Exploring OLED vs MicroLED in Architectural Lighting Design

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED and MicroLED Lighting Evolution and Objectives

The evolution of lighting technology has witnessed significant transformations over the past century, from incandescent bulbs to fluorescent lighting, and now to advanced solid-state lighting solutions. OLED (Organic Light Emitting Diode) and MicroLED technologies represent the cutting edge of this evolution, offering unprecedented possibilities for architectural lighting design. These technologies have emerged from different developmental trajectories but are converging as potential solutions for next-generation lighting applications.

OLED technology, first demonstrated in the 1980s by Eastman Kodak researchers, has evolved from simple monochrome displays to sophisticated lighting panels capable of producing high-quality illumination. The technology's development accelerated in the early 2000s when manufacturers began exploring its potential beyond displays. By 2010, several companies had introduced OLED lighting panels for commercial applications, marking a significant milestone in architectural lighting possibilities.

MicroLED, a more recent innovation, traces its origins to the late 1990s but gained substantial momentum only in the past decade. Unlike OLEDs, which evolved primarily from display applications toward lighting, MicroLED development has been driven by both lighting and display industries simultaneously. The technology has seen rapid advancement since 2016, when major electronics manufacturers began significant investments in research and production capabilities.

The current technological trajectory suggests a convergence of capabilities, with both technologies striving to address similar objectives in architectural lighting design. These objectives include achieving greater energy efficiency, improved color rendering, enhanced durability, flexible form factors, and seamless integration with smart building systems. Both technologies aim to transcend the limitations of conventional LED lighting by offering diffuse, glare-free illumination that can be incorporated into architectural elements themselves.

A key objective for both technologies is sustainability. OLED and MicroLED lighting solutions aim to reduce energy consumption while minimizing environmental impact throughout their lifecycle. This includes the development of manufacturing processes that use fewer hazardous materials and the creation of products with longer operational lifespans and improved recyclability.

Another critical goal is the democratization of these advanced lighting technologies. Current research and development efforts focus on scaling production and reducing costs to make OLED and MicroLED lighting accessible beyond premium applications. The industry anticipates that as manufacturing processes mature and economies of scale take effect, these technologies will transition from specialized architectural projects to mainstream lighting solutions.

The ultimate objective for both OLED and MicroLED in architectural contexts is to transform the relationship between light and space. These technologies promise to evolve lighting from a purely functional element to an integral component of architectural design, capable of adapting to human needs, enhancing wellbeing, and creating responsive environments that blur the distinction between illumination and architecture itself.

OLED technology, first demonstrated in the 1980s by Eastman Kodak researchers, has evolved from simple monochrome displays to sophisticated lighting panels capable of producing high-quality illumination. The technology's development accelerated in the early 2000s when manufacturers began exploring its potential beyond displays. By 2010, several companies had introduced OLED lighting panels for commercial applications, marking a significant milestone in architectural lighting possibilities.

MicroLED, a more recent innovation, traces its origins to the late 1990s but gained substantial momentum only in the past decade. Unlike OLEDs, which evolved primarily from display applications toward lighting, MicroLED development has been driven by both lighting and display industries simultaneously. The technology has seen rapid advancement since 2016, when major electronics manufacturers began significant investments in research and production capabilities.

The current technological trajectory suggests a convergence of capabilities, with both technologies striving to address similar objectives in architectural lighting design. These objectives include achieving greater energy efficiency, improved color rendering, enhanced durability, flexible form factors, and seamless integration with smart building systems. Both technologies aim to transcend the limitations of conventional LED lighting by offering diffuse, glare-free illumination that can be incorporated into architectural elements themselves.

A key objective for both technologies is sustainability. OLED and MicroLED lighting solutions aim to reduce energy consumption while minimizing environmental impact throughout their lifecycle. This includes the development of manufacturing processes that use fewer hazardous materials and the creation of products with longer operational lifespans and improved recyclability.

Another critical goal is the democratization of these advanced lighting technologies. Current research and development efforts focus on scaling production and reducing costs to make OLED and MicroLED lighting accessible beyond premium applications. The industry anticipates that as manufacturing processes mature and economies of scale take effect, these technologies will transition from specialized architectural projects to mainstream lighting solutions.

