Examining EUV Lithography's Contribution to Energy Efficiency

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EUV Lithography Evolution and Efficiency Goals

Extreme Ultraviolet (EUV) lithography represents a revolutionary advancement in semiconductor manufacturing technology, marking a significant departure from traditional Deep Ultraviolet (DUV) lithography methods. The evolution of this technology spans over three decades, beginning in the 1980s with initial research into short-wavelength lithography solutions. By utilizing 13.5nm wavelength light, EUV lithography enables the production of semiconductor components at scales below 7nm, addressing the limitations of previous optical lithography techniques.

The development trajectory of EUV technology has been characterized by persistent engineering challenges and breakthrough innovations. Early research focused primarily on light source development and reflective optics, as traditional refractive optics absorb EUV radiation. The industry witnessed a significant milestone in 2006 when ASML demonstrated the first full-field EUV lithography system, though commercial viability remained distant.

Between 2010 and 2018, intensive research efforts concentrated on increasing EUV source power, enhancing mask infrastructure, and developing suitable photoresists. These advancements culminated in ASML's delivery of production-ready EUV systems in 2019, enabling high-volume manufacturing at the 7nm node and beyond.

The primary efficiency goals driving EUV lithography development extend beyond mere node scaling. A fundamental objective is reducing multi-patterning requirements that plague DUV lithography at advanced nodes. While DUV processes might require quadruple patterning for certain layers, EUV can achieve the same resolution with single exposure, significantly reducing process steps, chemical usage, and energy consumption.

Energy efficiency represents a critical focus area for ongoing EUV development. Current EUV systems consume substantial power—approximately 1MW per tool—primarily due to the energy-intensive plasma generation process required for the EUV light source. Industry roadmaps target 30-40% reduction in energy consumption per wafer processed by 2025, with further improvements projected through 2030.

Material efficiency goals are equally important, with efforts directed toward reducing the consumption of rare gases (particularly hydrogen and helium) used in the EUV process. Additionally, research aims to minimize the use of critical materials in mirrors and other system components while extending their operational lifetime to improve overall sustainability.

The semiconductor industry has established collaborative initiatives to address these efficiency challenges, including the EUV Lithography Energy Efficiency Consortium (ELEEC) and participation in broader semiconductor sustainability programs. These efforts align with both economic imperatives and increasing regulatory pressure for reduced environmental impact in high-tech manufacturing.

The development trajectory of EUV technology has been characterized by persistent engineering challenges and breakthrough innovations. Early research focused primarily on light source development and reflective optics, as traditional refractive optics absorb EUV radiation. The industry witnessed a significant milestone in 2006 when ASML demonstrated the first full-field EUV lithography system, though commercial viability remained distant.

Between 2010 and 2018, intensive research efforts concentrated on increasing EUV source power, enhancing mask infrastructure, and developing suitable photoresists. These advancements culminated in ASML's delivery of production-ready EUV systems in 2019, enabling high-volume manufacturing at the 7nm node and beyond.

The primary efficiency goals driving EUV lithography development extend beyond mere node scaling. A fundamental objective is reducing multi-patterning requirements that plague DUV lithography at advanced nodes. While DUV processes might require quadruple patterning for certain layers, EUV can achieve the same resolution with single exposure, significantly reducing process steps, chemical usage, and energy consumption.

Energy efficiency represents a critical focus area for ongoing EUV development. Current EUV systems consume substantial power—approximately 1MW per tool—primarily due to the energy-intensive plasma generation process required for the EUV light source. Industry roadmaps target 30-40% reduction in energy consumption per wafer processed by 2025, with further improvements projected through 2030.

Material efficiency goals are equally important, with efforts directed toward reducing the consumption of rare gases (particularly hydrogen and helium) used in the EUV process. Additionally, research aims to minimize the use of critical materials in mirrors and other system components while extending their operational lifetime to improve overall sustainability.

The semiconductor industry has established collaborative initiatives to address these efficiency challenges, including the EUV Lithography Energy Efficiency Consortium (ELEEC) and participation in broader semiconductor sustainability programs. These efforts align with both economic imperatives and increasing regulatory pressure for reduced environmental impact in high-tech manufacturing.

Market Demand for Energy-Efficient Semiconductor Manufacturing

The semiconductor industry is experiencing a significant shift towards energy-efficient manufacturing processes, driven by both economic and environmental imperatives. Market research indicates that energy costs represent between 5-10% of the total operational expenses in semiconductor fabrication facilities, creating a substantial financial incentive for energy optimization. This demand is further amplified by increasingly stringent environmental regulations and corporate sustainability commitments across the global technology sector.

