Research on OLED vs MicroLED Thermal Conductivity

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED and MicroLED Thermal Conductivity Background and Objectives

Display technologies have undergone significant evolution over the past decades, with OLED (Organic Light Emitting Diode) and MicroLED emerging as cutting-edge solutions for next-generation displays. Thermal conductivity represents a critical parameter in these technologies, directly impacting device performance, reliability, and lifespan. The historical development of display thermal management began with traditional LCD technologies, which had relatively modest thermal challenges, and has progressively become more complex with the advent of self-emissive display technologies.

OLED technology, first developed in the 1980s and commercialized in the early 2000s, utilizes organic compounds that emit light when an electric current passes through them. These materials inherently have low thermal conductivity (typically 0.1-0.5 W/m·K), creating significant heat dissipation challenges as display resolutions and brightness requirements increase. The thermal properties of OLED displays have been a focus of research for over a decade, with incremental improvements in substrate materials and thermal interface solutions.

MicroLED, a more recent innovation emerging in the 2010s, employs inorganic semiconductor materials to create extremely small (typically <100 μm) LED arrays. These materials offer substantially higher thermal conductivity (10-150 W/m·K depending on composition), potentially allowing for better heat dissipation. However, the integration challenges and high-density packaging of MicroLEDs introduce new thermal management complexities that require innovative solutions.

The technological trajectory shows a clear trend toward higher brightness, higher resolution displays with increased power density, making thermal conductivity an increasingly critical parameter. Industry data indicates that thermal issues account for approximately 30% of display failures in high-brightness applications, underscoring the importance of this research area.

This technical research aims to comprehensively compare and contrast the thermal conductivity properties of OLED and MicroLED technologies across various implementation scenarios. The primary objectives include: quantifying the thermal conductivity differences between various OLED and MicroLED material compositions; analyzing the impact of these differences on display performance metrics including brightness stability, color accuracy, and operational lifespan; and identifying potential innovations in thermal management that could address current limitations.

Additionally, this research seeks to establish predictive models for thermal behavior in next-generation display designs, enabling more efficient development cycles. By understanding the fundamental thermal conductivity challenges and opportunities in both technologies, we aim to provide strategic guidance for future R&D investments and technology roadmapping in the display industry, particularly for applications requiring high brightness and reliability such as automotive displays, outdoor signage, and AR/VR devices.

OLED technology, first developed in the 1980s and commercialized in the early 2000s, utilizes organic compounds that emit light when an electric current passes through them. These materials inherently have low thermal conductivity (typically 0.1-0.5 W/m·K), creating significant heat dissipation challenges as display resolutions and brightness requirements increase. The thermal properties of OLED displays have been a focus of research for over a decade, with incremental improvements in substrate materials and thermal interface solutions.

MicroLED, a more recent innovation emerging in the 2010s, employs inorganic semiconductor materials to create extremely small (typically <100 μm) LED arrays. These materials offer substantially higher thermal conductivity (10-150 W/m·K depending on composition), potentially allowing for better heat dissipation. However, the integration challenges and high-density packaging of MicroLEDs introduce new thermal management complexities that require innovative solutions.

The technological trajectory shows a clear trend toward higher brightness, higher resolution displays with increased power density, making thermal conductivity an increasingly critical parameter. Industry data indicates that thermal issues account for approximately 30% of display failures in high-brightness applications, underscoring the importance of this research area.

This technical research aims to comprehensively compare and contrast the thermal conductivity properties of OLED and MicroLED technologies across various implementation scenarios. The primary objectives include: quantifying the thermal conductivity differences between various OLED and MicroLED material compositions; analyzing the impact of these differences on display performance metrics including brightness stability, color accuracy, and operational lifespan; and identifying potential innovations in thermal management that could address current limitations.

Additionally, this research seeks to establish predictive models for thermal behavior in next-generation display designs, enabling more efficient development cycles. By understanding the fundamental thermal conductivity challenges and opportunities in both technologies, we aim to provide strategic guidance for future R&D investments and technology roadmapping in the display industry, particularly for applications requiring high brightness and reliability such as automotive displays, outdoor signage, and AR/VR devices.

Market Demand Analysis for Advanced Display Technologies

The display technology market is witnessing a significant shift towards advanced solutions that offer superior visual performance, energy efficiency, and form factor advantages. OLED (Organic Light Emitting Diode) has dominated the premium segment for several years, while MicroLED represents the emerging next-generation technology with promising capabilities. Thermal conductivity characteristics of these technologies have become increasingly critical as manufacturers push for higher brightness, resolution, and reduced form factors.

