How Are SiC MOSFETs Used In Wind Turbine Power Electronics?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Technology Evolution in Wind Energy

The evolution of Silicon Carbide (SiC) MOSFET technology in wind energy represents a significant technological advancement in power electronics for renewable energy systems. Initially developed in the early 2000s, SiC MOSFETs have undergone substantial improvements in performance, reliability, and cost-effectiveness, making them increasingly viable for wind turbine applications.

The first generation of SiC MOSFETs faced challenges related to high manufacturing costs and reliability issues, limiting their adoption in wind energy systems. However, by the mid-2010s, significant breakthroughs in manufacturing processes and material quality led to enhanced device performance and reduced production costs, marking the second generation of these devices.

From 2015 onwards, third-generation SiC MOSFETs emerged with substantially improved switching characteristics, lower on-resistance, and enhanced thermal performance. These advancements enabled higher power density and efficiency in wind turbine power converters, facilitating the trend toward larger offshore wind installations with capacities exceeding 10 MW.

The technology evolution timeline shows a clear progression in key parameters: switching frequencies increased from 20 kHz to over 100 kHz, on-resistance decreased by approximately 75%, and thermal conductivity improved by 30-40%. These improvements directly translated to higher efficiency power conversion systems for wind turbines, with modern SiC-based converters achieving efficiencies above 98%.

Recent developments since 2020 have focused on enhancing reliability under harsh environmental conditions typical in offshore wind installations. Manufacturers have introduced advanced packaging technologies and improved gate driver designs to ensure stable operation under high humidity, temperature cycling, and vibration conditions common in wind turbine nacelles.

The roadmap for SiC MOSFET evolution in wind energy applications continues to focus on increasing voltage ratings beyond the current 1700V standard to support higher power wind turbines. Research efforts are also directed toward optimizing device characteristics specifically for wind energy applications, including customized switching behaviors to reduce electromagnetic interference in long cable runs typical in wind farms.

Looking forward, the integration of SiC MOSFETs with advanced digital control algorithms and monitoring systems represents the next frontier, enabling predictive maintenance capabilities and adaptive control strategies that can optimize energy harvest under varying wind conditions while extending component lifetime.

The first generation of SiC MOSFETs faced challenges related to high manufacturing costs and reliability issues, limiting their adoption in wind energy systems. However, by the mid-2010s, significant breakthroughs in manufacturing processes and material quality led to enhanced device performance and reduced production costs, marking the second generation of these devices.

From 2015 onwards, third-generation SiC MOSFETs emerged with substantially improved switching characteristics, lower on-resistance, and enhanced thermal performance. These advancements enabled higher power density and efficiency in wind turbine power converters, facilitating the trend toward larger offshore wind installations with capacities exceeding 10 MW.

The technology evolution timeline shows a clear progression in key parameters: switching frequencies increased from 20 kHz to over 100 kHz, on-resistance decreased by approximately 75%, and thermal conductivity improved by 30-40%. These improvements directly translated to higher efficiency power conversion systems for wind turbines, with modern SiC-based converters achieving efficiencies above 98%.

Recent developments since 2020 have focused on enhancing reliability under harsh environmental conditions typical in offshore wind installations. Manufacturers have introduced advanced packaging technologies and improved gate driver designs to ensure stable operation under high humidity, temperature cycling, and vibration conditions common in wind turbine nacelles.

The roadmap for SiC MOSFET evolution in wind energy applications continues to focus on increasing voltage ratings beyond the current 1700V standard to support higher power wind turbines. Research efforts are also directed toward optimizing device characteristics specifically for wind energy applications, including customized switching behaviors to reduce electromagnetic interference in long cable runs typical in wind farms.

Looking forward, the integration of SiC MOSFETs with advanced digital control algorithms and monitoring systems represents the next frontier, enabling predictive maintenance capabilities and adaptive control strategies that can optimize energy harvest under varying wind conditions while extending component lifetime.

Market Demand Analysis for SiC in Wind Power Systems

The global wind energy market has experienced substantial growth over the past decade, with installed capacity reaching approximately 837 GW by the end of 2022. This expansion has created significant demand for more efficient power electronics systems within wind turbines, particularly in converter technologies that can handle higher voltages and frequencies while minimizing energy losses.

