Exploring PTFE’s Use in Filtration Systems

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Filtration Evolution

The evolution of PTFE in filtration systems represents a significant advancement in membrane technology. Initially developed in the 1930s, polytetrafluoroethylene (PTFE) gained prominence in filtration applications during the 1960s and 1970s. Its unique properties, including chemical inertness, high temperature resistance, and low surface energy, made it an ideal material for various filtration processes.

In the early stages, PTFE membranes were primarily used in laboratory settings for microfiltration and ultrafiltration. The 1980s saw a breakthrough in PTFE membrane manufacturing techniques, particularly the development of expanded PTFE (ePTFE) membranes. This innovation significantly enhanced the material's porosity and filtration efficiency, leading to its widespread adoption in industrial applications.

The 1990s marked a period of rapid growth in PTFE filtration technology. Manufacturers began to produce PTFE membranes with more controlled pore sizes and distributions, enabling their use in more specialized applications such as pharmaceutical processing and semiconductor manufacturing. This decade also saw the integration of PTFE membranes into composite structures, combining the material's excellent filtration properties with the mechanical strength of supporting materials.

As environmental concerns grew in the 2000s, PTFE filtration systems found new applications in air and water purification. The material's ability to capture fine particles while maintaining high flow rates made it particularly valuable in these fields. Concurrently, advancements in surface modification techniques allowed for the development of hydrophilic PTFE membranes, expanding their use in aqueous filtration processes.

The 2010s witnessed a focus on nanotechnology in PTFE membrane development. Researchers began exploring ways to incorporate nanoparticles and nanofibers into PTFE structures, aiming to enhance selectivity and flux rates. This period also saw increased efforts to improve the sustainability of PTFE production and recycling processes, addressing concerns about the material's environmental impact.

In recent years, the evolution of PTFE in filtration has been driven by the demand for more efficient and versatile filtration solutions. Current research is focused on developing "smart" PTFE membranes with responsive properties, capable of adapting to changing filtration conditions. Additionally, there is growing interest in combining PTFE with other advanced materials to create hybrid filtration systems that can tackle complex separation challenges.

Looking ahead, the future of PTFE in filtration systems is likely to involve further miniaturization, increased durability, and enhanced functionalization. As industries continue to demand more precise and efficient filtration solutions, PTFE's role in this field is expected to expand, with ongoing innovations pushing the boundaries of what is possible in membrane technology.

In the early stages, PTFE membranes were primarily used in laboratory settings for microfiltration and ultrafiltration. The 1980s saw a breakthrough in PTFE membrane manufacturing techniques, particularly the development of expanded PTFE (ePTFE) membranes. This innovation significantly enhanced the material's porosity and filtration efficiency, leading to its widespread adoption in industrial applications.

The 1990s marked a period of rapid growth in PTFE filtration technology. Manufacturers began to produce PTFE membranes with more controlled pore sizes and distributions, enabling their use in more specialized applications such as pharmaceutical processing and semiconductor manufacturing. This decade also saw the integration of PTFE membranes into composite structures, combining the material's excellent filtration properties with the mechanical strength of supporting materials.

As environmental concerns grew in the 2000s, PTFE filtration systems found new applications in air and water purification. The material's ability to capture fine particles while maintaining high flow rates made it particularly valuable in these fields. Concurrently, advancements in surface modification techniques allowed for the development of hydrophilic PTFE membranes, expanding their use in aqueous filtration processes.

The 2010s witnessed a focus on nanotechnology in PTFE membrane development. Researchers began exploring ways to incorporate nanoparticles and nanofibers into PTFE structures, aiming to enhance selectivity and flux rates. This period also saw increased efforts to improve the sustainability of PTFE production and recycling processes, addressing concerns about the material's environmental impact.

In recent years, the evolution of PTFE in filtration has been driven by the demand for more efficient and versatile filtration solutions. Current research is focused on developing "smart" PTFE membranes with responsive properties, capable of adapting to changing filtration conditions. Additionally, there is growing interest in combining PTFE with other advanced materials to create hybrid filtration systems that can tackle complex separation challenges.

Looking ahead, the future of PTFE in filtration systems is likely to involve further miniaturization, increased durability, and enhanced functionalization. As industries continue to demand more precise and efficient filtration solutions, PTFE's role in this field is expected to expand, with ongoing innovations pushing the boundaries of what is possible in membrane technology.