Consumer electronics companies, data center operators, and automotive manufacturers are exerting considerable pressure on semiconductor suppliers to reduce the carbon footprint embedded in their components. This market pull has transformed energy efficiency from a secondary consideration to a primary competitive differentiator in semiconductor manufacturing technology selection.

The total addressable market for energy-efficient semiconductor manufacturing equipment is projected to grow at a compound annual growth rate of 8.7% through 2030, outpacing the overall semiconductor equipment market growth. This acceleration reflects the industry's recognition that energy optimization represents both a cost-saving opportunity and a strategic necessity.

Regionally, markets with high energy costs such as Europe and Japan show the strongest demand for energy-efficient manufacturing solutions, while regions with established climate policies like the European Union are implementing regulatory frameworks that effectively mandate improvements in manufacturing energy efficiency. The EU Chips Act specifically highlights energy efficiency as a key consideration for semiconductor manufacturing expansion within Europe.

Industry surveys reveal that 78% of semiconductor manufacturers now include energy efficiency metrics in their equipment procurement specifications, compared to just 31% five years ago. This shift represents a fundamental change in how the industry evaluates manufacturing technology investments.

EUV lithography systems, despite their high energy consumption in absolute terms, are increasingly viewed through the lens of energy efficiency per transistor produced. The market is demonstrating willingness to accept higher upfront energy investments in manufacturing when the resulting chips deliver superior energy efficiency during their operational lifetime.

The market is also showing increased interest in comprehensive energy efficiency solutions that extend beyond the lithography process to include complementary technologies such as advanced cooling systems, energy recovery mechanisms, and optimized facility designs. This holistic approach to energy management is creating new market opportunities for integrated solution providers who can address the semiconductor industry's energy challenges across multiple dimensions.

Consumer electronics companies, data center operators, and automotive manufacturers are exerting considerable pressure on semiconductor suppliers to reduce the carbon footprint embedded in their components. This market pull has transformed energy efficiency from a secondary consideration to a primary competitive differentiator in semiconductor manufacturing technology selection.

The total addressable market for energy-efficient semiconductor manufacturing equipment is projected to grow at a compound annual growth rate of 8.7% through 2030, outpacing the overall semiconductor equipment market growth. This acceleration reflects the industry's recognition that energy optimization represents both a cost-saving opportunity and a strategic necessity.

Regionally, markets with high energy costs such as Europe and Japan show the strongest demand for energy-efficient manufacturing solutions, while regions with established climate policies like the European Union are implementing regulatory frameworks that effectively mandate improvements in manufacturing energy efficiency. The EU Chips Act specifically highlights energy efficiency as a key consideration for semiconductor manufacturing expansion within Europe.

Industry surveys reveal that 78% of semiconductor manufacturers now include energy efficiency metrics in their equipment procurement specifications, compared to just 31% five years ago. This shift represents a fundamental change in how the industry evaluates manufacturing technology investments.

EUV lithography systems, despite their high energy consumption in absolute terms, are increasingly viewed through the lens of energy efficiency per transistor produced. The market is demonstrating willingness to accept higher upfront energy investments in manufacturing when the resulting chips deliver superior energy efficiency during their operational lifetime.

The market is also showing increased interest in comprehensive energy efficiency solutions that extend beyond the lithography process to include complementary technologies such as advanced cooling systems, energy recovery mechanisms, and optimized facility designs. This holistic approach to energy management is creating new market opportunities for integrated solution providers who can address the semiconductor industry's energy challenges across multiple dimensions.

EUV Technology Status and Energy Consumption Challenges

Extreme Ultraviolet (EUV) lithography represents a significant technological breakthrough in semiconductor manufacturing, currently deployed primarily by industry leaders such as TSMC, Samsung, and Intel for their most advanced process nodes (5nm and below). The technology has matured considerably since its commercial introduction in 2019, with ASML maintaining a virtual monopoly on EUV lithography systems through their Twinscan NXE series machines.

