Soft-Switching Techniques For SiC MOSFET Applications

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Soft-Switching Background and Objectives

Silicon Carbide (SiC) MOSFETs have emerged as revolutionary power semiconductor devices, offering superior performance characteristics compared to traditional silicon-based counterparts. The evolution of SiC technology began in the early 1990s with research primarily focused on material development, followed by device fabrication advancements in the 2000s. By the 2010s, commercial SiC MOSFETs became available, marking a significant milestone in power electronics.

The technological trajectory of SiC MOSFETs has been characterized by continuous improvements in device parameters, including reduced on-resistance, enhanced thermal conductivity, and higher breakdown voltage capabilities. These advancements have positioned SiC MOSFETs as ideal candidates for high-frequency, high-temperature, and high-power applications where traditional silicon devices face fundamental limitations.

Despite their superior characteristics, SiC MOSFETs face challenges during switching transitions, particularly regarding electromagnetic interference (EMI), switching losses, and device stress. These issues become more pronounced at higher switching frequencies, which are otherwise desirable for reducing passive component sizes and increasing power density in converter designs.

Soft-switching techniques represent a critical approach to mitigating these challenges by ensuring that device voltage or current transitions occur when the complementary parameter is zero or near-zero. This significantly reduces switching losses and stress on the devices, enabling operation at higher frequencies while maintaining system efficiency and reliability.

The primary objectives of developing soft-switching techniques for SiC MOSFET applications include: maximizing the inherent benefits of SiC technology through reduced switching losses; enabling higher switching frequencies without compromising efficiency; mitigating EMI concerns through controlled switching transitions; extending device lifetime by reducing thermal and electrical stress; and ultimately achieving higher power density in converter designs.

Recent technological trends indicate a growing convergence between advanced semiconductor materials like SiC and sophisticated switching methodologies. This synergy aims to overcome the traditional trade-offs between switching frequency, efficiency, and thermal management in power electronic systems.

The anticipated technological goals include developing soft-switching topologies specifically optimized for SiC characteristics, creating driver circuits capable of precisely controlling SiC MOSFET switching transitions, establishing design methodologies that balance performance and reliability, and formulating standardized approaches for implementing soft-switching techniques across various application domains including automotive, renewable energy, and industrial drives.

As SiC MOSFET technology continues to mature, soft-switching techniques will play an increasingly vital role in unlocking the full potential of these devices, potentially revolutionizing power conversion systems across multiple industries and applications.

The technological trajectory of SiC MOSFETs has been characterized by continuous improvements in device parameters, including reduced on-resistance, enhanced thermal conductivity, and higher breakdown voltage capabilities. These advancements have positioned SiC MOSFETs as ideal candidates for high-frequency, high-temperature, and high-power applications where traditional silicon devices face fundamental limitations.

Despite their superior characteristics, SiC MOSFETs face challenges during switching transitions, particularly regarding electromagnetic interference (EMI), switching losses, and device stress. These issues become more pronounced at higher switching frequencies, which are otherwise desirable for reducing passive component sizes and increasing power density in converter designs.

Soft-switching techniques represent a critical approach to mitigating these challenges by ensuring that device voltage or current transitions occur when the complementary parameter is zero or near-zero. This significantly reduces switching losses and stress on the devices, enabling operation at higher frequencies while maintaining system efficiency and reliability.

The primary objectives of developing soft-switching techniques for SiC MOSFET applications include: maximizing the inherent benefits of SiC technology through reduced switching losses; enabling higher switching frequencies without compromising efficiency; mitigating EMI concerns through controlled switching transitions; extending device lifetime by reducing thermal and electrical stress; and ultimately achieving higher power density in converter designs.

Recent technological trends indicate a growing convergence between advanced semiconductor materials like SiC and sophisticated switching methodologies. This synergy aims to overcome the traditional trade-offs between switching frequency, efficiency, and thermal management in power electronic systems.

