Evaluating PTFE dielectric film mechanical reinforcement strategies

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Film Background

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery by Roy Plunkett in 1938. As a dielectric film, PTFE offers exceptional electrical insulation properties, chemical resistance, and thermal stability. These characteristics have made it indispensable in applications ranging from electronics to aerospace.

The development of PTFE films has been driven by the increasing demand for high-performance insulation materials in miniaturized electronic devices and high-frequency applications. The unique molecular structure of PTFE, consisting of a carbon backbone with fluorine atoms, contributes to its low dielectric constant and dissipation factor, making it an ideal choice for high-frequency circuit boards and cable insulation.

However, despite its excellent electrical properties, PTFE films have historically faced challenges in terms of mechanical strength and dimensional stability. The same molecular structure that provides its desirable electrical characteristics also results in a relatively soft and pliable material. This has limited its use in applications requiring higher mechanical robustness, particularly in thin film formats.

The need for mechanical reinforcement of PTFE dielectric films has become increasingly apparent as the electronics industry continues to push the boundaries of device miniaturization and performance. Thin PTFE films, while offering superior electrical properties, are prone to deformation, tearing, and dimensional instability under mechanical stress or thermal cycling.

Over the years, researchers and engineers have explored various strategies to enhance the mechanical properties of PTFE films without compromising their electrical characteristics. These efforts have included the development of composite materials, surface modification techniques, and novel manufacturing processes. The goal has been to create PTFE films that maintain their excellent dielectric properties while exhibiting improved tensile strength, tear resistance, and dimensional stability.

The evolution of PTFE film reinforcement strategies has been closely tied to advancements in material science and nanotechnology. Early approaches focused on blending PTFE with other polymers or incorporating fibrous materials. More recent innovations have explored the potential of nanoparticle additives and controlled crystallization processes to enhance the film's mechanical properties at the molecular level.

As the demand for high-performance dielectric materials continues to grow across various industries, the development of mechanically reinforced PTFE films remains an active area of research and innovation. The challenge lies in striking the optimal balance between electrical performance and mechanical robustness, opening up new possibilities for PTFE films in demanding applications such as flexible electronics, high-frequency communications, and aerospace technologies.

The development of PTFE films has been driven by the increasing demand for high-performance insulation materials in miniaturized electronic devices and high-frequency applications. The unique molecular structure of PTFE, consisting of a carbon backbone with fluorine atoms, contributes to its low dielectric constant and dissipation factor, making it an ideal choice for high-frequency circuit boards and cable insulation.

However, despite its excellent electrical properties, PTFE films have historically faced challenges in terms of mechanical strength and dimensional stability. The same molecular structure that provides its desirable electrical characteristics also results in a relatively soft and pliable material. This has limited its use in applications requiring higher mechanical robustness, particularly in thin film formats.

The need for mechanical reinforcement of PTFE dielectric films has become increasingly apparent as the electronics industry continues to push the boundaries of device miniaturization and performance. Thin PTFE films, while offering superior electrical properties, are prone to deformation, tearing, and dimensional instability under mechanical stress or thermal cycling.

Over the years, researchers and engineers have explored various strategies to enhance the mechanical properties of PTFE films without compromising their electrical characteristics. These efforts have included the development of composite materials, surface modification techniques, and novel manufacturing processes. The goal has been to create PTFE films that maintain their excellent dielectric properties while exhibiting improved tensile strength, tear resistance, and dimensional stability.

The evolution of PTFE film reinforcement strategies has been closely tied to advancements in material science and nanotechnology. Early approaches focused on blending PTFE with other polymers or incorporating fibrous materials. More recent innovations have explored the potential of nanoparticle additives and controlled crystallization processes to enhance the film's mechanical properties at the molecular level.

As the demand for high-performance dielectric materials continues to grow across various industries, the development of mechanically reinforced PTFE films remains an active area of research and innovation. The challenge lies in striking the optimal balance between electrical performance and mechanical robustness, opening up new possibilities for PTFE films in demanding applications such as flexible electronics, high-frequency communications, and aerospace technologies.