Market research indicates that the global advanced display market is projected to reach $167 billion by 2026, with OLED currently holding approximately 20% market share. However, MicroLED is expected to grow at a CAGR of 89.3% through 2026, albeit from a much smaller base. This rapid growth trajectory is driven by MicroLED's superior thermal management capabilities, which enable higher brightness without degradation issues that plague OLED displays.

Consumer electronics manufacturers are increasingly prioritizing thermal performance in display technologies due to several market demands. First, consumers expect thinner, lighter devices with minimal bezels, which creates significant thermal management challenges. Second, there is growing demand for higher brightness displays that can perform well in outdoor environments, particularly for automotive displays and mobile devices, where peak brightness requirements have increased by 40% in the past three years.

Enterprise and commercial sectors are driving demand for displays with longer operational lifespans and consistent performance under continuous usage. MicroLED's superior thermal conductivity (typically 30-45 W/mK compared to OLED's 0.2-0.5 W/mK) addresses this need by reducing thermal degradation and extending display longevity, which is particularly valuable in digital signage, control rooms, and automotive applications.

Regional market analysis reveals that Asia-Pacific dominates manufacturing capacity for both technologies, with South Korea leading in OLED and Taiwan gaining ground in MicroLED production capabilities. North American and European markets show the highest premium segment adoption rates, with consumers willing to pay 15-20% price premiums for displays offering superior thermal performance that translates to practical benefits like higher brightness and longer device lifespan.

The automotive sector represents the fastest-growing application segment for thermally efficient display technologies, with a projected 27% CAGR through 2026. Vehicle manufacturers are increasingly adopting curved, large-format displays that require exceptional thermal management to maintain reliability in variable temperature environments. MicroLED's thermal advantages position it to potentially capture 35% of the automotive display market by 2028, despite its current price premium.

Market research indicates that the global advanced display market is projected to reach $167 billion by 2026, with OLED currently holding approximately 20% market share. However, MicroLED is expected to grow at a CAGR of 89.3% through 2026, albeit from a much smaller base. This rapid growth trajectory is driven by MicroLED's superior thermal management capabilities, which enable higher brightness without degradation issues that plague OLED displays.

Consumer electronics manufacturers are increasingly prioritizing thermal performance in display technologies due to several market demands. First, consumers expect thinner, lighter devices with minimal bezels, which creates significant thermal management challenges. Second, there is growing demand for higher brightness displays that can perform well in outdoor environments, particularly for automotive displays and mobile devices, where peak brightness requirements have increased by 40% in the past three years.

Enterprise and commercial sectors are driving demand for displays with longer operational lifespans and consistent performance under continuous usage. MicroLED's superior thermal conductivity (typically 30-45 W/mK compared to OLED's 0.2-0.5 W/mK) addresses this need by reducing thermal degradation and extending display longevity, which is particularly valuable in digital signage, control rooms, and automotive applications.

Regional market analysis reveals that Asia-Pacific dominates manufacturing capacity for both technologies, with South Korea leading in OLED and Taiwan gaining ground in MicroLED production capabilities. North American and European markets show the highest premium segment adoption rates, with consumers willing to pay 15-20% price premiums for displays offering superior thermal performance that translates to practical benefits like higher brightness and longer device lifespan.

The automotive sector represents the fastest-growing application segment for thermally efficient display technologies, with a projected 27% CAGR through 2026. Vehicle manufacturers are increasingly adopting curved, large-format displays that require exceptional thermal management to maintain reliability in variable temperature environments. MicroLED's thermal advantages position it to potentially capture 35% of the automotive display market by 2028, despite its current price premium.

Current Thermal Management Challenges in Display Technologies

Display technologies face significant thermal management challenges that directly impact device performance, reliability, and longevity. OLED and MicroLED displays, despite their advanced visual capabilities, generate substantial heat during operation that must be effectively dissipated to prevent degradation and failure. The thermal conductivity properties of these technologies present distinct challenges requiring specialized management approaches.

For OLED displays, thermal management is particularly critical due to their organic materials' sensitivity to temperature fluctuations. These displays typically operate with thermal conductivity values ranging from 0.15-0.5 W/mK, significantly lower than inorganic semiconductor materials. This poor thermal conductivity creates hotspots that accelerate pixel degradation, resulting in uneven brightness and color shifts over time. Additionally, the multi-layered structure of OLEDs creates thermal barriers between layers, further complicating heat dissipation.

