Power Module Design Using Hybrid SiC MOSFET And IGBT Solutions

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC-IGBT Hybrid Power Module Background and Objectives

Power modules combining Silicon Carbide (SiC) MOSFETs and Insulated Gate Bipolar Transistors (IGBTs) represent a significant evolution in power electronics technology. This hybrid approach has emerged from decades of power semiconductor development, beginning with the dominance of silicon-based devices and progressing through various technological iterations to address increasing demands for efficiency and performance in power conversion systems.

The evolution of power electronics has been driven by the need for higher power density, improved thermal management, and enhanced switching characteristics. Traditional silicon-based IGBTs have long been the industry standard for medium to high-voltage applications due to their robust performance and cost-effectiveness. However, they face inherent limitations in switching frequency and thermal performance that impact overall system efficiency.

SiC technology emerged as a promising alternative, offering superior material properties including wider bandgap, higher thermal conductivity, and greater electric field strength. These characteristics enable SiC devices to operate at higher temperatures, voltages, and frequencies while maintaining lower switching and conduction losses compared to their silicon counterparts.

The hybrid SiC MOSFET and IGBT solution represents a strategic technological compromise that leverages the strengths of both technologies. This approach aims to optimize performance metrics across various operating conditions while managing implementation costs that would be prohibitive with pure SiC solutions in certain applications.

Current market trends indicate growing adoption of power electronics in electric vehicles, renewable energy systems, industrial drives, and grid infrastructure. These applications demand increasingly efficient power conversion with minimal losses, compact form factors, and reliable operation under challenging environmental conditions.

The primary technical objectives for hybrid SiC-IGBT power modules include achieving optimal balance between switching performance and conduction losses across diverse load profiles. Engineers seek to develop modules that maintain the robustness and surge capability of IGBTs while incorporating the high-frequency switching benefits of SiC MOSFETs.

Additional goals include improving thermal management through advanced packaging techniques, enhancing reliability through optimized gate drive designs, and developing cost-effective manufacturing processes that can scale with increasing market demand.

The integration of these disparate semiconductor technologies presents unique challenges in terms of gate drive requirements, protection circuitry, and thermal design considerations. Successful implementation requires comprehensive understanding of the dynamic interaction between SiC and IGBT devices under various operating conditions.

As the power electronics industry continues its trajectory toward higher efficiency and power density, hybrid SiC-IGBT solutions represent an important transitional technology that bridges current capabilities with future requirements, potentially enabling new applications and performance standards previously unattainable with single-technology approaches.

The evolution of power electronics has been driven by the need for higher power density, improved thermal management, and enhanced switching characteristics. Traditional silicon-based IGBTs have long been the industry standard for medium to high-voltage applications due to their robust performance and cost-effectiveness. However, they face inherent limitations in switching frequency and thermal performance that impact overall system efficiency.

SiC technology emerged as a promising alternative, offering superior material properties including wider bandgap, higher thermal conductivity, and greater electric field strength. These characteristics enable SiC devices to operate at higher temperatures, voltages, and frequencies while maintaining lower switching and conduction losses compared to their silicon counterparts.

The hybrid SiC MOSFET and IGBT solution represents a strategic technological compromise that leverages the strengths of both technologies. This approach aims to optimize performance metrics across various operating conditions while managing implementation costs that would be prohibitive with pure SiC solutions in certain applications.

Current market trends indicate growing adoption of power electronics in electric vehicles, renewable energy systems, industrial drives, and grid infrastructure. These applications demand increasingly efficient power conversion with minimal losses, compact form factors, and reliable operation under challenging environmental conditions.

The primary technical objectives for hybrid SiC-IGBT power modules include achieving optimal balance between switching performance and conduction losses across diverse load profiles. Engineers seek to develop modules that maintain the robustness and surge capability of IGBTs while incorporating the high-frequency switching benefits of SiC MOSFETs.

