SiC MOSFET Applications In Renewable Energy Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Objectives

Silicon Carbide (SiC) MOSFET technology has undergone significant evolution since its initial development in the early 1990s. The journey began with rudimentary devices characterized by high on-resistance and limited switching capabilities, primarily confined to laboratory environments. By the early 2000s, commercial viability started to emerge as manufacturing processes improved, allowing for reduced defect densities in SiC wafers and enhanced device performance characteristics.

The technological progression accelerated notably between 2010 and 2015, when several major power semiconductor manufacturers introduced first-generation commercial SiC MOSFETs with voltage ratings of 1200V and 1700V. This period marked a critical transition from silicon-based power devices to wide bandgap semiconductors in practical applications, particularly in high-voltage, high-temperature environments where traditional silicon devices faced inherent physical limitations.

Recent years have witnessed remarkable advancements in SiC MOSFET technology, with third and fourth-generation devices featuring significantly reduced on-resistance, improved thermal performance, and enhanced reliability. The specific on-resistance has decreased by approximately 75% compared to first-generation devices, while switching losses have been reduced by up to 80%, enabling higher frequency operation and improved system efficiency.

The evolution trajectory has been driven by several key objectives that continue to guide development efforts. Primary among these is the reduction of specific on-resistance to minimize conduction losses, which remains crucial for improving overall system efficiency in renewable energy applications. Equally important is the enhancement of switching performance to enable higher frequency operation, thereby allowing for smaller passive components and increased power density in converter designs.

Reliability improvement represents another critical objective, particularly regarding gate oxide stability and robustness under high-temperature cycling conditions typical in renewable energy systems. Current development efforts focus on achieving a 30-year operational lifetime under field conditions, compared to earlier generations that offered 10-15 years of reliable operation.

Cost reduction stands as perhaps the most significant objective for widespread adoption in renewable energy systems. While SiC MOSFETs currently command a premium of 2-3 times over equivalent silicon devices, the technology roadmap aims to reduce this differential to 1.2-1.5 times by 2025 through improved manufacturing yields, larger wafer sizes, and economies of scale.

The ultimate objective driving SiC MOSFET evolution is enabling more efficient, compact, and reliable power conversion systems for renewable energy applications, including solar inverters, wind power converters, and energy storage systems, where efficiency improvements of even 1-2% translate to significant energy and cost savings over system lifetime.

The technological progression accelerated notably between 2010 and 2015, when several major power semiconductor manufacturers introduced first-generation commercial SiC MOSFETs with voltage ratings of 1200V and 1700V. This period marked a critical transition from silicon-based power devices to wide bandgap semiconductors in practical applications, particularly in high-voltage, high-temperature environments where traditional silicon devices faced inherent physical limitations.

Recent years have witnessed remarkable advancements in SiC MOSFET technology, with third and fourth-generation devices featuring significantly reduced on-resistance, improved thermal performance, and enhanced reliability. The specific on-resistance has decreased by approximately 75% compared to first-generation devices, while switching losses have been reduced by up to 80%, enabling higher frequency operation and improved system efficiency.

The evolution trajectory has been driven by several key objectives that continue to guide development efforts. Primary among these is the reduction of specific on-resistance to minimize conduction losses, which remains crucial for improving overall system efficiency in renewable energy applications. Equally important is the enhancement of switching performance to enable higher frequency operation, thereby allowing for smaller passive components and increased power density in converter designs.

Reliability improvement represents another critical objective, particularly regarding gate oxide stability and robustness under high-temperature cycling conditions typical in renewable energy systems. Current development efforts focus on achieving a 30-year operational lifetime under field conditions, compared to earlier generations that offered 10-15 years of reliable operation.

Cost reduction stands as perhaps the most significant objective for widespread adoption in renewable energy systems. While SiC MOSFETs currently command a premium of 2-3 times over equivalent silicon devices, the technology roadmap aims to reduce this differential to 1.2-1.5 times by 2025 through improved manufacturing yields, larger wafer sizes, and economies of scale.

The ultimate objective driving SiC MOSFET evolution is enabling more efficient, compact, and reliable power conversion systems for renewable energy applications, including solar inverters, wind power converters, and energy storage systems, where efficiency improvements of even 1-2% translate to significant energy and cost savings over system lifetime.