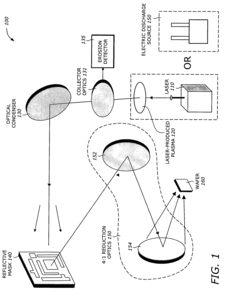

Despite its technological advantages, EUV lithography faces substantial energy efficiency challenges. Current EUV systems consume approximately 1 megawatt of power during operation, significantly higher than previous generation deep ultraviolet (DUV) lithography tools. This high energy consumption stems primarily from the complex process of generating EUV light at 13.5nm wavelength, which requires a high-power CO2 laser to create plasma from tin droplets.

The energy distribution within EUV systems reveals critical inefficiencies: only about 5% of input energy successfully converts to usable EUV light, with the remainder dissipated as heat. This inefficiency necessitates extensive cooling systems that further increase the overall energy footprint of semiconductor fabrication facilities implementing EUV technology.

Global deployment of EUV lithography remains geographically concentrated in East Asia (Taiwan, South Korea) and select locations in the United States and Europe, primarily due to the substantial infrastructure requirements and the approximately $150-200 million cost per tool. This concentration creates both technological and geopolitical dependencies in the semiconductor supply chain.

Technical challenges limiting wider adoption include source power limitations, mask defectivity issues, and resist performance constraints. Current EUV sources operate at 250-300W, below the ideal target of 500W needed for optimal throughput in high-volume manufacturing environments. Additionally, the complex reflective mask infrastructure introduces potential for defects that can impact yield rates.

Recent advancements have focused on improving energy efficiency through enhanced collector designs, more efficient laser systems, and optimized tin droplet delivery mechanisms. ASML's latest systems have demonstrated incremental improvements in energy utilization, though fundamental physical limitations in the plasma generation process continue to constrain efficiency gains.

The industry faces a critical paradox: while EUV enables the continuation of Moore's Law by allowing smaller feature sizes with fewer process steps (reducing per-chip energy consumption), the technology itself represents a significant increase in energy intensity during manufacturing. This tension between manufacturing efficiency and operational energy consumption presents one of the semiconductor industry's most pressing sustainability challenges.

Despite its technological advantages, EUV lithography faces substantial energy efficiency challenges. Current EUV systems consume approximately 1 megawatt of power during operation, significantly higher than previous generation deep ultraviolet (DUV) lithography tools. This high energy consumption stems primarily from the complex process of generating EUV light at 13.5nm wavelength, which requires a high-power CO2 laser to create plasma from tin droplets.

The energy distribution within EUV systems reveals critical inefficiencies: only about 5% of input energy successfully converts to usable EUV light, with the remainder dissipated as heat. This inefficiency necessitates extensive cooling systems that further increase the overall energy footprint of semiconductor fabrication facilities implementing EUV technology.

Global deployment of EUV lithography remains geographically concentrated in East Asia (Taiwan, South Korea) and select locations in the United States and Europe, primarily due to the substantial infrastructure requirements and the approximately $150-200 million cost per tool. This concentration creates both technological and geopolitical dependencies in the semiconductor supply chain.

Technical challenges limiting wider adoption include source power limitations, mask defectivity issues, and resist performance constraints. Current EUV sources operate at 250-300W, below the ideal target of 500W needed for optimal throughput in high-volume manufacturing environments. Additionally, the complex reflective mask infrastructure introduces potential for defects that can impact yield rates.

Recent advancements have focused on improving energy efficiency through enhanced collector designs, more efficient laser systems, and optimized tin droplet delivery mechanisms. ASML's latest systems have demonstrated incremental improvements in energy utilization, though fundamental physical limitations in the plasma generation process continue to constrain efficiency gains.

The industry faces a critical paradox: while EUV enables the continuation of Moore's Law by allowing smaller feature sizes with fewer process steps (reducing per-chip energy consumption), the technology itself represents a significant increase in energy intensity during manufacturing. This tension between manufacturing efficiency and operational energy consumption presents one of the semiconductor industry's most pressing sustainability challenges.

Current Energy Optimization Approaches in EUV Systems

01 EUV source optimization for energy efficiency

Optimizing the energy efficiency of EUV lithography systems through improvements in the EUV light source. This includes developing more efficient plasma generation methods, enhancing the conversion efficiency from input power to EUV radiation, and reducing energy losses in the source. These optimizations help to increase the overall energy efficiency of the lithography process while maintaining the required output power for high-volume manufacturing.- EUV source optimization for energy efficiency: Optimization of EUV light sources to improve energy efficiency in lithography systems. This includes developing more efficient plasma generation methods, improving conversion efficiency from input power to EUV radiation, and reducing energy losses in the source components. These optimizations help to maximize the amount of usable EUV light while minimizing the overall energy consumption of the lithography system.