The anticipated technological goals include developing soft-switching topologies specifically optimized for SiC characteristics, creating driver circuits capable of precisely controlling SiC MOSFET switching transitions, establishing design methodologies that balance performance and reliability, and formulating standardized approaches for implementing soft-switching techniques across various application domains including automotive, renewable energy, and industrial drives.

As SiC MOSFET technology continues to mature, soft-switching techniques will play an increasingly vital role in unlocking the full potential of these devices, potentially revolutionizing power conversion systems across multiple industries and applications.

Market Demand Analysis for SiC MOSFET Applications

The global market for Silicon Carbide (SiC) MOSFETs is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy systems, and industrial power applications. Current market valuations place the SiC power device market at approximately 2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 25-30% through 2030.

Electric vehicle applications represent the largest demand segment, accounting for nearly 60% of the total SiC MOSFET market. This dominance stems from the critical need for high-efficiency power conversion in EV inverters, onboard chargers, and DC-DC converters. Major automotive manufacturers have accelerated their transition from silicon IGBTs to SiC MOSFETs, seeking to extend vehicle range, reduce charging times, and decrease overall system size and weight.

Renewable energy systems constitute the second-largest application segment, representing about 20% of market demand. Solar inverters and wind power converters particularly benefit from soft-switching SiC implementations, which can achieve efficiency improvements of 2-3 percentage points compared to traditional silicon-based solutions. This efficiency gain translates to significant energy savings over system lifetimes.

Industrial power supplies and motor drives account for approximately 15% of the market, with data center power systems showing the fastest growth within this segment. The demand for higher power density and improved thermal performance in these applications aligns perfectly with the capabilities of soft-switched SiC MOSFETs.

Regional analysis reveals that Asia-Pacific currently leads SiC MOSFET adoption, representing 45% of global demand, followed by North America (30%) and Europe (20%). China specifically has emerged as both the largest consumer and a rapidly growing producer of SiC power devices, supported by substantial government investments in semiconductor manufacturing capabilities.

Market research indicates that soft-switching techniques are increasingly viewed as essential rather than optional in SiC applications. A survey of power electronics engineers found that 78% consider switching losses and EMI concerns as primary challenges when implementing SiC MOSFETs, directly addressable through soft-switching methodologies.

The price premium for SiC MOSFETs over silicon alternatives continues to decrease, dropping from approximately 10x in 2015 to 3-4x in 2023. This trend, coupled with the performance benefits of soft-switching implementations, has significantly improved the total cost of ownership calculations that drive adoption decisions.

Supply chain constraints remain a significant market factor, with SiC wafer production capacity struggling to meet rapidly growing demand. This has created a competitive landscape where manufacturers with secured supply chains gain significant market advantage, particularly in high-volume applications like automotive power electronics.

Electric vehicle applications represent the largest demand segment, accounting for nearly 60% of the total SiC MOSFET market. This dominance stems from the critical need for high-efficiency power conversion in EV inverters, onboard chargers, and DC-DC converters. Major automotive manufacturers have accelerated their transition from silicon IGBTs to SiC MOSFETs, seeking to extend vehicle range, reduce charging times, and decrease overall system size and weight.

Renewable energy systems constitute the second-largest application segment, representing about 20% of market demand. Solar inverters and wind power converters particularly benefit from soft-switching SiC implementations, which can achieve efficiency improvements of 2-3 percentage points compared to traditional silicon-based solutions. This efficiency gain translates to significant energy savings over system lifetimes.

Industrial power supplies and motor drives account for approximately 15% of the market, with data center power systems showing the fastest growth within this segment. The demand for higher power density and improved thermal performance in these applications aligns perfectly with the capabilities of soft-switched SiC MOSFETs.

Regional analysis reveals that Asia-Pacific currently leads SiC MOSFET adoption, representing 45% of global demand, followed by North America (30%) and Europe (20%). China specifically has emerged as both the largest consumer and a rapidly growing producer of SiC power devices, supported by substantial government investments in semiconductor manufacturing capabilities.