The ultimate objective for both OLED and MicroLED in architectural contexts is to transform the relationship between light and space. These technologies promise to evolve lighting from a purely functional element to an integral component of architectural design, capable of adapting to human needs, enhancing wellbeing, and creating responsive environments that blur the distinction between illumination and architecture itself.

Architectural Lighting Market Demand Analysis

The architectural lighting market has witnessed significant growth in recent years, driven by increasing urbanization, smart city initiatives, and growing emphasis on energy efficiency. The global architectural lighting market was valued at approximately 8.3 billion USD in 2022 and is projected to reach 13.2 billion USD by 2028, growing at a CAGR of around 6.8% during the forecast period. This growth trajectory underscores the expanding demand for innovative lighting solutions in architectural applications.

Within this market, there is a notable shift towards advanced technologies like OLED and MicroLED, which are gradually replacing traditional lighting systems. This transition is primarily fueled by the growing demand for energy-efficient lighting solutions that offer enhanced aesthetic appeal, flexibility in design, and reduced environmental impact. Commercial buildings, including offices, retail spaces, and hospitality venues, represent the largest market segment, accounting for nearly 45% of the total architectural lighting demand.

Regionally, North America and Europe currently dominate the architectural lighting market, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading in adoption of cutting-edge lighting technologies like OLED and MicroLED. This regional growth is attributed to rapid urbanization, increasing construction activities, and government initiatives promoting energy-efficient building solutions.

Consumer preferences are increasingly leaning towards customizable lighting solutions that can adapt to different moods, occasions, and functional requirements. This trend has created a substantial demand for dynamic lighting systems capable of color changing, dimming, and integration with smart building management systems. According to industry surveys, approximately 72% of architects and interior designers now consider advanced lighting technologies as essential components in their projects, compared to just 45% five years ago.

Sustainability concerns are also reshaping market demands, with building owners and operators seeking lighting solutions with longer lifespans, reduced energy consumption, and minimal environmental footprint. Both OLED and MicroLED technologies address these concerns, albeit through different technical approaches. The market shows a growing willingness to invest in premium lighting solutions that offer long-term operational savings and environmental benefits, with an estimated 65% of commercial building projects now allocating higher budgets for advanced lighting systems.

The COVID-19 pandemic has further accelerated certain market trends, particularly the demand for lighting solutions that can contribute to healthier indoor environments. Technologies that offer better color rendering, reduced flicker, and the ability to mimic natural daylight patterns have seen increased adoption in both commercial and residential applications.

Within this market, there is a notable shift towards advanced technologies like OLED and MicroLED, which are gradually replacing traditional lighting systems. This transition is primarily fueled by the growing demand for energy-efficient lighting solutions that offer enhanced aesthetic appeal, flexibility in design, and reduced environmental impact. Commercial buildings, including offices, retail spaces, and hospitality venues, represent the largest market segment, accounting for nearly 45% of the total architectural lighting demand.

Regionally, North America and Europe currently dominate the architectural lighting market, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading in adoption of cutting-edge lighting technologies like OLED and MicroLED. This regional growth is attributed to rapid urbanization, increasing construction activities, and government initiatives promoting energy-efficient building solutions.

Consumer preferences are increasingly leaning towards customizable lighting solutions that can adapt to different moods, occasions, and functional requirements. This trend has created a substantial demand for dynamic lighting systems capable of color changing, dimming, and integration with smart building management systems. According to industry surveys, approximately 72% of architects and interior designers now consider advanced lighting technologies as essential components in their projects, compared to just 45% five years ago.

Sustainability concerns are also reshaping market demands, with building owners and operators seeking lighting solutions with longer lifespans, reduced energy consumption, and minimal environmental footprint. Both OLED and MicroLED technologies address these concerns, albeit through different technical approaches. The market shows a growing willingness to invest in premium lighting solutions that offer long-term operational savings and environmental benefits, with an estimated 65% of commercial building projects now allocating higher budgets for advanced lighting systems.

The COVID-19 pandemic has further accelerated certain market trends, particularly the demand for lighting solutions that can contribute to healthier indoor environments. Technologies that offer better color rendering, reduced flicker, and the ability to mimic natural daylight patterns have seen increased adoption in both commercial and residential applications.