Market Demand Analysis

The market demand for PTFE dielectric film mechanical reinforcement strategies has been steadily growing, driven by the increasing need for high-performance materials in various industries. The electronics sector, particularly in the production of capacitors and printed circuit boards, has been a significant driver of this demand. As electronic devices become more compact and powerful, there is a growing requirement for dielectric materials that can withstand higher voltages and temperatures while maintaining their electrical properties.

The aerospace and automotive industries have also contributed to the rising demand for reinforced PTFE dielectric films. These sectors require materials that can perform reliably under extreme conditions, such as high temperatures, pressure variations, and exposure to harsh chemicals. The enhanced mechanical properties of reinforced PTFE films make them ideal for these applications, leading to increased adoption in critical components like fuel systems, electrical insulation, and sensor technologies.

In the renewable energy sector, particularly in solar panel manufacturing and wind turbine production, there is a growing need for durable and efficient dielectric materials. Reinforced PTFE films offer improved longevity and performance in these applications, contributing to the overall efficiency and lifespan of renewable energy systems. This has led to a notable increase in demand from this sector, with projections indicating continued growth as global renewable energy initiatives expand.

The medical industry has also shown increasing interest in reinforced PTFE dielectric films. Applications in medical devices, implantable electronics, and diagnostic equipment require materials with excellent biocompatibility, chemical resistance, and electrical insulation properties. The mechanical reinforcement of PTFE films addresses these requirements, leading to their increased use in cutting-edge medical technologies.

Market analysis indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing the fastest growth in demand for reinforced PTFE dielectric films. This is largely due to the rapid expansion of electronics manufacturing and technological innovation in these countries. North America and Europe continue to be significant markets, driven by advancements in aerospace, automotive, and medical technologies.

The global trend towards miniaturization and increased functionality in electronic devices is expected to further boost the demand for reinforced PTFE dielectric films. As devices become smaller and more complex, the need for materials that can maintain their dielectric properties under mechanical stress becomes more critical. This trend is likely to continue, opening up new opportunities for innovation in PTFE reinforcement strategies.

The aerospace and automotive industries have also contributed to the rising demand for reinforced PTFE dielectric films. These sectors require materials that can perform reliably under extreme conditions, such as high temperatures, pressure variations, and exposure to harsh chemicals. The enhanced mechanical properties of reinforced PTFE films make them ideal for these applications, leading to increased adoption in critical components like fuel systems, electrical insulation, and sensor technologies.

In the renewable energy sector, particularly in solar panel manufacturing and wind turbine production, there is a growing need for durable and efficient dielectric materials. Reinforced PTFE films offer improved longevity and performance in these applications, contributing to the overall efficiency and lifespan of renewable energy systems. This has led to a notable increase in demand from this sector, with projections indicating continued growth as global renewable energy initiatives expand.

The medical industry has also shown increasing interest in reinforced PTFE dielectric films. Applications in medical devices, implantable electronics, and diagnostic equipment require materials with excellent biocompatibility, chemical resistance, and electrical insulation properties. The mechanical reinforcement of PTFE films addresses these requirements, leading to their increased use in cutting-edge medical technologies.

Market analysis indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing the fastest growth in demand for reinforced PTFE dielectric films. This is largely due to the rapid expansion of electronics manufacturing and technological innovation in these countries. North America and Europe continue to be significant markets, driven by advancements in aerospace, automotive, and medical technologies.

The global trend towards miniaturization and increased functionality in electronic devices is expected to further boost the demand for reinforced PTFE dielectric films. As devices become smaller and more complex, the need for materials that can maintain their dielectric properties under mechanical stress becomes more critical. This trend is likely to continue, opening up new opportunities for innovation in PTFE reinforcement strategies.