Additional goals include improving thermal management through advanced packaging techniques, enhancing reliability through optimized gate drive designs, and developing cost-effective manufacturing processes that can scale with increasing market demand.

The integration of these disparate semiconductor technologies presents unique challenges in terms of gate drive requirements, protection circuitry, and thermal design considerations. Successful implementation requires comprehensive understanding of the dynamic interaction between SiC and IGBT devices under various operating conditions.

As the power electronics industry continues its trajectory toward higher efficiency and power density, hybrid SiC-IGBT solutions represent an important transitional technology that bridges current capabilities with future requirements, potentially enabling new applications and performance standards previously unattainable with single-technology approaches.

Market Demand Analysis for Hybrid Power Solutions

The global power electronics market is witnessing a significant shift toward hybrid power solutions that combine Silicon Carbide (SiC) MOSFETs with traditional Insulated Gate Bipolar Transistors (IGBTs). This market transformation is primarily driven by the increasing demand for energy-efficient power conversion systems across multiple industries. According to recent market research, the power module market is projected to reach $25 billion by 2027, with hybrid solutions expected to capture approximately 18% of this market.

The automotive sector represents the largest demand driver for hybrid power modules, particularly in electric vehicle (EV) applications. As EV production continues to accelerate globally, manufacturers are seeking power solutions that maximize efficiency while managing costs. Hybrid SiC MOSFET and IGBT modules offer an optimal balance, allowing automotive companies to achieve higher power density and switching frequencies than pure IGBT solutions, but at a lower cost than full SiC implementations.

Industrial automation represents another significant market segment, with increasing adoption of variable frequency drives and motor control systems that benefit from the performance advantages of hybrid power modules. The industrial sector values the reliability improvements and energy savings that these hybrid solutions provide, particularly in high-power applications where system efficiency directly impacts operational costs.

Renewable energy systems, particularly solar inverters and wind power converters, constitute a rapidly growing application area for hybrid power modules. The market demand in this sector is being fueled by global sustainability initiatives and the decreasing cost of renewable energy installations. Hybrid power solutions enable higher conversion efficiencies, which directly translate to improved return on investment for renewable energy projects.

Consumer electronics and data center power supplies are emerging markets for hybrid power solutions, driven by the need for higher power density and improved thermal performance. The compact size and enhanced efficiency of hybrid modules address the space constraints and energy consumption concerns in these applications.

Regional analysis indicates that Asia-Pacific, particularly China, Japan, and South Korea, represents the largest market for hybrid power modules, followed by Europe and North America. This geographic distribution aligns with the concentration of automotive manufacturing, industrial automation, and electronics production in these regions.

Market surveys indicate that customers prioritize three key factors when selecting power module solutions: efficiency improvements, thermal performance, and cost-effectiveness. Hybrid SiC MOSFET and IGBT solutions address these priorities by offering performance improvements over traditional solutions while maintaining reasonable cost structures compared to full wide-bandgap semiconductor implementations.

The automotive sector represents the largest demand driver for hybrid power modules, particularly in electric vehicle (EV) applications. As EV production continues to accelerate globally, manufacturers are seeking power solutions that maximize efficiency while managing costs. Hybrid SiC MOSFET and IGBT modules offer an optimal balance, allowing automotive companies to achieve higher power density and switching frequencies than pure IGBT solutions, but at a lower cost than full SiC implementations.

Industrial automation represents another significant market segment, with increasing adoption of variable frequency drives and motor control systems that benefit from the performance advantages of hybrid power modules. The industrial sector values the reliability improvements and energy savings that these hybrid solutions provide, particularly in high-power applications where system efficiency directly impacts operational costs.

Renewable energy systems, particularly solar inverters and wind power converters, constitute a rapidly growing application area for hybrid power modules. The market demand in this sector is being fueled by global sustainability initiatives and the decreasing cost of renewable energy installations. Hybrid power solutions enable higher conversion efficiencies, which directly translate to improved return on investment for renewable energy projects.

