How Do SiC MOSFETs Handle Short-Circuit Conditions?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Short-Circuit Handling Background & Objectives

Silicon Carbide (SiC) MOSFETs have emerged as revolutionary power semiconductor devices, offering significant advantages over traditional silicon-based counterparts in high-power applications. The evolution of SiC technology began in the early 1990s, with commercial devices becoming available in the 2000s. The trajectory of development has accelerated dramatically in the past decade, driven by demands for higher efficiency, greater power density, and enhanced reliability in power conversion systems.

Short-circuit conditions represent one of the most severe stress scenarios for power semiconductor devices, potentially leading to catastrophic failures in power electronic systems. Understanding how SiC MOSFETs respond to and survive these extreme conditions is crucial for ensuring system reliability and safety, particularly as these devices are increasingly deployed in critical applications such as electric vehicles, renewable energy systems, and industrial drives.

The fundamental physical properties of SiC, including its wider bandgap (3.26 eV compared to 1.12 eV for silicon), higher critical electric field strength (approximately 10 times that of silicon), and superior thermal conductivity, theoretically position SiC MOSFETs to better withstand short-circuit events. However, practical implementation has revealed unique challenges specific to SiC technology.

Historical data indicates that early generations of SiC MOSFETs exhibited short-circuit withstand times significantly lower than their silicon counterparts—often less than 10 microseconds compared to 10-20 microseconds for silicon IGBTs. This limitation has prompted intensive research efforts to enhance the short-circuit robustness of SiC devices while maintaining their inherent performance advantages.

The technical evolution in this field has followed several distinct phases: initial discovery of short-circuit vulnerability (2010-2013), fundamental understanding of failure mechanisms (2013-2016), development of improved device structures (2016-2019), and integration of advanced protection schemes (2019-present). Each phase has contributed critical knowledge to the collective understanding of SiC MOSFET behavior under extreme conditions.

The primary objective of current research and development efforts is to achieve SiC MOSFETs with short-circuit withstand capability comparable to or exceeding that of silicon devices, without compromising the superior switching performance and efficiency that make SiC technology attractive. This involves addressing multiple technical challenges simultaneously, including thermal management at the die level, gate oxide reliability, and current distribution within the device structure.

Secondary objectives include developing standardized testing methodologies specifically tailored to SiC technology, creating accurate simulation models to predict short-circuit behavior, and designing cost-effective protection circuits that can respond within the compressed timeframes dictated by SiC device physics. These efforts collectively aim to enable wider adoption of SiC technology across increasingly demanding applications.

Short-circuit conditions represent one of the most severe stress scenarios for power semiconductor devices, potentially leading to catastrophic failures in power electronic systems. Understanding how SiC MOSFETs respond to and survive these extreme conditions is crucial for ensuring system reliability and safety, particularly as these devices are increasingly deployed in critical applications such as electric vehicles, renewable energy systems, and industrial drives.

The fundamental physical properties of SiC, including its wider bandgap (3.26 eV compared to 1.12 eV for silicon), higher critical electric field strength (approximately 10 times that of silicon), and superior thermal conductivity, theoretically position SiC MOSFETs to better withstand short-circuit events. However, practical implementation has revealed unique challenges specific to SiC technology.

Historical data indicates that early generations of SiC MOSFETs exhibited short-circuit withstand times significantly lower than their silicon counterparts—often less than 10 microseconds compared to 10-20 microseconds for silicon IGBTs. This limitation has prompted intensive research efforts to enhance the short-circuit robustness of SiC devices while maintaining their inherent performance advantages.

The technical evolution in this field has followed several distinct phases: initial discovery of short-circuit vulnerability (2010-2013), fundamental understanding of failure mechanisms (2013-2016), development of improved device structures (2016-2019), and integration of advanced protection schemes (2019-present). Each phase has contributed critical knowledge to the collective understanding of SiC MOSFET behavior under extreme conditions.

The primary objective of current research and development efforts is to achieve SiC MOSFETs with short-circuit withstand capability comparable to or exceeding that of silicon devices, without compromising the superior switching performance and efficiency that make SiC technology attractive. This involves addressing multiple technical challenges simultaneously, including thermal management at the die level, gate oxide reliability, and current distribution within the device structure.