Technical Challenges

PTFE (polytetrafluoroethylene) dielectric films are widely used in various electronic applications due to their excellent electrical insulation properties. However, these films often face challenges in terms of mechanical strength and durability, which can limit their performance and lifespan in demanding environments. The primary technical challenge in evaluating PTFE dielectric film mechanical reinforcement strategies lies in finding the optimal balance between enhancing mechanical properties and maintaining the film's desirable electrical characteristics.

One of the main obstacles is the inherent nature of PTFE, which is known for its low surface energy and chemical inertness. These properties, while beneficial for many applications, make it difficult to achieve strong adhesion between PTFE and reinforcing materials. This poor adhesion can lead to delamination or separation of the reinforcing layer from the PTFE film, compromising the overall mechanical integrity of the composite structure.

Another significant challenge is the potential impact of reinforcement strategies on the dielectric properties of the PTFE film. Many reinforcement techniques involve the addition of materials or the modification of the PTFE structure, which can alter the film's dielectric constant, dissipation factor, or breakdown strength. Maintaining these critical electrical properties while improving mechanical strength requires careful consideration and precise control of the reinforcement process.

The thermal stability of PTFE dielectric films is also a concern when evaluating reinforcement strategies. PTFE has excellent thermal resistance, but some reinforcement methods may introduce materials or create interfaces that are less thermally stable. This can lead to degradation of the composite film at elevated temperatures, potentially compromising its performance in high-temperature applications.

Uniformity and consistency in the reinforcement process present another technical hurdle. Achieving a homogeneous distribution of reinforcing agents or uniform application of reinforcement techniques across large film areas can be challenging. Non-uniform reinforcement can result in localized weak points or variations in electrical properties, which may lead to premature failure or inconsistent performance of the dielectric film.

Furthermore, the scalability of reinforcement strategies from laboratory-scale experiments to industrial production poses a significant challenge. Techniques that show promise in small-scale studies may face difficulties when scaled up, due to issues such as process control, cost-effectiveness, or compatibility with existing manufacturing equipment.

Lastly, the long-term stability and aging behavior of reinforced PTFE dielectric films remain areas of concern. The interaction between the PTFE matrix and reinforcing elements over time, especially under various environmental conditions and electrical stresses, needs to be thoroughly evaluated to ensure the sustained performance of the reinforced films throughout their intended service life.

One of the main obstacles is the inherent nature of PTFE, which is known for its low surface energy and chemical inertness. These properties, while beneficial for many applications, make it difficult to achieve strong adhesion between PTFE and reinforcing materials. This poor adhesion can lead to delamination or separation of the reinforcing layer from the PTFE film, compromising the overall mechanical integrity of the composite structure.

Another significant challenge is the potential impact of reinforcement strategies on the dielectric properties of the PTFE film. Many reinforcement techniques involve the addition of materials or the modification of the PTFE structure, which can alter the film's dielectric constant, dissipation factor, or breakdown strength. Maintaining these critical electrical properties while improving mechanical strength requires careful consideration and precise control of the reinforcement process.

The thermal stability of PTFE dielectric films is also a concern when evaluating reinforcement strategies. PTFE has excellent thermal resistance, but some reinforcement methods may introduce materials or create interfaces that are less thermally stable. This can lead to degradation of the composite film at elevated temperatures, potentially compromising its performance in high-temperature applications.

Uniformity and consistency in the reinforcement process present another technical hurdle. Achieving a homogeneous distribution of reinforcing agents or uniform application of reinforcement techniques across large film areas can be challenging. Non-uniform reinforcement can result in localized weak points or variations in electrical properties, which may lead to premature failure or inconsistent performance of the dielectric film.

Furthermore, the scalability of reinforcement strategies from laboratory-scale experiments to industrial production poses a significant challenge. Techniques that show promise in small-scale studies may face difficulties when scaled up, due to issues such as process control, cost-effectiveness, or compatibility with existing manufacturing equipment.

Lastly, the long-term stability and aging behavior of reinforced PTFE dielectric films remain areas of concern. The interaction between the PTFE matrix and reinforcing elements over time, especially under various environmental conditions and electrical stresses, needs to be thoroughly evaluated to ensure the sustained performance of the reinforced films throughout their intended service life.