Consumer electronics and data center power supplies are emerging markets for hybrid power solutions, driven by the need for higher power density and improved thermal performance. The compact size and enhanced efficiency of hybrid modules address the space constraints and energy consumption concerns in these applications.

Regional analysis indicates that Asia-Pacific, particularly China, Japan, and South Korea, represents the largest market for hybrid power modules, followed by Europe and North America. This geographic distribution aligns with the concentration of automotive manufacturing, industrial automation, and electronics production in these regions.

Market surveys indicate that customers prioritize three key factors when selecting power module solutions: efficiency improvements, thermal performance, and cost-effectiveness. Hybrid SiC MOSFET and IGBT solutions address these priorities by offering performance improvements over traditional solutions while maintaining reasonable cost structures compared to full wide-bandgap semiconductor implementations.

Current State and Challenges in Power Semiconductor Technology

Power semiconductor technology has witnessed significant advancements over the past decades, evolving from traditional silicon-based devices to wide bandgap (WBG) semiconductors. Currently, the industry is experiencing a transition phase where silicon-based IGBTs (Insulated Gate Bipolar Transistors) still dominate many high-power applications, while Silicon Carbide (SiC) MOSFETs are rapidly gaining market share due to their superior performance characteristics.

The global power semiconductor market reached approximately $46 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2028. This growth is primarily driven by increasing demand for energy-efficient power conversion systems across automotive, industrial, renewable energy, and consumer electronics sectors. SiC devices, specifically, have seen a market expansion of over 30% annually, indicating strong industry adoption despite higher costs.

Despite these advancements, several significant challenges persist in power semiconductor technology. Cost remains a primary barrier for widespread SiC adoption, with SiC MOSFETs typically costing 3-5 times more than their silicon counterparts. Manufacturing complexities and lower yields contribute to this cost differential, though economies of scale are gradually reducing this gap.

Reliability concerns present another major challenge, particularly in hybrid solutions combining SiC MOSFETs and IGBTs. These systems must withstand harsh operating conditions including high temperatures (175°C+), thermal cycling, and high voltage stresses. Gate oxide reliability in SiC MOSFETs remains less mature than silicon technology, requiring additional protection circuits and careful design considerations.

Thermal management represents a critical challenge in power module design. While SiC can operate at higher temperatures than silicon, this advantage is often limited by packaging technologies that haven't evolved at the same pace as the semiconductor materials themselves. Current packaging solutions struggle to efficiently dissipate heat from increasingly power-dense modules.

The integration challenges between SiC MOSFETs and IGBTs in hybrid solutions are substantial. Different switching characteristics, gate drive requirements, and thermal behaviors necessitate sophisticated control strategies and protection mechanisms. Parasitic inductances in hybrid module layouts can lead to voltage overshoots and electromagnetic interference issues that compromise system reliability.

Geographically, power semiconductor technology development shows distinct patterns. Japan and Europe lead in IGBT technology, while the United States has established strong positions in SiC development. China is rapidly expanding its capabilities across both technologies, with significant government investment in domestic supply chains. This global distribution creates both competitive pressures and opportunities for technological collaboration.

The global power semiconductor market reached approximately $46 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2028. This growth is primarily driven by increasing demand for energy-efficient power conversion systems across automotive, industrial, renewable energy, and consumer electronics sectors. SiC devices, specifically, have seen a market expansion of over 30% annually, indicating strong industry adoption despite higher costs.

Despite these advancements, several significant challenges persist in power semiconductor technology. Cost remains a primary barrier for widespread SiC adoption, with SiC MOSFETs typically costing 3-5 times more than their silicon counterparts. Manufacturing complexities and lower yields contribute to this cost differential, though economies of scale are gradually reducing this gap.

