Research on OLED vs MicroLED Impacts in Healthcare

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution in Healthcare

Display technology in healthcare has undergone significant transformation over the past decades, evolving from simple monochrome cathode ray tube (CRT) monitors to sophisticated high-resolution displays. The 1980s marked the beginning of digital imaging in healthcare with the introduction of basic LCD displays for viewing radiological images. These early displays suffered from limited resolution, poor contrast ratios, and inadequate color reproduction, constraining their clinical utility.

The 1990s witnessed the transition to active-matrix LCDs, offering improved image quality and reliability for diagnostic applications. By the early 2000s, medical-grade LCDs became standardized in healthcare settings, with specialized features such as DICOM calibration for consistent grayscale representation across different displays, critical for accurate diagnosis in radiology.

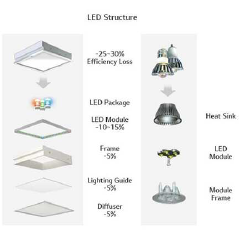

The mid-2000s saw the emergence of LED-backlit LCD technology, providing enhanced brightness, better energy efficiency, and longer operational lifespans compared to traditional CCFL-backlit displays. This advancement significantly improved the visualization of subtle clinical details in medical imaging.

OLED technology entered the healthcare market around 2010, introducing perfect black levels, superior contrast ratios, and wider viewing angles. These characteristics proved particularly valuable in surgical environments and for mobile medical devices where visual performance under varying lighting conditions is crucial.

Recent years have witnessed the integration of 4K and 8K ultra-high-definition displays in operating rooms and diagnostic imaging centers, enabling unprecedented detail visualization during minimally invasive procedures and for complex diagnostic interpretation. The higher pixel density allows surgeons to discern minute anatomical structures and pathological changes previously difficult to observe.

Touch-enabled and 3D display technologies have further revolutionized healthcare visualization, facilitating interactive medical education, surgical planning, and patient communication. These technologies enable healthcare professionals to manipulate and explore complex anatomical structures in intuitive ways.

The latest frontier in healthcare display technology involves the emerging competition between advanced OLED and MicroLED technologies. While OLED offers excellent contrast and flexibility advantages, MicroLED promises superior brightness, longevity, and resistance to burn-in—critical factors in 24/7 healthcare environments. This technological rivalry is driving innovation in areas such as augmented reality surgical guidance systems, wearable health monitors, and next-generation diagnostic displays.

As healthcare continues its digital transformation, display technology evolution remains fundamental to improving diagnostic accuracy, procedural precision, and overall patient outcomes across the medical spectrum.

The 1990s witnessed the transition to active-matrix LCDs, offering improved image quality and reliability for diagnostic applications. By the early 2000s, medical-grade LCDs became standardized in healthcare settings, with specialized features such as DICOM calibration for consistent grayscale representation across different displays, critical for accurate diagnosis in radiology.

The mid-2000s saw the emergence of LED-backlit LCD technology, providing enhanced brightness, better energy efficiency, and longer operational lifespans compared to traditional CCFL-backlit displays. This advancement significantly improved the visualization of subtle clinical details in medical imaging.

OLED technology entered the healthcare market around 2010, introducing perfect black levels, superior contrast ratios, and wider viewing angles. These characteristics proved particularly valuable in surgical environments and for mobile medical devices where visual performance under varying lighting conditions is crucial.

Recent years have witnessed the integration of 4K and 8K ultra-high-definition displays in operating rooms and diagnostic imaging centers, enabling unprecedented detail visualization during minimally invasive procedures and for complex diagnostic interpretation. The higher pixel density allows surgeons to discern minute anatomical structures and pathological changes previously difficult to observe.

Touch-enabled and 3D display technologies have further revolutionized healthcare visualization, facilitating interactive medical education, surgical planning, and patient communication. These technologies enable healthcare professionals to manipulate and explore complex anatomical structures in intuitive ways.

The latest frontier in healthcare display technology involves the emerging competition between advanced OLED and MicroLED technologies. While OLED offers excellent contrast and flexibility advantages, MicroLED promises superior brightness, longevity, and resistance to burn-in—critical factors in 24/7 healthcare environments. This technological rivalry is driving innovation in areas such as augmented reality surgical guidance systems, wearable health monitors, and next-generation diagnostic displays.

As healthcare continues its digital transformation, display technology evolution remains fundamental to improving diagnostic accuracy, procedural precision, and overall patient outcomes across the medical spectrum.