Secondary objectives include developing standardized testing methodologies specifically tailored to SiC technology, creating accurate simulation models to predict short-circuit behavior, and designing cost-effective protection circuits that can respond within the compressed timeframes dictated by SiC device physics. These efforts collectively aim to enable wider adoption of SiC technology across increasingly demanding applications.

Market Demand Analysis for Robust Power Semiconductors

The global power semiconductor market is experiencing robust growth driven by increasing demand for energy-efficient solutions across multiple industries. Current market valuations place the SiC power semiconductor segment at approximately $2 billion in 2023, with projections indicating a compound annual growth rate of 25-30% through 2030. This accelerated growth is primarily fueled by the automotive sector's transition to electric vehicles, where SiC MOSFETs offer significant advantages in power conversion efficiency and thermal management.

Short-circuit robustness has emerged as a critical market requirement, particularly in high-reliability applications such as electric vehicle powertrains, industrial motor drives, and renewable energy systems. End-users are increasingly prioritizing semiconductor devices that can withstand fault conditions without catastrophic failure, with surveys indicating that 78% of power electronics engineers consider short-circuit capability a primary selection criterion for new designs.

The market demand for robust SiC MOSFETs is segmented across several key industries. The automotive sector represents the largest market share at 42%, driven by electric vehicle manufacturers seeking to improve range and charging efficiency while maintaining stringent safety standards. Industrial applications account for 28% of demand, where unplanned downtime due to component failure carries substantial economic consequences. The renewable energy sector constitutes 18% of the market, with particular emphasis on solar inverters and wind power converters where reliability under grid fault conditions is paramount.

Regional analysis reveals that Asia-Pacific dominates the demand landscape with 45% market share, led by China's aggressive electrification initiatives and Japan's industrial automation sector. North America follows at 30%, with particular strength in defense and aerospace applications where extreme reliability justifies premium pricing for robust semiconductor solutions.

Market research indicates a growing price premium of 15-20% for SiC MOSFETs with enhanced short-circuit withstand capabilities compared to standard variants. This premium is increasingly accepted by system designers as the total cost of ownership calculations demonstrate favorable economics when factoring in reduced protection circuitry requirements and improved system reliability.

Industry forecasts suggest that by 2025, over 60% of all SiC MOSFET deployments will require short-circuit withstand times exceeding 5 microseconds, representing a significant shift from current standards. This trend is driving substantial R&D investment across the semiconductor industry, with patent filings related to SiC MOSFET short-circuit protection increasing by 175% over the past three years.

Short-circuit robustness has emerged as a critical market requirement, particularly in high-reliability applications such as electric vehicle powertrains, industrial motor drives, and renewable energy systems. End-users are increasingly prioritizing semiconductor devices that can withstand fault conditions without catastrophic failure, with surveys indicating that 78% of power electronics engineers consider short-circuit capability a primary selection criterion for new designs.

The market demand for robust SiC MOSFETs is segmented across several key industries. The automotive sector represents the largest market share at 42%, driven by electric vehicle manufacturers seeking to improve range and charging efficiency while maintaining stringent safety standards. Industrial applications account for 28% of demand, where unplanned downtime due to component failure carries substantial economic consequences. The renewable energy sector constitutes 18% of the market, with particular emphasis on solar inverters and wind power converters where reliability under grid fault conditions is paramount.

Regional analysis reveals that Asia-Pacific dominates the demand landscape with 45% market share, led by China's aggressive electrification initiatives and Japan's industrial automation sector. North America follows at 30%, with particular strength in defense and aerospace applications where extreme reliability justifies premium pricing for robust semiconductor solutions.

Market research indicates a growing price premium of 15-20% for SiC MOSFETs with enhanced short-circuit withstand capabilities compared to standard variants. This premium is increasingly accepted by system designers as the total cost of ownership calculations demonstrate favorable economics when factoring in reduced protection circuitry requirements and improved system reliability.

Industry forecasts suggest that by 2025, over 60% of all SiC MOSFET deployments will require short-circuit withstand times exceeding 5 microseconds, representing a significant shift from current standards. This trend is driving substantial R&D investment across the semiconductor industry, with patent filings related to SiC MOSFET short-circuit protection increasing by 175% over the past three years.