Reliability concerns present another major challenge, particularly in hybrid solutions combining SiC MOSFETs and IGBTs. These systems must withstand harsh operating conditions including high temperatures (175°C+), thermal cycling, and high voltage stresses. Gate oxide reliability in SiC MOSFETs remains less mature than silicon technology, requiring additional protection circuits and careful design considerations.

Thermal management represents a critical challenge in power module design. While SiC can operate at higher temperatures than silicon, this advantage is often limited by packaging technologies that haven't evolved at the same pace as the semiconductor materials themselves. Current packaging solutions struggle to efficiently dissipate heat from increasingly power-dense modules.

The integration challenges between SiC MOSFETs and IGBTs in hybrid solutions are substantial. Different switching characteristics, gate drive requirements, and thermal behaviors necessitate sophisticated control strategies and protection mechanisms. Parasitic inductances in hybrid module layouts can lead to voltage overshoots and electromagnetic interference issues that compromise system reliability.

Geographically, power semiconductor technology development shows distinct patterns. Japan and Europe lead in IGBT technology, while the United States has established strong positions in SiC development. China is rapidly expanding its capabilities across both technologies, with significant government investment in domestic supply chains. This global distribution creates both competitive pressures and opportunities for technological collaboration.

Current Hybrid SiC-IGBT Integration Approaches

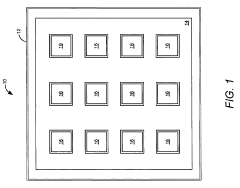

01 Hybrid SiC MOSFET and IGBT module design architecture

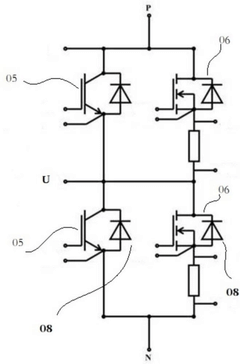

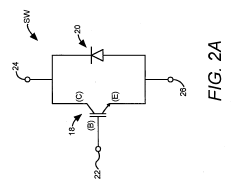

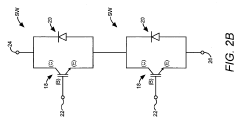

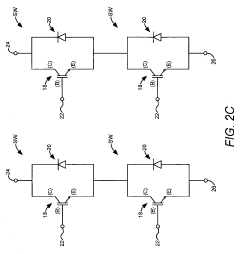

Hybrid power modules that integrate Silicon Carbide (SiC) MOSFETs with Insulated Gate Bipolar Transistors (IGBTs) leverage the advantages of both technologies. The architecture typically features SiC MOSFETs for high-frequency switching operations and IGBTs for handling high current loads. This combination optimizes switching performance while maintaining cost-effectiveness and reliability. The module design includes specialized packaging to manage thermal issues and interconnection layouts that minimize parasitic inductance.- Integration of SiC MOSFETs and IGBTs in hybrid power modules: Hybrid power modules that integrate Silicon Carbide (SiC) MOSFETs and Insulated Gate Bipolar Transistors (IGBTs) combine the advantages of both technologies. SiC MOSFETs offer faster switching speeds and lower losses at high frequencies, while IGBTs provide robust performance at higher currents. This integration allows for optimized performance across different operating conditions, resulting in improved efficiency and power density in power conversion applications.

- Thermal management solutions for hybrid power modules: Effective thermal management is critical for hybrid SiC MOSFET and IGBT power modules due to the high power density and heat generation. Advanced cooling techniques including direct liquid cooling, double-sided cooling structures, and specialized thermal interface materials are implemented to maintain optimal operating temperatures. These thermal solutions help maximize the performance benefits of the hybrid architecture while ensuring reliability and extending the operational lifetime of the modules.