Renewable Energy Market Demand Analysis

The renewable energy market has experienced unprecedented growth over the past decade, driven by increasing environmental concerns, government policies promoting clean energy adoption, and significant cost reductions in renewable technologies. The global renewable energy market was valued at approximately $881.7 billion in 2020 and is projected to reach $1,977.6 billion by 2030, growing at a CAGR of 8.4% during this period. This robust growth creates substantial demand for advanced power electronics, particularly SiC MOSFETs, which offer superior performance characteristics essential for renewable energy systems.

Solar energy represents the largest segment within the renewable market, with global installed capacity exceeding 760 GW in 2020. The solar inverter market, where SiC MOSFETs play a crucial role, was valued at $7.7 billion in 2020 and is expected to reach $13.5 billion by 2026. Higher switching frequencies and efficiency requirements in solar inverters are driving the adoption of SiC technology, with potential energy conversion efficiency improvements of 1-3% compared to traditional silicon-based solutions.

Wind energy, the second-largest renewable sector, has reached global installed capacity of approximately 743 GW in 2020. The market for wind power converters, which benefit significantly from SiC MOSFET implementation, is projected to grow at 8.9% CAGR through 2027. SiC MOSFETs enable more compact and efficient power conversion systems in wind turbines, reducing weight and maintenance requirements while improving reliability in harsh operating environments.

Energy storage systems represent another rapidly expanding market segment, with global deployment reaching 17 GW/34 GWh in 2020 and expected to grow tenfold by 2030. SiC MOSFETs are increasingly essential in battery management systems and grid-tie inverters, where their high-temperature operation capability and reduced switching losses provide substantial advantages over silicon alternatives.

The electric vehicle charging infrastructure market, closely linked to renewable energy integration, was valued at $5.03 billion in 2020 and is projected to reach $36.87 billion by 2026. Fast-charging stations particularly benefit from SiC MOSFET implementation, with efficiency improvements of up to 5% and significant size reductions of 30-40% compared to silicon-based designs.

Regional analysis indicates that Asia-Pacific dominates the renewable energy market with 45% share, followed by Europe (25%) and North America (20%). China leads global renewable energy investments, allocating $83.4 billion in 2020 alone. The European Green Deal and the US Inflation Reduction Act further accelerate market growth in their respective regions, creating substantial opportunities for SiC MOSFET applications across diverse renewable energy systems.

Solar energy represents the largest segment within the renewable market, with global installed capacity exceeding 760 GW in 2020. The solar inverter market, where SiC MOSFETs play a crucial role, was valued at $7.7 billion in 2020 and is expected to reach $13.5 billion by 2026. Higher switching frequencies and efficiency requirements in solar inverters are driving the adoption of SiC technology, with potential energy conversion efficiency improvements of 1-3% compared to traditional silicon-based solutions.

Wind energy, the second-largest renewable sector, has reached global installed capacity of approximately 743 GW in 2020. The market for wind power converters, which benefit significantly from SiC MOSFET implementation, is projected to grow at 8.9% CAGR through 2027. SiC MOSFETs enable more compact and efficient power conversion systems in wind turbines, reducing weight and maintenance requirements while improving reliability in harsh operating environments.

Energy storage systems represent another rapidly expanding market segment, with global deployment reaching 17 GW/34 GWh in 2020 and expected to grow tenfold by 2030. SiC MOSFETs are increasingly essential in battery management systems and grid-tie inverters, where their high-temperature operation capability and reduced switching losses provide substantial advantages over silicon alternatives.

The electric vehicle charging infrastructure market, closely linked to renewable energy integration, was valued at $5.03 billion in 2020 and is projected to reach $36.87 billion by 2026. Fast-charging stations particularly benefit from SiC MOSFET implementation, with efficiency improvements of up to 5% and significant size reductions of 30-40% compared to silicon-based designs.

Regional analysis indicates that Asia-Pacific dominates the renewable energy market with 45% share, followed by Europe (25%) and North America (20%). China leads global renewable energy investments, allocating $83.4 billion in 2020 alone. The European Green Deal and the US Inflation Reduction Act further accelerate market growth in their respective regions, creating substantial opportunities for SiC MOSFET applications across diverse renewable energy systems.

