Exploration of PTFE Applications in Quantum Computing

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Quantum Computing: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a material of significant interest in the field of quantum computing. This synthetic fluoropolymer, initially developed for industrial applications, is now being explored for its unique properties that could potentially enhance quantum computing systems.

The journey of PTFE in quantum computing began with the recognition of its exceptional dielectric properties and low loss tangent at high frequencies. These characteristics make PTFE an ideal candidate for use in quantum circuits, where maintaining quantum coherence is paramount. As quantum computing has evolved from theoretical concepts to practical implementations, the need for materials that can support and protect delicate quantum states has become increasingly apparent.

The primary objective of exploring PTFE applications in quantum computing is to leverage its properties to improve the performance and reliability of quantum systems. Researchers aim to utilize PTFE's excellent electrical insulation, thermal stability, and chemical inertness to address some of the key challenges in quantum computing, such as decoherence and environmental interference.

One of the critical areas of focus is the use of PTFE in quantum circuit boards and substrates. The material's low dielectric constant and loss tangent contribute to reduced signal loss and improved signal integrity, which are crucial for maintaining quantum information over extended periods. Additionally, PTFE's hydrophobic nature and resistance to a wide range of chemicals make it an attractive option for protecting sensitive quantum components from environmental factors that could disrupt quantum states.

The exploration of PTFE in quantum computing also extends to its potential role in cryogenic environments. Many quantum computing systems operate at extremely low temperatures to minimize thermal noise and maintain quantum coherence. PTFE's ability to maintain its mechanical and electrical properties at cryogenic temperatures makes it a promising material for various components within these systems, from wiring insulation to structural supports.

As the field of quantum computing continues to advance, the development of new materials and applications for PTFE is expected to play a crucial role in overcoming current limitations. Researchers are investigating ways to modify and enhance PTFE to further improve its performance in quantum computing applications, such as developing composite materials or tailoring its surface properties to better suit specific quantum architectures.

The ongoing research into PTFE applications in quantum computing represents a convergence of materials science and quantum physics, highlighting the interdisciplinary nature of advances in this field. As quantum computing moves closer to practical, large-scale implementations, the role of materials like PTFE in enabling these technologies becomes increasingly significant, driving innovation and opening new possibilities for the future of computing.

The journey of PTFE in quantum computing began with the recognition of its exceptional dielectric properties and low loss tangent at high frequencies. These characteristics make PTFE an ideal candidate for use in quantum circuits, where maintaining quantum coherence is paramount. As quantum computing has evolved from theoretical concepts to practical implementations, the need for materials that can support and protect delicate quantum states has become increasingly apparent.

The primary objective of exploring PTFE applications in quantum computing is to leverage its properties to improve the performance and reliability of quantum systems. Researchers aim to utilize PTFE's excellent electrical insulation, thermal stability, and chemical inertness to address some of the key challenges in quantum computing, such as decoherence and environmental interference.

One of the critical areas of focus is the use of PTFE in quantum circuit boards and substrates. The material's low dielectric constant and loss tangent contribute to reduced signal loss and improved signal integrity, which are crucial for maintaining quantum information over extended periods. Additionally, PTFE's hydrophobic nature and resistance to a wide range of chemicals make it an attractive option for protecting sensitive quantum components from environmental factors that could disrupt quantum states.

The exploration of PTFE in quantum computing also extends to its potential role in cryogenic environments. Many quantum computing systems operate at extremely low temperatures to minimize thermal noise and maintain quantum coherence. PTFE's ability to maintain its mechanical and electrical properties at cryogenic temperatures makes it a promising material for various components within these systems, from wiring insulation to structural supports.

As the field of quantum computing continues to advance, the development of new materials and applications for PTFE is expected to play a crucial role in overcoming current limitations. Researchers are investigating ways to modify and enhance PTFE to further improve its performance in quantum computing applications, such as developing composite materials or tailoring its surface properties to better suit specific quantum architectures.

