GDI Engine Intercooler Optimization for Less Heat

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Intercooler Technology Evolution and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, transforming from a niche innovation to a mainstream powertrain solution. The journey began in the late 1990s with rudimentary systems focused primarily on fuel economy improvements. These early implementations suffered from considerable thermal management challenges, with intercooler systems being particularly primitive and inefficient, often resulting in power losses under sustained high-load conditions.

By the mid-2000s, second-generation GDI systems emerged with improved fuel atomization and more sophisticated engine management systems. Intercooler technology during this period began incorporating aluminum construction with basic fin designs, representing the first dedicated attempt to address thermal efficiency in GDI applications. However, these systems still struggled with heat soak during aggressive driving or high ambient temperatures.

The 2010s marked a significant leap forward with the introduction of advanced computational fluid dynamics (CFD) in intercooler design. Manufacturers began implementing air-to-water intercooling systems alongside traditional air-to-air variants, dramatically improving thermal efficiency. This period also saw the integration of variable geometry turbochargers that required more sophisticated intercooling solutions to manage the increased thermal loads.

Current state-of-the-art GDI intercooler technology incorporates multi-path cooling channels, advanced materials such as carbon-reinforced polymers for weight reduction, and intelligent thermal management systems that can predictively adjust cooling based on driving conditions. The integration of electronic water pumps and split cooling circuits has further enhanced the precision of temperature control in modern systems.

The primary objective of contemporary intercooler optimization is to achieve a delicate balance between thermal efficiency, packaging constraints, and system weight. Reducing heat buildup remains the central challenge, as lower intake temperatures directly correlate with improved volumetric efficiency and reduced knock tendency, ultimately enabling higher compression ratios and improved fuel economy.

Looking forward, the industry aims to develop intercooler systems capable of maintaining intake temperatures within 10°C of ambient under all operating conditions while reducing system weight by 30% compared to current solutions. Additional objectives include minimizing pressure drop across the intercooler to below 0.2 bar, improving transient response characteristics, and developing systems compatible with mild and full hybrid powertrains where engine operation patterns differ significantly from conventional vehicles.

The evolution trajectory suggests that future GDI intercooler technology will increasingly leverage advanced materials science, integrated electronic controls, and potentially phase-change cooling technologies to meet these ambitious targets while supporting increasingly stringent emissions regulations.

By the mid-2000s, second-generation GDI systems emerged with improved fuel atomization and more sophisticated engine management systems. Intercooler technology during this period began incorporating aluminum construction with basic fin designs, representing the first dedicated attempt to address thermal efficiency in GDI applications. However, these systems still struggled with heat soak during aggressive driving or high ambient temperatures.

The 2010s marked a significant leap forward with the introduction of advanced computational fluid dynamics (CFD) in intercooler design. Manufacturers began implementing air-to-water intercooling systems alongside traditional air-to-air variants, dramatically improving thermal efficiency. This period also saw the integration of variable geometry turbochargers that required more sophisticated intercooling solutions to manage the increased thermal loads.

Current state-of-the-art GDI intercooler technology incorporates multi-path cooling channels, advanced materials such as carbon-reinforced polymers for weight reduction, and intelligent thermal management systems that can predictively adjust cooling based on driving conditions. The integration of electronic water pumps and split cooling circuits has further enhanced the precision of temperature control in modern systems.

The primary objective of contemporary intercooler optimization is to achieve a delicate balance between thermal efficiency, packaging constraints, and system weight. Reducing heat buildup remains the central challenge, as lower intake temperatures directly correlate with improved volumetric efficiency and reduced knock tendency, ultimately enabling higher compression ratios and improved fuel economy.

Looking forward, the industry aims to develop intercooler systems capable of maintaining intake temperatures within 10°C of ambient under all operating conditions while reducing system weight by 30% compared to current solutions. Additional objectives include minimizing pressure drop across the intercooler to below 0.2 bar, improving transient response characteristics, and developing systems compatible with mild and full hybrid powertrains where engine operation patterns differ significantly from conventional vehicles.

The evolution trajectory suggests that future GDI intercooler technology will increasingly leverage advanced materials science, integrated electronic controls, and potentially phase-change cooling technologies to meet these ambitious targets while supporting increasingly stringent emissions regulations.