Current Technological Landscape and Barriers

The architectural lighting industry is currently witnessing a technological transition with OLED and MicroLED technologies emerging as potential game-changers. OLED (Organic Light Emitting Diode) technology has reached commercial maturity in recent years, with manufacturers like LG Display, Philips Lighting, and Acuity Brands offering architectural lighting solutions. These products feature thin, flexible form factors with excellent color rendering capabilities and uniform light distribution. However, OLED adoption in architectural applications remains limited due to high production costs, relatively low luminance levels (typically 3,000-8,000 cd/m²), and concerns about longevity in high-brightness applications.

MicroLED technology, while still in earlier stages of commercialization for architectural lighting, demonstrates remarkable potential with superior brightness (capable of exceeding 100,000 cd/m²), energy efficiency, and longevity. Companies like Samsung, Sony, and Lumileds are investing heavily in MicroLED development, though most current applications focus on display technology rather than architectural lighting specifically. The miniaturization of LED chips to microscopic dimensions (typically under 100 micrometers) enables unprecedented design possibilities but presents significant manufacturing challenges.

A primary technical barrier for both technologies is cost-effective mass production. OLED manufacturing still struggles with yield rates and scaling issues, particularly for larger panels suitable for architectural applications. The vacuum deposition processes required for OLED production remain expensive and time-consuming. MicroLED faces even greater manufacturing hurdles, including the precise transfer and placement of millions of microscopic LED chips, achieving consistent performance across large arrays, and developing cost-effective inspection and repair processes.

Energy efficiency presents another significant consideration. While both technologies offer improvements over traditional lighting, MicroLED currently demonstrates superior efficiency metrics, with theoretical efficacy exceeding 200 lm/W compared to OLED's typical range of 60-100 lm/W. However, this advantage is partially offset by OLED's ability to provide more diffuse, glare-free illumination that may require less overall luminance for equivalent visual comfort in architectural settings.

Durability and lifespan considerations also present challenges. OLED technology remains vulnerable to moisture and oxygen degradation, necessitating sophisticated encapsulation techniques that add cost and complexity. Current commercial OLED lighting products typically offer lifespans of 30,000-50,000 hours to L70 (70% of initial brightness), whereas MicroLED potentially offers 100,000+ hours with minimal degradation, though long-term performance data in real-world architectural applications remains limited.

Integration capabilities represent another critical factor. OLED panels offer inherent advantages in seamless integration with building materials due to their thin, lightweight nature and ability to function as transparent or mirror-like surfaces when inactive. MicroLED technology, while potentially more versatile in brightness and color capabilities, currently faces greater challenges in achieving the same level of architectural integration due to heat management requirements and more complex driving electronics.

MicroLED technology, while still in earlier stages of commercialization for architectural lighting, demonstrates remarkable potential with superior brightness (capable of exceeding 100,000 cd/m²), energy efficiency, and longevity. Companies like Samsung, Sony, and Lumileds are investing heavily in MicroLED development, though most current applications focus on display technology rather than architectural lighting specifically. The miniaturization of LED chips to microscopic dimensions (typically under 100 micrometers) enables unprecedented design possibilities but presents significant manufacturing challenges.

A primary technical barrier for both technologies is cost-effective mass production. OLED manufacturing still struggles with yield rates and scaling issues, particularly for larger panels suitable for architectural applications. The vacuum deposition processes required for OLED production remain expensive and time-consuming. MicroLED faces even greater manufacturing hurdles, including the precise transfer and placement of millions of microscopic LED chips, achieving consistent performance across large arrays, and developing cost-effective inspection and repair processes.

Energy efficiency presents another significant consideration. While both technologies offer improvements over traditional lighting, MicroLED currently demonstrates superior efficiency metrics, with theoretical efficacy exceeding 200 lm/W compared to OLED's typical range of 60-100 lm/W. However, this advantage is partially offset by OLED's ability to provide more diffuse, glare-free illumination that may require less overall luminance for equivalent visual comfort in architectural settings.

Durability and lifespan considerations also present challenges. OLED technology remains vulnerable to moisture and oxygen degradation, necessitating sophisticated encapsulation techniques that add cost and complexity. Current commercial OLED lighting products typically offer lifespans of 30,000-50,000 hours to L70 (70% of initial brightness), whereas MicroLED potentially offers 100,000+ hours with minimal degradation, though long-term performance data in real-world architectural applications remains limited.