Silicon Carbide (SiC) MOSFETs are emerging as a critical component in this market, with demand projected to grow at a CAGR of 25% specifically within the wind power sector through 2028. This growth is primarily driven by the industry's shift toward larger turbines with higher power ratings, often exceeding 10 MW for offshore installations, which require more advanced power conversion solutions.

Market research indicates that SiC-based power electronics can reduce conversion losses by 30-50% compared to traditional silicon-based systems, translating to approximately 1-2% improvement in overall turbine efficiency. For utility-scale wind farms, this efficiency gain represents millions of dollars in additional revenue over the operational lifetime of the installation.

The demand for SiC MOSFETs in wind power applications is segmented across three primary areas: generator-side converters, grid-side converters, and auxiliary power systems. Among these, grid-side converters represent the largest market segment, accounting for roughly 60% of SiC device implementation in wind power electronics due to their critical role in meeting stringent grid code requirements.

Geographically, Europe currently leads the market for SiC adoption in wind power systems, driven by aggressive offshore wind development in the North Sea region. However, China is expected to become the fastest-growing market, with projected annual growth rates exceeding 30% as the country pursues its ambitious renewable energy targets.

The market is further stimulated by regulatory frameworks that increasingly emphasize grid stability and power quality. These regulations require wind farms to provide grid support functions such as reactive power control and fault ride-through capability, which are more effectively delivered through SiC-based power electronics.

Cost remains a significant factor influencing market penetration, with SiC MOSFETs currently commanding a premium of 2-3 times over traditional silicon IGBTs. However, this price differential is narrowing by approximately 8-10% annually as manufacturing scales up and yields improve. Industry analysts predict price parity for certain power ratings could be achieved by 2027, potentially triggering widespread adoption across the wind power sector.

Silicon Carbide (SiC) MOSFETs are emerging as a critical component in this market, with demand projected to grow at a CAGR of 25% specifically within the wind power sector through 2028. This growth is primarily driven by the industry's shift toward larger turbines with higher power ratings, often exceeding 10 MW for offshore installations, which require more advanced power conversion solutions.

Market research indicates that SiC-based power electronics can reduce conversion losses by 30-50% compared to traditional silicon-based systems, translating to approximately 1-2% improvement in overall turbine efficiency. For utility-scale wind farms, this efficiency gain represents millions of dollars in additional revenue over the operational lifetime of the installation.

The demand for SiC MOSFETs in wind power applications is segmented across three primary areas: generator-side converters, grid-side converters, and auxiliary power systems. Among these, grid-side converters represent the largest market segment, accounting for roughly 60% of SiC device implementation in wind power electronics due to their critical role in meeting stringent grid code requirements.

Geographically, Europe currently leads the market for SiC adoption in wind power systems, driven by aggressive offshore wind development in the North Sea region. However, China is expected to become the fastest-growing market, with projected annual growth rates exceeding 30% as the country pursues its ambitious renewable energy targets.

The market is further stimulated by regulatory frameworks that increasingly emphasize grid stability and power quality. These regulations require wind farms to provide grid support functions such as reactive power control and fault ride-through capability, which are more effectively delivered through SiC-based power electronics.

Cost remains a significant factor influencing market penetration, with SiC MOSFETs currently commanding a premium of 2-3 times over traditional silicon IGBTs. However, this price differential is narrowing by approximately 8-10% annually as manufacturing scales up and yields improve. Industry analysts predict price parity for certain power ratings could be achieved by 2027, potentially triggering widespread adoption across the wind power sector.

Technical Challenges in Wind Turbine Power Electronics

Wind turbine power electronics face significant technical challenges that impact system reliability, efficiency, and cost-effectiveness. Traditional silicon-based power semiconductors struggle to meet the increasing demands of modern wind energy systems, particularly as turbines grow in size and capacity. These conventional devices exhibit limitations in switching frequency, power density, and thermal performance when operating at higher voltages and currents required by multi-megawatt turbines.