Filtration Market Analysis

The global filtration market has been experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and the growing demand for clean water and air across various industries. The market for filtration systems is expected to continue its upward trajectory, with a particular focus on advanced materials like Polytetrafluoroethylene (PTFE) that offer superior performance in challenging environments.

In recent years, the industrial sector has emerged as a major contributor to the filtration market's expansion. Industries such as chemical processing, pharmaceuticals, and food and beverage are increasingly adopting sophisticated filtration systems to meet quality standards and regulatory requirements. The automotive industry, too, has been a key driver, with the rising demand for high-efficiency particulate air (HEPA) filters in vehicles.

The water treatment segment of the filtration market has shown remarkable growth, fueled by the global water scarcity crisis and the need for efficient wastewater management. Municipalities and industrial facilities are investing heavily in advanced filtration technologies to ensure the supply of clean, potable water and to minimize environmental impact. This trend is particularly pronounced in developing countries where rapid industrialization and urbanization are putting pressure on water resources.

Air filtration systems have also gained prominence, especially in light of growing awareness about indoor air quality and the health risks associated with air pollution. The COVID-19 pandemic has further accelerated this trend, with increased demand for air purification systems in commercial, residential, and healthcare settings.

PTFE's unique properties, including its chemical inertness, high temperature resistance, and low friction coefficient, make it an ideal material for filtration applications. The market for PTFE-based filtration systems is expanding, particularly in industries that require high-purity filtration or deal with corrosive substances. This growth is supported by ongoing research and development efforts to enhance PTFE's filtration efficiency and durability.

Geographically, North America and Europe continue to dominate the filtration market, owing to strict environmental regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The filtration market is characterized by intense competition among key players, with a focus on innovation and product differentiation. Companies are investing in research and development to create more efficient, cost-effective, and sustainable filtration solutions. The trend towards smart filtration systems, incorporating IoT and AI technologies for real-time monitoring and predictive maintenance, is expected to shape the future of the market.

In recent years, the industrial sector has emerged as a major contributor to the filtration market's expansion. Industries such as chemical processing, pharmaceuticals, and food and beverage are increasingly adopting sophisticated filtration systems to meet quality standards and regulatory requirements. The automotive industry, too, has been a key driver, with the rising demand for high-efficiency particulate air (HEPA) filters in vehicles.

The water treatment segment of the filtration market has shown remarkable growth, fueled by the global water scarcity crisis and the need for efficient wastewater management. Municipalities and industrial facilities are investing heavily in advanced filtration technologies to ensure the supply of clean, potable water and to minimize environmental impact. This trend is particularly pronounced in developing countries where rapid industrialization and urbanization are putting pressure on water resources.

Air filtration systems have also gained prominence, especially in light of growing awareness about indoor air quality and the health risks associated with air pollution. The COVID-19 pandemic has further accelerated this trend, with increased demand for air purification systems in commercial, residential, and healthcare settings.

PTFE's unique properties, including its chemical inertness, high temperature resistance, and low friction coefficient, make it an ideal material for filtration applications. The market for PTFE-based filtration systems is expanding, particularly in industries that require high-purity filtration or deal with corrosive substances. This growth is supported by ongoing research and development efforts to enhance PTFE's filtration efficiency and durability.

Geographically, North America and Europe continue to dominate the filtration market, owing to strict environmental regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The filtration market is characterized by intense competition among key players, with a focus on innovation and product differentiation. Companies are investing in research and development to create more efficient, cost-effective, and sustainable filtration solutions. The trend towards smart filtration systems, incorporating IoT and AI technologies for real-time monitoring and predictive maintenance, is expected to shape the future of the market.

PTFE Challenges in Filters

Polytetrafluoroethylene (PTFE) has been widely adopted in filtration systems due to its exceptional chemical resistance and non-stick properties. However, its application in filters presents several challenges that require careful consideration and innovative solutions.

One of the primary challenges is the inherent hydrophobicity of PTFE. While this property is beneficial in many applications, it can hinder the filtration of aqueous solutions. The non-wetting nature of PTFE can lead to reduced flow rates and decreased efficiency in water-based filtration systems. This limitation necessitates the development of surface modification techniques or the incorporation of hydrophilic additives to enhance the material's compatibility with aqueous media.