Market Demand Analysis for Medical Displays

The medical display market is experiencing significant growth driven by the increasing adoption of digital healthcare solutions and advanced imaging technologies. Current market analysis indicates that the global medical display market is projected to reach $3.2 billion by 2025, with a compound annual growth rate of 4.9% from 2020. This growth is primarily fueled by the rising prevalence of chronic diseases requiring advanced diagnostic imaging, increasing digitization of healthcare systems, and growing investments in healthcare infrastructure worldwide.

Within this expanding market, there is a notable shift in demand toward higher resolution, color accuracy, and energy-efficient display technologies. Healthcare professionals, particularly in specialties such as radiology, surgery, and pathology, require displays with exceptional image quality, consistent brightness, and precise color reproduction to make accurate diagnoses and perform complex procedures. Traditional LCD displays are gradually being replaced by advanced technologies like OLED and emerging MicroLED solutions.

OLED technology has gained significant traction in medical imaging applications due to its superior contrast ratios, wider viewing angles, and ability to display true blacks - critical features for diagnostic accuracy. Market research indicates that approximately 28% of premium medical displays shipped in 2021 utilized OLED technology, with adoption rates increasing in specialized fields such as digital pathology and surgical visualization.

MicroLED, though still in early adoption phases for medical applications, is generating substantial interest due to its potential advantages in brightness, longevity, and energy efficiency. Market forecasts suggest that MicroLED displays could capture up to 15% of the high-end medical display market by 2027, particularly in operating rooms and intervention suites where brightness and reliability are paramount.

Regional analysis reveals that North America currently dominates the medical display market with approximately 42% market share, followed by Europe (27%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing healthcare expenditure, growing medical tourism, and rapid technological adoption in countries like China, Japan, and South Korea.

End-user segmentation shows hospitals remain the largest consumers of medical displays, accounting for 68% of the market. However, diagnostic imaging centers and specialized clinics represent the fastest-growing segment with an estimated growth rate of 6.3% annually, driven by the increasing trend toward outpatient care and specialized medical services.

The COVID-19 pandemic has accelerated demand for remote diagnostic capabilities, creating new market opportunities for high-quality medical displays in telehealth applications. This trend is expected to continue post-pandemic, with an estimated 35% of diagnostic reviews now conducted remotely compared to just 12% pre-pandemic.

Within this expanding market, there is a notable shift in demand toward higher resolution, color accuracy, and energy-efficient display technologies. Healthcare professionals, particularly in specialties such as radiology, surgery, and pathology, require displays with exceptional image quality, consistent brightness, and precise color reproduction to make accurate diagnoses and perform complex procedures. Traditional LCD displays are gradually being replaced by advanced technologies like OLED and emerging MicroLED solutions.

OLED technology has gained significant traction in medical imaging applications due to its superior contrast ratios, wider viewing angles, and ability to display true blacks - critical features for diagnostic accuracy. Market research indicates that approximately 28% of premium medical displays shipped in 2021 utilized OLED technology, with adoption rates increasing in specialized fields such as digital pathology and surgical visualization.

MicroLED, though still in early adoption phases for medical applications, is generating substantial interest due to its potential advantages in brightness, longevity, and energy efficiency. Market forecasts suggest that MicroLED displays could capture up to 15% of the high-end medical display market by 2027, particularly in operating rooms and intervention suites where brightness and reliability are paramount.

Regional analysis reveals that North America currently dominates the medical display market with approximately 42% market share, followed by Europe (27%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing healthcare expenditure, growing medical tourism, and rapid technological adoption in countries like China, Japan, and South Korea.

End-user segmentation shows hospitals remain the largest consumers of medical displays, accounting for 68% of the market. However, diagnostic imaging centers and specialized clinics represent the fastest-growing segment with an estimated growth rate of 6.3% annually, driven by the increasing trend toward outpatient care and specialized medical services.

The COVID-19 pandemic has accelerated demand for remote diagnostic capabilities, creating new market opportunities for high-quality medical displays in telehealth applications. This trend is expected to continue post-pandemic, with an estimated 35% of diagnostic reviews now conducted remotely compared to just 12% pre-pandemic.

OLED vs MicroLED Technical Challenges

Both OLED and MicroLED technologies face significant technical challenges in healthcare applications, though their specific limitations differ considerably. OLED displays currently struggle with limited operational lifespans, particularly when displaying static images common in medical monitoring, which can lead to pixel degradation and burn-in effects. This issue becomes critical in healthcare settings where display reliability directly impacts diagnostic accuracy and patient monitoring.