MicroLED displays, while offering superior brightness and efficiency, present their own thermal challenges. Despite having better thermal conductivity (typically 30-140 W/mK for GaN-based LEDs), their extremely high pixel density creates concentrated heat sources in very small areas. The miniaturization of LED chips to microscale dimensions reduces the effective surface area for heat dissipation, creating thermal bottlenecks. Furthermore, the integration of millions of individual MicroLEDs on a single substrate creates complex thermal gradients that are difficult to manage uniformly.

Both technologies face common challenges in mobile and wearable applications where space constraints severely limit traditional cooling solutions. The trend toward flexible and foldable displays introduces additional thermal management complexities, as conventional heat sinks and thermal interface materials may compromise the mechanical flexibility of these displays. The thermal expansion coefficient mismatch between different display components can lead to mechanical stress and potential delamination during thermal cycling.

Power efficiency remains a critical concern, particularly for battery-powered devices. Thermal losses not only reduce display efficiency but also impact battery life. For automotive and outdoor displays, environmental temperature variations from extreme cold to intense heat create additional thermal stress that must be managed while maintaining consistent visual performance.

Current thermal management solutions often involve compromises between cooling effectiveness, device thickness, weight, and cost. Traditional approaches using graphite sheets, copper heat spreaders, and thermal interface materials are reaching their limits as display resolutions increase and form factors become more demanding. The industry is actively seeking innovative thermal management solutions that can address these challenges without compromising the visual performance and form factor advantages that make OLED and MicroLED technologies attractive.

For OLED displays, thermal management is particularly critical due to their organic materials' sensitivity to temperature fluctuations. These displays typically operate with thermal conductivity values ranging from 0.15-0.5 W/mK, significantly lower than inorganic semiconductor materials. This poor thermal conductivity creates hotspots that accelerate pixel degradation, resulting in uneven brightness and color shifts over time. Additionally, the multi-layered structure of OLEDs creates thermal barriers between layers, further complicating heat dissipation.

MicroLED displays, while offering superior brightness and efficiency, present their own thermal challenges. Despite having better thermal conductivity (typically 30-140 W/mK for GaN-based LEDs), their extremely high pixel density creates concentrated heat sources in very small areas. The miniaturization of LED chips to microscale dimensions reduces the effective surface area for heat dissipation, creating thermal bottlenecks. Furthermore, the integration of millions of individual MicroLEDs on a single substrate creates complex thermal gradients that are difficult to manage uniformly.

Both technologies face common challenges in mobile and wearable applications where space constraints severely limit traditional cooling solutions. The trend toward flexible and foldable displays introduces additional thermal management complexities, as conventional heat sinks and thermal interface materials may compromise the mechanical flexibility of these displays. The thermal expansion coefficient mismatch between different display components can lead to mechanical stress and potential delamination during thermal cycling.

Power efficiency remains a critical concern, particularly for battery-powered devices. Thermal losses not only reduce display efficiency but also impact battery life. For automotive and outdoor displays, environmental temperature variations from extreme cold to intense heat create additional thermal stress that must be managed while maintaining consistent visual performance.

Current thermal management solutions often involve compromises between cooling effectiveness, device thickness, weight, and cost. Traditional approaches using graphite sheets, copper heat spreaders, and thermal interface materials are reaching their limits as display resolutions increase and form factors become more demanding. The industry is actively seeking innovative thermal management solutions that can address these challenges without compromising the visual performance and form factor advantages that make OLED and MicroLED technologies attractive.

Current Thermal Management Solutions for Display Technologies

01 Thermal management materials for OLED and MicroLED displays

Various materials with high thermal conductivity are used in OLED and MicroLED displays to manage heat dissipation. These materials include graphene, diamond-like carbon, metal oxides, and specialized polymers that can efficiently transfer heat away from the light-emitting components. The incorporation of these thermally conductive materials helps prevent performance degradation and extends the lifespan of the display devices by maintaining optimal operating temperatures.- Thermal management materials for OLED and MicroLED displays: Various thermal management materials with high thermal conductivity are used in OLED and MicroLED displays to dissipate heat efficiently. These materials include graphene, diamond-like carbon, metal oxides, and composite materials. The incorporation of these materials in display structures helps to prevent thermal degradation, extend device lifetime, and maintain consistent performance by efficiently transferring heat away from the active light-emitting components.