Another significant challenge is the mechanical strength of PTFE membranes. Although PTFE possesses excellent chemical resistance, its relatively low tensile strength can lead to membrane rupture or deformation under high pressure or flow conditions. This issue is particularly pronounced in applications requiring high throughput or dealing with viscous fluids. Researchers and engineers are continuously working on reinforcing PTFE membranes with support structures or developing composite materials to improve their mechanical properties without compromising filtration efficiency.

The pore size control and distribution in PTFE filters pose another technical hurdle. Achieving consistent and precise pore sizes across the entire membrane surface is crucial for maintaining filtration accuracy and efficiency. The manufacturing process of PTFE membranes, typically involving stretching of the material, can result in variations in pore size and distribution. This variability can lead to inconsistent filtration performance and reduced reliability in critical applications.

Fouling and clogging of PTFE filters represent ongoing challenges in many filtration applications. Despite PTFE's non-stick properties, prolonged use can still result in the accumulation of particles or biological materials on the membrane surface. This buildup can reduce flow rates, increase pressure drop across the filter, and ultimately shorten the filter's lifespan. Developing effective cleaning protocols and designing self-cleaning or anti-fouling PTFE surfaces are areas of active research to address this issue.

The environmental impact and sustainability of PTFE filters also present challenges. PTFE is a synthetic fluoropolymer that is not biodegradable and can persist in the environment for extended periods. The production and disposal of PTFE filters raise concerns about their long-term environmental effects. Efforts are being made to develop more sustainable alternatives or to improve the recyclability and end-of-life management of PTFE filtration systems.

Lastly, the cost-effectiveness of PTFE filters remains a challenge in certain applications. While PTFE offers superior performance in many scenarios, its production costs can be higher compared to alternative filter materials. Balancing the benefits of PTFE with its economic implications is an ongoing consideration for manufacturers and end-users alike. Research into more efficient production methods and the development of hybrid materials that combine PTFE's advantages with lower-cost substrates are potential avenues for addressing this challenge.

One of the primary challenges is the inherent hydrophobicity of PTFE. While this property is beneficial in many applications, it can hinder the filtration of aqueous solutions. The non-wetting nature of PTFE can lead to reduced flow rates and decreased efficiency in water-based filtration systems. This limitation necessitates the development of surface modification techniques or the incorporation of hydrophilic additives to enhance the material's compatibility with aqueous media.

Another significant challenge is the mechanical strength of PTFE membranes. Although PTFE possesses excellent chemical resistance, its relatively low tensile strength can lead to membrane rupture or deformation under high pressure or flow conditions. This issue is particularly pronounced in applications requiring high throughput or dealing with viscous fluids. Researchers and engineers are continuously working on reinforcing PTFE membranes with support structures or developing composite materials to improve their mechanical properties without compromising filtration efficiency.

The pore size control and distribution in PTFE filters pose another technical hurdle. Achieving consistent and precise pore sizes across the entire membrane surface is crucial for maintaining filtration accuracy and efficiency. The manufacturing process of PTFE membranes, typically involving stretching of the material, can result in variations in pore size and distribution. This variability can lead to inconsistent filtration performance and reduced reliability in critical applications.

Fouling and clogging of PTFE filters represent ongoing challenges in many filtration applications. Despite PTFE's non-stick properties, prolonged use can still result in the accumulation of particles or biological materials on the membrane surface. This buildup can reduce flow rates, increase pressure drop across the filter, and ultimately shorten the filter's lifespan. Developing effective cleaning protocols and designing self-cleaning or anti-fouling PTFE surfaces are areas of active research to address this issue.

The environmental impact and sustainability of PTFE filters also present challenges. PTFE is a synthetic fluoropolymer that is not biodegradable and can persist in the environment for extended periods. The production and disposal of PTFE filters raise concerns about their long-term environmental effects. Efforts are being made to develop more sustainable alternatives or to improve the recyclability and end-of-life management of PTFE filtration systems.

Lastly, the cost-effectiveness of PTFE filters remains a challenge in certain applications. While PTFE offers superior performance in many scenarios, its production costs can be higher compared to alternative filter materials. Balancing the benefits of PTFE with its economic implications is an ongoing consideration for manufacturers and end-users alike. Research into more efficient production methods and the development of hybrid materials that combine PTFE's advantages with lower-cost substrates are potential avenues for addressing this challenge.