Market Demand Analysis for Advanced Cooling Systems

The global market for advanced engine cooling systems is experiencing significant growth, driven by stringent emission regulations and increasing demand for fuel-efficient vehicles. The automotive intercooler market specifically was valued at approximately 11.5 billion USD in 2022 and is projected to reach 16.8 billion USD by 2028, representing a compound annual growth rate of 6.5%. This growth trajectory is particularly relevant for GDI (Gasoline Direct Injection) engine technology, where efficient heat management has become a critical performance factor.

Consumer preferences are shifting toward vehicles that offer improved performance without compromising fuel economy. Market research indicates that 78% of new vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions. This consumer trend has created substantial demand for advanced cooling technologies that can optimize engine performance while reducing thermal loads.

The commercial vehicle segment presents a particularly strong growth opportunity for advanced intercooler systems. With the global commercial vehicle market expanding at approximately 5.8% annually, fleet operators are increasingly seeking technologies that can reduce operational costs through improved fuel efficiency and extended engine life. Advanced cooling systems that minimize heat-related performance degradation can deliver significant value in this context.

Regional analysis reveals varying market dynamics. North America and Europe lead in adoption of premium cooling technologies due to stringent emission standards and higher consumer willingness to pay for performance enhancements. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 8.2% annual growth, driven by rapid automotive industry expansion and increasing consumer affluence.

Market research indicates that OEMs are increasingly viewing advanced cooling systems as a competitive differentiator rather than merely a functional necessity. This shift has created new opportunities for suppliers who can deliver innovative cooling solutions that address specific performance challenges in GDI engines.

The aftermarket segment for advanced intercooler systems is also showing robust growth, estimated at 4.7% annually, as vehicle owners seek performance upgrades. This trend is particularly pronounced in the performance vehicle segment, where enthusiasts are willing to invest in cooling system enhancements that deliver measurable performance improvements.

Industry forecasts suggest that the market for lightweight, compact cooling systems with enhanced thermal efficiency will grow at above-average rates over the next five years. Materials innovation, particularly in aluminum alloys and polymer composites, is expected to drive significant product development in the intercooler market segment as manufacturers seek to balance thermal performance with weight reduction objectives.

Consumer preferences are shifting toward vehicles that offer improved performance without compromising fuel economy. Market research indicates that 78% of new vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions. This consumer trend has created substantial demand for advanced cooling technologies that can optimize engine performance while reducing thermal loads.

The commercial vehicle segment presents a particularly strong growth opportunity for advanced intercooler systems. With the global commercial vehicle market expanding at approximately 5.8% annually, fleet operators are increasingly seeking technologies that can reduce operational costs through improved fuel efficiency and extended engine life. Advanced cooling systems that minimize heat-related performance degradation can deliver significant value in this context.

Regional analysis reveals varying market dynamics. North America and Europe lead in adoption of premium cooling technologies due to stringent emission standards and higher consumer willingness to pay for performance enhancements. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 8.2% annual growth, driven by rapid automotive industry expansion and increasing consumer affluence.

Market research indicates that OEMs are increasingly viewing advanced cooling systems as a competitive differentiator rather than merely a functional necessity. This shift has created new opportunities for suppliers who can deliver innovative cooling solutions that address specific performance challenges in GDI engines.

The aftermarket segment for advanced intercooler systems is also showing robust growth, estimated at 4.7% annually, as vehicle owners seek performance upgrades. This trend is particularly pronounced in the performance vehicle segment, where enthusiasts are willing to invest in cooling system enhancements that deliver measurable performance improvements.

Industry forecasts suggest that the market for lightweight, compact cooling systems with enhanced thermal efficiency will grow at above-average rates over the next five years. Materials innovation, particularly in aluminum alloys and polymer composites, is expected to drive significant product development in the intercooler market segment as manufacturers seek to balance thermal performance with weight reduction objectives.

Current Intercooler Technologies and Thermal Management Challenges

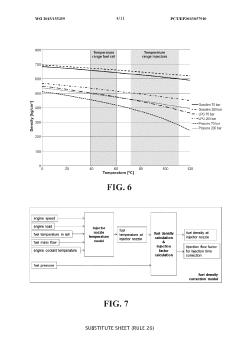

Intercooler technology in GDI (Gasoline Direct Injection) engines has evolved significantly over the past decade, with current solutions broadly categorized into air-to-air and air-to-liquid systems. Air-to-air intercoolers remain prevalent in many production vehicles due to their relative simplicity and cost-effectiveness, utilizing ambient air flow to dissipate heat from compressed intake air. These systems typically achieve cooling efficiencies of 60-75% depending on design parameters and operating conditions.