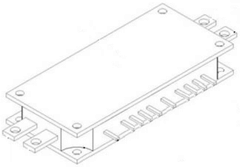

- Packaging technologies for hybrid power modules: Specialized packaging technologies are developed for hybrid SiC MOSFET and IGBT power modules to address challenges related to parasitic inductance, thermal cycling reliability, and electrical isolation. Advanced packaging approaches include silver sintering for die attachment, copper wire bonding or clip bonding for interconnections, and optimized substrate materials. These packaging innovations enable higher power density, improved thermal performance, and enhanced reliability in demanding applications.

- Gate drive and control strategies for hybrid modules: Specialized gate drive and control strategies are essential for optimizing the performance of hybrid SiC MOSFET and IGBT power modules. These include adaptive gate driving techniques that account for the different switching characteristics of SiC MOSFETs and IGBTs, intelligent protection schemes, and coordinated switching control. Advanced control algorithms enable dynamic selection between device types based on operating conditions, maximizing efficiency across the full operating range of the power module.

- Application-specific hybrid module configurations: Hybrid SiC MOSFET and IGBT power modules are designed in various configurations optimized for specific applications such as electric vehicle traction inverters, renewable energy converters, and industrial motor drives. These application-specific designs feature customized topologies, optimized current ratings, and tailored switching characteristics. By strategically placing SiC MOSFETs and IGBTs within the circuit topology, these modules deliver improved efficiency, reduced size, and enhanced performance for their target applications.

02 Thermal management solutions for hybrid power modules

Effective thermal management is critical in hybrid SiC MOSFET and IGBT power modules due to the high power density and heat generation. Advanced cooling techniques include direct liquid cooling, double-sided cooling structures, and specialized thermal interface materials. These modules often incorporate innovative heat sink designs, thermal vias, and optimized substrate materials to enhance heat dissipation. Proper thermal management ensures reliable operation and extends the lifetime of these hybrid power modules under high-load conditions.Expand Specific Solutions03 Gate driver optimization for hybrid modules

Gate driver circuits for hybrid SiC MOSFET and IGBT modules require specialized design to accommodate the different switching characteristics of each device type. These drivers feature adaptive gate control algorithms, isolated power supplies, and protection circuits to prevent shoot-through and overvoltage conditions. Advanced gate drivers may include temperature compensation, active Miller clamping, and separate driving parameters for SiC MOSFETs and IGBTs to optimize switching performance while maintaining safe operation across various operating conditions.Expand Specific Solutions04 Application-specific hybrid module configurations

Hybrid SiC MOSFET and IGBT power modules are designed in various configurations to meet specific application requirements. For electric vehicle traction inverters, modules may emphasize high power density and efficiency. For industrial motor drives, the focus might be on reliability and surge handling capability. Grid-connected applications often require modules with enhanced EMI suppression and fault tolerance. These application-specific designs optimize the balance between SiC MOSFETs and IGBTs based on the switching frequency, voltage levels, and current requirements of the target application.Expand Specific Solutions05 Protection and reliability enhancement techniques

Ensuring reliability in hybrid power modules involves implementing various protection mechanisms. These include short-circuit protection with fast detection circuits, overvoltage protection using snubber networks or active clamping, and temperature monitoring with integrated sensors. Advanced modules incorporate condition monitoring features that track device degradation over time. Reliability enhancement techniques also address bond wire fatigue, solder joint reliability, and protection against environmental factors through specialized encapsulation materials and hermetic packaging solutions.Expand Specific Solutions