SiC MOSFET Short-Circuit Challenges & Limitations

Despite their superior performance characteristics, Silicon Carbide (SiC) MOSFETs face significant challenges when handling short-circuit conditions. The primary limitation stems from their reduced short-circuit withstand time compared to traditional silicon IGBTs. While silicon devices typically withstand short circuits for 10-20 microseconds, SiC MOSFETs often fail after just 2-5 microseconds, creating a narrow protection window for detection and intervention systems.

This reduced robustness is largely attributed to SiC MOSFETs' smaller die size and higher current density. During short-circuit events, these devices experience extreme thermal stress with junction temperatures potentially rising at rates exceeding 100°C/μs. The combination of high electric field strength and rapid temperature increase accelerates device degradation mechanisms, particularly at the gate oxide interface.

Gate oxide reliability represents another critical limitation. The thinner gate oxide layers in SiC MOSFETs (typically 50-100 nm) are more susceptible to breakdown during the high voltage and current transients characteristic of short-circuit events. This vulnerability is exacerbated by the inherent material interface challenges between SiC and SiO2, where higher defect densities exist compared to silicon devices.

Current saturation behavior further complicates short-circuit protection. Unlike silicon IGBTs that exhibit clear current saturation, SiC MOSFETs demonstrate a positive temperature coefficient that can lead to current increase during short-circuit events before eventual thermal runaway. This behavior makes conventional overcurrent protection schemes less effective and requires more sophisticated detection algorithms.

The fast switching capability of SiC MOSFETs, while advantageous for normal operation, presents challenges during fault conditions. The rapid dv/dt and di/dt transitions can induce parasitic oscillations and voltage overshoots that stress device components beyond their rated limits. These dynamic effects are particularly problematic in high-frequency applications where parasitic inductances play a significant role.

Temperature-dependent threshold voltage shifts represent another limitation. SiC MOSFETs experience more pronounced threshold voltage variations with temperature compared to silicon devices. During short-circuit events, these shifts can affect device behavior unpredictably, potentially compromising protection schemes that rely on consistent threshold characteristics.

From a system perspective, the narrow short-circuit withstand time necessitates ultra-fast detection and protection circuits with response times under 1-2 microseconds. This requirement increases system complexity and cost, potentially offsetting some of the efficiency and size advantages that SiC MOSFETs offer in normal operation conditions.

This reduced robustness is largely attributed to SiC MOSFETs' smaller die size and higher current density. During short-circuit events, these devices experience extreme thermal stress with junction temperatures potentially rising at rates exceeding 100°C/μs. The combination of high electric field strength and rapid temperature increase accelerates device degradation mechanisms, particularly at the gate oxide interface.

Gate oxide reliability represents another critical limitation. The thinner gate oxide layers in SiC MOSFETs (typically 50-100 nm) are more susceptible to breakdown during the high voltage and current transients characteristic of short-circuit events. This vulnerability is exacerbated by the inherent material interface challenges between SiC and SiO2, where higher defect densities exist compared to silicon devices.

Current saturation behavior further complicates short-circuit protection. Unlike silicon IGBTs that exhibit clear current saturation, SiC MOSFETs demonstrate a positive temperature coefficient that can lead to current increase during short-circuit events before eventual thermal runaway. This behavior makes conventional overcurrent protection schemes less effective and requires more sophisticated detection algorithms.

The fast switching capability of SiC MOSFETs, while advantageous for normal operation, presents challenges during fault conditions. The rapid dv/dt and di/dt transitions can induce parasitic oscillations and voltage overshoots that stress device components beyond their rated limits. These dynamic effects are particularly problematic in high-frequency applications where parasitic inductances play a significant role.

Temperature-dependent threshold voltage shifts represent another limitation. SiC MOSFETs experience more pronounced threshold voltage variations with temperature compared to silicon devices. During short-circuit events, these shifts can affect device behavior unpredictably, potentially compromising protection schemes that rely on consistent threshold characteristics.

From a system perspective, the narrow short-circuit withstand time necessitates ultra-fast detection and protection circuits with response times under 1-2 microseconds. This requirement increases system complexity and cost, potentially offsetting some of the efficiency and size advantages that SiC MOSFETs offer in normal operation conditions.