SiC MOSFET Technology Status and Barriers

Silicon Carbide (SiC) MOSFET technology has made significant strides in recent years, yet faces several technological barriers that impact its widespread adoption in renewable energy systems. Currently, SiC MOSFETs have achieved commercial maturity with 650V-1700V rated devices widely available from multiple manufacturers including Wolfspeed, ROHM, Infineon, and STMicroelectronics. These devices demonstrate superior switching performance with switching frequencies up to 100kHz in practical applications, substantially higher than silicon alternatives.

The global landscape of SiC technology development shows concentration in North America, Europe, and East Asia, with the United States and Japan leading in patent filings and commercial production. China has recently increased investments significantly, establishing domestic supply chains to reduce dependency on imports for this critical power semiconductor technology.

Despite progress, several technical challenges persist. Channel mobility remains substantially lower than theoretical limits, typically achieving only 20-40 cm²/V·s compared to the potential 800 cm²/V·s. This limitation stems from interface traps and defects at the SiC/SiO₂ interface, resulting in higher on-resistance than theoretically possible and limiting efficiency gains.

Threshold voltage instability presents another significant barrier, with SiC MOSFETs exhibiting shifts under high-temperature operation and during long-term bias stress. This phenomenon, attributed to charge trapping in the gate oxide, complicates reliable operation in renewable energy applications where stable performance over decades is expected.

Manufacturing yield and consistency issues continue to affect production costs. Defect densities in SiC wafers remain higher than silicon counterparts, with micropipes, basal plane dislocations, and stacking faults contributing to device failures and performance variations. The industry has improved from 2-3 inch wafers to predominantly 6-inch wafers, with 8-inch wafer technology emerging but not yet mainstream.

Packaging technology represents another constraint, as traditional packaging methods struggle to fully exploit SiC's high-temperature capabilities. While SiC devices can theoretically operate at junction temperatures up to 250°C, most commercial packages limit operation to 175°C due to interconnect reliability and molding compound limitations.

Long-term reliability data remains limited compared to mature silicon technology. Accelerated lifetime testing methodologies are still evolving for SiC devices, creating uncertainty for applications requiring 20+ year operational lifespans typical in renewable energy installations. Recent studies indicate promising results, but field validation in actual renewable energy systems is still accumulating.

The global landscape of SiC technology development shows concentration in North America, Europe, and East Asia, with the United States and Japan leading in patent filings and commercial production. China has recently increased investments significantly, establishing domestic supply chains to reduce dependency on imports for this critical power semiconductor technology.

Despite progress, several technical challenges persist. Channel mobility remains substantially lower than theoretical limits, typically achieving only 20-40 cm²/V·s compared to the potential 800 cm²/V·s. This limitation stems from interface traps and defects at the SiC/SiO₂ interface, resulting in higher on-resistance than theoretically possible and limiting efficiency gains.

Threshold voltage instability presents another significant barrier, with SiC MOSFETs exhibiting shifts under high-temperature operation and during long-term bias stress. This phenomenon, attributed to charge trapping in the gate oxide, complicates reliable operation in renewable energy applications where stable performance over decades is expected.

Manufacturing yield and consistency issues continue to affect production costs. Defect densities in SiC wafers remain higher than silicon counterparts, with micropipes, basal plane dislocations, and stacking faults contributing to device failures and performance variations. The industry has improved from 2-3 inch wafers to predominantly 6-inch wafers, with 8-inch wafer technology emerging but not yet mainstream.

Packaging technology represents another constraint, as traditional packaging methods struggle to fully exploit SiC's high-temperature capabilities. While SiC devices can theoretically operate at junction temperatures up to 250°C, most commercial packages limit operation to 175°C due to interconnect reliability and molding compound limitations.

Long-term reliability data remains limited compared to mature silicon technology. Accelerated lifetime testing methodologies are still evolving for SiC devices, creating uncertainty for applications requiring 20+ year operational lifespans typical in renewable energy installations. Recent studies indicate promising results, but field validation in actual renewable energy systems is still accumulating.