The ongoing research into PTFE applications in quantum computing represents a convergence of materials science and quantum physics, highlighting the interdisciplinary nature of advances in this field. As quantum computing moves closer to practical, large-scale implementations, the role of materials like PTFE in enabling these technologies becomes increasingly significant, driving innovation and opening new possibilities for the future of computing.

Market Analysis for PTFE in Quantum Technologies

The market for PTFE in quantum technologies is experiencing significant growth, driven by the unique properties of this material that make it particularly suitable for quantum computing applications. PTFE, or polytetrafluoroethylene, offers exceptional chemical resistance, low dielectric constant, and excellent thermal stability, which are crucial characteristics for quantum computing components.

The quantum computing market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 25% through 2030. This growth is fueled by increasing investments in quantum research and development across various sectors, including finance, healthcare, and defense. As quantum computers require highly specialized materials to maintain quantum states and minimize decoherence, PTFE is emerging as a key enabler in this field.

One of the primary applications of PTFE in quantum technologies is in the fabrication of quantum circuits and components. Its low dielectric constant helps reduce signal loss and interference, which is critical for maintaining quantum coherence. Additionally, PTFE's excellent insulating properties make it ideal for creating high-performance waveguides and resonators used in quantum systems.

The demand for PTFE in cryogenic environments, essential for many quantum computing setups, is also on the rise. PTFE maintains its mechanical properties at extremely low temperatures, making it suitable for use in quantum cryostats and other low-temperature applications. This has led to an increased focus on developing specialized PTFE formulations optimized for cryogenic conditions.

Another growing market segment is the use of PTFE in quantum sensing devices. These sensors, which leverage quantum effects for ultra-precise measurements, often require materials with low thermal expansion and high dimensional stability. PTFE's properties make it an excellent choice for components in quantum magnetometers, gravimeters, and other advanced sensing technologies.

The market for PTFE in quantum technologies is not limited to hardware components. There is also a growing demand for PTFE-based coatings and films used in the manufacturing and packaging of quantum devices. These coatings provide protection against environmental factors that could degrade quantum performance, such as moisture and electromagnetic interference.

As the quantum computing industry matures, we can expect to see increased specialization in PTFE products tailored specifically for quantum applications. This may include the development of new PTFE composites with enhanced properties, such as improved thermal conductivity or reduced outgassing, to meet the exacting requirements of next-generation quantum systems.

The quantum computing market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 25% through 2030. This growth is fueled by increasing investments in quantum research and development across various sectors, including finance, healthcare, and defense. As quantum computers require highly specialized materials to maintain quantum states and minimize decoherence, PTFE is emerging as a key enabler in this field.

One of the primary applications of PTFE in quantum technologies is in the fabrication of quantum circuits and components. Its low dielectric constant helps reduce signal loss and interference, which is critical for maintaining quantum coherence. Additionally, PTFE's excellent insulating properties make it ideal for creating high-performance waveguides and resonators used in quantum systems.

The demand for PTFE in cryogenic environments, essential for many quantum computing setups, is also on the rise. PTFE maintains its mechanical properties at extremely low temperatures, making it suitable for use in quantum cryostats and other low-temperature applications. This has led to an increased focus on developing specialized PTFE formulations optimized for cryogenic conditions.

Another growing market segment is the use of PTFE in quantum sensing devices. These sensors, which leverage quantum effects for ultra-precise measurements, often require materials with low thermal expansion and high dimensional stability. PTFE's properties make it an excellent choice for components in quantum magnetometers, gravimeters, and other advanced sensing technologies.

The market for PTFE in quantum technologies is not limited to hardware components. There is also a growing demand for PTFE-based coatings and films used in the manufacturing and packaging of quantum devices. These coatings provide protection against environmental factors that could degrade quantum performance, such as moisture and electromagnetic interference.

As the quantum computing industry matures, we can expect to see increased specialization in PTFE products tailored specifically for quantum applications. This may include the development of new PTFE composites with enhanced properties, such as improved thermal conductivity or reduced outgassing, to meet the exacting requirements of next-generation quantum systems.