Current Solutions

01 Incorporation of reinforcing materials

PTFE dielectric films can be mechanically reinforced by incorporating various materials such as fibers, particles, or other polymers. These reinforcing agents are dispersed within the PTFE matrix to enhance its mechanical properties, including tensile strength, tear resistance, and dimensional stability. The choice of reinforcing material depends on the specific application requirements and desired properties of the final film.- Incorporation of reinforcing materials: PTFE dielectric films can be mechanically reinforced by incorporating various materials such as fibers, particles, or other polymers. These reinforcing agents are dispersed within the PTFE matrix to enhance its mechanical properties, including tensile strength, tear resistance, and dimensional stability. The choice of reinforcing material depends on the specific application requirements and desired properties of the final film.

- Surface modification techniques: Surface modification of PTFE dielectric films can improve their mechanical properties and adhesion to other materials. Techniques such as plasma treatment, chemical etching, or grafting of functional groups onto the PTFE surface can enhance its compatibility with reinforcing agents or substrates. These modifications can lead to better interfacial bonding and overall mechanical performance of the film.

- Multilayer film structures: Creating multilayer film structures that incorporate PTFE as one of the layers can provide mechanical reinforcement while maintaining the desirable dielectric properties of PTFE. These structures may include alternating layers of PTFE with other polymers or reinforcing materials, resulting in a composite film with enhanced mechanical strength and durability.

- Heat treatment and stretching processes: Applying specific heat treatment and stretching processes during the manufacturing of PTFE dielectric films can significantly improve their mechanical properties. Controlled heating and biaxial stretching can orient the polymer chains, leading to increased tensile strength, tear resistance, and dimensional stability. These processes can be optimized to achieve the desired balance between mechanical reinforcement and dielectric performance.

- Nanocomposite formulations: Incorporating nanoparticles or nanostructures into PTFE dielectric films can provide mechanical reinforcement at the nanoscale. These nanocomposite formulations can include materials such as carbon nanotubes, graphene, or ceramic nanoparticles. The nanoscale reinforcement can significantly enhance the mechanical properties of the film while maintaining its flexibility and dielectric characteristics.

02 Surface modification techniques

Surface modification techniques can be applied to PTFE dielectric films to improve their mechanical properties and adhesion characteristics. These methods may include plasma treatment, chemical etching, or the application of coupling agents. Such modifications can enhance the film's surface energy, allowing for better bonding with other materials and improving overall mechanical performance.Expand Specific Solutions03 Multilayer film structures

Mechanical reinforcement of PTFE dielectric films can be achieved by creating multilayer structures. These structures may combine PTFE layers with other polymer films or reinforcing layers, such as polyimide or glass fiber fabrics. The resulting composite films exhibit improved mechanical strength, dimensional stability, and resistance to tearing while maintaining excellent dielectric properties.Expand Specific Solutions04 Heat treatment and stretching processes

PTFE dielectric films can be mechanically reinforced through specific heat treatment and stretching processes. These techniques involve carefully controlled heating, stretching, and cooling cycles to orient the polymer chains and improve the film's mechanical properties. The resulting films exhibit enhanced tensile strength, tear resistance, and dimensional stability while maintaining their dielectric characteristics.Expand Specific Solutions05 Nanocomposite formulations

Incorporating nanoparticles or nanostructures into PTFE dielectric films can significantly enhance their mechanical properties. These nanocomposite formulations may include materials such as carbon nanotubes, graphene, or ceramic nanoparticles. The nanoscale reinforcements provide improved mechanical strength, thermal stability, and wear resistance while maintaining the film's excellent dielectric properties.Expand Specific Solutions