Water vapor and oxygen sensitivity remains another major obstacle for OLED implementation in medical environments. The organic materials in OLEDs degrade when exposed to moisture and oxygen, necessitating complex encapsulation solutions that add to manufacturing complexity and cost while potentially limiting form factor flexibility in medical devices.

MicroLED technology, while promising, confronts substantial manufacturing hurdles that have delayed its widespread adoption in healthcare. The mass transfer process—moving millions of tiny LED chips from growth substrates to display substrates—presents yield challenges that directly affect production costs and scalability. Current transfer techniques struggle to achieve the precision required for high-resolution medical imaging displays.

Color uniformity represents another significant technical barrier for MicroLED in medical applications. Achieving consistent color reproduction across the entire display surface requires precise control of each microLED element, which becomes increasingly difficult at the microscale dimensions needed for compact medical devices. This challenge is particularly acute for diagnostic imaging where color accuracy can influence clinical decisions.

Power efficiency at low brightness levels remains problematic for MicroLED technology. While MicroLEDs excel in high-brightness scenarios, they become less efficient at the lower brightness levels often required in healthcare environments, potentially limiting battery life in portable medical devices.

Integration complexity presents challenges for both technologies. OLED requires sophisticated thin-film transistor backplanes for active matrix driving, while MicroLED demands advanced driving circuits capable of precisely controlling millions of individual LED elements. These requirements increase system complexity and potential points of failure in medical devices where reliability is paramount.

Heat management constitutes a shared challenge, though manifesting differently. OLEDs generate less heat but are more sensitive to temperature fluctuations, while MicroLEDs produce more heat that must be efficiently dissipated to prevent performance degradation and ensure patient safety in wearable or implantable healthcare applications.

Water vapor and oxygen sensitivity remains another major obstacle for OLED implementation in medical environments. The organic materials in OLEDs degrade when exposed to moisture and oxygen, necessitating complex encapsulation solutions that add to manufacturing complexity and cost while potentially limiting form factor flexibility in medical devices.

MicroLED technology, while promising, confronts substantial manufacturing hurdles that have delayed its widespread adoption in healthcare. The mass transfer process—moving millions of tiny LED chips from growth substrates to display substrates—presents yield challenges that directly affect production costs and scalability. Current transfer techniques struggle to achieve the precision required for high-resolution medical imaging displays.

Color uniformity represents another significant technical barrier for MicroLED in medical applications. Achieving consistent color reproduction across the entire display surface requires precise control of each microLED element, which becomes increasingly difficult at the microscale dimensions needed for compact medical devices. This challenge is particularly acute for diagnostic imaging where color accuracy can influence clinical decisions.

Power efficiency at low brightness levels remains problematic for MicroLED technology. While MicroLEDs excel in high-brightness scenarios, they become less efficient at the lower brightness levels often required in healthcare environments, potentially limiting battery life in portable medical devices.

Integration complexity presents challenges for both technologies. OLED requires sophisticated thin-film transistor backplanes for active matrix driving, while MicroLED demands advanced driving circuits capable of precisely controlling millions of individual LED elements. These requirements increase system complexity and potential points of failure in medical devices where reliability is paramount.

Heat management constitutes a shared challenge, though manifesting differently. OLEDs generate less heat but are more sensitive to temperature fluctuations, while MicroLEDs produce more heat that must be efficiently dissipated to prevent performance degradation and ensure patient safety in wearable or implantable healthcare applications.