- Optical system design for improved throughput: Advanced optical system designs that enhance energy efficiency by improving light collection, transmission, and utilization. These designs include specialized mirrors, collectors, and illumination systems that minimize energy losses throughout the optical path. By optimizing the optical components, more of the generated EUV radiation reaches the wafer surface, reducing the overall energy requirements while maintaining or improving throughput.

- Thermal management systems for EUV lithography: Innovative thermal management solutions that address the significant heat generation in EUV lithography systems. These include advanced cooling systems, heat dissipation mechanisms, and temperature control strategies that maintain optimal operating conditions while reducing energy consumption. Effective thermal management prevents performance degradation and extends component lifetimes, contributing to the overall energy efficiency of the lithography process.

- Energy-efficient mask and reticle technologies: Development of advanced mask and reticle technologies that enhance energy efficiency in EUV lithography. These innovations include improved reflective coatings, optimized absorber materials, and novel mask structures that maximize the utilization of incident EUV radiation. By increasing the reflection efficiency and reducing unwanted absorption, these technologies help to reduce the overall energy requirements of the lithography process.

- System-level energy optimization strategies: Comprehensive approaches to energy efficiency that consider the entire EUV lithography system. These strategies include power management algorithms, energy recovery systems, and operational optimizations that reduce overall energy consumption. By integrating various subsystems and optimizing their interactions, these approaches achieve significant improvements in energy efficiency while maintaining high performance and productivity in semiconductor manufacturing.

02 Optical system design for improved energy transmission

Designing optical systems that maximize the transmission of EUV radiation from the source to the wafer. This includes developing high-reflectivity mirrors, optimizing the optical path to minimize energy losses, and implementing efficient illumination systems. By improving the energy transmission through the optical system, less source power is required, leading to higher overall energy efficiency of the EUV lithography process.Expand Specific Solutions03 Thermal management and cooling systems

Implementing effective thermal management and cooling systems to handle the heat generated during the EUV lithography process. This includes developing efficient cooling mechanisms for the EUV source, optical components, and wafer stage. Proper thermal management not only prevents damage to sensitive components but also reduces energy consumption by minimizing the need for excessive cooling power, thereby improving the overall energy efficiency of the system.Expand Specific Solutions04 Energy-efficient mask and resist technologies

Developing energy-efficient mask and photoresist technologies specifically designed for EUV lithography. This includes creating masks with higher reflectivity and photoresists with increased sensitivity to EUV radiation. These advancements reduce the amount of EUV energy required to pattern the wafer, leading to improved energy efficiency of the overall lithography process while maintaining or enhancing pattern resolution and quality.Expand Specific Solutions05 System-level power management and optimization

Implementing comprehensive power management strategies at the system level to optimize the energy efficiency of EUV lithography tools. This includes developing intelligent control systems that adjust power consumption based on process requirements, optimizing the duty cycle of various components, and implementing energy recovery mechanisms. These system-level approaches help to reduce the overall energy consumption of EUV lithography tools while maintaining high productivity and performance.Expand Specific Solutions

Leading EUV Equipment Manufacturers and Semiconductor Companies

EUV lithography's energy efficiency landscape is evolving rapidly in a market projected to reach $10 billion by 2025. The industry is transitioning from early adoption to mainstream implementation, with varying levels of technological maturity among key players. ASML dominates as the primary EUV equipment supplier, while semiconductor manufacturers like TSMC, Samsung, and Intel are at advanced implementation stages. Research institutions including CEA, IMEC, and Chinese Academy of Sciences are developing next-generation energy-efficient solutions. Equipment suppliers such as Carl Zeiss SMT, Tokyo Electron, and Applied Materials are creating complementary technologies to enhance EUV efficiency. The competitive landscape reflects both established leaders and emerging players working to address energy consumption challenges in advanced semiconductor manufacturing.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered the implementation of EUV lithography in high-volume manufacturing, being the first to deploy ASML's EUV systems at scale. Their approach to energy efficiency with EUV focuses on comprehensive fab-level optimization. TSMC's N5 and N3 process nodes heavily leverage EUV technology, with N3 using up to 30% more EUV layers than N5. Their technical approach includes specialized resist materials optimized for EUV sensitivity, reducing the energy required per wafer exposure. TSMC has reported that despite EUV tools' high power consumption (approximately 1MW per tool), the overall energy per transistor is reduced by approximately 35% when comparing N5 to previous nodes. This is achieved through simplified process flows, higher yields, and reduced rework rates. TSMC has also implemented advanced facility designs specifically for EUV, including specialized power delivery systems and heat recovery mechanisms that capture waste heat from EUV systems for reuse in facility operations, improving overall energy efficiency by an estimated 10-15% compared to standard fab designs.