Current PTFE Applications and Challenges in Quantum Systems

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has found its way into various applications within quantum computing systems. Its unique properties, such as low dielectric constant, excellent thermal stability, and chemical inertness, make it an attractive material for several components in quantum devices.

One of the primary applications of PTFE in quantum systems is as a substrate material for superconducting qubits. The low dielectric loss of PTFE helps minimize energy dissipation and decoherence in these sensitive quantum circuits. Additionally, PTFE's thermal stability allows it to maintain its properties across a wide range of temperatures, which is crucial for quantum systems that often operate at cryogenic temperatures.

PTFE is also utilized in the fabrication of microwave resonators and waveguides in quantum circuits. Its low dielectric constant enables the creation of high-quality factor resonators, which are essential for maintaining quantum coherence. Furthermore, PTFE's hydrophobic nature helps protect sensitive quantum components from moisture-related degradation.

In quantum sensing applications, PTFE serves as an insulating material for various components, such as superconducting quantum interference devices (SQUIDs). Its excellent electrical insulation properties contribute to reducing noise and improving the overall sensitivity of these quantum sensors.

Despite its advantages, PTFE faces several challenges in quantum computing applications. One significant issue is its relatively high thermal expansion coefficient, which can lead to mechanical stress and potential misalignment of quantum components during temperature cycling. This challenge becomes particularly pronounced in systems that require frequent transitions between room temperature and cryogenic conditions.

Another limitation of PTFE in quantum systems is its relatively low thermal conductivity. While this property can be beneficial for thermal isolation in some cases, it can also hinder efficient heat dissipation in high-power quantum devices. This limitation necessitates careful thermal management strategies when incorporating PTFE into quantum computing hardware.

The outgassing of fluorine-containing compounds from PTFE at elevated temperatures poses another challenge, particularly in ultra-high vacuum environments often required for quantum systems. This outgassing can potentially contaminate sensitive quantum components and degrade their performance over time.

Researchers and engineers are actively working on addressing these challenges through various approaches. These include developing composite materials that combine PTFE with other substances to enhance its thermal and mechanical properties, as well as exploring surface treatment techniques to mitigate outgassing issues. Additionally, alternative fluoropolymers with improved characteristics for quantum applications are being investigated as potential replacements for traditional PTFE in certain quantum computing components.

One of the primary applications of PTFE in quantum systems is as a substrate material for superconducting qubits. The low dielectric loss of PTFE helps minimize energy dissipation and decoherence in these sensitive quantum circuits. Additionally, PTFE's thermal stability allows it to maintain its properties across a wide range of temperatures, which is crucial for quantum systems that often operate at cryogenic temperatures.

PTFE is also utilized in the fabrication of microwave resonators and waveguides in quantum circuits. Its low dielectric constant enables the creation of high-quality factor resonators, which are essential for maintaining quantum coherence. Furthermore, PTFE's hydrophobic nature helps protect sensitive quantum components from moisture-related degradation.

In quantum sensing applications, PTFE serves as an insulating material for various components, such as superconducting quantum interference devices (SQUIDs). Its excellent electrical insulation properties contribute to reducing noise and improving the overall sensitivity of these quantum sensors.

Despite its advantages, PTFE faces several challenges in quantum computing applications. One significant issue is its relatively high thermal expansion coefficient, which can lead to mechanical stress and potential misalignment of quantum components during temperature cycling. This challenge becomes particularly pronounced in systems that require frequent transitions between room temperature and cryogenic conditions.

Another limitation of PTFE in quantum systems is its relatively low thermal conductivity. While this property can be beneficial for thermal isolation in some cases, it can also hinder efficient heat dissipation in high-power quantum devices. This limitation necessitates careful thermal management strategies when incorporating PTFE into quantum computing hardware.

The outgassing of fluorine-containing compounds from PTFE at elevated temperatures poses another challenge, particularly in ultra-high vacuum environments often required for quantum systems. This outgassing can potentially contaminate sensitive quantum components and degrade their performance over time.