Integration capabilities represent another critical factor. OLED panels offer inherent advantages in seamless integration with building materials due to their thin, lightweight nature and ability to function as transparent or mirror-like surfaces when inactive. MicroLED technology, while potentially more versatile in brightness and color capabilities, currently faces greater challenges in achieving the same level of architectural integration due to heat management requirements and more complex driving electronics.

Contemporary Architectural Lighting Solutions

01 Manufacturing processes for OLED and MicroLED displays

Various manufacturing techniques are employed for producing OLED and MicroLED displays, including specialized deposition methods, transfer processes, and integration approaches. These processes focus on improving yield rates, reducing production costs, and enabling mass production of high-resolution displays. Advanced manufacturing methods allow for precise placement of micro-scale LED elements and organic materials to create efficient display panels with superior performance characteristics.- Manufacturing processes for OLED and MicroLED displays: Various manufacturing techniques are employed to produce OLED and MicroLED displays, including specialized deposition methods, transfer processes, and integration approaches. These processes focus on improving yield rates, reducing production costs, and enabling mass production of high-resolution displays. Advanced manufacturing methods address challenges in pixel placement accuracy, uniformity, and integration with driving circuits.

- Device structures and materials for enhanced display performance: Innovations in device architectures and materials for OLED and MicroLED technologies focus on improving efficiency, brightness, and color performance. These include novel electrode configurations, light-emitting materials, and quantum dot integration. Structural designs address issues like light extraction efficiency, power consumption, and operational stability while maintaining high color gamut and contrast ratios.

- Integration technologies for flexible and foldable displays: Advanced integration methods enable the development of flexible, foldable, and stretchable OLED and MicroLED displays. These technologies incorporate specialized substrates, encapsulation techniques, and interconnect solutions that maintain display performance while allowing for mechanical deformation. Innovations in this area focus on addressing challenges related to stress distribution, durability during repeated folding, and maintaining electrical connectivity in dynamic form factors.

- Driving and control systems for high-resolution displays: Sophisticated driving and control systems are developed to address the unique requirements of high-resolution OLED and MicroLED displays. These include advanced thin-film transistor (TFT) backplanes, compensation circuits for uniformity, and innovative addressing schemes. The technologies focus on minimizing power consumption while maintaining image quality, addressing issues like pixel-to-pixel variations, and enabling high refresh rates for demanding applications.

- Thermal management and reliability enhancement: Thermal management solutions and reliability enhancement techniques are critical for OLED and MicroLED displays, particularly in high-brightness applications. These technologies include heat dissipation structures, protective layers, and operational algorithms that extend device lifetime. Innovations address challenges related to thermal degradation, color shift over time, and maintaining consistent performance across the display area under various environmental conditions.

02 Device structures and materials for display technologies

Innovations in device architectures and materials are critical for advancing OLED and MicroLED technologies. These include novel electrode configurations, light-emitting materials, substrate designs, and encapsulation techniques. Material developments focus on improving efficiency, color purity, lifetime, and brightness of displays. Structural innovations enable thinner, more flexible, and more durable display panels while maintaining or enhancing visual performance.Expand Specific Solutions03 Driving and control systems for display panels

Specialized driving circuits and control systems are developed to operate OLED and MicroLED displays efficiently. These systems manage power delivery, pixel addressing, brightness control, and color reproduction. Advanced driving schemes help reduce power consumption while maintaining display quality and enabling features like high refresh rates and high dynamic range. Control systems also incorporate compensation mechanisms to address issues like non-uniformity and aging effects in display panels.Expand Specific Solutions04 Integration technologies for display applications

Integration technologies focus on incorporating OLED and MicroLED displays into various devices and applications. These include methods for embedding displays in consumer electronics, automotive interfaces, wearable devices, and specialized equipment. Integration approaches address challenges related to form factor constraints, environmental conditions, power limitations, and interface requirements. Solutions include flexible display integration, modular display systems, and specialized mounting techniques.Expand Specific Solutions05 Optical enhancement techniques for display performance

Various optical technologies are employed to enhance the performance of OLED and MicroLED displays. These include light extraction structures, color conversion layers, quantum dot integration, and specialized optical films. These techniques improve brightness efficiency, color gamut, viewing angles, and outdoor visibility while reducing power consumption. Optical enhancements also address issues like ambient light reflection and color shift at different viewing angles.Expand Specific Solutions