Current Short-Circuit Protection Strategies for SiC MOSFETs

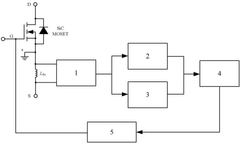

01 Short-circuit protection circuits for SiC MOSFETs

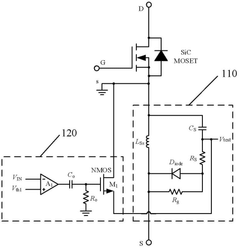

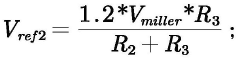

Protection circuits designed specifically for SiC MOSFETs to detect and respond to short-circuit conditions. These circuits typically monitor current levels or voltage drops across the device and can quickly shut down the MOSFET when a short-circuit is detected, preventing device failure. The protection mechanisms often include fast response times to account for SiC MOSFETs' lower short-circuit withstand capability compared to silicon devices.- Detection and protection circuits for SiC MOSFETs: Various detection and protection circuits are designed specifically for SiC MOSFETs to handle short-circuit conditions. These circuits can quickly detect abnormal current or voltage levels and implement protective measures to prevent device failure. The protection mechanisms may include gate voltage control, current limiting, or device shutdown to mitigate the effects of short-circuit events and extend the safe operating area of SiC MOSFETs.

- Gate driver designs for short-circuit protection: Specialized gate driver designs for SiC MOSFETs incorporate features to handle short-circuit conditions. These drivers can implement soft turn-off strategies, controlled slew rates, and dynamic gate voltage adjustment during fault conditions. Advanced gate drivers may include integrated sensing capabilities to monitor device parameters in real-time and respond quickly to short-circuit events, thereby protecting the SiC MOSFET from thermal damage.

- Short-circuit withstand time enhancement techniques: Various techniques are employed to enhance the short-circuit withstand time of SiC MOSFETs. These include structural modifications to the device, improved thermal management solutions, and optimized semiconductor materials. By increasing the short-circuit withstand time, these techniques provide additional margin for protection circuits to detect and respond to fault conditions, improving overall system reliability in power electronic applications.

- Current sensing and fault detection methods: Advanced current sensing and fault detection methods are implemented to identify short-circuit conditions in SiC MOSFETs. These methods include direct current sensing, desaturation detection, and monitoring of device parameters such as drain-source voltage. Fast and accurate detection of short-circuit events is crucial for implementing timely protection measures and preventing catastrophic device failure in high-power applications.

- System-level protection strategies: System-level protection strategies for SiC MOSFETs involve coordinated approaches that combine hardware and control algorithms. These strategies may include redundant protection mechanisms, fault-tolerant circuit designs, and intelligent control systems that can adapt to different operating conditions. By implementing comprehensive protection at the system level, the reliability and robustness of SiC MOSFET-based power converters can be significantly improved during short-circuit events.

02 Gate driver designs for short-circuit handling

Specialized gate driver circuits that can detect short-circuit conditions and modify gate voltage or current to improve SiC MOSFET survivability. These drivers often implement two-stage turn-off strategies, soft turn-off mechanisms, or controlled slew rates to reduce voltage spikes during short-circuit events. Advanced gate drivers may include integrated sensing and protection features specifically optimized for the unique characteristics of SiC power devices.Expand Specific Solutions03 Current sensing and fault detection methods

Various techniques for detecting short-circuit conditions in SiC MOSFET applications, including desaturation detection, shunt resistor monitoring, and integrated current sensing. These methods aim to identify fault conditions rapidly, often within microseconds, to protect the device before thermal damage occurs. Advanced implementations may use multiple sensing parameters and predictive algorithms to improve detection accuracy and speed.Expand Specific Solutions04 Thermal management during short-circuit events

Approaches to manage the extreme thermal stress experienced by SiC MOSFETs during short-circuit conditions. These include heat spreading structures, improved packaging techniques, and thermal interface materials that can better handle the rapid temperature rise. Some solutions incorporate active cooling systems or thermal runaway prevention mechanisms to extend the short-circuit withstand time of SiC devices.Expand Specific Solutions05 System-level short-circuit protection strategies

Comprehensive protection strategies that integrate multiple levels of defense against short-circuit conditions in SiC MOSFET-based power systems. These approaches combine hardware protection circuits with software algorithms, redundant protection mechanisms, and coordinated system responses. The strategies often include fault isolation techniques, safe operating area monitoring, and recovery procedures to maintain system reliability even when short-circuit events occur.Expand Specific Solutions