Researchers and engineers are actively working on addressing these challenges through various approaches. These include developing composite materials that combine PTFE with other substances to enhance its thermal and mechanical properties, as well as exploring surface treatment techniques to mitigate outgassing issues. Additionally, alternative fluoropolymers with improved characteristics for quantum applications are being investigated as potential replacements for traditional PTFE in certain quantum computing components.

Existing PTFE Solutions for Quantum Computing

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.- PTFE manufacturing and processing methods: Various techniques for manufacturing and processing PTFE are described, including methods for producing PTFE fibers, films, and molded articles. These processes often involve specific temperature and pressure conditions, as well as the use of specialized equipment to achieve desired properties in the final PTFE products.

- PTFE composites and blends: PTFE is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve characteristics such as wear resistance, thermal conductivity, or mechanical strength. The resulting materials find applications in various industries, including automotive, aerospace, and electronics.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE are explored to enhance its properties or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings to improve adhesion, wettability, or other surface characteristics of PTFE.

- PTFE in membrane and filtration applications: PTFE is widely used in membrane and filtration technologies due to its chemical resistance and non-stick properties. Applications include water treatment, gas separation, and industrial filtration. Research focuses on improving membrane performance, durability, and efficiency in various environmental conditions.

- PTFE in medical and biomedical applications: The use of PTFE in medical and biomedical fields is explored, including applications in implants, surgical materials, and drug delivery systems. Research focuses on improving biocompatibility, reducing inflammation, and enhancing the integration of PTFE-based materials with biological tissues.

02 PTFE composite materials

PTFE is combined with other materials to create composite structures with enhanced properties. These composites may include reinforcing fibers, nanoparticles, or other polymers to improve mechanical strength, thermal stability, or electrical conductivity while maintaining PTFE's unique characteristics.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface properties of PTFE are explored to enhance its adhesion, wettability, or compatibility with other materials. These modifications can involve chemical treatments, plasma processing, or the application of coatings to alter the surface characteristics of PTFE products.Expand Specific Solutions04 PTFE in filtration and separation technologies

PTFE is utilized in various filtration and separation applications due to its non-stick properties and chemical resistance. This includes the development of PTFE membranes, filters, and separation media for use in industrial processes, water treatment, and gas separation.Expand Specific Solutions05 PTFE in coating applications

The use of PTFE in coating formulations is explored for various industries. These coatings leverage PTFE's non-stick and low friction properties to create durable, chemical-resistant surfaces for cookware, industrial equipment, and other applications requiring release properties or corrosion resistance.Expand Specific Solutions

Key Players in PTFE and Quantum Computing Industries

The exploration of PTFE applications in quantum computing is in its early stages, with the market still emerging and showing significant growth potential. The technology's maturity is evolving rapidly, driven by collaborations between industry leaders and research institutions. Companies like W. L. Gore & Associates, AGC, Inc., and Daikin Industries are leveraging their expertise in PTFE materials to develop specialized solutions for quantum computing applications. Simultaneously, quantum-focused firms such as Zapata Computing and QC Ware are partnering with materials science experts to integrate PTFE into quantum hardware designs. This convergence of traditional materials manufacturers and quantum technology innovators is accelerating the development of PTFE-based components for quantum systems, potentially addressing challenges in qubit stability and coherence times.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has been exploring PTFE applications in quantum computing, leveraging their expertise in advanced materials and PTFE processing. Their approach focuses on developing specialized PTFE-based products for quantum computing environments. Gore has been researching the use of their expanded PTFE (ePTFE) technology in quantum systems, particularly for its potential in improving thermal management and electrical insulation in cryogenic environments[11]. They have also been investigating the use of PTFE-based microwave and RF components in quantum control systems, where low-loss and high-frequency performance are critical[12]. Additionally, Gore has been exploring the development of PTFE-based packaging solutions for quantum processors, aiming to enhance qubit protection from environmental interference and improve overall system reliability[13].