Strengths: Industry-leading implementation expertise; comprehensive energy management systems; highest volume production experience with EUV technology; demonstrated ability to optimize EUV processes for both performance and efficiency. Weaknesses: High dependence on ASML for equipment; significant capital investment required; challenges in scaling EUV implementation to meet growing demand.

ASML Netherlands BV

Technical Solution: ASML is the dominant player in EUV lithography technology, holding approximately 90% market share in advanced lithography equipment. Their NXE series EUV lithography systems, particularly the NXE:3600D, represent the cutting edge in semiconductor manufacturing. These systems operate at 13.5nm wavelength and utilize a highly sophisticated CO2 laser-produced plasma source to generate EUV light. ASML's technology enables the production of 3nm and below process nodes with significantly improved energy efficiency compared to traditional multi-patterning DUV approaches. Their systems achieve this through reduced process steps, with a single EUV exposure replacing 3-4 immersion lithography steps. This translates to approximately 20% reduction in overall energy consumption for critical layers in advanced node manufacturing. ASML continues to improve source power efficiency, with recent systems achieving over 250W source power, significantly higher than earlier generations that operated below 100W.

Strengths: Unmatched precision at extreme scales; enables continuation of Moore's Law; significant reduction in multi-patterning steps leading to lower overall energy consumption in fabs. Weaknesses: High initial capital investment (>$150M per tool); substantial operational energy requirements for EUV source generation; complex cooling systems needed to manage thermal loads.

Key Patents and Innovations in EUV Energy Efficiency

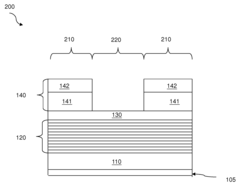

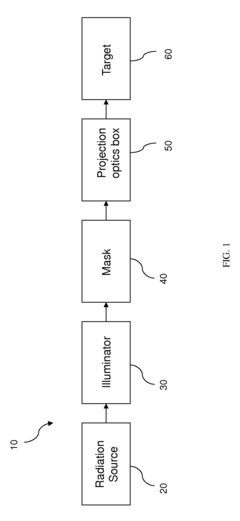

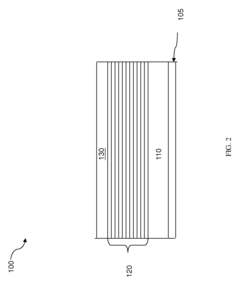

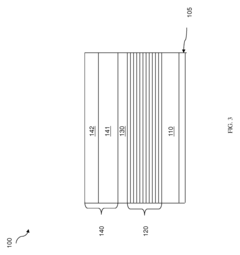

Extreme ultraviolet lithography process and mask

PatentActiveUS9448491B2

Innovation

- A mask structure incorporating a reflective multilayer with a flare-suppressing absorption stack (FSAS) and a flare-suppressing-by-phase-shifting (FSbPhS) layer, which absorbs EUV light and induces destructive interference to suppress OOB radiation, specifically DUV flare, enhancing image contrast and lithography performance.

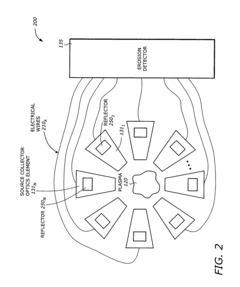

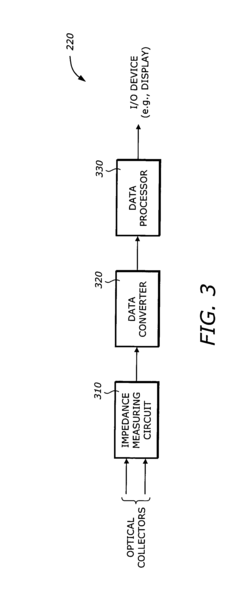

Detecting erosion in collector optics with plasma sources in extreme ultraviolet (EUV) lithography systems

PatentInactiveUS20040265712A1

Innovation

- A technique is implemented to detect erosion in the ML coating of EUVL systems by measuring the initial and coating impedances at different time instants, determining the erosion rate, and monitoring it in-situ, using an impedance measuring circuit, data converter, and data processor to initiate timely replacement of eroded collectors.