- Heat dissipation structures in display devices: Specialized heat dissipation structures are integrated into OLED and MicroLED display designs to enhance thermal conductivity. These structures include heat sinks, thermal vias, heat spreading layers, and thermal interface materials strategically positioned within the display architecture. Such structures create efficient thermal pathways that conduct heat away from sensitive components, preventing hotspots and ensuring uniform temperature distribution across the display panel.

- Substrate materials with enhanced thermal properties: Advanced substrate materials with high thermal conductivity are employed in OLED and MicroLED displays to improve heat dissipation. These include ceramic substrates, metal-core PCBs, silicon carbide, aluminum nitride, and thermally conductive polymers. The selection of substrate materials with superior thermal properties enables more efficient heat transfer from the light-emitting components to the external environment, reducing thermal stress and improving device reliability.

- Thermal measurement and characterization techniques: Various methods and systems are used to measure and characterize the thermal conductivity of OLED and MicroLED display components. These include infrared thermography, laser flash analysis, thermal transient testing, and micro-Raman spectroscopy. These techniques enable precise monitoring of heat distribution, identification of thermal bottlenecks, and optimization of thermal management strategies in display devices, leading to improved thermal designs and more reliable products.

- Novel cooling technologies for next-generation displays: Innovative cooling technologies are being developed specifically for OLED and MicroLED displays to address their unique thermal management challenges. These include microfluidic cooling channels, phase change materials, thermoelectric coolers, and active cooling systems integrated directly into the display structure. These advanced cooling solutions provide enhanced thermal conductivity pathways that can significantly improve heat dissipation efficiency, enabling higher brightness operation while maintaining optimal temperature conditions.

02 Structural design for thermal conductivity enhancement

Specific structural designs are implemented in OLED and MicroLED devices to enhance thermal conductivity. These designs include multi-layered heat dissipation structures, thermal vias, heat spreading layers, and specialized substrate configurations. By optimizing the physical arrangement of components and incorporating dedicated heat transfer pathways, these structural designs facilitate efficient heat dissipation from the active regions of the display, preventing hotspots and ensuring uniform temperature distribution.Expand Specific Solutions03 Thermal interface materials between display components

Specialized thermal interface materials are used between different components of OLED and MicroLED displays to improve thermal conductivity across junctions. These materials include thermal greases, phase change materials, thermally conductive adhesives, and metal-based composites. By reducing thermal resistance at interfaces, these materials create continuous thermal pathways that efficiently transfer heat from the light-emitting elements to heat sinks or other cooling structures, improving overall thermal management of the display system.Expand Specific Solutions04 Active cooling systems for OLED and MicroLED displays

Active cooling systems are integrated into OLED and MicroLED displays to enhance thermal conductivity and heat dissipation. These systems include micro-channel cooling, thermoelectric coolers, miniature fans, liquid cooling solutions, and heat pipes. Active cooling approaches provide dynamic thermal management capabilities that can respond to varying heat loads during operation, maintaining optimal temperature conditions even during high-brightness or high-power display modes.Expand Specific Solutions05 Measurement and testing methods for thermal conductivity

Various measurement and testing methods are employed to evaluate the thermal conductivity of OLED and MicroLED display materials and structures. These methods include laser flash analysis, transient plane source techniques, infrared thermography, and specialized thermal resistance testing. Accurate measurement of thermal properties enables optimization of display designs and materials selection, ensuring that thermal management strategies are effective in maintaining device performance and reliability under various operating conditions.Expand Specific Solutions