Strengths: Gore's extensive experience with PTFE and ePTFE technologies provides a unique advantage in developing specialized materials for quantum computing. Their expertise in high-performance microwave and RF components is particularly relevant for quantum control systems. Weaknesses: As a materials company, Gore may face challenges in directly integrating their PTFE solutions into complex quantum computing architectures, potentially requiring close collaboration with quantum hardware manufacturers.

Zapata Computing, Inc.

Technical Solution: Zapata Computing has been exploring the use of PTFE in quantum computing through their quantum algorithm and software development efforts. While not directly manufacturing quantum hardware, Zapata has been working on optimizing quantum circuits and algorithms that can benefit from the unique properties of PTFE in quantum systems. Their approach focuses on developing software solutions that can leverage the improved coherence times and reduced noise levels provided by PTFE-based quantum hardware[4]. Zapata has also been investigating the potential of PTFE in error mitigation techniques, particularly in the context of near-term quantum devices. Their research aims to create algorithms that can exploit the stability offered by PTFE-enhanced quantum systems to achieve quantum advantage in practical applications[5].

Strengths: Zapata's software-focused approach allows for flexibility in adapting to various quantum hardware platforms that utilize PTFE. Their expertise in quantum algorithms can help maximize the benefits of PTFE in quantum systems. Weaknesses: As a software company, Zapata relies on hardware partners for physical implementation, which may limit their direct influence on PTFE integration in quantum hardware.

Innovative PTFE Technologies for Quantum Applications

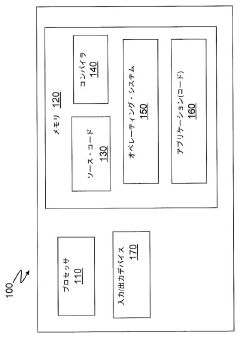

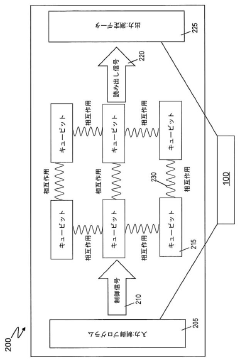

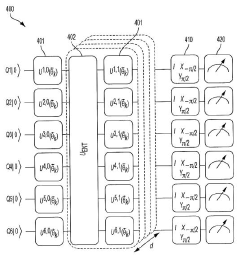

Systems, Methods, Quantum Computing Devices, and Computer Programs for Realizing High-Hardware-Efficient Variational Quantum Eigensolvers for Quantum Computing Machines

PatentActiveJP2020534607A

Innovation

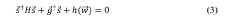

- A variational quantum eigenvalue solver (VQE) is implemented using a quantum computer with interleaved sequences of single-qubit rotations and entangler operations, employing a fixed-frequency architecture with microwave qubit control and microwave-only reset schemes to maintain coherence, and using gradient descent algorithms like Simultaneous Perturbation Stochastic Approximation (SPSA) for optimization.

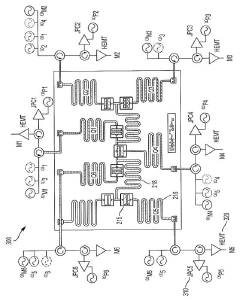

Quantum computer system and method for partial differential equation-constrained optimization

PatentWO2021092351A1

Innovation

- A hybrid quantum-classical computer transforms PDE-constrained optimization problems into polynomial unconstrained binary optimization (PUBO) problems, allowing for efficient solution using quantum annealing or quantum approximate optimization algorithms by eliminating design variables and formulating the problem as an Ising Hamiltonian.

Environmental Impact of PTFE in Quantum Technologies

The use of Polytetrafluoroethylene (PTFE) in quantum technologies has raised significant environmental concerns due to its persistence and potential ecological impact. PTFE, commonly known as Teflon, is a synthetic fluoropolymer widely used in quantum computing applications for its excellent dielectric properties and chemical inertness. However, its production and disposal processes pose substantial environmental challenges.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although efforts have been made to phase out PFOA in PTFE production, alternative chemicals used may still have unknown long-term environmental consequences. The production process also releases greenhouse gases, contributing to climate change.