Current PTFE Filter Designs

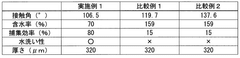

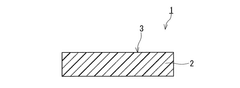

01 PTFE membrane structure for improved filtration efficiency

PTFE membranes with specific pore structures, such as asymmetric or gradient pore designs, can enhance filtration efficiency. These structures allow for better particle capture while maintaining high flow rates, making them suitable for various filtration applications.- PTFE membrane structure for improved filtration efficiency: PTFE membranes with specific pore structures, such as asymmetric or gradient pore designs, can enhance filtration efficiency. These structures allow for better particle capture while maintaining high flow rates, making them suitable for various filtration applications.

- Surface modification of PTFE for enhanced filtration: Modifying the surface of PTFE membranes through chemical treatments or plasma processes can improve their filtration efficiency. These modifications can alter the surface properties, enhancing particle capture and reducing fouling, leading to better overall performance.

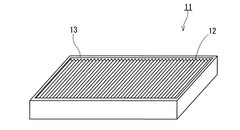

- Composite PTFE filters for increased efficiency: Combining PTFE with other materials to create composite filters can significantly improve filtration efficiency. These composites may include multiple layers or incorporate additional materials such as activated carbon or nanofibers to target specific contaminants or particle sizes.

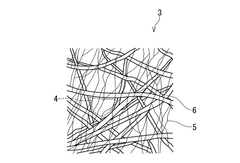

- PTFE nanofiber technology for high-efficiency filtration: Utilizing PTFE nanofibers in filter media can greatly enhance filtration efficiency due to their high surface area and small pore sizes. These nanofiber-based filters can capture ultra-fine particles while maintaining good air permeability.

- Optimization of PTFE filter design and manufacturing processes: Improving the design and manufacturing processes of PTFE filters can lead to enhanced filtration efficiency. This includes optimizing parameters such as fiber diameter, pore size distribution, and overall filter structure to achieve better particle capture and flow characteristics.

02 Surface modification of PTFE for enhanced filtration

Modifying the surface of PTFE membranes through chemical treatments or plasma processes can improve their filtration efficiency. These modifications can alter the surface properties, such as hydrophobicity or charge, to enhance particle capture and reduce fouling.Expand Specific Solutions03 Composite PTFE filters for increased efficiency

Combining PTFE with other materials to create composite filters can significantly improve filtration efficiency. These composites may include multiple layers of different materials or incorporate nanofibers to enhance particle capture across a wide range of sizes.Expand Specific Solutions04 Optimization of PTFE fiber properties for filtration

Tailoring the properties of PTFE fibers, such as diameter, length, and orientation, can enhance filtration efficiency. This optimization can lead to improved particle capture and reduced pressure drop across the filter media.Expand Specific Solutions05 PTFE filter manufacturing techniques for efficiency improvement

Advanced manufacturing techniques, such as electrospinning or expanded PTFE (ePTFE) processing, can produce PTFE filters with enhanced filtration efficiency. These methods allow for precise control over pore size, distribution, and overall filter structure.Expand Specific Solutions

Key PTFE Filter Producers

The filtration systems market utilizing PTFE is in a mature growth stage, with a global market size estimated to exceed $10 billion by 2025. The technology's maturity is evident from the diverse applications across industries and the presence of established players. Companies like W. L. Gore & Associates, DuPont, and Pall Corporation are at the forefront, leveraging their extensive R&D capabilities and patent portfolios. Emerging players such as Nitto Denko and Daikin Industries are also making significant strides, particularly in Asia. The competitive landscape is characterized by ongoing innovation in PTFE membrane technology, focusing on enhancing filtration efficiency and expanding application areas in sectors like water treatment, pharmaceuticals, and electronics.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE membrane technology for filtration systems. Their ePTFE (expanded PTFE) membranes offer high porosity and small pore size, enabling efficient particle capture while maintaining high air and liquid flow rates[1]. The company's GORE® Filtration Products utilize a unique microstructure that combines hydrophobic and oleophobic properties, making them suitable for a wide range of applications, including air pollution control, liquid filtration, and gas-liquid separation[2]. Gore's PTFE membranes are engineered to withstand harsh chemical and thermal environments, with some products capable of operating at temperatures up to 288°C (550°F)[3].