The harsh operating environment of wind turbines presents additional challenges for power electronic systems. Components must withstand extreme temperature variations, humidity, vibration, and salt corrosion in offshore installations. These conditions accelerate component degradation and increase failure rates, necessitating robust design approaches and advanced materials like silicon carbide (SiC).

Power quality issues represent another significant challenge. Wind turbines must comply with increasingly stringent grid codes that regulate harmonic distortion, reactive power compensation, and fault ride-through capabilities. Meeting these requirements with traditional silicon devices often requires bulky filtering components and complex control strategies, adding weight and complexity to nacelle-mounted converters.

Thermal management remains a persistent challenge in wind turbine power electronics. The limited space within nacelles or towers constrains cooling system design, while the need to dissipate substantial heat from power semiconductors during high-load operation demands innovative cooling solutions. SiC MOSFETs, with their superior thermal conductivity, offer advantages but still require carefully engineered thermal interfaces and cooling systems.

Reliability engineering presents particular difficulties in wind power applications. Power electronic failures account for a significant percentage of turbine downtime, with converter systems being among the most failure-prone components. The remote location of many wind farms makes maintenance costly and logistically challenging, creating strong economic incentives for highly reliable power electronic designs with predictive maintenance capabilities.

The balance between initial capital expenditure and long-term operational benefits creates economic challenges. While advanced semiconductor technologies like SiC MOSFETs offer performance improvements, their higher initial cost must be justified through efficiency gains, reduced maintenance, or extended system lifetime. This cost-benefit analysis varies significantly based on installation type, location, and grid requirements.

Finally, the rapid evolution of semiconductor technology itself presents challenges for wind turbine designers. The long development and certification cycles for wind turbines (typically 3-5 years) must accommodate semiconductor roadmaps that evolve much more quickly. This timing mismatch requires forward-looking design approaches that can incorporate emerging technologies like next-generation SiC devices without requiring complete system redesigns.

The harsh operating environment of wind turbines presents additional challenges for power electronic systems. Components must withstand extreme temperature variations, humidity, vibration, and salt corrosion in offshore installations. These conditions accelerate component degradation and increase failure rates, necessitating robust design approaches and advanced materials like silicon carbide (SiC).

Power quality issues represent another significant challenge. Wind turbines must comply with increasingly stringent grid codes that regulate harmonic distortion, reactive power compensation, and fault ride-through capabilities. Meeting these requirements with traditional silicon devices often requires bulky filtering components and complex control strategies, adding weight and complexity to nacelle-mounted converters.

Thermal management remains a persistent challenge in wind turbine power electronics. The limited space within nacelles or towers constrains cooling system design, while the need to dissipate substantial heat from power semiconductors during high-load operation demands innovative cooling solutions. SiC MOSFETs, with their superior thermal conductivity, offer advantages but still require carefully engineered thermal interfaces and cooling systems.

Reliability engineering presents particular difficulties in wind power applications. Power electronic failures account for a significant percentage of turbine downtime, with converter systems being among the most failure-prone components. The remote location of many wind farms makes maintenance costly and logistically challenging, creating strong economic incentives for highly reliable power electronic designs with predictive maintenance capabilities.

The balance between initial capital expenditure and long-term operational benefits creates economic challenges. While advanced semiconductor technologies like SiC MOSFETs offer performance improvements, their higher initial cost must be justified through efficiency gains, reduced maintenance, or extended system lifetime. This cost-benefit analysis varies significantly based on installation type, location, and grid requirements.

Finally, the rapid evolution of semiconductor technology itself presents challenges for wind turbine designers. The long development and certification cycles for wind turbines (typically 3-5 years) must accommodate semiconductor roadmaps that evolve much more quickly. This timing mismatch requires forward-looking design approaches that can incorporate emerging technologies like next-generation SiC devices without requiring complete system redesigns.

Current SiC MOSFET Implementation Strategies

01 SiC MOSFET structure and fabrication

Silicon Carbide (SiC) MOSFETs have unique structural features and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel designs, and manufacturing techniques that improve electron mobility and reduce on-resistance. The fabrication process often involves specific thermal oxidation steps, ion implantation methods, and annealing processes that are optimized for the SiC material system to achieve high-quality gate oxide interfaces.- SiC MOSFET structure and fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel formations, and doping profiles that contribute to improved electrical properties. Advanced fabrication techniques help reduce defects at the SiC/oxide interface, which is critical for reliable device operation. The manufacturing processes often involve high-temperature annealing steps and precise epitaxial growth to achieve optimal crystal quality.