Air-to-liquid intercoolers have gained prominence in premium and performance applications, offering superior cooling capacity through dedicated cooling circuits. These systems can maintain more consistent intake temperatures across varying driving conditions, with some advanced implementations achieving cooling efficiencies exceeding 85% even under high load scenarios.

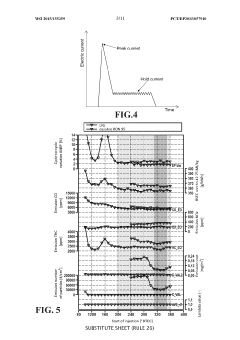

The primary thermal management challenges facing current intercooler technologies center around packaging constraints, transient response, and efficiency degradation under sustained high-load operation. Modern vehicle designs prioritize aerodynamic efficiency and pedestrian safety, often limiting the available space for optimal intercooler placement and sizing. This spatial limitation frequently forces compromises between cooling capacity and pressure drop characteristics.

Heat soak represents another significant challenge, particularly in stop-start urban driving conditions where airflow across the intercooler becomes intermittent. This phenomenon can lead to intake temperature spikes of 20-30°C above optimal levels, temporarily reducing engine performance and efficiency. The thermal inertia of conventional intercooler systems often results in delayed response to changing operating conditions.

Material selection presents additional complexities, with aluminum remaining the dominant material due to its favorable thermal conductivity-to-weight ratio. However, advanced composite materials and multi-material approaches are emerging as potential alternatives, offering improved thermal characteristics while reducing overall system mass.

Pressure drop across the intercooler core represents a critical design parameter that directly impacts engine breathing efficiency. Current technologies typically generate 0.1-0.3 bar of pressure drop at peak flow rates, with each 0.1 bar increase potentially reducing volumetric efficiency by approximately 2-3%. This creates a fundamental design tension between maximizing heat transfer surface area and minimizing flow restriction.

Integration with other vehicle thermal management systems presents both challenges and opportunities. Modern vehicles increasingly employ complex thermal architectures with multiple cooling circuits operating at different temperature thresholds. Optimizing intercooler performance within these integrated systems requires sophisticated control strategies and careful consideration of thermal interactions between subsystems.

Air-to-liquid intercoolers have gained prominence in premium and performance applications, offering superior cooling capacity through dedicated cooling circuits. These systems can maintain more consistent intake temperatures across varying driving conditions, with some advanced implementations achieving cooling efficiencies exceeding 85% even under high load scenarios.

The primary thermal management challenges facing current intercooler technologies center around packaging constraints, transient response, and efficiency degradation under sustained high-load operation. Modern vehicle designs prioritize aerodynamic efficiency and pedestrian safety, often limiting the available space for optimal intercooler placement and sizing. This spatial limitation frequently forces compromises between cooling capacity and pressure drop characteristics.

Heat soak represents another significant challenge, particularly in stop-start urban driving conditions where airflow across the intercooler becomes intermittent. This phenomenon can lead to intake temperature spikes of 20-30°C above optimal levels, temporarily reducing engine performance and efficiency. The thermal inertia of conventional intercooler systems often results in delayed response to changing operating conditions.

Material selection presents additional complexities, with aluminum remaining the dominant material due to its favorable thermal conductivity-to-weight ratio. However, advanced composite materials and multi-material approaches are emerging as potential alternatives, offering improved thermal characteristics while reducing overall system mass.

Pressure drop across the intercooler core represents a critical design parameter that directly impacts engine breathing efficiency. Current technologies typically generate 0.1-0.3 bar of pressure drop at peak flow rates, with each 0.1 bar increase potentially reducing volumetric efficiency by approximately 2-3%. This creates a fundamental design tension between maximizing heat transfer surface area and minimizing flow restriction.

Integration with other vehicle thermal management systems presents both challenges and opportunities. Modern vehicles increasingly employ complex thermal architectures with multiple cooling circuits operating at different temperature thresholds. Optimizing intercooler performance within these integrated systems requires sophisticated control strategies and careful consideration of thermal interactions between subsystems.