Industry Leaders and Competitive Dynamics

The OLED vs MicroLED architectural lighting market is currently in a transitional phase, with OLED technology being more mature while MicroLED represents the emerging frontier. The global architectural lighting market is projected to reach $18 billion by 2026, with advanced display technologies capturing an increasing share. BOE Technology Group and TCL China Star Optoelectronics lead in OLED manufacturing scale, while companies like Lumileds and Rayleigh Vision Intelligence are advancing MicroLED development. Major players like Philips, Barco, and Applied Materials are investing in both technologies, recognizing their complementary applications in architectural contexts. The competitive landscape is characterized by established display manufacturers expanding into lighting applications while specialized lighting companies incorporate these advanced technologies into their product portfolios.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed comprehensive solutions in both OLED and MicroLED technologies for architectural lighting applications. Their OLED panels feature ultra-thin profiles (less than 1mm thickness) with flexible form factors that can be curved or bent to create unique lighting installations. BOE's architectural OLED solutions deliver uniform illumination with no visible pixels at normal viewing distances, high color rendering index (CRI>90), and wide viewing angles exceeding 170 degrees. For MicroLED, BOE has pioneered high-density mini/micro LED display technology with pixel pitches below 0.9mm for indoor architectural applications. Their MicroLED solutions incorporate advanced mass transfer processes to achieve precise LED placement with transfer yields exceeding 99.99%. BOE's architectural lighting systems integrate smart control capabilities allowing dynamic color temperature adjustment (1800K-6500K) and IoT connectivity for integration with building management systems.

Strengths: Industry-leading manufacturing capacity for both technologies; vertical integration from panel production to system integration; strong R&D capabilities with over 10,000 patents in display technologies. Weaknesses: Higher production costs compared to conventional lighting; OLED technology still faces lifetime challenges in high-brightness applications; MicroLED mass production efficiency still being optimized.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced architectural lighting solutions leveraging both OLED and MicroLED technologies. Their OLED architectural lighting panels deliver uniform, glare-free illumination with ultra-thin form factors (approximately 2mm thickness) and flexibility for curved installations. Philips' OLED solutions feature high color rendering (CRI>90), tunable white light (2700K-6500K), and seamless integration capabilities with their Hue ecosystem for smart control. For MicroLED, Philips has focused on modular architectural lighting systems that combine exceptional brightness (up to 2000 nits) with precise control over individual pixels. Their MicroLED technology incorporates advanced heat management systems to maintain optimal performance while extending operational lifetime beyond 100,000 hours. Philips has also pioneered hybrid solutions that strategically combine OLED and MicroLED technologies within single architectural installations to leverage the complementary strengths of each technology.

Strengths: Extensive lighting industry experience and distribution network; comprehensive ecosystem of lighting control systems; strong brand recognition and established relationships with architects and designers. Weaknesses: Premium pricing positions products primarily for high-end applications; OLED manufacturing capacity more limited than some competitors; MicroLED technology still facing cost challenges for widespread architectural adoption.

Key Patents and Innovations in Display Lighting

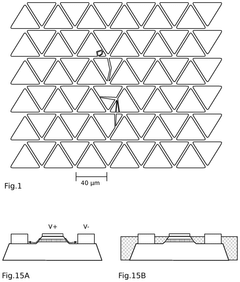

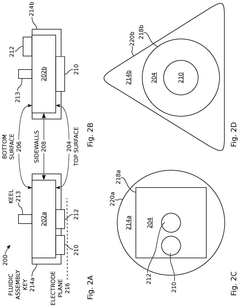

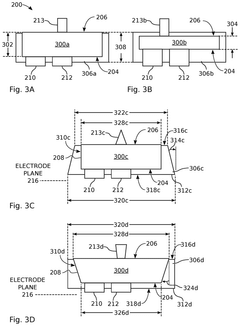

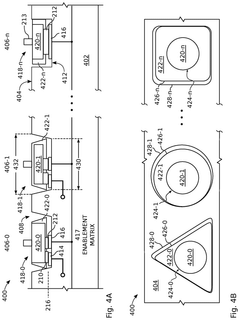

Encapsulated light emitting diodes for selective fluidic assembly

PatentActiveUS12119432B2

Innovation

- The use of partially encapsulated semiconductor-based inorganic micro-LEDs with a patternable polymer encapsulant that protects the LEDs from collisions and optimizes their shape for efficient assembly, allowing for higher speed and yield while preventing defects, and enabling precise alignment of LED colors on a display substrate.