Current SiC MOSFET Implementation Strategies

01 SiC MOSFET Structure and Fabrication

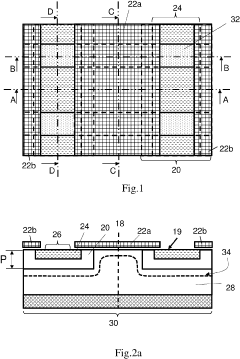

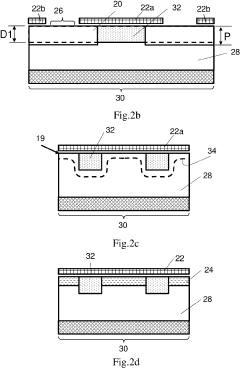

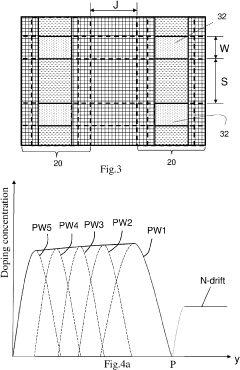

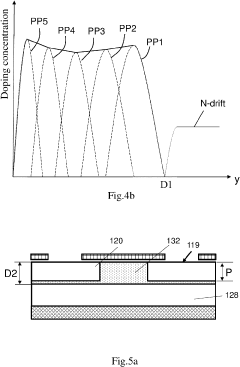

Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel formations, and doping profiles that contribute to their high-voltage handling capabilities. The fabrication process often involves specific thermal oxidation techniques to create high-quality gate oxides on SiC substrates, which is critical for device reliability and performance.- SiC MOSFET Structure and Fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel formations, and doping profiles that contribute to their high-voltage handling capabilities. The fabrication process often involves specific thermal oxidation techniques, ion implantation methods, and annealing processes to create high-quality interfaces between SiC and gate dielectrics, which are crucial for reliable device operation.

- Power Conversion Applications: SiC MOSFETs are extensively used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system size reduction and increased power density.

- Gate Drive and Control Techniques: Specialized gate drive and control techniques are essential for optimizing SiC MOSFET performance. These include advanced gate driver circuits designed to handle the unique switching characteristics of SiC devices, protection mechanisms against voltage spikes and oscillations, and control strategies that minimize switching losses while maintaining safe operation. Proper gate drive design addresses challenges such as threshold voltage instability and ensures reliable operation across varying temperature and voltage conditions.

- Thermal Management and Reliability: Effective thermal management is critical for SiC MOSFET reliability and performance. Various packaging technologies and cooling solutions are employed to dissipate heat efficiently from these high-power devices. Reliability enhancement techniques include specialized die-attach materials, optimized wire bonding methods, and improved encapsulation processes. These approaches address common failure mechanisms such as gate oxide degradation, threshold voltage instability, and package-related failures under high-temperature and high-voltage operating conditions.

- Integration and System Design: The integration of SiC MOSFETs into power electronic systems requires specialized design considerations to fully leverage their advantages. This includes optimized circuit layouts to minimize parasitic inductances, customized protection schemes, and system-level thermal management. Advanced module designs incorporate multiple SiC MOSFETs with integrated gate drivers and protection circuits to create compact, high-performance power modules. These integrated solutions enable higher switching frequencies, reduced electromagnetic interference, and improved overall system efficiency.

02 Power Conversion Applications

SiC MOSFETs are extensively used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system efficiency improvements.Expand Specific Solutions03 Thermal Management Solutions

Effective thermal management is crucial for SiC MOSFETs operating at high power densities. Various cooling techniques and packaging solutions have been developed to address the thermal challenges associated with these devices. These include advanced heat sink designs, novel packaging materials with improved thermal conductivity, and integrated cooling systems that efficiently dissipate heat from the device junction, ensuring reliable operation under demanding conditions.Expand Specific Solutions04 Gate Drive Optimization

Specialized gate drive circuits are essential for optimizing the switching performance of SiC MOSFETs. These circuits address the unique requirements of SiC devices, including higher gate voltages, faster switching speeds, and protection against voltage spikes. Advanced gate drive designs incorporate features such as adjustable slew rates, temperature compensation, and protection mechanisms that enhance the reliability and efficiency of SiC MOSFET operation in various applications.Expand Specific Solutions05 Reliability Enhancement Techniques

Improving the long-term reliability of SiC MOSFETs involves addressing specific failure mechanisms and performance degradation factors. Various techniques have been developed to enhance device reliability, including optimized channel and oxide interface treatments, specialized passivation layers, and robust packaging solutions. These approaches focus on mitigating issues such as threshold voltage instability, gate oxide degradation, and package-related failures, thereby extending the operational lifetime of SiC MOSFETs in demanding applications.Expand Specific Solutions