Key Industry Players in SiC and IGBT Manufacturing

The power module design market using hybrid SiC MOSFET and IGBT solutions is in a growth phase, driven by increasing demand for high-efficiency power electronics in electric vehicles and renewable energy applications. The market is expected to reach significant scale as these applications proliferate globally. Technologically, this field is advancing rapidly with companies like Wolfspeed, ROHM, and Mitsubishi Electric leading innovation in SiC technology, while traditional IGBT manufacturers such as Hitachi and Toshiba are developing hybrid solutions. Academic institutions including North Carolina State University and Hunan University are contributing fundamental research. Chinese manufacturers like CRRC Times Semiconductor and Yangzhou Yangjie are rapidly expanding capabilities, creating a competitive landscape that spans established semiconductor giants and emerging specialized players.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered hybrid power module designs that integrate SiC MOSFETs with IGBTs to optimize performance in high-power applications. Their XM3 power module platform combines 1200V SiC MOSFETs with IGBTs in a common package, allowing for strategic placement of each technology to maximize efficiency. The SiC MOSFETs handle high-frequency switching operations while IGBTs manage high-current steady-state conditions. This approach enables power modules that operate at switching frequencies up to 100kHz while maintaining thermal stability. Wolfspeed's hybrid modules feature advanced packaging technology with direct bonded copper (DBC) substrates and optimized thermal interfaces that reduce junction-to-case thermal resistance by approximately 30% compared to conventional modules. Their latest hybrid designs incorporate silver sintering die-attach technology that improves thermal cycling capability by 10x over traditional solder methods, significantly enhancing reliability in applications with frequent thermal cycling.

Strengths: Industry-leading SiC expertise with vertical integration from substrate to module; superior thermal management; higher reliability in thermal cycling applications. Weaknesses: Higher initial cost compared to pure IGBT solutions; requires more sophisticated gate drive circuits; limited availability due to SiC production constraints.

ROHM Co., Ltd.

Technical Solution: ROHM has developed hybrid power modules that strategically combine their 4th generation SiC MOSFETs with optimized IGBTs to create balanced solutions for industrial drives and renewable energy applications. Their hybrid approach focuses on "function partitioning" where SiC MOSFETs handle high-frequency switching operations (typically above 20kHz) while IGBTs manage high-current conduction phases. ROHM's hybrid modules feature their proprietary Trench Gate structure for the IGBT components and planar SiC MOSFET technology with enhanced short-circuit withstand capability. The company's hybrid modules incorporate advanced thermal management with direct liquid cooling options that achieve thermal resistance values below 0.15°C/W. ROHM's packaging technology uses copper pin-fin structures and high-thermal-conductivity insulating substrates to maximize heat dissipation. Their latest hybrid modules demonstrate switching losses reduced by approximately 67% compared to pure IGBT solutions while maintaining cost-effectiveness through the strategic deployment of SiC only where it provides maximum benefit.

Strengths: Excellent thermal management solutions; balanced cost-performance ratio; strong reliability testing protocols with demonstrated field performance. Weaknesses: Less vertical integration in SiC production compared to some competitors; more conservative approach to SiC implementation may limit performance in cutting-edge applications.

Critical Technologies in SiC-IGBT Co-packaging

Hybrid power module based on Si IGBT and SiC MOSFET and manufacturing method

PatentPendingCN119361549A

Innovation

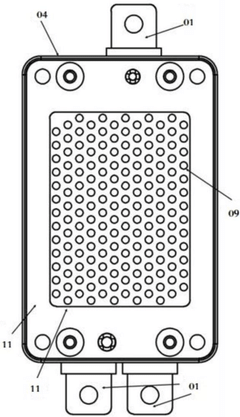

- Adopting a wavy plate fin 10-cylindrical pin fin 09 hybrid heat dissipation structure, the wavy plate fin is set at the SiC MOSFET chip position to increase the heat dissipation contact area, and the cylindrical pin fin structure is maintained in other areas, combined with the fixation of rivets and screws method to improve the connection strength between the package shell and the heat dissipation substrate.

Hybrid power module

PatentInactiveJP2023164888A

Innovation

- A power module design incorporating silicon carbide insulated gate bipolar transistors (IGBTs) and metal oxide semiconductor field effect transistors (MOSFETs) in parallel, or IGBTs and diodes in antiparallel configurations, to improve trade-offs between forward and reverse conduction currents and efficiency.