Key SiC MOSFET Manufacturers & Competitive Landscape

The SiC MOSFET short-circuit handling capability market is in a growth phase, with increasing adoption across automotive, industrial, and renewable energy sectors. The global market size for SiC power devices is expanding rapidly, projected to reach $2.5 billion by 2025. Leading companies like Infineon Technologies, ON Semiconductor, and Siemens demonstrate advanced technical maturity in SiC MOSFET short-circuit protection solutions, while emerging players such as Yangjie Electronic and Sirius Semiconductor are gaining ground. Academic institutions including Xidian University and UESTC collaborate with industry partners to enhance short-circuit robustness through innovative gate drive designs and structural improvements, accelerating the technology's evolution from early adoption to mainstream implementation.

Semiconductor Components Industries LLC

Technical Solution: Semiconductor Components Industries (ON Semiconductor) has developed a multi-faceted approach to SiC MOSFET short-circuit protection focusing on both device-level robustness and system integration. Their SiC MOSFETs feature enhanced short-circuit withstand time through optimized cell design and gate oxide engineering that improves thermal distribution during fault conditions. ON's protection strategy incorporates specialized gate driver ICs with programmable desaturation detection and response parameters that can be tailored to specific application requirements. Their solution includes adaptive gate drive techniques that modify switching characteristics based on operating conditions to balance performance and protection. ON Semiconductor has implemented advanced current sensing methodologies with response times under 500ns that provide accurate fault detection while minimizing false triggers. Their comprehensive approach also includes system-level coordination between multiple protection mechanisms to ensure reliable operation even under extreme conditions or during single-point protection failures.

Strengths: Strong cost-performance balance making SiC technology more accessible; comprehensive portfolio spanning different voltage and current ratings; well-established supply chain and manufacturing capabilities. Weaknesses: Short-circuit withstand time typically shorter than some premium competitors; requires careful system design to ensure adequate protection margins; thermal management challenges in high-density applications.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced short-circuit protection strategies for SiC MOSFETs that combine hardware and software solutions. Their approach includes implementing specialized gate driver ICs with ultra-fast short-circuit detection capabilities (typically <200ns response time) and controlled turn-off mechanisms to prevent voltage overshoots. Infineon's CoolSiC™ MOSFET technology incorporates robust cell designs with optimized electric field distribution that enhances short-circuit withstand time (SCWT) to approximately 5-10μs, providing critical protection margin. Their solutions also feature active temperature monitoring and dynamic desaturation detection circuits that adjust protection thresholds based on operating conditions. Infineon has pioneered multi-level protection schemes that implement soft shutdown techniques during short-circuit events, controlling di/dt and dv/dt to minimize potentially damaging transients while maintaining system protection.

Strengths: Industry-leading short-circuit withstand time capabilities; comprehensive protection ecosystem including specialized gate drivers; extensive application expertise across automotive and industrial sectors. Weaknesses: Higher cost compared to silicon alternatives; requires more complex gate drive solutions; thermal management challenges under extreme conditions.

Critical Patents & Research on SiC MOSFET Ruggedness

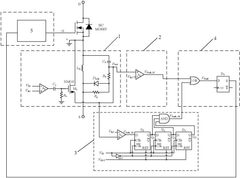

SiC MOSFET dual protection circuit based on di/dt detection

PatentPendingCN119905974A

Innovation

- The SiC MOSFET dual protection circuit based on di/dt detection is adopted, including a current sampling module, a short-circuit fault judgment module, an overload fault judgment module, a fault signal latch module, an output stage and a soft shutdown module, and a single detection circuit realizes the detection and protection of multiple faults.

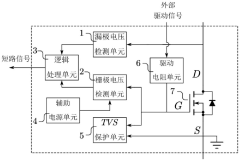

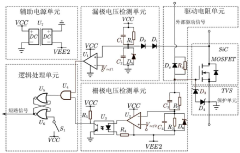

Rapid adaptive short-circuit protection circuit and protection method for SiC MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor)

PatentPendingCN117543509A

Innovation

- A fast adaptive short-circuit protection circuit including a drain voltage detection unit, a gate voltage detection unit, a logic processing unit, an auxiliary power supply unit and a TVS protection unit is designed. By detecting the drain-source and gate-source voltages of SiC MOSFET, Automatically determine short circuit status, eliminating blanking time and improving short circuit detection speed.