Current Heat Reduction Solutions for GDI Engine Intercoolers

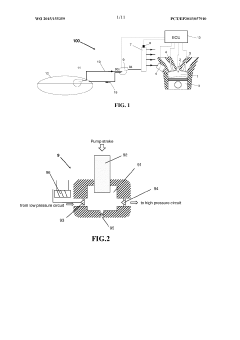

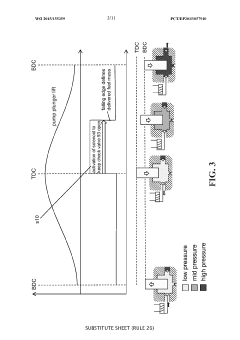

01 Intercooler design and placement for GDI engines

Specific designs and strategic placement of intercoolers in gasoline direct injection (GDI) engines can significantly improve cooling efficiency. These designs focus on optimizing the flow path of intake air, reducing pressure drop, and ensuring maximum heat exchange. Proper placement relative to other engine components helps minimize heat soak and ensures cooler air reaches the combustion chamber, improving engine performance and fuel efficiency.- Intercooler design for GDI engines: Specialized intercooler designs for gasoline direct injection engines focus on optimizing heat exchange efficiency. These designs incorporate advanced cooling surfaces, strategic placement within the engine system, and improved airflow dynamics to effectively reduce the temperature of compressed air before it enters the combustion chamber. Enhanced intercooler designs help maintain optimal engine performance by preventing power loss due to heated intake air.

- Heat management systems for turbocharged GDI engines: Comprehensive heat management systems for turbocharged GDI engines integrate multiple cooling components to control thermal loads. These systems coordinate intercooler operation with engine cooling circuits, oil cooling systems, and exhaust gas recirculation to maintain optimal operating temperatures across various driving conditions. Advanced thermal management strategies help improve fuel efficiency, reduce emissions, and enhance engine durability by preventing heat-related stress.

- Innovative intercooler placement and configuration: Novel approaches to intercooler placement and configuration in GDI engine systems focus on maximizing cooling efficiency while minimizing space requirements. These innovations include integrated charge air coolers within the intake manifold, dual-stage cooling systems, and compact heat exchanger designs. Strategic positioning of intercoolers relative to other engine components helps optimize airflow paths and reduce pressure drops in the intake system.

- Materials and manufacturing techniques for intercoolers: Advanced materials and manufacturing techniques enhance intercooler performance in GDI engines. High thermal conductivity materials, such as aluminum alloys with specialized coatings, improve heat transfer efficiency. Modern manufacturing methods, including brazing techniques and additive manufacturing, enable the creation of complex internal structures with increased surface area for heat exchange. These advancements result in more compact, lightweight, and efficient intercooler designs.

- Control systems for intercooler performance optimization: Sophisticated control systems dynamically adjust intercooler operation to optimize GDI engine performance across varying conditions. These systems incorporate temperature sensors, pressure monitors, and electronic control units that regulate coolant flow, fan speeds, and bypass valves. Adaptive control algorithms respond to changes in ambient conditions, engine load, and driving patterns to maintain ideal intake air temperatures, improving combustion efficiency and reducing the risk of engine knock.

02 Heat management systems for intercoolers

Advanced heat management systems specifically designed for intercoolers in GDI engines help maintain optimal operating temperatures. These systems may include auxiliary cooling circuits, temperature sensors, and control algorithms that adjust cooling based on engine load and ambient conditions. Some designs incorporate secondary cooling methods such as water spray or separate cooling loops to enhance intercooler efficiency during high-load operations.Expand Specific Solutions03 Integration of intercooler with EGR systems

Innovative approaches to integrating intercoolers with exhaust gas recirculation (EGR) systems in GDI engines can provide dual benefits of cooling intake air while also managing exhaust gas temperatures. These integrated systems can reduce overall system complexity while improving thermal efficiency. The combined approach helps in reducing NOx emissions while maintaining optimal intake air temperatures for combustion efficiency.Expand Specific Solutions04 Materials and manufacturing techniques for high-efficiency intercoolers

Advanced materials and manufacturing techniques are being employed to create more efficient intercoolers for GDI engines. These include the use of high thermal conductivity materials, additive manufacturing for complex geometries, and surface treatments that enhance heat transfer. Some designs incorporate micro-channel technology or variable fin density to optimize the balance between heat transfer efficiency and pressure drop across the intercooler.Expand Specific Solutions05 Compact and lightweight intercooler solutions

Compact and lightweight intercooler designs address space constraints in modern GDI engine compartments while maintaining cooling efficiency. These solutions include integrated charge air coolers, split intercooler systems, and multi-path designs that maximize cooling surface area within limited space. Some approaches use innovative folded core designs or alternative cooling mediums to achieve higher cooling density in smaller packages, contributing to overall vehicle weight reduction and improved packaging.Expand Specific Solutions