Strengths: Superior filtration efficiency, chemical resistance, and high-temperature stability. Weaknesses: Higher cost compared to traditional filter materials, potential for membrane fouling in certain applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed a range of PTFE-based filtration solutions, including their NEOFLON™ PTFE fine powder for high-performance filter membranes. Their technology focuses on creating uniform pore structures and optimizing the balance between filtration efficiency and pressure drop[4]. DAIKIN's PTFE membranes are used in various applications, including water treatment, air purification, and industrial process filtration. The company has also developed surface-modified PTFE membranes that enhance hydrophilicity or oleophobicity for specific filtration needs[5]. DAIKIN's research has led to the development of PTFE nanofiber membranes, which offer increased surface area and improved filtration performance[6].

Strengths: Wide range of customizable PTFE solutions, expertise in surface modification. Weaknesses: May have limited market presence compared to some competitors in certain regions.

PTFE Filter Innovations

Filter media with nanoweb layer

PatentActiveEP2364196A1

Innovation

- A composite filter media comprising a nanoweb layer as a depth filtration layer in fluid contact with a microporous polymeric membrane, where the nanoweb is produced using electrospinning or electroblowing processes, and a prefiltration layer, enhancing filtration efficiency and reducing pressure drop.

Filter medium and filter unit provided with same

PatentWO2019230984A1

Innovation

- A filter medium with a breathable base layer modified by polytetrafluoroethylene (PTFE) fibrils, reducing water permeation by dividing the ventilation area and enhancing surface water repellency.

Environmental Impact

The use of PTFE in filtration systems has significant environmental implications, both positive and negative. On the positive side, PTFE's exceptional chemical resistance and non-stick properties contribute to the longevity and efficiency of filtration systems. This durability reduces the frequency of filter replacements, thereby minimizing waste generation and resource consumption associated with manufacturing and disposing of filters.

PTFE's hydrophobic nature allows for effective separation of water from oil and other contaminants, making it particularly valuable in industrial wastewater treatment and oil spill cleanup operations. By facilitating the removal of pollutants from water sources, PTFE filters play a crucial role in environmental protection and water conservation efforts.

However, the environmental impact of PTFE production and disposal raises concerns. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. While many manufacturers have phased out PFOA use, alternative production methods may still have environmental implications that require further study.

The disposal of PTFE filters at the end of their lifecycle presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrogen fluoride and other toxic compounds, necessitating specialized disposal methods to mitigate environmental risks.

Efforts to address these environmental concerns include the development of PFOA-free PTFE production processes and the exploration of recycling technologies for PTFE materials. Some companies are investigating methods to recover and reuse PTFE from discarded filters, potentially reducing the environmental footprint of PTFE-based filtration systems.

The energy efficiency of PTFE filters in various applications also contributes to their environmental impact. In air filtration systems, PTFE membranes can enhance energy efficiency by allowing for higher airflow rates at lower pressure drops compared to traditional filter materials. This can lead to reduced energy consumption in HVAC systems and industrial processes, indirectly contributing to lower greenhouse gas emissions.

In conclusion, while PTFE offers significant benefits in filtration applications that can positively impact environmental protection efforts, the material's production and end-of-life management present environmental challenges that require ongoing research and innovation to address. Balancing these factors is crucial for the sustainable use of PTFE in filtration systems.

PTFE's hydrophobic nature allows for effective separation of water from oil and other contaminants, making it particularly valuable in industrial wastewater treatment and oil spill cleanup operations. By facilitating the removal of pollutants from water sources, PTFE filters play a crucial role in environmental protection and water conservation efforts.

However, the environmental impact of PTFE production and disposal raises concerns. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. While many manufacturers have phased out PFOA use, alternative production methods may still have environmental implications that require further study.

The disposal of PTFE filters at the end of their lifecycle presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful substances, including hydrogen fluoride and other toxic compounds, necessitating specialized disposal methods to mitigate environmental risks.

Efforts to address these environmental concerns include the development of PFOA-free PTFE production processes and the exploration of recycling technologies for PTFE materials. Some companies are investigating methods to recover and reuse PTFE from discarded filters, potentially reducing the environmental footprint of PTFE-based filtration systems.