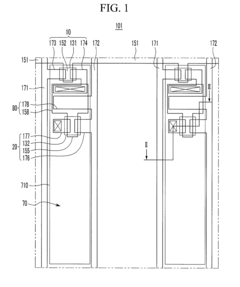

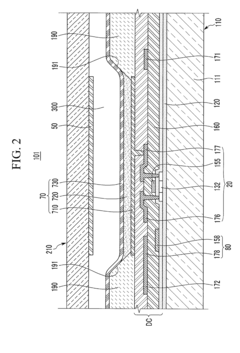

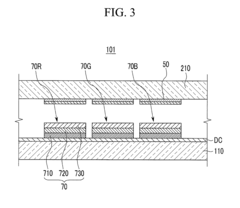

Organic light emitting diode (OLED) display

PatentActiveUS20110215302A1

Innovation

- The implementation of a translucent insulating layer filter on the encapsulation substrate, which forms a microcavity with the encapsulation substrate, reduces the need for fine metal masks by using separate patterned portions for each pixel and a continuous layer for all pixels, improving light efficiency and reducing mask usage.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in architectural lighting design, with OLED and MicroLED technologies offering distinct environmental profiles. OLED technology demonstrates impressive energy efficiency characteristics, consuming significantly less power than traditional lighting solutions while providing uniform illumination. The organic materials in OLEDs enable them to operate at lower temperatures, reducing cooling requirements in buildings and contributing to overall energy savings. Additionally, OLEDs contain no mercury or other hazardous materials commonly found in fluorescent lighting, making them environmentally safer throughout their lifecycle.

MicroLED technology presents its own sustainability advantages, particularly in longevity and durability. With lifespans potentially exceeding 100,000 hours, MicroLEDs significantly reduce replacement frequency and associated waste. Their exceptional energy efficiency rivals that of OLEDs, with some implementations achieving up to 30% greater efficiency due to direct light emission properties and advanced control systems. This efficiency translates directly to reduced carbon footprints in architectural applications.

Both technologies offer substantial improvements in recyclability compared to conventional lighting systems. OLEDs utilize organic compounds that can be more readily biodegraded, though current recycling infrastructure remains limited. MicroLEDs, composed primarily of inorganic materials, present different end-of-life considerations but benefit from established electronic waste recycling channels. The semiconductor industry's experience with similar materials facilitates more effective recovery of valuable components.

From a lifecycle assessment perspective, manufacturing processes present different environmental challenges. OLED production currently involves energy-intensive vacuum deposition processes and requires stringent clean room environments. MicroLED manufacturing faces yield challenges and complex assembly processes that impact resource efficiency. However, rapid advancements in production techniques are improving sustainability metrics for both technologies.

Building integration considerations further differentiate these technologies' environmental impact. OLEDs' inherent flexibility and thinness reduce structural requirements and associated embodied carbon. MicroLEDs' exceptional brightness-to-power ratio enables precise lighting control systems that can dramatically reduce energy consumption through adaptive illumination strategies. When paired with smart building management systems, both technologies can optimize energy usage based on occupancy, daylight availability, and user preferences.

MicroLED technology presents its own sustainability advantages, particularly in longevity and durability. With lifespans potentially exceeding 100,000 hours, MicroLEDs significantly reduce replacement frequency and associated waste. Their exceptional energy efficiency rivals that of OLEDs, with some implementations achieving up to 30% greater efficiency due to direct light emission properties and advanced control systems. This efficiency translates directly to reduced carbon footprints in architectural applications.

Both technologies offer substantial improvements in recyclability compared to conventional lighting systems. OLEDs utilize organic compounds that can be more readily biodegraded, though current recycling infrastructure remains limited. MicroLEDs, composed primarily of inorganic materials, present different end-of-life considerations but benefit from established electronic waste recycling channels. The semiconductor industry's experience with similar materials facilitates more effective recovery of valuable components.

From a lifecycle assessment perspective, manufacturing processes present different environmental challenges. OLED production currently involves energy-intensive vacuum deposition processes and requires stringent clean room environments. MicroLED manufacturing faces yield challenges and complex assembly processes that impact resource efficiency. However, rapid advancements in production techniques are improving sustainability metrics for both technologies.