PTFE's extreme durability, while beneficial for quantum computing applications, becomes problematic at the end of its lifecycle. The material is non-biodegradable and can persist in the environment for centuries. When improperly disposed of, PTFE can break down into microplastics, potentially entering food chains and ecosystems. Incineration of PTFE waste can release toxic fumes, including hydrogen fluoride and perfluoroisobutylene.

In quantum computing facilities, the use of PTFE in cryogenic systems and as insulation material presents challenges for sustainable practices. The material's low thermal conductivity makes it ideal for maintaining the ultra-low temperatures required in quantum computers, but this also means that large quantities are needed, exacerbating the environmental impact of its production and eventual disposal.

Efforts to mitigate the environmental impact of PTFE in quantum technologies are ongoing. Research into alternative materials with similar properties but lower environmental footprints is gaining momentum. Some quantum technology companies are exploring bio-based polymers and recyclable composites as potential substitutes for PTFE in certain applications.

Recycling PTFE from quantum computing equipment presents another avenue for reducing environmental impact. However, the process is complex due to the material's chemical stability and the need to separate it from other components. Advanced recycling technologies, such as chemical depolymerization, are being developed to address these challenges and create a more circular economy for PTFE in high-tech applications.

As the quantum computing industry grows, there is an increasing focus on lifecycle assessments of materials used, including PTFE. This holistic approach considers environmental impacts from raw material extraction through manufacturing, use, and disposal. Such assessments are crucial for developing more sustainable practices in quantum technologies and guiding future material choices and design decisions.

The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although efforts have been made to phase out PFOA in PTFE production, alternative chemicals used may still have unknown long-term environmental consequences. The production process also releases greenhouse gases, contributing to climate change.

PTFE's extreme durability, while beneficial for quantum computing applications, becomes problematic at the end of its lifecycle. The material is non-biodegradable and can persist in the environment for centuries. When improperly disposed of, PTFE can break down into microplastics, potentially entering food chains and ecosystems. Incineration of PTFE waste can release toxic fumes, including hydrogen fluoride and perfluoroisobutylene.

In quantum computing facilities, the use of PTFE in cryogenic systems and as insulation material presents challenges for sustainable practices. The material's low thermal conductivity makes it ideal for maintaining the ultra-low temperatures required in quantum computers, but this also means that large quantities are needed, exacerbating the environmental impact of its production and eventual disposal.

Efforts to mitigate the environmental impact of PTFE in quantum technologies are ongoing. Research into alternative materials with similar properties but lower environmental footprints is gaining momentum. Some quantum technology companies are exploring bio-based polymers and recyclable composites as potential substitutes for PTFE in certain applications.

Recycling PTFE from quantum computing equipment presents another avenue for reducing environmental impact. However, the process is complex due to the material's chemical stability and the need to separate it from other components. Advanced recycling technologies, such as chemical depolymerization, are being developed to address these challenges and create a more circular economy for PTFE in high-tech applications.

As the quantum computing industry grows, there is an increasing focus on lifecycle assessments of materials used, including PTFE. This holistic approach considers environmental impacts from raw material extraction through manufacturing, use, and disposal. Such assessments are crucial for developing more sustainable practices in quantum technologies and guiding future material choices and design decisions.

Quantum-PTFE Interface: Opportunities and Risks

The intersection of quantum computing and PTFE (Polytetrafluoroethylene) presents both exciting opportunities and potential risks that warrant careful consideration. As quantum computing continues to advance, the unique properties of PTFE offer promising applications in this cutting-edge field.

One of the primary opportunities lies in PTFE's exceptional dielectric properties. Its low dielectric constant and high dielectric strength make it an ideal material for insulating quantum circuits and components. This characteristic is crucial in maintaining the delicate quantum states required for quantum computations, potentially leading to improved qubit coherence times and overall system performance.