Current Display Solutions in Healthcare Applications

01 OLED display structure and materials

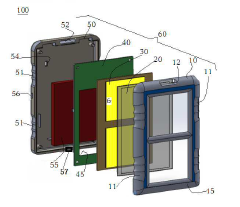

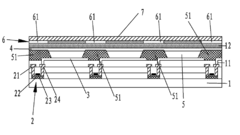

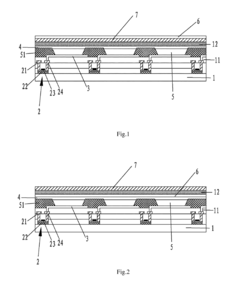

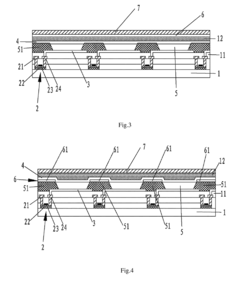

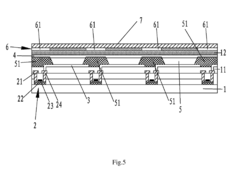

Organic Light Emitting Diode (OLED) displays utilize organic compounds that emit light when electricity is applied. These displays feature multiple layers including cathode, organic layers, and anode. The organic materials can be designed for different colors and brightness levels. OLED technology offers advantages such as flexibility, thinness, and high contrast ratios compared to traditional display technologies. Various improvements in OLED materials and structures have been developed to enhance efficiency, lifespan, and color accuracy.- OLED Display Structure and Materials: Organic Light Emitting Diode (OLED) displays utilize organic compounds that emit light when electricity is applied. The structure typically includes multiple layers such as cathode, organic layers, and anode on a substrate. Advanced OLED materials and configurations enable features like flexibility, transparency, and high color accuracy. These displays offer advantages including deep blacks, high contrast ratios, and reduced power consumption compared to traditional LCD technology.

- MicroLED Fabrication and Integration: MicroLED technology involves the integration of microscopic LED arrays to create displays with superior brightness and efficiency. The fabrication process includes transfer techniques to position tiny LED elements onto display substrates with high precision. Advanced methods for mass transfer of microLEDs help overcome manufacturing challenges and improve yield rates. These displays offer exceptional brightness, energy efficiency, and longevity compared to other display technologies.

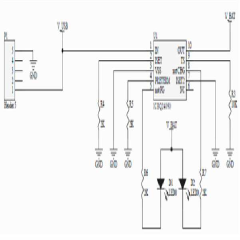

- Display Driving and Control Systems: Sophisticated driving circuits and control systems are essential for both OLED and MicroLED displays. These systems manage pixel addressing, brightness control, and color reproduction. Advanced technologies include thin-film transistor (TFT) backplanes, pulse width modulation techniques, and specialized integrated circuits. These control systems enable features like high refresh rates, dynamic range adjustment, and power management to optimize display performance.

- Energy Efficiency and Power Management: Both OLED and MicroLED technologies incorporate advanced power management systems to optimize energy consumption. These include pixel-level power control, adaptive brightness adjustment based on ambient light, and selective pixel activation. Power-saving algorithms and circuit designs help extend battery life in portable devices while maintaining display quality. Energy efficiency innovations focus on reducing heat generation and improving overall sustainability of display technologies.

- Display Applications and Form Factors: OLED and MicroLED technologies enable diverse applications and novel form factors beyond conventional flat panels. These include flexible displays, transparent displays, foldable screens, and curved surfaces. The technologies are being implemented in various devices ranging from smartphones and televisions to automotive displays, wearables, and augmented reality devices. Advanced manufacturing techniques allow for customized shapes and sizes to meet specific application requirements.

02 MicroLED fabrication and integration

MicroLED displays consist of arrays of microscopic LED elements that serve as individual pixels. The fabrication process involves creating tiny LED structures, typically less than 100 micrometers, and transferring them to a display substrate. Various methods have been developed for mass transfer of these micro-scale LEDs to achieve efficient manufacturing. The integration process includes connecting these microLEDs to driving circuits and addressing mechanisms. MicroLED technology offers benefits such as high brightness, energy efficiency, and longer lifespan compared to other display technologies.Expand Specific Solutions03 Display driver and control systems

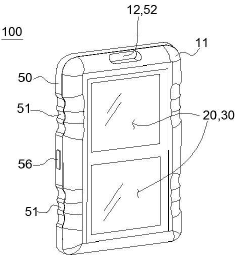

Advanced driver and control systems are essential for both OLED and MicroLED displays. These systems manage pixel addressing, brightness control, and color reproduction. They include integrated circuits that provide precise current and voltage control to individual pixels or pixel groups. Innovations in this area focus on reducing power consumption, increasing refresh rates, and enabling high dynamic range (HDR) capabilities. The driver architecture also addresses challenges such as uniform brightness across the display and compensation for pixel degradation over time.Expand Specific Solutions04 Flexible and foldable display technologies

Both OLED and MicroLED technologies can be implemented in flexible and foldable display configurations. These displays use substrates that can bend or fold without damaging the light-emitting elements. Special encapsulation techniques protect the sensitive components from oxygen and moisture while maintaining flexibility. The development includes innovations in flexible circuit connections, neutral plane engineering to minimize stress during bending, and durable cover materials. These technologies enable new form factors for devices such as smartphones, wearables, and rollable displays.Expand Specific Solutions05 Energy efficiency and power management