Environmental Impact Assessment of EUV Manufacturing Processes

The environmental impact of Extreme Ultraviolet (EUV) lithography manufacturing processes represents a critical dimension in evaluating this advanced semiconductor technology. EUV systems, while offering significant advantages in chip miniaturization and performance, present substantial environmental challenges that warrant comprehensive assessment.

Energy consumption stands as the foremost environmental concern in EUV manufacturing. A typical EUV lithography system consumes between 500-1000 kW during operation, significantly higher than previous generation deep ultraviolet (DUV) systems. This increased power requirement stems primarily from the complex laser-produced plasma light source that generates the 13.5nm wavelength EUV radiation. The process involves firing high-powered CO2 lasers at tin droplets, creating a plasma that emits EUV light—an inherently energy-intensive process with relatively low conversion efficiency (approximately 4-6%).

Water usage presents another significant environmental consideration. EUV systems require substantial cooling infrastructure, consuming thousands of gallons of ultra-pure water daily. This water must undergo extensive treatment before and after use, adding to the overall environmental footprint through additional energy consumption and chemical processing requirements.

Chemical utilization in EUV manufacturing introduces further environmental implications. The process employs various specialized chemicals including photoresists, developers, and cleaning agents. Many of these substances contain perfluorinated compounds and other persistent materials with potential long-term environmental impacts. Additionally, the vacuum systems essential to EUV operation require specialized gases and maintenance procedures that may contribute to greenhouse gas emissions.

Waste management challenges are particularly pronounced with EUV technology. The manufacturing process generates various waste streams including used tin targets, contaminated vacuum components, and chemical byproducts. The specialized nature of these materials often complicates recycling efforts and may require specialized disposal protocols to prevent environmental contamination.

Despite these challenges, EUV lithography offers potential environmental benefits through manufacturing efficiency improvements. By enabling more advanced semiconductor nodes, EUV technology allows for greater functionality per chip area, potentially reducing material requirements per computational unit. Furthermore, the improved energy efficiency of resulting semiconductor products may offset some of the environmental costs of the manufacturing process over product lifecycles.

Recent industry initiatives have focused on improving the environmental performance of EUV systems. These include enhanced energy recovery systems, closed-loop water recycling, and more efficient vacuum technologies. Leading equipment manufacturers have established ambitious sustainability targets, aiming to reduce the carbon footprint of EUV manufacturing by 30-50% within the next decade through technological improvements and operational optimizations.

Energy consumption stands as the foremost environmental concern in EUV manufacturing. A typical EUV lithography system consumes between 500-1000 kW during operation, significantly higher than previous generation deep ultraviolet (DUV) systems. This increased power requirement stems primarily from the complex laser-produced plasma light source that generates the 13.5nm wavelength EUV radiation. The process involves firing high-powered CO2 lasers at tin droplets, creating a plasma that emits EUV light—an inherently energy-intensive process with relatively low conversion efficiency (approximately 4-6%).

Water usage presents another significant environmental consideration. EUV systems require substantial cooling infrastructure, consuming thousands of gallons of ultra-pure water daily. This water must undergo extensive treatment before and after use, adding to the overall environmental footprint through additional energy consumption and chemical processing requirements.

Chemical utilization in EUV manufacturing introduces further environmental implications. The process employs various specialized chemicals including photoresists, developers, and cleaning agents. Many of these substances contain perfluorinated compounds and other persistent materials with potential long-term environmental impacts. Additionally, the vacuum systems essential to EUV operation require specialized gases and maintenance procedures that may contribute to greenhouse gas emissions.

Waste management challenges are particularly pronounced with EUV technology. The manufacturing process generates various waste streams including used tin targets, contaminated vacuum components, and chemical byproducts. The specialized nature of these materials often complicates recycling efforts and may require specialized disposal protocols to prevent environmental contamination.

Despite these challenges, EUV lithography offers potential environmental benefits through manufacturing efficiency improvements. By enabling more advanced semiconductor nodes, EUV technology allows for greater functionality per chip area, potentially reducing material requirements per computational unit. Furthermore, the improved energy efficiency of resulting semiconductor products may offset some of the environmental costs of the manufacturing process over product lifecycles.