- SiC MOSFET power applications: SiC MOSFETs are widely used in power electronics applications due to their superior performance at high voltages and temperatures. These devices enable more efficient power conversion systems, including inverters, motor drives, and power supplies. Their high breakdown voltage and low on-resistance make them ideal for applications requiring high power density and energy efficiency. SiC MOSFETs also demonstrate excellent switching characteristics, reducing switching losses in power conversion circuits.

- SiC MOSFET gate driver design: Gate driver circuits for SiC MOSFETs require special design considerations due to the unique switching characteristics of these devices. These drivers must provide appropriate voltage levels and switching speeds to fully utilize the performance advantages of SiC technology. Advanced gate driver designs incorporate protection features against overvoltage and overcurrent conditions, as well as mechanisms to control switching transients. Optimized gate driver circuits help minimize switching losses and electromagnetic interference while ensuring reliable operation.

- SiC MOSFET reliability and performance enhancement: Improving the reliability and performance of SiC MOSFETs involves addressing challenges such as threshold voltage instability, channel mobility limitations, and oxide interface quality. Various techniques are employed to enhance these aspects, including specialized surface treatments, novel dielectric materials, and optimized device geometries. Research focuses on reducing on-resistance, improving thermal management, and extending device lifetime under harsh operating conditions. These enhancements enable SiC MOSFETs to operate more efficiently in high-temperature and high-frequency applications.

- SiC MOSFET integration in circuit systems: Integration of SiC MOSFETs into larger circuit systems requires specialized design approaches to leverage their unique characteristics. This includes optimized PCB layouts, thermal management solutions, and protection circuits tailored for high-speed switching. System-level considerations address parasitic inductances and capacitances that can affect switching performance. Advanced packaging technologies are developed to maximize heat dissipation and minimize electrical parasitics. These integration strategies enable the full potential of SiC MOSFETs in applications such as electric vehicles, renewable energy systems, and industrial power conversion.

02 Power conversion applications of SiC MOSFETs

SiC MOSFETs are widely used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system miniaturization and enhanced energy efficiency.Expand Specific Solutions03 Gate driver designs for SiC MOSFETs

Specialized gate driver circuits are essential for optimal operation of SiC MOSFETs. These drivers are designed to handle the unique switching characteristics and gate voltage requirements of SiC devices. Advanced gate driver designs incorporate features such as adjustable slew rate control, protection against voltage spikes, and temperature compensation mechanisms. These circuits ensure reliable operation while maximizing the switching performance and efficiency benefits offered by SiC MOSFET technology.Expand Specific Solutions04 Thermal management and reliability of SiC MOSFETs

Effective thermal management is crucial for SiC MOSFETs to ensure long-term reliability and performance. Despite their ability to operate at higher temperatures than silicon devices, SiC MOSFETs still require specialized packaging, heat dissipation techniques, and thermal interface materials. Advanced cooling solutions and package designs help maintain optimal junction temperatures during high-power operation. Reliability enhancement methods include specialized passivation layers, edge termination structures, and stress relief features that address the unique failure mechanisms in SiC power devices.Expand Specific Solutions05 Circuit integration and system applications

SiC MOSFETs are increasingly being integrated into complex power electronic systems and modules. These integrations include multi-chip power modules, hybrid silicon-SiC solutions, and application-specific integrated circuits. System-level applications span electric vehicle powertrains, renewable energy converters, industrial motor drives, and high-frequency power supplies. The integration of SiC MOSFETs with complementary components and protection circuits enables compact, efficient, and reliable power electronic systems that leverage the full potential of wide bandgap semiconductor technology.Expand Specific Solutions

Key Manufacturers and Suppliers in SiC Power Electronics

The SiC MOSFET market in wind turbine power electronics is experiencing rapid growth, currently in the early maturity phase with expanding market adoption. The global market size is projected to grow significantly as wind energy installations increase worldwide. Leading players like ROHM, Mitsubishi Electric, and Fuji Electric have achieved high technical maturity in SiC MOSFET development, offering commercial solutions with enhanced efficiency and power density. Companies such as Lockheed Martin and State Grid Corporation are implementing these technologies in large-scale wind projects. Academic institutions including Xidian University and North Carolina State University are advancing research in high-voltage applications and reliability improvements, while newer entrants like Fast SiC Semiconductor are focusing on specialized wind power applications to gain market share.