Energy efficiency is a critical aspect of both OLED and MicroLED display technologies. Various approaches have been developed to reduce power consumption while maintaining display quality. These include pixel-level power management, adaptive brightness control based on ambient light and displayed content, and optimized driving schemes. MicroLEDs offer inherently better energy efficiency for bright content, while OLEDs consume less power when displaying dark content. Advanced power management circuits and algorithms help extend battery life in portable devices while preserving visual performance.Expand Specific Solutions

Key Industry Players in Medical Display Manufacturing

The OLED vs MicroLED healthcare technology landscape is currently in an early growth phase, with the market expanding as display technologies find novel medical applications. The global market is projected to grow significantly as healthcare facilities adopt advanced visualization systems. Technologically, OLED is more mature with established players like BOE Technology, Universal Display Corporation, and Samsung Electronics leading commercial applications, while MicroLED remains predominantly in R&D stages with companies like X Display Co. and Applied Materials developing prototypes. Healthcare-focused companies such as Roche Diagnostics are beginning to integrate these technologies into medical imaging and diagnostic equipment, creating partnerships with display manufacturers to enhance visualization capabilities for precision medicine applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed specialized OLED and MicroLED display solutions targeting healthcare applications. Their medical-grade OLED panels feature high resolution (up to 8K UHD) with pixel densities exceeding 500 PPI, enabling detailed visualization of medical images. BOE's healthcare OLEDs incorporate proprietary color calibration technology that maintains DICOM Part 14 compliance for grayscale consistency, essential for accurate radiological interpretation. Their panels achieve a color accuracy of ΔE<1 across the entire screen, with uniformity variation below 3%. For surgical applications, BOE has engineered OLEDs with wide color gamut (>99% DCI-P3) and high refresh rates (up to 240Hz) to display real-time procedural imagery without motion artifacts. Their MicroLED development focuses on high-brightness displays (>3000 nits) that maintain visibility under intense surgical lighting conditions. BOE's healthcare displays incorporate specialized blue light filtering technology that reduces harmful wavelengths by up to 60% while maintaining color accuracy, addressing concerns about prolonged screen exposure for healthcare professionals working extended shifts.

Strengths: BOE offers comprehensive manufacturing capabilities spanning both OLED and MicroLED technologies, allowing integrated healthcare display solutions. Their displays feature exceptional color accuracy and DICOM compliance essential for diagnostic applications, with advanced blue light reduction technology addressing healthcare worker wellbeing. Weaknesses: BOE's MicroLED technology remains in earlier commercialization stages compared to their mature OLED offerings, with higher production costs limiting widespread adoption. Their displays typically consume more power than some competitors, potentially limiting battery life in portable medical applications.

Universal Display Corp.

Technical Solution: Universal Display Corporation (UDC) has developed proprietary phosphorescent OLED (PHOLED) technology that dramatically improves energy efficiency for healthcare applications. Their PHOLED materials convert nearly 100% of electrical energy into light, compared to 25% efficiency in conventional fluorescent OLEDs, resulting in power consumption reductions of up to 75%. This is particularly valuable for portable medical devices with limited battery capacity. UDC has engineered specialized OLED materials with spectral outputs optimized for phototherapy applications, including blue light (450-470nm) for treating neonatal jaundice and red light (630-700nm) for wound healing and pain management. Their healthcare-focused OLED panels maintain color stability throughout their operational lifetime, with color shift below 0.003 in CIE coordinates over 10,000 hours of operation. UDC has also pioneered flexible and transparent OLED technologies, enabling conformable displays that can be integrated into wearable health monitors with curvatures down to 1mm radius, while their transparent OLEDs achieve over 80% transparency when inactive.

Strengths: UDC's PHOLED technology offers superior energy efficiency crucial for portable medical devices, with their flexible display technology enabling innovative form factors for patient-worn monitors. Their extensive IP portfolio (over 5,000 patents) provides strong market positioning. Weaknesses: UDC focuses primarily on materials development rather than complete display manufacturing, requiring partnerships for full implementation. Their OLED technology still faces challenges with blue emitter lifetimes, which degrade faster than red and green, potentially affecting long-term color accuracy in medical displays.