The energy efficiency of PTFE filters in various applications also contributes to their environmental impact. In air filtration systems, PTFE membranes can enhance energy efficiency by allowing for higher airflow rates at lower pressure drops compared to traditional filter materials. This can lead to reduced energy consumption in HVAC systems and industrial processes, indirectly contributing to lower greenhouse gas emissions.

In conclusion, while PTFE offers significant benefits in filtration applications that can positively impact environmental protection efforts, the material's production and end-of-life management present environmental challenges that require ongoing research and innovation to address. Balancing these factors is crucial for the sustainable use of PTFE in filtration systems.

PTFE Filter Applications

Polytetrafluoroethylene (PTFE) has emerged as a versatile material in filtration systems, offering unique properties that make it ideal for a wide range of applications. In the realm of liquid filtration, PTFE membranes excel in separating oil from water, a crucial process in environmental protection and industrial wastewater treatment. These membranes demonstrate exceptional hydrophobicity and oleophilicity, allowing for efficient oil-water separation even in complex emulsions.

In air filtration systems, PTFE filters have gained prominence due to their ability to capture fine particles while maintaining high airflow rates. This characteristic is particularly valuable in clean room environments, where maintaining air purity is paramount. PTFE filters are commonly used in HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filtration systems, providing superior performance in removing submicron particles from the air.

The chemical industry benefits greatly from PTFE's resistance to corrosive substances. PTFE filters are employed in aggressive chemical environments where other materials would quickly degrade. This resistance allows for the filtration of acids, bases, and solvents without compromising the integrity of the filter media. In pharmaceutical manufacturing, PTFE filters play a crucial role in ensuring the purity of drug formulations and in sterile filtration processes.

PTFE's non-stick properties make it an excellent choice for filtration in food and beverage processing. These filters prevent the adhesion of particles and microorganisms, reducing the risk of contamination and facilitating easier cleaning and maintenance. In dairy processing, PTFE membranes are used for milk concentration and whey protein separation, improving product quality and process efficiency.

The automotive industry utilizes PTFE filters in various applications, including fuel systems and engine air intake. PTFE's resistance to fuel and oil contamination ensures long-lasting performance in these critical systems. Additionally, PTFE-based cabin air filters provide enhanced protection against fine particulates and allergens, improving air quality for vehicle occupants.

In the field of biotechnology, PTFE membranes are employed in cell culture applications and protein purification processes. The material's low protein binding characteristics make it ideal for filtration tasks that require minimal interaction between the filter media and the biological substances being processed.

As environmental concerns grow, PTFE filters are finding new applications in air pollution control systems. These filters are effective in capturing fine particulate matter from industrial emissions, helping companies meet stringent environmental regulations while maintaining operational efficiency.

In air filtration systems, PTFE filters have gained prominence due to their ability to capture fine particles while maintaining high airflow rates. This characteristic is particularly valuable in clean room environments, where maintaining air purity is paramount. PTFE filters are commonly used in HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filtration systems, providing superior performance in removing submicron particles from the air.

The chemical industry benefits greatly from PTFE's resistance to corrosive substances. PTFE filters are employed in aggressive chemical environments where other materials would quickly degrade. This resistance allows for the filtration of acids, bases, and solvents without compromising the integrity of the filter media. In pharmaceutical manufacturing, PTFE filters play a crucial role in ensuring the purity of drug formulations and in sterile filtration processes.

PTFE's non-stick properties make it an excellent choice for filtration in food and beverage processing. These filters prevent the adhesion of particles and microorganisms, reducing the risk of contamination and facilitating easier cleaning and maintenance. In dairy processing, PTFE membranes are used for milk concentration and whey protein separation, improving product quality and process efficiency.

The automotive industry utilizes PTFE filters in various applications, including fuel systems and engine air intake. PTFE's resistance to fuel and oil contamination ensures long-lasting performance in these critical systems. Additionally, PTFE-based cabin air filters provide enhanced protection against fine particulates and allergens, improving air quality for vehicle occupants.

In the field of biotechnology, PTFE membranes are employed in cell culture applications and protein purification processes. The material's low protein binding characteristics make it ideal for filtration tasks that require minimal interaction between the filter media and the biological substances being processed.

As environmental concerns grow, PTFE filters are finding new applications in air pollution control systems. These filters are effective in capturing fine particulate matter from industrial emissions, helping companies meet stringent environmental regulations while maintaining operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!