Key Industry Players

The evaluation of PTFE dielectric film mechanical reinforcement strategies is currently in a growth phase, with increasing market demand driven by advancements in electronics and aerospace industries. The global market size for PTFE films is projected to expand significantly in the coming years. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing mechanical properties. Key players like W. L. Gore & Associates and Daikin Industries are leading in R&D efforts, while companies such as Shandong Dongyue Future Hydrogen Energy Materials and AGC, Inc. are making strides in developing novel reinforcement techniques. Emerging players like Nanjing Comptech Composites and Shandong Senrong New Material are also contributing to the competitive landscape with specialized solutions.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates, Inc. has developed advanced PTFE dielectric film reinforcement strategies, focusing on their ePTFE (expanded PTFE) technology. Their approach involves creating a microporous structure in PTFE films, which enhances mechanical strength while maintaining excellent dielectric properties. The company utilizes a unique stretching process that creates a network of interconnected nodes and fibrils, resulting in a material with high tensile strength and flexibility[1]. This reinforced ePTFE film demonstrates improved tear resistance and dimensional stability compared to standard PTFE films[2]. Gore's reinforcement strategy also incorporates the use of composite structures, combining ePTFE with other materials to further enhance mechanical properties while preserving the desirable electrical characteristics of PTFE[3].

Strengths: Superior mechanical strength, excellent dielectric properties, high flexibility, and improved tear resistance. Weaknesses: Potentially higher production costs and complexity in manufacturing process compared to standard PTFE films.

AGC, Inc. (Japan)

Technical Solution: AGC, Inc. has developed advanced strategies for reinforcing PTFE dielectric films, leveraging their expertise in glass and fluoropolymer technologies. Their approach combines the use of glass fiber reinforcement with modified PTFE formulations to create high-performance dielectric films. AGC's reinforcement strategy involves the incorporation of ultra-thin glass fibers into the PTFE matrix, which significantly enhances the film's tensile strength and dimensional stability[7]. The company has also developed a proprietary surface treatment process for the glass fibers, ensuring optimal adhesion between the fibers and the PTFE matrix, resulting in improved overall mechanical properties[8]. Additionally, AGC has explored the use of hybrid materials, combining PTFE with other fluoropolymers to create films with tailored mechanical and dielectric properties for specific applications[9].

Strengths: Significantly improved mechanical strength, excellent dimensional stability, and customizable properties. Weaknesses: Potential challenges in maintaining uniform dielectric properties across the reinforced film and increased production complexity.

Core Innovations

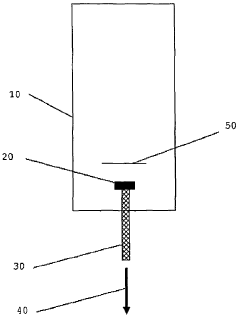

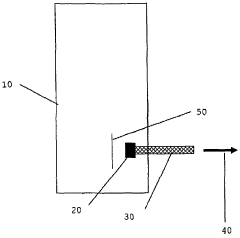

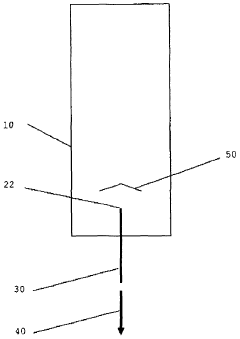

Method of producing monoaxially drawn films of polytetrafluoroethylene

PatentInactiveEP0076246A1

Innovation

- The method involves heating and monoaxially stretching PTFE films between 327°C and 400°C, preferably between 380°C and 390°C, with stretching ratios between 1:1.5 and 1:10, to enhance mechanical and electrical properties.

Method of increasing film tear strength

PatentWO2012033977A1

Innovation

- Incorporating load distribution elements such as slits, perforations, and apertures near the points of applied load or attachment in polymer films to redistribute stress and increase the load required for tear propagation, thereby enhancing the tear strength and suture retention of the films.

Material Properties

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer widely used in various industries due to its exceptional properties. As a dielectric material, PTFE exhibits excellent electrical insulation characteristics, making it ideal for applications in electronics and telecommunications. The material properties of PTFE are crucial in determining its suitability for mechanical reinforcement strategies in dielectric film applications.