Leading SiC MOSFET Manufacturers and Competitors

The SiC MOSFET market in renewable energy systems is experiencing rapid growth, currently in the early mainstream adoption phase with an estimated market size of $500-700 million and projected CAGR of 25-30%. Leading players include established power semiconductor manufacturers like ROHM, Mitsubishi Electric, and Toshiba, alongside emerging specialists such as Power Integrations and Semiconductor Components Industries. The technology has reached commercial maturity for solar inverters and wind power applications, with companies like Huawei and State Grid China deploying SiC solutions at scale. Academic institutions including University of Warwick and Zhejiang University are collaborating with industry to advance next-generation designs, focusing on higher efficiency, reliability, and cost reduction to accelerate adoption across broader renewable energy applications.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered SiC MOSFET technology for renewable energy applications through their proprietary DMOS (Double-implanted Metal-Oxide-Semiconductor) structure. Their N-series SiC power modules integrate multiple SiC MOSFETs with optimized packaging to handle the high power requirements of utility-scale solar inverters and wind turbine converters. These modules feature direct liquid cooling technology that achieves thermal resistance below 0.02°C/W[3], enabling power densities exceeding 100kW/L in renewable energy conversion systems. Mitsubishi's SiC solutions incorporate advanced gate control algorithms that dynamically adjust switching parameters based on load conditions, maximizing efficiency across the variable power generation profiles typical in renewable sources. Their latest modules operate at junction temperatures up to 175°C while maintaining reliability, with demonstrated field MTBF (Mean Time Between Failures) exceeding 100 years in solar applications[4].

Strengths: Highly integrated power modules simplify system design and improve reliability through reduced component count. Industry-leading power density enables more compact renewable energy conversion systems. Weaknesses: Premium pricing positions products primarily for utility-scale applications rather than residential systems. Proprietary gate drive requirements can limit flexibility in system design.

ROHM Co., Ltd.

Technical Solution: ROHM has developed advanced SiC MOSFET solutions specifically optimized for renewable energy applications. Their 4th generation SiC MOSFETs feature significantly reduced ON-resistance and improved short-circuit withstand time, crucial for solar inverters and wind power converters. ROHM's technology implements a trench gate structure that achieves 40% lower ON-resistance compared to conventional planar designs[1], enabling higher power density in renewable energy systems. Their SiC MOSFETs operate at switching frequencies up to 100kHz, substantially higher than silicon alternatives, allowing for smaller passive components in inverter designs. ROHM has also developed specialized gate driver ICs with built-in protection features specifically designed to maximize SiC MOSFET performance in renewable applications while ensuring system reliability under harsh environmental conditions typical in solar and wind installations[2].

Strengths: Superior switching performance with minimal switching losses enables higher efficiency renewable energy conversion (>98% efficiency). Excellent thermal performance allows operation at higher temperatures without derating. Weaknesses: Higher initial component cost compared to silicon alternatives, potentially limiting adoption in cost-sensitive markets. Requires more sophisticated gate drive circuits to fully optimize performance.

Key SiC MOSFET Patents and Technical Innovations

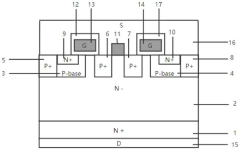

Sic mosfet with transverse p+ region

PatentActiveUS20230053874A1

Innovation

- The design incorporates a silicon carbide MOSFET structure with specific doping layers and geometries, including a polysilicon gate layer, to enhance the protection of the gate oxide without increasing the MOSFET cell area, utilizing epitaxy and ion implantation processes to create N+ and P+ regions that act as shields, ensuring adequate body diode performance and channel mobility.