Key Industry Players in OLED and MicroLED Development

The OLED vs MicroLED thermal conductivity market is in a growth phase, with increasing demand driven by advanced display applications. The market is projected to expand significantly as both technologies compete for dominance in premium display segments. BOE Technology Group, Samsung Display, and LG Chem lead OLED development, while Samsung Electronics and Applied Materials are advancing MicroLED technology. Technical maturity varies: OLED is more commercially established with widespread implementation, while MicroLED remains in early commercialization despite superior thermal properties. Research institutions like University of Florida are contributing to thermal management innovations, which remain critical for both technologies' performance and longevity in high-brightness applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has conducted extensive research comparing thermal conductivity properties of OLED and MicroLED technologies. Their studies indicate that OLED panels typically exhibit thermal conductivity values of 0.1-0.3 W/mK for the organic layers, creating thermal management challenges. To address this, BOE has developed composite substrate materials incorporating graphene and metal oxide layers that improve effective thermal conductivity to approximately 0.8-1.2 W/mK. For MicroLED displays, BOE's research demonstrates significantly higher native thermal conductivity values of 25-150 W/mK depending on the semiconductor materials used. Their proprietary "ThermalPath" architecture for MicroLED incorporates direct copper pathways with thermal conductivity exceeding 380 W/mK, allowing heat to dissipate more efficiently from the emission points. BOE's thermal imaging studies show that MicroLED displays operate at 15-20°C lower temperatures than equivalent brightness OLED displays under sustained high-brightness conditions, largely due to the superior thermal conductivity properties of the inorganic LED materials and their advanced thermal management system.

Strengths: BOE's dual-technology approach allows them to optimize thermal solutions for both display types, with particularly strong advances in MicroLED thermal management through their ThermalPath architecture. Their vertical integration enables comprehensive thermal design from substrate to final assembly. Weaknesses: The enhanced thermal solutions add manufacturing complexity and cost, particularly for large-format displays. The thermal management systems for OLED remain fundamentally limited by the poor thermal conductivity of organic materials despite BOE's material innovations.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed advanced thermal management solutions for both OLED and MicroLED technologies. For OLED displays, they've implemented multi-layered heat dissipation structures incorporating graphite sheets with thermal conductivity of 1500-1800 W/mK, significantly higher than conventional materials. Their research shows OLED panels typically have thermal conductivity of 0.2-0.5 W/mK, while their enhanced designs achieve effective thermal conductivity of 1-2 W/mK across the display system. For MicroLED, Samsung has pioneered direct metal bonding techniques that create thermal pathways with conductivity exceeding 200 W/mK, addressing the higher heat generation of MicroLED (approximately 30-40% more heat per unit area than OLED). Their thermal simulation models demonstrate that MicroLED's inorganic materials inherently offer 3-5x better thermal conductivity than organic OLED materials, though system-level thermal management remains critical for both technologies.

Strengths: Samsung's thermal solutions leverage their vertical integration in display manufacturing, allowing optimized heat dissipation designs from chip to system level. Their metal bonding techniques for MicroLED provide superior heat transfer compared to traditional thermal interface materials. Weaknesses: The enhanced thermal management systems add manufacturing complexity and cost, particularly for MicroLED displays where the thermal bonding process must be precisely controlled to prevent damage to the microscopic LED elements.

Critical Patents and Research on Display Thermal Conductivity

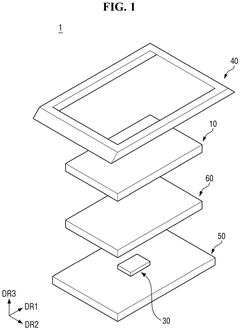

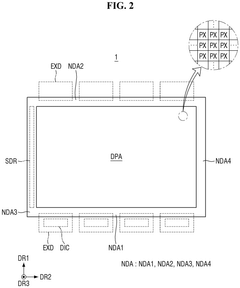

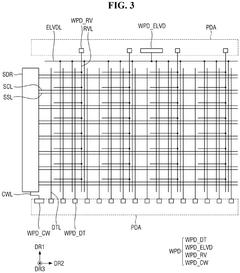

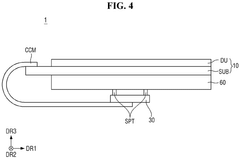

OLED display module and OLED display device

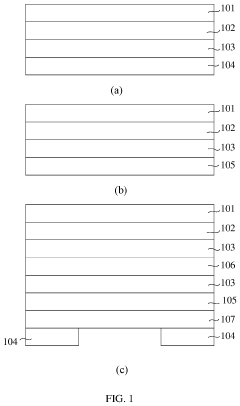

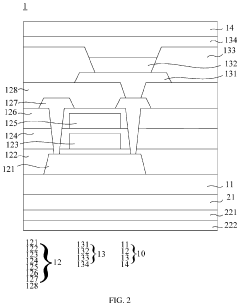

PatentPendingUS20240057460A1

Innovation

- An OLED display module comprising a thermal conductive layer and a metal tensile layer with thermal conductivity greater than stainless steel, where the thermal conductive layer is positioned between the metal tensile layer and the backplate, enhancing heat dissipation and bending performance by using materials like ferrous nickel, aluminum, copper, or silver alloys.