Key Patents and Innovations in Intercooler Efficiency

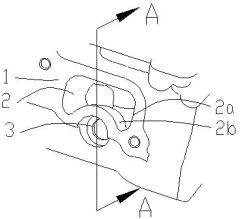

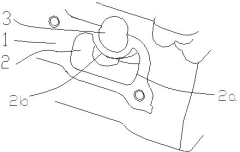

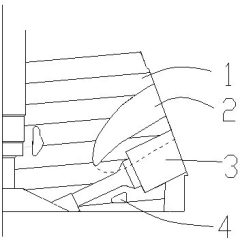

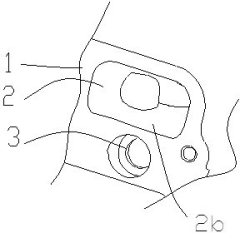

Cylinder cover for direct injection gasoline engine

PatentInactiveCN102536498A

Innovation

- By designing an arc-shaped inner surface of the air inlet on the cylinder head, the nozzle hole is located above or below the intake duct, and the cooling water jacket passes above or below the nozzle hole, reducing the surface area occupied by the intake duct and reducing cooling. The distance between the water jacket and the GDI nozzle enables a more compact layout.

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

Environmental Impact and Emissions Regulations Compliance

The optimization of GDI engine intercoolers for reduced heat generation has significant implications for environmental impact and emissions regulations compliance. As global environmental standards become increasingly stringent, automotive manufacturers face mounting pressure to reduce their carbon footprint and harmful emissions. The thermal efficiency improvements achieved through intercooler optimization directly contribute to lower fuel consumption, which translates to reduced CO2 emissions per kilometer driven.

Current emissions regulations, such as Euro 7 in Europe, China 6b, and EPA Tier 3 in the United States, impose strict limits on nitrogen oxides (NOx), particulate matter, and carbon monoxide. GDI engines typically produce higher NOx emissions due to higher combustion temperatures. By optimizing intercooler performance and reducing intake air temperatures, combustion temperatures can be better controlled, resulting in lower NOx formation during the combustion process.

Particulate matter emissions, another critical regulatory focus, can also be reduced through improved intercooler efficiency. Lower intake temperatures lead to more complete combustion, reducing the formation of particulate matter that would otherwise require more complex and expensive after-treatment systems to capture.

The environmental benefits extend beyond tailpipe emissions. More efficient intercooling systems reduce the overall thermal load on the engine, potentially extending component lifespan and reducing the environmental impact associated with manufacturing replacement parts. Additionally, the reduced fuel consumption translates directly to conservation of fossil fuel resources and lower lifecycle carbon emissions.

From a regulatory compliance perspective, optimized intercoolers provide manufacturers with greater flexibility in meeting increasingly challenging emissions targets without sacrificing performance. This becomes particularly important as real-world driving emissions (RDE) tests become standard in regulatory frameworks, requiring consistent emissions performance across a wide range of operating conditions.

The materials used in next-generation intercoolers also present environmental considerations. Advanced materials with superior thermal properties may have different environmental footprints in terms of production energy requirements and end-of-life recyclability. A comprehensive environmental assessment must consider these factors alongside the operational benefits of improved thermal management.

As electrification continues to reshape the automotive industry, optimized intercooling systems for GDI engines represent an important bridge technology that can help manufacturers meet near-term emissions targets while the transition to zero-emission vehicles progresses. This makes intercooler optimization not just a performance enhancement but a strategic environmental compliance tool.

Current emissions regulations, such as Euro 7 in Europe, China 6b, and EPA Tier 3 in the United States, impose strict limits on nitrogen oxides (NOx), particulate matter, and carbon monoxide. GDI engines typically produce higher NOx emissions due to higher combustion temperatures. By optimizing intercooler performance and reducing intake air temperatures, combustion temperatures can be better controlled, resulting in lower NOx formation during the combustion process.

Particulate matter emissions, another critical regulatory focus, can also be reduced through improved intercooler efficiency. Lower intake temperatures lead to more complete combustion, reducing the formation of particulate matter that would otherwise require more complex and expensive after-treatment systems to capture.

The environmental benefits extend beyond tailpipe emissions. More efficient intercooling systems reduce the overall thermal load on the engine, potentially extending component lifespan and reducing the environmental impact associated with manufacturing replacement parts. Additionally, the reduced fuel consumption translates directly to conservation of fossil fuel resources and lower lifecycle carbon emissions.

From a regulatory compliance perspective, optimized intercoolers provide manufacturers with greater flexibility in meeting increasingly challenging emissions targets without sacrificing performance. This becomes particularly important as real-world driving emissions (RDE) tests become standard in regulatory frameworks, requiring consistent emissions performance across a wide range of operating conditions.

