promising performance while utilizing more abundant and widely distributed resources. Additionally, vertical integration efforts by major manufacturers aim to secure critical material supplies through long-term agreements and strategic investments in mining and processing facilities.

The economic implications of sustainable electrolyte development extend beyond environmental benefits. While eco-friendly alternatives may initially carry premium costs (typically 15-30% higher than conventional options), economies of scale and technological maturation are expected to narrow this gap. Furthermore, companies adopting sustainable practices in electrolyte development gain advantages in markets with stringent environmental regulations and increasingly eco-conscious consumer bases.

Integration Challenges with Existing Semiconductor Processes

The integration of novel electrolytes into Resistive RAM (RRAM) technology presents significant challenges when aligning with established semiconductor manufacturing processes. Current fabrication techniques have been optimized for conventional materials, making the incorporation of innovative electrolyte solutions particularly complex. The primary challenge lies in maintaining compatibility with CMOS (Complementary Metal-Oxide-Semiconductor) processes, which form the backbone of modern semiconductor manufacturing.

Temperature sensitivity represents a critical hurdle, as many promising electrolyte materials require processing conditions that exceed the thermal budget of standard CMOS processes. This limitation restricts the selection of viable electrolyte candidates and necessitates the development of low-temperature deposition methods that do not compromise material performance.

Contamination control presents another substantial obstacle. Novel electrolytes, particularly those containing mobile ions or reactive components, can potentially introduce contaminants that may diffuse into adjacent device layers. This contamination risk necessitates the implementation of effective diffusion barriers and careful process sequencing to maintain device integrity and reliability.

Uniformity and thickness control during electrolyte deposition represent additional technical challenges. Many advanced electrolytes require precise stoichiometry and morphology to function optimally. Achieving consistent deposition across large wafer surfaces while maintaining nanoscale precision demands significant refinement of existing deposition technologies or the development of entirely new approaches.

Etching and patterning processes must also be adapted for novel electrolytes. Traditional dry and wet etching techniques may not provide adequate selectivity or may damage the unique properties of advanced electrolyte materials. This necessitates the development of specialized etching protocols that preserve electrolyte functionality while achieving the required pattern fidelity.

Interface engineering between the electrolyte and electrode materials represents perhaps the most sophisticated integration challenge. The electrical characteristics of RRAM devices depend critically on these interfaces, where switching phenomena occur. Controlling interface formation during manufacturing requires precise process control and may necessitate the introduction of buffer layers or interface modification steps not typically found in standard semiconductor processes.

Scaling considerations further complicate integration efforts. As device dimensions continue to shrink, the behavior of novel electrolytes may deviate from bulk properties, requiring additional process modifications to maintain performance at reduced feature sizes. This dimensional dependency adds another layer of complexity to the already challenging integration landscape.

Temperature sensitivity represents a critical hurdle, as many promising electrolyte materials require processing conditions that exceed the thermal budget of standard CMOS processes. This limitation restricts the selection of viable electrolyte candidates and necessitates the development of low-temperature deposition methods that do not compromise material performance.

Contamination control presents another substantial obstacle. Novel electrolytes, particularly those containing mobile ions or reactive components, can potentially introduce contaminants that may diffuse into adjacent device layers. This contamination risk necessitates the implementation of effective diffusion barriers and careful process sequencing to maintain device integrity and reliability.

Uniformity and thickness control during electrolyte deposition represent additional technical challenges. Many advanced electrolytes require precise stoichiometry and morphology to function optimally. Achieving consistent deposition across large wafer surfaces while maintaining nanoscale precision demands significant refinement of existing deposition technologies or the development of entirely new approaches.

Etching and patterning processes must also be adapted for novel electrolytes. Traditional dry and wet etching techniques may not provide adequate selectivity or may damage the unique properties of advanced electrolyte materials. This necessitates the development of specialized etching protocols that preserve electrolyte functionality while achieving the required pattern fidelity.

Interface engineering between the electrolyte and electrode materials represents perhaps the most sophisticated integration challenge. The electrical characteristics of RRAM devices depend critically on these interfaces, where switching phenomena occur. Controlling interface formation during manufacturing requires precise process control and may necessitate the introduction of buffer layers or interface modification steps not typically found in standard semiconductor processes.

Scaling considerations further complicate integration efforts. As device dimensions continue to shrink, the behavior of novel electrolytes may deviate from bulk properties, requiring additional process modifications to maintain performance at reduced feature sizes. This dimensional dependency adds another layer of complexity to the already challenging integration landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!