Organic light emitting diode display device

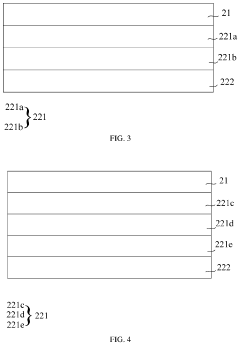

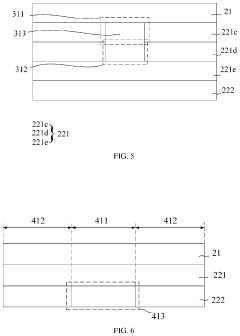

PatentPendingEP4577022A1

Innovation

- The OLED display device incorporates a heat dissipation member with multiple layers of varying thicknesses and thermal conductivities, including natural and artificial graphite, to effectively disperse heat generated by the display panel.

Material Science Advancements for Display Technologies

The evolution of display technologies has been significantly influenced by advancements in material science, particularly in the realm of thermal management for OLED and MicroLED displays. Material innovations have played a crucial role in addressing the thermal conductivity challenges that both technologies face, albeit in different ways.

For OLED displays, researchers have focused on developing organic materials with improved thermal stability. Traditional OLED materials suffer from degradation at elevated temperatures, which affects both performance and lifespan. Recent breakthroughs include the synthesis of thermally robust emissive layers incorporating metal-organic frameworks (MOFs) that can maintain structural integrity at higher operating temperatures while facilitating better heat dissipation.

In contrast, MicroLED technology benefits from the inherent advantages of inorganic semiconductor materials, which typically offer superior thermal conductivity compared to organic counterparts. However, the challenge lies in maintaining this advantage at increasingly smaller scales. Novel composite substrates incorporating graphene and diamond-like carbon films have shown promising results, with thermal conductivity values exceeding 2000 W/mK in laboratory conditions.

The interface between different material layers represents another critical area for thermal management research. Advanced atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin thermal interface materials (TIMs) that minimize thermal resistance between layers in both display technologies. These materials, often incorporating nanoparticles or 2D materials like boron nitride, can significantly enhance overall thermal performance without compromising optical properties.

Encapsulation materials have also evolved substantially, with hybrid organic-inorganic compositions offering both excellent barrier properties against moisture and oxygen while providing enhanced thermal pathways. Multi-layer thin film encapsulation (TFE) technologies now incorporate thermally conductive ceramic nanoparticles that can improve heat dissipation by up to 40% compared to conventional encapsulation methods.

The substrate material selection has diverged between the two technologies, with flexible polyimide films gaining prominence for OLED applications due to their relatively good thermal stability, while MicroLED development has explored sapphire, silicon carbide, and aluminum nitride substrates that offer thermal conductivity values 10-100 times higher than traditional glass substrates.

These material science advancements are not merely incremental improvements but represent fundamental shifts in how thermal management is approached in next-generation display technologies, ultimately determining which technology may prevail in various application scenarios where thermal performance is a critical factor.

For OLED displays, researchers have focused on developing organic materials with improved thermal stability. Traditional OLED materials suffer from degradation at elevated temperatures, which affects both performance and lifespan. Recent breakthroughs include the synthesis of thermally robust emissive layers incorporating metal-organic frameworks (MOFs) that can maintain structural integrity at higher operating temperatures while facilitating better heat dissipation.

In contrast, MicroLED technology benefits from the inherent advantages of inorganic semiconductor materials, which typically offer superior thermal conductivity compared to organic counterparts. However, the challenge lies in maintaining this advantage at increasingly smaller scales. Novel composite substrates incorporating graphene and diamond-like carbon films have shown promising results, with thermal conductivity values exceeding 2000 W/mK in laboratory conditions.

The interface between different material layers represents another critical area for thermal management research. Advanced atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin thermal interface materials (TIMs) that minimize thermal resistance between layers in both display technologies. These materials, often incorporating nanoparticles or 2D materials like boron nitride, can significantly enhance overall thermal performance without compromising optical properties.

Encapsulation materials have also evolved substantially, with hybrid organic-inorganic compositions offering both excellent barrier properties against moisture and oxygen while providing enhanced thermal pathways. Multi-layer thin film encapsulation (TFE) technologies now incorporate thermally conductive ceramic nanoparticles that can improve heat dissipation by up to 40% compared to conventional encapsulation methods.