PTFE's thermal stability and resistance to extreme temperatures also present advantages in quantum computing applications. Quantum systems often operate at cryogenic temperatures, and PTFE's ability to maintain its properties across a wide temperature range makes it a suitable material for various components within quantum computers, from wiring insulation to structural supports.

The material's chemical inertness offers another significant opportunity. In quantum computing environments, where even minor contamination can disrupt quantum states, PTFE's resistance to chemical reactions and its non-stick properties can help maintain a clean and stable operating environment. This characteristic could prove invaluable in protecting sensitive quantum components from degradation over time.

However, the integration of PTFE in quantum computing systems also presents certain risks and challenges. One primary concern is the potential for outgassing in vacuum environments, which are often required for quantum computing operations. Although PTFE has low outgassing properties compared to many other polymers, even minimal outgassing could introduce contaminants that interfere with quantum states.

Another risk lies in PTFE's mechanical properties. While its flexibility can be advantageous in some applications, it may also lead to dimensional instability under certain conditions. In the precise world of quantum computing, where nanoscale accuracy is often required, this could pose challenges in maintaining the exact positioning and alignment of quantum components.

The electrical insulation properties of PTFE, while generally beneficial, may also present risks in terms of static charge accumulation. In sensitive quantum systems, uncontrolled static charges could potentially disrupt quantum states or damage delicate components. Careful design considerations and appropriate grounding techniques would be necessary to mitigate this risk.

In conclusion, the interface between quantum computing and PTFE offers significant opportunities for advancing quantum technologies, particularly in areas of insulation, thermal management, and contamination prevention. However, the successful integration of PTFE in quantum systems will require careful management of potential risks, including outgassing, dimensional stability, and static charge control. As research in this area progresses, a balanced approach that leverages PTFE's unique properties while addressing its limitations will be crucial for realizing its full potential in quantum computing applications.

One of the primary opportunities lies in PTFE's exceptional dielectric properties. Its low dielectric constant and high dielectric strength make it an ideal material for insulating quantum circuits and components. This characteristic is crucial in maintaining the delicate quantum states required for quantum computations, potentially leading to improved qubit coherence times and overall system performance.

PTFE's thermal stability and resistance to extreme temperatures also present advantages in quantum computing applications. Quantum systems often operate at cryogenic temperatures, and PTFE's ability to maintain its properties across a wide temperature range makes it a suitable material for various components within quantum computers, from wiring insulation to structural supports.

The material's chemical inertness offers another significant opportunity. In quantum computing environments, where even minor contamination can disrupt quantum states, PTFE's resistance to chemical reactions and its non-stick properties can help maintain a clean and stable operating environment. This characteristic could prove invaluable in protecting sensitive quantum components from degradation over time.

However, the integration of PTFE in quantum computing systems also presents certain risks and challenges. One primary concern is the potential for outgassing in vacuum environments, which are often required for quantum computing operations. Although PTFE has low outgassing properties compared to many other polymers, even minimal outgassing could introduce contaminants that interfere with quantum states.

Another risk lies in PTFE's mechanical properties. While its flexibility can be advantageous in some applications, it may also lead to dimensional instability under certain conditions. In the precise world of quantum computing, where nanoscale accuracy is often required, this could pose challenges in maintaining the exact positioning and alignment of quantum components.

The electrical insulation properties of PTFE, while generally beneficial, may also present risks in terms of static charge accumulation. In sensitive quantum systems, uncontrolled static charges could potentially disrupt quantum states or damage delicate components. Careful design considerations and appropriate grounding techniques would be necessary to mitigate this risk.

In conclusion, the interface between quantum computing and PTFE offers significant opportunities for advancing quantum technologies, particularly in areas of insulation, thermal management, and contamination prevention. However, the successful integration of PTFE in quantum systems will require careful management of potential risks, including outgassing, dimensional stability, and static charge control. As research in this area progresses, a balanced approach that leverages PTFE's unique properties while addressing its limitations will be crucial for realizing its full potential in quantum computing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!