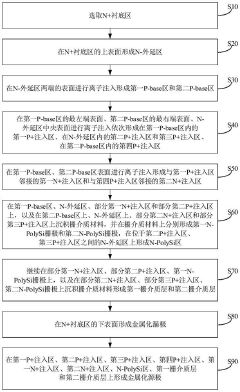

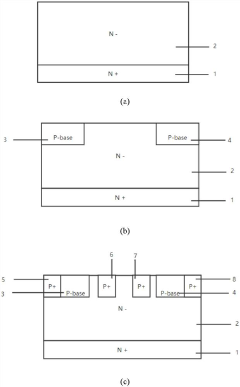

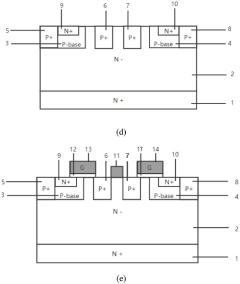

SiC DMOSFET device integrated with HJD and preparation method thereof

PatentPendingCN115842056A

Innovation

- Design a SiC DMOSFET device with an integrated heterojunction diode (HJD). By setting the heterojunction contact between the N-PolySi region and the N-epitaxial region inside the device, it replaces the traditional SBD or JBS structure and adopts a split gate structure. , reduce the gate capacitance.

Thermal Management Solutions for SiC MOSFETs

Thermal management is a critical aspect of SiC MOSFET implementation in renewable energy systems due to the high power density and switching frequencies these devices operate at. Despite SiC MOSFETs' superior thermal conductivity compared to silicon counterparts (approximately 3-4 times higher), the concentrated heat generation during operation necessitates sophisticated cooling solutions to maintain optimal performance and reliability.

Traditional cooling methods such as forced-air convection prove inadequate for high-power SiC applications in renewable energy inverters and converters. Advanced liquid cooling systems have emerged as the preferred solution, offering thermal resistance values as low as 0.1°C/W compared to 0.3-0.5°C/W for air-cooled systems. These systems typically employ water-glycol mixtures circulating through cold plates directly attached to MOSFET modules.

Direct substrate cooling represents another innovative approach, where coolant flows directly beneath the ceramic substrate supporting the SiC dies. This method reduces thermal resistance by eliminating multiple interface layers, achieving junction-to-coolant thermal resistance below 0.05°C/W in optimized designs.

Phase-change cooling technologies utilizing the latent heat of vaporization offer promising results for high-density applications. Two-phase immersion cooling systems can handle heat fluxes exceeding 500 W/cm², making them suitable for the most demanding renewable energy applications such as utility-scale solar inverters and wind power converters.

Advanced thermal interface materials (TIMs) play a crucial role in the thermal management stack. Silver sintering has emerged as a superior alternative to conventional solder, reducing thermal resistance by up to 50% while improving reliability under thermal cycling conditions common in renewable energy systems.

Computational fluid dynamics (CFD) modeling has become essential in thermal solution design, enabling accurate prediction of temperature distributions and hotspots. Recent developments in multi-physics simulation tools allow simultaneous electrical and thermal analysis, optimizing both electrical performance and thermal management.

Industry trends indicate a move toward integrated cooling solutions where thermal management is considered from the earliest design stages rather than as an afterthought. This approach has yielded compact renewable energy conversion systems with power densities exceeding 100 kW/L while maintaining junction temperatures below critical thresholds of 150°C during continuous operation.

Traditional cooling methods such as forced-air convection prove inadequate for high-power SiC applications in renewable energy inverters and converters. Advanced liquid cooling systems have emerged as the preferred solution, offering thermal resistance values as low as 0.1°C/W compared to 0.3-0.5°C/W for air-cooled systems. These systems typically employ water-glycol mixtures circulating through cold plates directly attached to MOSFET modules.

Direct substrate cooling represents another innovative approach, where coolant flows directly beneath the ceramic substrate supporting the SiC dies. This method reduces thermal resistance by eliminating multiple interface layers, achieving junction-to-coolant thermal resistance below 0.05°C/W in optimized designs.

Phase-change cooling technologies utilizing the latent heat of vaporization offer promising results for high-density applications. Two-phase immersion cooling systems can handle heat fluxes exceeding 500 W/cm², making them suitable for the most demanding renewable energy applications such as utility-scale solar inverters and wind power converters.

Advanced thermal interface materials (TIMs) play a crucial role in the thermal management stack. Silver sintering has emerged as a superior alternative to conventional solder, reducing thermal resistance by up to 50% while improving reliability under thermal cycling conditions common in renewable energy systems.

Computational fluid dynamics (CFD) modeling has become essential in thermal solution design, enabling accurate prediction of temperature distributions and hotspots. Recent developments in multi-physics simulation tools allow simultaneous electrical and thermal analysis, optimizing both electrical performance and thermal management.