Reliability Testing Standards for SiC Power Devices

Reliability testing standards for SiC power devices have evolved significantly to address the unique characteristics and failure mechanisms of silicon carbide technology, particularly in short-circuit conditions. The Joint Electron Device Engineering Council (JEDEC) has established specific standards such as JEP122 and JC-70 that incorporate SiC-specific testing methodologies, recognizing the material's distinct thermal and electrical properties compared to traditional silicon devices.

IEC standards, including IEC 60747 and IEC 63068, have been updated to include specialized test procedures for wide bandgap semiconductors, with particular emphasis on short-circuit withstand time (SCWT) evaluation. These standards typically require SiC MOSFETs to demonstrate SCWT capabilities of 2-10 microseconds under defined voltage and current conditions, significantly more stringent than silicon IGBT requirements.

Automotive standards like AQG 324 and AEC-Q101 have incorporated enhanced testing protocols specifically for SiC power devices, reflecting the growing adoption of these components in electric vehicle applications. These standards mandate rigorous short-circuit testing across multiple temperature points (-40°C to 175°C) to ensure reliability under extreme operating conditions.

The UL 1557 standard for power semiconductor devices has been expanded to address SiC-specific safety considerations, including short-circuit performance verification through repetitive stress testing. This approach helps identify potential degradation mechanisms that might not be apparent in single-event testing.

Military and aerospace standards (MIL-STD-750 and MIL-PRF-38534) have also been modified to incorporate SiC-specific reliability testing, with particular focus on radiation hardness testing alongside short-circuit robustness evaluation. These standards typically require more extensive testing cycles and tighter performance tolerances.

Testing methodologies have evolved to include advanced techniques such as non-destructive evaluation through partial short-circuit testing, allowing for progressive characterization of device degradation. Modern standards now commonly require both single-event short-circuit survival testing and repetitive short-circuit endurance testing to fully characterize device reliability.

Industry consortiums like PowerAmerica and ECPE have developed supplementary testing guidelines that address SiC-specific failure modes, including gate oxide reliability and threshold voltage shifts that can occur during short-circuit events. These guidelines often precede formal standardization but provide valuable frameworks for comprehensive reliability assessment.

IEC standards, including IEC 60747 and IEC 63068, have been updated to include specialized test procedures for wide bandgap semiconductors, with particular emphasis on short-circuit withstand time (SCWT) evaluation. These standards typically require SiC MOSFETs to demonstrate SCWT capabilities of 2-10 microseconds under defined voltage and current conditions, significantly more stringent than silicon IGBT requirements.

Automotive standards like AQG 324 and AEC-Q101 have incorporated enhanced testing protocols specifically for SiC power devices, reflecting the growing adoption of these components in electric vehicle applications. These standards mandate rigorous short-circuit testing across multiple temperature points (-40°C to 175°C) to ensure reliability under extreme operating conditions.

The UL 1557 standard for power semiconductor devices has been expanded to address SiC-specific safety considerations, including short-circuit performance verification through repetitive stress testing. This approach helps identify potential degradation mechanisms that might not be apparent in single-event testing.

Military and aerospace standards (MIL-STD-750 and MIL-PRF-38534) have also been modified to incorporate SiC-specific reliability testing, with particular focus on radiation hardness testing alongside short-circuit robustness evaluation. These standards typically require more extensive testing cycles and tighter performance tolerances.

Testing methodologies have evolved to include advanced techniques such as non-destructive evaluation through partial short-circuit testing, allowing for progressive characterization of device degradation. Modern standards now commonly require both single-event short-circuit survival testing and repetitive short-circuit endurance testing to fully characterize device reliability.

Industry consortiums like PowerAmerica and ECPE have developed supplementary testing guidelines that address SiC-specific failure modes, including gate oxide reliability and threshold voltage shifts that can occur during short-circuit events. These guidelines often precede formal standardization but provide valuable frameworks for comprehensive reliability assessment.