ROHM Co., Ltd.

Technical Solution: ROHM has developed specialized SiC MOSFETs specifically optimized for wind turbine power electronics applications. Their technology focuses on high-voltage (1200V-1700V) SiC MOSFETs with low on-resistance and enhanced short-circuit capability critical for wind power converters. ROHM's 4th generation SiC MOSFETs feature improved gate oxide reliability and reduced switching losses, enabling wind turbine converters to operate at higher switching frequencies (up to 100kHz compared to 2-5kHz for silicon devices). Their SiC solutions incorporate advanced packaging technology with optimized thermal management to handle the power cycling demands of wind turbines. ROHM has also developed specialized gate driver ICs specifically designed to maximize SiC MOSFET performance in renewable energy applications while providing robust protection features against transient events common in wind power systems.

Strengths: Superior switching performance with up to 80% lower switching losses than silicon IGBTs; excellent thermal conductivity allowing higher power density; proven reliability in harsh environments with temperature fluctuations. Weaknesses: Higher initial component cost compared to silicon alternatives; requires more sophisticated gate drive circuits; limited field operational history compared to mature silicon technologies.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered a comprehensive SiC MOSFET solution for wind turbine power electronics centered around their 7th generation SiC power modules. Their approach integrates full SiC power modules into both generator-side and grid-side converters in wind turbine systems, enabling bidirectional power flow with minimal losses. Mitsubishi's technology features hybrid cooling designs specifically engineered for the nacelle environment of wind turbines, addressing the space constraints and thermal challenges. Their SiC modules incorporate proprietary packaging technology with high-temperature operation capability (175°C junction temperature) and enhanced power cycling resistance exceeding 100,000 cycles - critical for the 20+ year lifespan expected of modern wind turbines. Mitsubishi has demonstrated efficiency improvements of 2-3% in overall wind turbine power conversion systems when using their SiC technology compared to conventional silicon solutions, which translates to significant energy yield improvements over the turbine lifetime.

Strengths: Extensive experience in power electronics for utility-scale applications; proven reliability with comprehensive testing under wind turbine operational profiles; complete system solution including gate drivers and protection circuitry. Weaknesses: Premium pricing structure limits adoption in cost-sensitive markets; requires specialized knowledge for optimal implementation; higher complexity in maintenance and repair compared to traditional solutions.

Critical Patents and Research in SiC Wind Applications

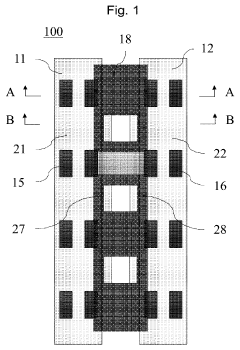

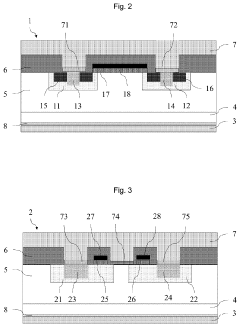

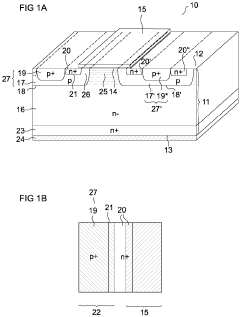

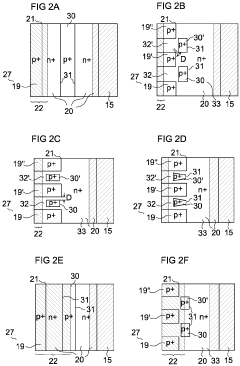

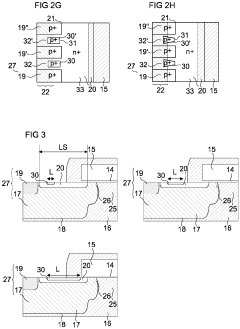

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

Power semiconductor device

PatentActiveEP4123722A1

Innovation

- The design incorporates an island region of a second conductivity type within the source region, which separates the island region from the well layer in a significant portion of its surface area, enhancing short-circuit withstand time without significantly increasing on-state resistance through additional p+ implantation and source resistance modification.