The materials used in next-generation intercoolers also present environmental considerations. Advanced materials with superior thermal properties may have different environmental footprints in terms of production energy requirements and end-of-life recyclability. A comprehensive environmental assessment must consider these factors alongside the operational benefits of improved thermal management.

As electrification continues to reshape the automotive industry, optimized intercooling systems for GDI engines represent an important bridge technology that can help manufacturers meet near-term emissions targets while the transition to zero-emission vehicles progresses. This makes intercooler optimization not just a performance enhancement but a strategic environmental compliance tool.

Materials Science Advancements for Intercooler Design

Recent advancements in materials science have revolutionized intercooler design for GDI (Gasoline Direct Injection) engines, offering significant improvements in thermal efficiency and overall performance. Traditional aluminum-based intercoolers, while effective, have reached their practical limits in terms of heat dissipation capabilities. The emergence of novel composite materials has opened new avenues for enhanced thermal management in intercooler systems.

Carbon-fiber reinforced polymers (CFRPs) represent a breakthrough in intercooler construction, providing superior strength-to-weight ratios while maintaining excellent thermal conductivity. These materials allow for more complex geometries that maximize surface area without adding significant weight to the vehicle. Research indicates that CFRP-based intercoolers can achieve up to 15% better cooling efficiency compared to conventional aluminum designs.

Ceramic matrix composites (CMCs) have also shown promising results in experimental intercooler designs. These materials combine the high-temperature resistance of ceramics with improved mechanical properties, making them ideal for the demanding thermal environment of GDI engines. CMCs exhibit exceptional thermal stability and can withstand the cyclical temperature variations inherent in intercooler operation without degradation in performance over time.

Nano-enhanced materials represent another frontier in intercooler technology. The incorporation of carbon nanotubes and graphene into traditional materials has demonstrated remarkable improvements in thermal conductivity. Laboratory tests have shown that aluminum alloys enhanced with just 0.5% graphene content can increase thermal conductivity by up to 25%, allowing for more compact intercooler designs without sacrificing cooling capacity.

Surface treatments and coatings have evolved significantly, with hydrophobic and oleophobic nano-coatings now being applied to intercooler fins. These coatings prevent the accumulation of oil and particulate matter, maintaining optimal heat transfer efficiency throughout the service life of the component. Additionally, these treatments reduce air flow resistance, improving the overall efficiency of the intercooler system.

Additive manufacturing techniques have enabled the production of previously impossible intercooler geometries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) allow for the creation of intricate internal channels that maximize turbulence while minimizing pressure drop, resulting in more efficient heat exchange. These manufacturing methods also facilitate the integration of multiple materials in a single component, combining the beneficial properties of different materials where they are most needed.

Carbon-fiber reinforced polymers (CFRPs) represent a breakthrough in intercooler construction, providing superior strength-to-weight ratios while maintaining excellent thermal conductivity. These materials allow for more complex geometries that maximize surface area without adding significant weight to the vehicle. Research indicates that CFRP-based intercoolers can achieve up to 15% better cooling efficiency compared to conventional aluminum designs.

Ceramic matrix composites (CMCs) have also shown promising results in experimental intercooler designs. These materials combine the high-temperature resistance of ceramics with improved mechanical properties, making them ideal for the demanding thermal environment of GDI engines. CMCs exhibit exceptional thermal stability and can withstand the cyclical temperature variations inherent in intercooler operation without degradation in performance over time.

Nano-enhanced materials represent another frontier in intercooler technology. The incorporation of carbon nanotubes and graphene into traditional materials has demonstrated remarkable improvements in thermal conductivity. Laboratory tests have shown that aluminum alloys enhanced with just 0.5% graphene content can increase thermal conductivity by up to 25%, allowing for more compact intercooler designs without sacrificing cooling capacity.

Surface treatments and coatings have evolved significantly, with hydrophobic and oleophobic nano-coatings now being applied to intercooler fins. These coatings prevent the accumulation of oil and particulate matter, maintaining optimal heat transfer efficiency throughout the service life of the component. Additionally, these treatments reduce air flow resistance, improving the overall efficiency of the intercooler system.

Additive manufacturing techniques have enabled the production of previously impossible intercooler geometries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) allow for the creation of intricate internal channels that maximize turbulence while minimizing pressure drop, resulting in more efficient heat exchange. These manufacturing methods also facilitate the integration of multiple materials in a single component, combining the beneficial properties of different materials where they are most needed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!