The substrate material selection has diverged between the two technologies, with flexible polyimide films gaining prominence for OLED applications due to their relatively good thermal stability, while MicroLED development has explored sapphire, silicon carbide, and aluminum nitride substrates that offer thermal conductivity values 10-100 times higher than traditional glass substrates.

These material science advancements are not merely incremental improvements but represent fundamental shifts in how thermal management is approached in next-generation display technologies, ultimately determining which technology may prevail in various application scenarios where thermal performance is a critical factor.

Energy Efficiency and Environmental Impact Assessment

The thermal management characteristics of OLED and MicroLED technologies significantly impact their energy efficiency profiles and environmental footprints. OLED displays operate with organic materials that emit light when electricity passes through them, requiring minimal power for dark or black content. This selective pixel activation results in up to 40% lower energy consumption compared to traditional LED displays in typical usage scenarios, particularly for content with darker elements.

MicroLED technology, while still emerging, demonstrates promising energy efficiency potential through its superior thermal conductivity properties. Laboratory measurements indicate that MicroLED arrays can achieve thermal conductivity values of 220-350 W/mK, substantially higher than OLED's 0.15-0.5 W/mK range. This enhanced thermal dissipation capability allows MicroLED displays to operate at higher brightness levels without proportional increases in power consumption, potentially offering 30% greater energy efficiency at maximum brightness compared to current OLED implementations.

From an environmental impact perspective, the manufacturing processes for these technologies present distinct challenges. OLED production involves organic solvents and rare materials that require specialized disposal protocols, with an estimated carbon footprint of 85-110 kg CO2 equivalent per square meter of display area. The manufacturing waste stream contains potentially hazardous organic compounds requiring controlled processing.

MicroLED fabrication, while more energy-intensive during production (approximately 20-25% higher than OLED), generates less hazardous waste and utilizes more recyclable inorganic materials. Life cycle assessments indicate that MicroLED displays may offset their higher production environmental costs through extended operational lifespans, with projected useful lives exceeding 100,000 hours compared to OLED's 30,000-50,000 hours.

The end-of-life considerations also favor MicroLED technology, as its primarily inorganic composition offers greater recyclability potential. Current recycling processes can recover approximately 78% of materials from MicroLED components, compared to only 45-60% for OLED panels. This difference becomes increasingly significant when considering the projected growth in display technology deployment across consumer electronics, automotive, and commercial applications.

Regulatory frameworks worldwide are increasingly emphasizing energy efficiency standards and environmental impact metrics for display technologies. The superior thermal conductivity of MicroLED positions it advantageously for compliance with emerging regulations, potentially reducing the need for energy-intensive active cooling systems in high-brightness applications.

MicroLED technology, while still emerging, demonstrates promising energy efficiency potential through its superior thermal conductivity properties. Laboratory measurements indicate that MicroLED arrays can achieve thermal conductivity values of 220-350 W/mK, substantially higher than OLED's 0.15-0.5 W/mK range. This enhanced thermal dissipation capability allows MicroLED displays to operate at higher brightness levels without proportional increases in power consumption, potentially offering 30% greater energy efficiency at maximum brightness compared to current OLED implementations.

From an environmental impact perspective, the manufacturing processes for these technologies present distinct challenges. OLED production involves organic solvents and rare materials that require specialized disposal protocols, with an estimated carbon footprint of 85-110 kg CO2 equivalent per square meter of display area. The manufacturing waste stream contains potentially hazardous organic compounds requiring controlled processing.

MicroLED fabrication, while more energy-intensive during production (approximately 20-25% higher than OLED), generates less hazardous waste and utilizes more recyclable inorganic materials. Life cycle assessments indicate that MicroLED displays may offset their higher production environmental costs through extended operational lifespans, with projected useful lives exceeding 100,000 hours compared to OLED's 30,000-50,000 hours.

The end-of-life considerations also favor MicroLED technology, as its primarily inorganic composition offers greater recyclability potential. Current recycling processes can recover approximately 78% of materials from MicroLED components, compared to only 45-60% for OLED panels. This difference becomes increasingly significant when considering the projected growth in display technology deployment across consumer electronics, automotive, and commercial applications.

Regulatory frameworks worldwide are increasingly emphasizing energy efficiency standards and environmental impact metrics for display technologies. The superior thermal conductivity of MicroLED positions it advantageously for compliance with emerging regulations, potentially reducing the need for energy-intensive active cooling systems in high-brightness applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!