PTFE possesses a unique combination of physical and chemical properties that contribute to its performance as a dielectric material. It has a low dielectric constant of approximately 2.1, which remains stable over a wide range of frequencies and temperatures. This property ensures minimal signal loss and distortion in high-frequency applications. Additionally, PTFE demonstrates a high dielectric strength, typically ranging from 50 to 170 kV/mm, allowing it to withstand strong electric fields without breakdown.

The mechanical properties of PTFE are equally important when considering reinforcement strategies. PTFE exhibits a low coefficient of friction, ranging from 0.05 to 0.10, which contributes to its non-stick and self-lubricating properties. However, this low friction can also present challenges in adhesion and bonding processes during reinforcement. The material's tensile strength varies between 20 to 35 MPa, while its elongation at break can reach up to 350%, indicating good flexibility but relatively low mechanical strength compared to other engineering plastics.

PTFE's thermal properties play a significant role in its performance and potential reinforcement strategies. With a melting point of around 327°C and a continuous service temperature of up to 260°C, PTFE maintains its properties over a wide temperature range. This thermal stability is advantageous for applications requiring consistent performance under varying temperature conditions. However, the material's high thermal expansion coefficient, approximately 135 × 10^-6 K^-1, must be considered when designing reinforcement strategies to prevent delamination or warping in composite structures.

The chemical inertness of PTFE is another critical property that influences its use and reinforcement. PTFE is resistant to almost all chemicals and solvents, which contributes to its durability and longevity in harsh environments. This chemical stability, however, can pose challenges in surface modification and bonding processes necessary for certain reinforcement techniques. The material's hydrophobicity, with a water contact angle of approximately 110°, further complicates adhesion in aqueous environments.

When evaluating mechanical reinforcement strategies for PTFE dielectric films, it is essential to consider the material's crystallinity and molecular structure. PTFE has a high degree of crystallinity, typically ranging from 50% to 70%, which contributes to its mechanical strength and dimensional stability. The material's unique molecular structure, consisting of a carbon backbone fully surrounded by fluorine atoms, results in its exceptional chemical and thermal resistance but also limits its compatibility with many conventional reinforcement materials and techniques.

PTFE possesses a unique combination of physical and chemical properties that contribute to its performance as a dielectric material. It has a low dielectric constant of approximately 2.1, which remains stable over a wide range of frequencies and temperatures. This property ensures minimal signal loss and distortion in high-frequency applications. Additionally, PTFE demonstrates a high dielectric strength, typically ranging from 50 to 170 kV/mm, allowing it to withstand strong electric fields without breakdown.

The mechanical properties of PTFE are equally important when considering reinforcement strategies. PTFE exhibits a low coefficient of friction, ranging from 0.05 to 0.10, which contributes to its non-stick and self-lubricating properties. However, this low friction can also present challenges in adhesion and bonding processes during reinforcement. The material's tensile strength varies between 20 to 35 MPa, while its elongation at break can reach up to 350%, indicating good flexibility but relatively low mechanical strength compared to other engineering plastics.

PTFE's thermal properties play a significant role in its performance and potential reinforcement strategies. With a melting point of around 327°C and a continuous service temperature of up to 260°C, PTFE maintains its properties over a wide temperature range. This thermal stability is advantageous for applications requiring consistent performance under varying temperature conditions. However, the material's high thermal expansion coefficient, approximately 135 × 10^-6 K^-1, must be considered when designing reinforcement strategies to prevent delamination or warping in composite structures.

The chemical inertness of PTFE is another critical property that influences its use and reinforcement. PTFE is resistant to almost all chemicals and solvents, which contributes to its durability and longevity in harsh environments. This chemical stability, however, can pose challenges in surface modification and bonding processes necessary for certain reinforcement techniques. The material's hydrophobicity, with a water contact angle of approximately 110°, further complicates adhesion in aqueous environments.