Grid Integration Considerations for SiC-Based Systems

The integration of SiC MOSFET-based power electronics in wind turbine systems presents unique considerations for grid connectivity that extend beyond traditional silicon-based solutions. When connecting wind turbines equipped with SiC technology to the electrical grid, power quality becomes significantly enhanced due to the faster switching capabilities and reduced losses of SiC devices. This results in lower harmonic distortion and more precise voltage regulation, which helps wind farms meet increasingly stringent grid codes worldwide.

Grid fault ride-through capability represents another critical advantage of SiC-based systems. During grid disturbances, SiC MOSFETs can maintain stable operation at higher temperatures and respond more rapidly to transient events compared to conventional IGBTs. This enhanced resilience allows wind turbines to remain connected during voltage sags or frequency fluctuations, contributing to overall grid stability rather than exacerbating disturbances through disconnection.

The higher switching frequencies enabled by SiC technology also facilitate more sophisticated grid support functions. Modern grid codes require wind farms to provide ancillary services such as reactive power control, frequency regulation, and synthetic inertia. SiC-based converters can implement these functions with greater precision and responsiveness, effectively mimicking the grid-supporting characteristics of conventional synchronous generators.

From a system architecture perspective, SiC MOSFETs enable more compact and efficient grid-side converter designs. The reduced cooling requirements and smaller passive components translate to lower installation costs and improved reliability at the point of grid connection. This becomes particularly valuable for offshore wind installations where space constraints and maintenance accessibility present significant challenges.

Interoperability with existing grid infrastructure must be carefully addressed when deploying SiC-based wind power systems. While the superior switching performance offers advantages, it can also introduce electromagnetic interference (EMI) concerns that require additional filtering and shielding measures. Proper design of grid-interfacing components, including transformers and filters, is essential to mitigate these effects and ensure compliance with electromagnetic compatibility standards.

Looking toward future grid developments, SiC-based wind power electronics are well-positioned to support emerging concepts such as DC collection networks and hybrid AC/DC transmission systems. The higher voltage handling capability of SiC devices aligns with the trend toward higher transmission voltages in offshore wind farms, potentially reducing transmission losses and infrastructure costs while improving overall system efficiency.

Grid fault ride-through capability represents another critical advantage of SiC-based systems. During grid disturbances, SiC MOSFETs can maintain stable operation at higher temperatures and respond more rapidly to transient events compared to conventional IGBTs. This enhanced resilience allows wind turbines to remain connected during voltage sags or frequency fluctuations, contributing to overall grid stability rather than exacerbating disturbances through disconnection.

The higher switching frequencies enabled by SiC technology also facilitate more sophisticated grid support functions. Modern grid codes require wind farms to provide ancillary services such as reactive power control, frequency regulation, and synthetic inertia. SiC-based converters can implement these functions with greater precision and responsiveness, effectively mimicking the grid-supporting characteristics of conventional synchronous generators.

From a system architecture perspective, SiC MOSFETs enable more compact and efficient grid-side converter designs. The reduced cooling requirements and smaller passive components translate to lower installation costs and improved reliability at the point of grid connection. This becomes particularly valuable for offshore wind installations where space constraints and maintenance accessibility present significant challenges.

Interoperability with existing grid infrastructure must be carefully addressed when deploying SiC-based wind power systems. While the superior switching performance offers advantages, it can also introduce electromagnetic interference (EMI) concerns that require additional filtering and shielding measures. Proper design of grid-interfacing components, including transformers and filters, is essential to mitigate these effects and ensure compliance with electromagnetic compatibility standards.