Thermal Management Strategies for Hybrid Power Modules

Thermal management represents a critical challenge in hybrid power modules that combine SiC MOSFETs and IGBTs. These hybrid solutions experience significant thermal stress due to the different operating characteristics and heat generation profiles of the two semiconductor technologies. SiC MOSFETs typically operate at higher switching frequencies and power densities than IGBTs, creating uneven thermal distributions within the module that must be carefully managed.

Advanced cooling strategies have emerged as essential components in hybrid module design. Direct liquid cooling systems that utilize specialized coolants with high thermal conductivity have demonstrated superior performance compared to traditional air cooling methods. These systems can reduce junction temperatures by up to 30% in high-power applications, significantly extending the operational lifetime of the modules.

Double-sided cooling architectures represent another innovative approach, where heat is extracted from both the top and bottom surfaces of the power semiconductors. This technique has shown particular promise for hybrid modules, as it helps balance the thermal load between SiC and silicon components. Implementation typically involves specialized substrates with integrated cooling channels and thermally conductive materials on both sides of the semiconductor dies.

Thermal interface materials (TIMs) play a crucial role in hybrid module thermal management. Advanced ceramic-filled silicone compounds and phase-change materials have been developed specifically for the temperature ranges encountered in hybrid applications. These materials must accommodate the different thermal expansion coefficients of SiC and silicon while maintaining consistent performance across the wide temperature ranges experienced during operation.

Dynamic thermal management systems that incorporate real-time temperature monitoring and adaptive cooling control have shown significant benefits for hybrid modules. These systems can adjust cooling parameters based on the actual operating conditions, optimizing performance while preventing thermal runaway scenarios. Implementation typically involves integrated temperature sensors, microcontrollers, and variable-speed cooling systems that respond to changing thermal loads.

Thermal simulation and modeling have become indispensable tools in hybrid module design. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable designers to predict hotspots and optimize thermal pathways before physical prototyping. These simulation approaches must account for the different thermal characteristics of SiC and silicon components, as well as the complex interactions between them under various operating conditions.

Advanced cooling strategies have emerged as essential components in hybrid module design. Direct liquid cooling systems that utilize specialized coolants with high thermal conductivity have demonstrated superior performance compared to traditional air cooling methods. These systems can reduce junction temperatures by up to 30% in high-power applications, significantly extending the operational lifetime of the modules.

Double-sided cooling architectures represent another innovative approach, where heat is extracted from both the top and bottom surfaces of the power semiconductors. This technique has shown particular promise for hybrid modules, as it helps balance the thermal load between SiC and silicon components. Implementation typically involves specialized substrates with integrated cooling channels and thermally conductive materials on both sides of the semiconductor dies.

Thermal interface materials (TIMs) play a crucial role in hybrid module thermal management. Advanced ceramic-filled silicone compounds and phase-change materials have been developed specifically for the temperature ranges encountered in hybrid applications. These materials must accommodate the different thermal expansion coefficients of SiC and silicon while maintaining consistent performance across the wide temperature ranges experienced during operation.

Dynamic thermal management systems that incorporate real-time temperature monitoring and adaptive cooling control have shown significant benefits for hybrid modules. These systems can adjust cooling parameters based on the actual operating conditions, optimizing performance while preventing thermal runaway scenarios. Implementation typically involves integrated temperature sensors, microcontrollers, and variable-speed cooling systems that respond to changing thermal loads.

Thermal simulation and modeling have become indispensable tools in hybrid module design. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable designers to predict hotspots and optimize thermal pathways before physical prototyping. These simulation approaches must account for the different thermal characteristics of SiC and silicon components, as well as the complex interactions between them under various operating conditions.

Cost-Performance Analysis of SiC-IGBT Hybrid Solutions

The integration of Silicon Carbide (SiC) MOSFETs with traditional Insulated Gate Bipolar Transistors (IGBTs) in hybrid power modules presents a complex cost-performance equation that requires thorough analysis. When evaluating these hybrid solutions, initial capital expenditure must be balanced against long-term operational benefits and system-level savings.