Critical Patents and Innovations in Medical Displays

Lighting Device for medical using the Organic Light Emitting Diodes

PatentActiveKR1020190092718A

Innovation

- A portable medical lighting device using an organic light emitting diode (OLED) with a detachable housing, grip parts for easy handling, a photocatalyst coating for antibacterial properties, and a lightweight design, featuring a lithium ion battery, PCB board, and touch panel for brightness control, which includes a photocatalyst coating layer to oxidatively decompose harmful substances.

Organic light-emitting diode (OLED) device and display device

PatentActiveUS9905625B2

Innovation

- Incorporating a light-blocking layer, made of materials like ZnO, IGZO, TiO2, or TiO2, between the organic light-emitting layer and the cathode, or at the light-exiting side of the OLED device to block UV light, thereby preventing performance degradation.

Clinical Validation Requirements for Display Technologies

The validation of display technologies for healthcare applications requires rigorous clinical testing protocols that exceed standard consumer electronics requirements. For OLED and MicroLED technologies to be integrated into medical devices and healthcare settings, they must undergo comprehensive validation processes aligned with regulatory frameworks such as FDA guidelines in the US and MDR in Europe.

Clinical validation begins with bench testing that simulates healthcare environments, including exposure to disinfectants, blood and bodily fluids, and extreme temperature conditions. Both OLED and MicroLED displays must maintain consistent performance metrics under these conditions, with MicroLED potentially offering advantages in durability and chemical resistance due to its inorganic composition.

Human factors validation represents a critical component, requiring assessment of display readability under various lighting conditions common in healthcare settings—from dimly lit patient rooms to brightly illuminated operating theaters. Studies must evaluate healthcare professionals' ability to accurately interpret critical patient data across different display technologies, with particular attention to color accuracy for diagnostic imaging applications.

Biocompatibility testing becomes essential when displays are incorporated into patient-contact devices. While neither technology typically has direct patient contact, the materials used in enclosures and the potential for electromagnetic emissions must be evaluated for patient safety, particularly in implantable or wearable medical devices.

Long-term reliability validation presents unique challenges in healthcare, where devices may need to operate continuously for years. Accelerated aging studies must demonstrate that both technologies can maintain consistent brightness, color accuracy, and response times throughout their expected clinical lifespan, with particular attention to OLED's organic components that may be more susceptible to degradation.

Clinical outcome studies represent the ultimate validation requirement, demonstrating that the display technology positively impacts patient care. These studies must evaluate whether the superior contrast ratio of OLED or the higher brightness of MicroLED translates to improved diagnostic accuracy, reduced clinician fatigue, or enhanced patient outcomes in real-world clinical settings.

Regulatory documentation must compile comprehensive validation data, including detailed technical specifications, clinical testing results, and risk management documentation. The validation process must address specific requirements for different healthcare applications, from diagnostic imaging displays requiring precise color reproduction to patient monitoring systems demanding high visibility from multiple viewing angles.

Clinical validation begins with bench testing that simulates healthcare environments, including exposure to disinfectants, blood and bodily fluids, and extreme temperature conditions. Both OLED and MicroLED displays must maintain consistent performance metrics under these conditions, with MicroLED potentially offering advantages in durability and chemical resistance due to its inorganic composition.

Human factors validation represents a critical component, requiring assessment of display readability under various lighting conditions common in healthcare settings—from dimly lit patient rooms to brightly illuminated operating theaters. Studies must evaluate healthcare professionals' ability to accurately interpret critical patient data across different display technologies, with particular attention to color accuracy for diagnostic imaging applications.

Biocompatibility testing becomes essential when displays are incorporated into patient-contact devices. While neither technology typically has direct patient contact, the materials used in enclosures and the potential for electromagnetic emissions must be evaluated for patient safety, particularly in implantable or wearable medical devices.

Long-term reliability validation presents unique challenges in healthcare, where devices may need to operate continuously for years. Accelerated aging studies must demonstrate that both technologies can maintain consistent brightness, color accuracy, and response times throughout their expected clinical lifespan, with particular attention to OLED's organic components that may be more susceptible to degradation.

Clinical outcome studies represent the ultimate validation requirement, demonstrating that the display technology positively impacts patient care. These studies must evaluate whether the superior contrast ratio of OLED or the higher brightness of MicroLED translates to improved diagnostic accuracy, reduced clinician fatigue, or enhanced patient outcomes in real-world clinical settings.