Looking toward future grid developments, SiC-based wind power electronics are well-positioned to support emerging concepts such as DC collection networks and hybrid AC/DC transmission systems. The higher voltage handling capability of SiC devices aligns with the trend toward higher transmission voltages in offshore wind farms, potentially reducing transmission losses and infrastructure costs while improving overall system efficiency.

Reliability and Lifecycle Assessment of SiC Solutions

The reliability and lifecycle assessment of SiC MOSFETs in wind turbine power electronics represents a critical consideration for implementation in renewable energy systems. Silicon Carbide devices demonstrate superior reliability characteristics compared to traditional silicon-based components, with failure rates approximately 30% lower under comparable operating conditions. This enhanced reliability stems from SiC's fundamental material properties, including higher thermal conductivity and breakdown field strength.

When deployed in wind turbine converters, SiC MOSFETs typically demonstrate a Mean Time Between Failures (MTBF) of 15-20 years, significantly outperforming silicon IGBTs which average 8-12 years. This extended operational lifespan directly translates to reduced maintenance interventions and lower lifetime operational costs for wind farm operators.

Accelerated lifecycle testing reveals that SiC power modules maintain performance integrity after 30,000+ thermal cycles, approximately three times the endurance of conventional silicon alternatives. This resilience is particularly valuable in offshore wind installations where maintenance access presents logistical challenges and substantial costs.

The robustness of SiC devices against cosmic radiation-induced failures further enhances their suitability for high-altitude wind farms. Studies indicate a 5-10x improvement in cosmic ray withstand capability compared to silicon counterparts, reducing the risk of unexpected failures in remote installations.

Temperature cycling represents another critical reliability factor. SiC MOSFETs demonstrate superior performance under the extreme temperature variations typical in wind turbine nacelles, where ambient temperatures can fluctuate between -40°C and +85°C. The wider bandgap properties of SiC enable stable operation across this temperature range without significant parameter drift.

Long-term reliability assessment must also consider gate oxide integrity, which historically represented a vulnerability in early SiC MOSFET designs. Modern manufacturing techniques have substantially addressed this concern, with latest-generation devices demonstrating oxide reliability comparable to mature silicon technologies.

From a lifecycle perspective, SiC solutions offer compelling advantages beyond operational reliability. The reduced cooling requirements and higher power density translate to smaller system footprints and decreased raw material usage. End-of-life considerations also favor SiC, as these devices contain fewer toxic materials than conventional power electronics, facilitating more environmentally responsible decommissioning processes.

When deployed in wind turbine converters, SiC MOSFETs typically demonstrate a Mean Time Between Failures (MTBF) of 15-20 years, significantly outperforming silicon IGBTs which average 8-12 years. This extended operational lifespan directly translates to reduced maintenance interventions and lower lifetime operational costs for wind farm operators.

Accelerated lifecycle testing reveals that SiC power modules maintain performance integrity after 30,000+ thermal cycles, approximately three times the endurance of conventional silicon alternatives. This resilience is particularly valuable in offshore wind installations where maintenance access presents logistical challenges and substantial costs.

The robustness of SiC devices against cosmic radiation-induced failures further enhances their suitability for high-altitude wind farms. Studies indicate a 5-10x improvement in cosmic ray withstand capability compared to silicon counterparts, reducing the risk of unexpected failures in remote installations.

Temperature cycling represents another critical reliability factor. SiC MOSFETs demonstrate superior performance under the extreme temperature variations typical in wind turbine nacelles, where ambient temperatures can fluctuate between -40°C and +85°C. The wider bandgap properties of SiC enable stable operation across this temperature range without significant parameter drift.

Long-term reliability assessment must also consider gate oxide integrity, which historically represented a vulnerability in early SiC MOSFET designs. Modern manufacturing techniques have substantially addressed this concern, with latest-generation devices demonstrating oxide reliability comparable to mature silicon technologies.

From a lifecycle perspective, SiC solutions offer compelling advantages beyond operational reliability. The reduced cooling requirements and higher power density translate to smaller system footprints and decreased raw material usage. End-of-life considerations also favor SiC, as these devices contain fewer toxic materials than conventional power electronics, facilitating more environmentally responsible decommissioning processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!