Industry trends indicate a move toward integrated cooling solutions where thermal management is considered from the earliest design stages rather than as an afterthought. This approach has yielded compact renewable energy conversion systems with power densities exceeding 100 kW/L while maintaining junction temperatures below critical thresholds of 150°C during continuous operation.

Cost-Benefit Analysis of SiC vs Silicon Technologies

The economic comparison between Silicon Carbide (SiC) MOSFET and traditional silicon technologies reveals a complex value proposition for renewable energy applications. Initial acquisition costs for SiC MOSFETs typically range 2-3 times higher than their silicon counterparts, presenting a significant upfront investment barrier. For a 50kW solar inverter, silicon-based solutions may cost $1,500-2,000, while equivalent SiC implementations can reach $3,000-4,500.

However, this cost premium is increasingly offset by substantial operational benefits. SiC MOSFETs demonstrate 30-40% lower switching losses and 50-60% reduction in conduction losses compared to silicon IGBTs. These efficiency improvements translate directly to energy savings, with SiC-based renewable energy systems achieving 1-3% higher overall efficiency. For utility-scale installations, this efficiency gain represents significant financial returns over system lifetime.

The thermal performance advantages of SiC further enhance the cost-benefit equation. Operating efficiently at temperatures up to 200°C versus silicon's 150°C limit, SiC MOSFETs require less elaborate cooling infrastructure. This results in 15-25% reduction in heatsink size and cooling system costs, while simultaneously improving system reliability and reducing maintenance expenses.

Component count reduction represents another economic advantage. SiC's higher switching frequency capabilities (up to 100kHz versus 20kHz for silicon) enable smaller passive components. Studies indicate a 30-50% reduction in filter size and up to 40% decrease in overall system volume, yielding savings in material costs, manufacturing complexity, and installation footprint.

Total Cost of Ownership (TCO) analysis reveals SiC solutions typically achieve payback within 2-4 years in renewable energy applications. For a 1MW solar installation, lifetime operational savings can exceed $150,000-200,000 through improved energy harvest and reduced maintenance requirements. This economic advantage grows proportionally with system scale and operational duration.

Market trends indicate rapidly decreasing SiC component costs, with prices declining approximately 10-15% annually as manufacturing scales. Industry projections suggest SiC MOSFETs will reach near price parity with premium silicon solutions by 2027-2028, further strengthening their value proposition. This convergence is accelerating adoption across renewable energy sectors, particularly in utility-scale solar, wind power conversion, and energy storage systems where efficiency premiums deliver maximum economic benefit.

However, this cost premium is increasingly offset by substantial operational benefits. SiC MOSFETs demonstrate 30-40% lower switching losses and 50-60% reduction in conduction losses compared to silicon IGBTs. These efficiency improvements translate directly to energy savings, with SiC-based renewable energy systems achieving 1-3% higher overall efficiency. For utility-scale installations, this efficiency gain represents significant financial returns over system lifetime.

The thermal performance advantages of SiC further enhance the cost-benefit equation. Operating efficiently at temperatures up to 200°C versus silicon's 150°C limit, SiC MOSFETs require less elaborate cooling infrastructure. This results in 15-25% reduction in heatsink size and cooling system costs, while simultaneously improving system reliability and reducing maintenance expenses.

Component count reduction represents another economic advantage. SiC's higher switching frequency capabilities (up to 100kHz versus 20kHz for silicon) enable smaller passive components. Studies indicate a 30-50% reduction in filter size and up to 40% decrease in overall system volume, yielding savings in material costs, manufacturing complexity, and installation footprint.

Total Cost of Ownership (TCO) analysis reveals SiC solutions typically achieve payback within 2-4 years in renewable energy applications. For a 1MW solar installation, lifetime operational savings can exceed $150,000-200,000 through improved energy harvest and reduced maintenance requirements. This economic advantage grows proportionally with system scale and operational duration.

Market trends indicate rapidly decreasing SiC component costs, with prices declining approximately 10-15% annually as manufacturing scales. Industry projections suggest SiC MOSFETs will reach near price parity with premium silicon solutions by 2027-2028, further strengthening their value proposition. This convergence is accelerating adoption across renewable energy sectors, particularly in utility-scale solar, wind power conversion, and energy storage systems where efficiency premiums deliver maximum economic benefit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!