Building integration considerations further differentiate these technologies' environmental impact. OLEDs' inherent flexibility and thinness reduce structural requirements and associated embodied carbon. MicroLEDs' exceptional brightness-to-power ratio enables precise lighting control systems that can dramatically reduce energy consumption through adaptive illumination strategies. When paired with smart building management systems, both technologies can optimize energy usage based on occupancy, daylight availability, and user preferences.

Integration Challenges in Building Infrastructure

The integration of OLED and MicroLED technologies into architectural lighting design presents significant challenges when considering building infrastructure. These advanced lighting solutions require specialized installation methods and support systems that often differ from traditional lighting infrastructure.

Power delivery represents one of the primary integration challenges. MicroLED systems typically require more complex power management due to their higher brightness capabilities and the need for precise current control to individual LED arrays. In contrast, OLED panels generally operate at lower voltages but may require more uniform power distribution across larger surface areas. Building infrastructure must accommodate these different power requirements, often necessitating upgrades to existing electrical systems or the implementation of dedicated power management solutions.

Thermal management constitutes another critical challenge, particularly for MicroLED installations. These systems generate considerable heat during operation, requiring effective dissipation mechanisms to prevent performance degradation and ensure longevity. Building designers must incorporate adequate ventilation, heat sinks, or active cooling systems, which may impact HVAC requirements and spatial planning. OLEDs generate less heat but remain sensitive to temperature fluctuations, requiring stable environmental conditions for optimal performance.

Physical integration challenges also differ significantly between technologies. OLEDs offer flexibility and thinness that theoretically simplifies installation, but their sensitivity to moisture and oxygen necessitates careful sealing and protection within building elements. MicroLED arrays, while more robust, require precise alignment and mounting systems to maintain visual consistency across large installations. Both technologies may demand structural reinforcement when implemented at scale, particularly for ceiling or wall-mounted applications.

Control system compatibility presents additional complexity. Modern architectural lighting demands sophisticated control capabilities, including dimming, color temperature adjustment, and integration with building management systems. Retrofitting existing buildings with the necessary data infrastructure to support these advanced control protocols often requires extensive rewiring or the implementation of wireless control solutions, which must overcome signal interference from building materials and other electronic systems.

Maintenance accessibility must also be considered during integration planning. Unlike traditional lighting systems where bulb replacement is straightforward, OLED and MicroLED installations may require specialized service protocols. Building infrastructure must accommodate maintenance pathways and access points that allow for component replacement or repair without disrupting architectural elements or requiring extensive disassembly.

Power delivery represents one of the primary integration challenges. MicroLED systems typically require more complex power management due to their higher brightness capabilities and the need for precise current control to individual LED arrays. In contrast, OLED panels generally operate at lower voltages but may require more uniform power distribution across larger surface areas. Building infrastructure must accommodate these different power requirements, often necessitating upgrades to existing electrical systems or the implementation of dedicated power management solutions.

Thermal management constitutes another critical challenge, particularly for MicroLED installations. These systems generate considerable heat during operation, requiring effective dissipation mechanisms to prevent performance degradation and ensure longevity. Building designers must incorporate adequate ventilation, heat sinks, or active cooling systems, which may impact HVAC requirements and spatial planning. OLEDs generate less heat but remain sensitive to temperature fluctuations, requiring stable environmental conditions for optimal performance.

Physical integration challenges also differ significantly between technologies. OLEDs offer flexibility and thinness that theoretically simplifies installation, but their sensitivity to moisture and oxygen necessitates careful sealing and protection within building elements. MicroLED arrays, while more robust, require precise alignment and mounting systems to maintain visual consistency across large installations. Both technologies may demand structural reinforcement when implemented at scale, particularly for ceiling or wall-mounted applications.

Control system compatibility presents additional complexity. Modern architectural lighting demands sophisticated control capabilities, including dimming, color temperature adjustment, and integration with building management systems. Retrofitting existing buildings with the necessary data infrastructure to support these advanced control protocols often requires extensive rewiring or the implementation of wireless control solutions, which must overcome signal interference from building materials and other electronic systems.

Maintenance accessibility must also be considered during integration planning. Unlike traditional lighting systems where bulb replacement is straightforward, OLED and MicroLED installations may require specialized service protocols. Building infrastructure must accommodate maintenance pathways and access points that allow for component replacement or repair without disrupting architectural elements or requiring extensive disassembly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!