SiC MOSFETs typically command a 3-5x price premium over silicon IGBTs of comparable ratings, representing a significant upfront cost barrier. However, this analysis reveals that hybrid approaches can optimize this cost structure by strategically deploying SiC devices only where their superior switching characteristics deliver maximum system benefits, while maintaining IGBTs in positions where their cost advantages outweigh performance limitations.

Performance metrics demonstrate that hybrid solutions achieve 30-40% reduction in switching losses compared to pure IGBT implementations, while requiring only 40-60% of the additional investment needed for full SiC solutions. This creates an attractive middle ground with a typical return on investment period of 1.5-3 years depending on application duty cycles and operating conditions.

Thermal management costs represent another critical factor. Hybrid modules typically require 15-25% less elaborate cooling infrastructure than IGBT-only solutions due to improved efficiency, translating to reduced heatsink dimensions and simpler cooling systems. These indirect savings often offset 20-30% of the initial SiC component premium when calculated over the system lifetime.

System-level benefits further enhance the value proposition of hybrid approaches. The improved switching performance enables higher operating frequencies, allowing for smaller passive components throughout the power conversion chain. Case studies from industrial drive applications demonstrate 15-25% reductions in filter component sizes and costs when implementing hybrid solutions.

Reliability analysis indicates that while SiC devices offer superior robustness in certain stress conditions, hybrid solutions must carefully address interface challenges between different semiconductor technologies. Thermal cycling performance and gate driver compatibility represent potential weak points that can impact long-term reliability if not properly addressed in the design phase.

Market data suggests that hybrid SiC-IGBT solutions currently offer the most favorable cost-performance ratio for medium-voltage (1200-1700V) applications with moderate switching frequencies (5-20 kHz). This sweet spot is expected to shift toward higher voltages as SiC manufacturing scales and costs decrease, with projections indicating a 8-12% annual reduction in the SiC cost premium over the next five years.

SiC MOSFETs typically command a 3-5x price premium over silicon IGBTs of comparable ratings, representing a significant upfront cost barrier. However, this analysis reveals that hybrid approaches can optimize this cost structure by strategically deploying SiC devices only where their superior switching characteristics deliver maximum system benefits, while maintaining IGBTs in positions where their cost advantages outweigh performance limitations.

Performance metrics demonstrate that hybrid solutions achieve 30-40% reduction in switching losses compared to pure IGBT implementations, while requiring only 40-60% of the additional investment needed for full SiC solutions. This creates an attractive middle ground with a typical return on investment period of 1.5-3 years depending on application duty cycles and operating conditions.

Thermal management costs represent another critical factor. Hybrid modules typically require 15-25% less elaborate cooling infrastructure than IGBT-only solutions due to improved efficiency, translating to reduced heatsink dimensions and simpler cooling systems. These indirect savings often offset 20-30% of the initial SiC component premium when calculated over the system lifetime.

System-level benefits further enhance the value proposition of hybrid approaches. The improved switching performance enables higher operating frequencies, allowing for smaller passive components throughout the power conversion chain. Case studies from industrial drive applications demonstrate 15-25% reductions in filter component sizes and costs when implementing hybrid solutions.

Reliability analysis indicates that while SiC devices offer superior robustness in certain stress conditions, hybrid solutions must carefully address interface challenges between different semiconductor technologies. Thermal cycling performance and gate driver compatibility represent potential weak points that can impact long-term reliability if not properly addressed in the design phase.

Market data suggests that hybrid SiC-IGBT solutions currently offer the most favorable cost-performance ratio for medium-voltage (1200-1700V) applications with moderate switching frequencies (5-20 kHz). This sweet spot is expected to shift toward higher voltages as SiC manufacturing scales and costs decrease, with projections indicating a 8-12% annual reduction in the SiC cost premium over the next five years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!