Regulatory documentation must compile comprehensive validation data, including detailed technical specifications, clinical testing results, and risk management documentation. The validation process must address specific requirements for different healthcare applications, from diagnostic imaging displays requiring precise color reproduction to patient monitoring systems demanding high visibility from multiple viewing angles.

Energy Efficiency and Sustainability Considerations

Energy efficiency represents a critical factor in the evaluation of display technologies for healthcare applications, with OLED and MicroLED presenting distinct sustainability profiles. OLED displays demonstrate superior energy efficiency in dark-mode healthcare applications due to their pixel-level illumination properties, consuming power only for active pixels. This characteristic makes them particularly valuable for patient monitoring devices and mobile healthcare equipment where battery life is paramount. Studies indicate that OLED displays can reduce power consumption by up to 40% compared to traditional LCD technologies when displaying predominantly dark content, which is common in medical imaging interfaces.

MicroLED technology, while still evolving, promises even greater energy efficiency potential in the long term. Current prototypes demonstrate 30-50% lower power consumption than comparable OLED displays at equivalent brightness levels. This efficiency stems from MicroLED's higher luminous efficacy and reduced heat generation, which translates to extended operational lifespans for critical healthcare equipment and reduced cooling requirements in clinical environments.

From a manufacturing sustainability perspective, OLED production currently involves several environmentally concerning processes, including the use of rare earth metals and organic solvents. The healthcare sector's increasing focus on environmental responsibility has prompted manufacturers to develop more sustainable OLED production methods, with recent innovations reducing hazardous waste by approximately 25% compared to earlier generation processes.

MicroLED manufacturing, though less mature, presents both challenges and opportunities for sustainability. While initial production requires significant energy input, the extended lifespan of MicroLED displays (potentially exceeding 100,000 hours versus 30,000-50,000 for OLEDs) creates a more favorable lifecycle assessment. Additionally, MicroLED components contain fewer toxic materials, potentially reducing end-of-life environmental impact by up to 60% compared to current display technologies.

The healthcare sector's transition toward carbon neutrality further emphasizes the importance of display technology efficiency. Hospitals and healthcare facilities, which operate continuously, can realize substantial energy savings through the adoption of more efficient display technologies. Calculations suggest that large healthcare networks could reduce their display-related carbon footprint by 15-20% through strategic implementation of energy-efficient OLED or MicroLED displays across their facilities.

Regulatory frameworks increasingly recognize these sustainability considerations, with several regions implementing energy efficiency standards specifically for medical display technologies. Manufacturers developing either OLED or MicroLED solutions for healthcare must now demonstrate compliance with these evolving standards, driving further innovation in energy-efficient design and sustainable manufacturing processes.

MicroLED technology, while still evolving, promises even greater energy efficiency potential in the long term. Current prototypes demonstrate 30-50% lower power consumption than comparable OLED displays at equivalent brightness levels. This efficiency stems from MicroLED's higher luminous efficacy and reduced heat generation, which translates to extended operational lifespans for critical healthcare equipment and reduced cooling requirements in clinical environments.

From a manufacturing sustainability perspective, OLED production currently involves several environmentally concerning processes, including the use of rare earth metals and organic solvents. The healthcare sector's increasing focus on environmental responsibility has prompted manufacturers to develop more sustainable OLED production methods, with recent innovations reducing hazardous waste by approximately 25% compared to earlier generation processes.

MicroLED manufacturing, though less mature, presents both challenges and opportunities for sustainability. While initial production requires significant energy input, the extended lifespan of MicroLED displays (potentially exceeding 100,000 hours versus 30,000-50,000 for OLEDs) creates a more favorable lifecycle assessment. Additionally, MicroLED components contain fewer toxic materials, potentially reducing end-of-life environmental impact by up to 60% compared to current display technologies.

The healthcare sector's transition toward carbon neutrality further emphasizes the importance of display technology efficiency. Hospitals and healthcare facilities, which operate continuously, can realize substantial energy savings through the adoption of more efficient display technologies. Calculations suggest that large healthcare networks could reduce their display-related carbon footprint by 15-20% through strategic implementation of energy-efficient OLED or MicroLED displays across their facilities.

Regulatory frameworks increasingly recognize these sustainability considerations, with several regions implementing energy efficiency standards specifically for medical display technologies. Manufacturers developing either OLED or MicroLED solutions for healthcare must now demonstrate compliance with these evolving standards, driving further innovation in energy-efficient design and sustainable manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!