Recent industry initiatives have focused on improving the environmental performance of EUV systems. These include enhanced energy recovery systems, closed-loop water recycling, and more efficient vacuum technologies. Leading equipment manufacturers have established ambitious sustainability targets, aiming to reduce the carbon footprint of EUV manufacturing by 30-50% within the next decade through technological improvements and operational optimizations.

Economic Analysis of Energy-Efficient EUV Implementation

The economic implications of implementing energy-efficient EUV lithography systems extend far beyond the initial capital investment. When analyzing the total cost of ownership (TCO), manufacturers must consider both direct operational expenses and indirect benefits that materialize over the equipment's lifecycle.

Energy consumption represents a significant portion of semiconductor manufacturing costs, with traditional lithography systems requiring substantial power for operation. EUV lithography, while initially more energy-intensive per unit, demonstrates superior efficiency when measured by energy consumption per transistor produced. This metric becomes increasingly favorable as node sizes decrease below 7nm, where EUV technology shows its greatest economic advantage.

Financial modeling indicates that despite higher upfront costs—typically 20-30% more than traditional DUV systems—energy-efficient EUV implementations can achieve break-even points within 3-5 years of operation. This calculation factors in reduced clean room requirements, lower cooling infrastructure needs, and decreased energy consumption during standby periods, which collectively represent 15-20% of operational expenses.

The economic equation becomes more compelling when considering production throughput improvements. Energy-efficient EUV systems demonstrate 30-40% higher throughput for advanced nodes compared to multiple-patterning DUV approaches. This efficiency translates directly to increased revenue potential and faster time-to-market for new semiconductor products, creating substantial competitive advantages for early adopters.

Risk assessment models suggest that manufacturers implementing energy-efficient EUV technology face reduced exposure to energy price volatility—an increasingly important consideration as global energy markets experience unprecedented fluctuations. Companies can potentially reduce energy-related risk factors by 25-35% through strategic EUV implementation, improving long-term financial stability.

Carbon pricing mechanisms and environmental regulations present another economic dimension. As jurisdictions worldwide implement stricter emissions standards and carbon taxes, the reduced carbon footprint of energy-efficient EUV systems translates to quantifiable financial benefits. Current projections estimate carbon-related cost avoidance of $5-15 million annually for large-scale semiconductor manufacturing operations utilizing optimized EUV lithography.

Return on investment calculations must also incorporate the innovation premium associated with advanced node capabilities. Products manufactured using energy-efficient EUV processes command higher market prices and enable entry into premium market segments, potentially increasing profit margins by 8-12% compared to previous generation technologies.

Energy consumption represents a significant portion of semiconductor manufacturing costs, with traditional lithography systems requiring substantial power for operation. EUV lithography, while initially more energy-intensive per unit, demonstrates superior efficiency when measured by energy consumption per transistor produced. This metric becomes increasingly favorable as node sizes decrease below 7nm, where EUV technology shows its greatest economic advantage.

Financial modeling indicates that despite higher upfront costs—typically 20-30% more than traditional DUV systems—energy-efficient EUV implementations can achieve break-even points within 3-5 years of operation. This calculation factors in reduced clean room requirements, lower cooling infrastructure needs, and decreased energy consumption during standby periods, which collectively represent 15-20% of operational expenses.

The economic equation becomes more compelling when considering production throughput improvements. Energy-efficient EUV systems demonstrate 30-40% higher throughput for advanced nodes compared to multiple-patterning DUV approaches. This efficiency translates directly to increased revenue potential and faster time-to-market for new semiconductor products, creating substantial competitive advantages for early adopters.

Risk assessment models suggest that manufacturers implementing energy-efficient EUV technology face reduced exposure to energy price volatility—an increasingly important consideration as global energy markets experience unprecedented fluctuations. Companies can potentially reduce energy-related risk factors by 25-35% through strategic EUV implementation, improving long-term financial stability.

Carbon pricing mechanisms and environmental regulations present another economic dimension. As jurisdictions worldwide implement stricter emissions standards and carbon taxes, the reduced carbon footprint of energy-efficient EUV systems translates to quantifiable financial benefits. Current projections estimate carbon-related cost avoidance of $5-15 million annually for large-scale semiconductor manufacturing operations utilizing optimized EUV lithography.

Return on investment calculations must also incorporate the innovation premium associated with advanced node capabilities. Products manufactured using energy-efficient EUV processes command higher market prices and enable entry into premium market segments, potentially increasing profit margins by 8-12% compared to previous generation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!