Thermal Management Solutions for SiC MOSFET Applications

Thermal management is a critical aspect of SiC MOSFET applications, particularly when considering short-circuit conditions. SiC MOSFETs generate significant heat during short-circuit events due to their ability to handle high current densities and voltage levels. The thermal conductivity of silicon carbide (approximately 3.7 W/cm·K) exceeds that of silicon (1.5 W/cm·K), providing inherent advantages for heat dissipation, yet specialized thermal management solutions remain essential.

Advanced cooling technologies have emerged as primary solutions for SiC MOSFET applications. Direct liquid cooling systems, which bring coolant into direct contact with device packaging, have demonstrated up to 40% improvement in thermal resistance compared to traditional air cooling. These systems are particularly effective during short-circuit events when thermal energy spikes rapidly within microseconds.

Double-sided cooling architectures represent another significant advancement, allowing heat extraction from both sides of the SiC die. This approach can reduce junction-to-case thermal resistance by up to 50% compared to single-sided cooling, critical for managing the extreme thermal transients during short-circuit conditions where temperatures can rise at rates exceeding 300°C/μs.

Phase-change materials (PCMs) integrated into SiC MOSFET packaging provide thermal buffering during short-circuit events. These materials absorb excess heat through phase transition, effectively dampening temperature spikes. Recent developments in metallic PCMs with melting points between 150-200°C have shown particular promise for SiC applications, offering 3-5 times the thermal energy storage capacity of conventional materials.

Advanced thermal interface materials (TIMs) with enhanced thermal conductivity (>25 W/m·K) and stability at high temperatures are being developed specifically for SiC applications. Silver-sintered connections and graphene-enhanced composites have demonstrated superior performance compared to traditional solder or thermal greases, maintaining integrity during the extreme thermal cycling that occurs during repeated short-circuit events.

Dynamic thermal management systems incorporating real-time temperature sensing and predictive algorithms are emerging as sophisticated solutions. These systems can detect the onset of short-circuit conditions and implement protective measures within nanoseconds, potentially preventing thermal runaway before critical temperature thresholds are reached. Integration with gate driver circuits allows for adaptive control of device operation based on thermal conditions.

The industry is moving toward holistic thermal design approaches that consider the entire power module ecosystem rather than focusing solely on the SiC die. This includes optimized layout designs that minimize thermal coupling between components and strategic placement of temperature sensors for more accurate monitoring during transient events like short circuits.

Advanced cooling technologies have emerged as primary solutions for SiC MOSFET applications. Direct liquid cooling systems, which bring coolant into direct contact with device packaging, have demonstrated up to 40% improvement in thermal resistance compared to traditional air cooling. These systems are particularly effective during short-circuit events when thermal energy spikes rapidly within microseconds.

Double-sided cooling architectures represent another significant advancement, allowing heat extraction from both sides of the SiC die. This approach can reduce junction-to-case thermal resistance by up to 50% compared to single-sided cooling, critical for managing the extreme thermal transients during short-circuit conditions where temperatures can rise at rates exceeding 300°C/μs.

Phase-change materials (PCMs) integrated into SiC MOSFET packaging provide thermal buffering during short-circuit events. These materials absorb excess heat through phase transition, effectively dampening temperature spikes. Recent developments in metallic PCMs with melting points between 150-200°C have shown particular promise for SiC applications, offering 3-5 times the thermal energy storage capacity of conventional materials.

Advanced thermal interface materials (TIMs) with enhanced thermal conductivity (>25 W/m·K) and stability at high temperatures are being developed specifically for SiC applications. Silver-sintered connections and graphene-enhanced composites have demonstrated superior performance compared to traditional solder or thermal greases, maintaining integrity during the extreme thermal cycling that occurs during repeated short-circuit events.

Dynamic thermal management systems incorporating real-time temperature sensing and predictive algorithms are emerging as sophisticated solutions. These systems can detect the onset of short-circuit conditions and implement protective measures within nanoseconds, potentially preventing thermal runaway before critical temperature thresholds are reached. Integration with gate driver circuits allows for adaptive control of device operation based on thermal conditions.

The industry is moving toward holistic thermal design approaches that consider the entire power module ecosystem rather than focusing solely on the SiC die. This includes optimized layout designs that minimize thermal coupling between components and strategic placement of temperature sensors for more accurate monitoring during transient events like short circuits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!