When evaluating mechanical reinforcement strategies for PTFE dielectric films, it is essential to consider the material's crystallinity and molecular structure. PTFE has a high degree of crystallinity, typically ranging from 50% to 70%, which contributes to its mechanical strength and dimensional stability. The material's unique molecular structure, consisting of a carbon backbone fully surrounded by fluorine atoms, results in its exceptional chemical and thermal resistance but also limits its compatibility with many conventional reinforcement materials and techniques.

Environmental Impact

The environmental impact of PTFE dielectric film mechanical reinforcement strategies is a critical consideration in the development and implementation of these technologies. PTFE, or polytetrafluoroethylene, is known for its excellent dielectric properties and chemical resistance. However, the production and disposal of PTFE films can have significant environmental implications.

The manufacturing process of PTFE involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The production of PTFE requires energy-intensive processes, potentially leading to increased carbon footprints. Additionally, the use of certain reinforcement materials may introduce further environmental concerns, depending on their sourcing and production methods.

Mechanical reinforcement strategies often involve the incorporation of additional materials into the PTFE film structure. These materials may include fibers, particles, or other polymers. The environmental impact of these additives must be carefully evaluated, considering factors such as biodegradability, recyclability, and potential for leaching harmful substances into the environment.

The durability and longevity of reinforced PTFE films can have both positive and negative environmental implications. On one hand, increased durability may lead to reduced replacement frequency, potentially lowering overall material consumption and waste generation. Conversely, the enhanced stability of reinforced PTFE films may result in prolonged environmental persistence, raising concerns about long-term accumulation in ecosystems.

End-of-life considerations for reinforced PTFE films are crucial from an environmental perspective. The complex composition of these materials may pose challenges for recycling and proper disposal. Developing effective recycling methods and exploring biodegradable reinforcement options could significantly mitigate the environmental impact of these materials.

Water and soil contamination risks associated with PTFE and its reinforcement materials must be thoroughly assessed. The potential release of perfluorinated compounds during production, use, or disposal of reinforced PTFE films could have far-reaching ecological consequences. Implementing stringent containment and treatment protocols is essential to minimize these risks.

Advancements in green chemistry and sustainable materials science offer promising avenues for reducing the environmental footprint of PTFE dielectric film reinforcement strategies. Exploring bio-based alternatives, developing closed-loop manufacturing processes, and improving end-of-life management can contribute to more environmentally friendly solutions in this field.

The manufacturing process of PTFE involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The production of PTFE requires energy-intensive processes, potentially leading to increased carbon footprints. Additionally, the use of certain reinforcement materials may introduce further environmental concerns, depending on their sourcing and production methods.

Mechanical reinforcement strategies often involve the incorporation of additional materials into the PTFE film structure. These materials may include fibers, particles, or other polymers. The environmental impact of these additives must be carefully evaluated, considering factors such as biodegradability, recyclability, and potential for leaching harmful substances into the environment.

The durability and longevity of reinforced PTFE films can have both positive and negative environmental implications. On one hand, increased durability may lead to reduced replacement frequency, potentially lowering overall material consumption and waste generation. Conversely, the enhanced stability of reinforced PTFE films may result in prolonged environmental persistence, raising concerns about long-term accumulation in ecosystems.

End-of-life considerations for reinforced PTFE films are crucial from an environmental perspective. The complex composition of these materials may pose challenges for recycling and proper disposal. Developing effective recycling methods and exploring biodegradable reinforcement options could significantly mitigate the environmental impact of these materials.

Water and soil contamination risks associated with PTFE and its reinforcement materials must be thoroughly assessed. The potential release of perfluorinated compounds during production, use, or disposal of reinforced PTFE films could have far-reaching ecological consequences. Implementing stringent containment and treatment protocols is essential to minimize these risks.

Advancements in green chemistry and sustainable materials science offer promising avenues for reducing the environmental footprint of PTFE dielectric film reinforcement strategies. Exploring bio-based alternatives, developing closed-loop manufacturing processes, and improving end-of-life management can contribute to more environmentally friendly solutions in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!