Market research indicates that soft-switching techniques are increasingly viewed as essential rather than optional in SiC applications. A survey of power electronics engineers found that 78% consider switching losses and EMI concerns as primary challenges when implementing SiC MOSFETs, directly addressable through soft-switching methodologies.

The price premium for SiC MOSFETs over silicon alternatives continues to decrease, dropping from approximately 10x in 2015 to 3-4x in 2023. This trend, coupled with the performance benefits of soft-switching implementations, has significantly improved the total cost of ownership calculations that drive adoption decisions.

Supply chain constraints remain a significant market factor, with SiC wafer production capacity struggling to meet rapidly growing demand. This has created a competitive landscape where manufacturers with secured supply chains gain significant market advantage, particularly in high-volume applications like automotive power electronics.

Current Status and Challenges in SiC Soft-Switching

Silicon Carbide (SiC) MOSFET technology has emerged as a revolutionary advancement in power electronics, offering superior performance characteristics compared to traditional silicon-based devices. However, the global landscape of SiC soft-switching technology reveals both significant progress and persistent challenges. Currently, SiC MOSFETs are being deployed in various high-power applications including electric vehicles, renewable energy systems, and industrial drives, with soft-switching techniques increasingly adopted to maximize their efficiency potential.

The current state of SiC soft-switching technology is characterized by a dichotomy between laboratory achievements and commercial implementation. Research institutions worldwide have demonstrated soft-switching converters achieving efficiency levels exceeding 99% at high switching frequencies (100-500 kHz), substantially outperforming hard-switched counterparts. However, commercial adoption remains selective, primarily concentrated in premium applications where performance justifies the increased system cost.

A major technical challenge facing SiC soft-switching implementation is the device's inherently faster switching speed, which creates more pronounced electromagnetic interference (EMI) issues. The rapid dv/dt and di/dt transitions, while beneficial for reducing switching losses, generate significant high-frequency noise that complicates circuit design and compliance with electromagnetic compatibility standards. This necessitates sophisticated gate drive designs and careful power loop layout considerations.

Another significant hurdle is the complex interaction between SiC device characteristics and resonant circuit components in soft-switching topologies. The non-linear output capacitance of SiC MOSFETs and their temperature-dependent behavior can disrupt the precise timing required for optimal zero-voltage switching (ZVS) or zero-current switching (ZCS) operation, particularly across varying load conditions.

Reliability concerns also persist in the industry. The repeated stress from resonant current and voltage oscillations in soft-switching circuits can potentially impact long-term device performance. Limited field data exists on the aging mechanisms of SiC devices under soft-switching conditions, creating uncertainty for applications requiring decades of operational life.

Geographically, SiC soft-switching technology development shows distinct patterns. North America and Europe lead in fundamental research and patent generation, with institutions like CPES at Virginia Tech and FREEDM Systems Center pioneering advanced topologies. Meanwhile, East Asian manufacturers, particularly in Japan and China, are rapidly scaling production capabilities and focusing on cost reduction strategies to enable broader commercial adoption.

The economic barrier remains substantial, with soft-switching SiC systems typically commanding a 20-40% premium over hard-switched alternatives. This cost differential stems from additional passive components, more sophisticated controllers, and increased design complexity. However, this gap is gradually narrowing as design tools mature and component costs decrease with volume production.

The current state of SiC soft-switching technology is characterized by a dichotomy between laboratory achievements and commercial implementation. Research institutions worldwide have demonstrated soft-switching converters achieving efficiency levels exceeding 99% at high switching frequencies (100-500 kHz), substantially outperforming hard-switched counterparts. However, commercial adoption remains selective, primarily concentrated in premium applications where performance justifies the increased system cost.

A major technical challenge facing SiC soft-switching implementation is the device's inherently faster switching speed, which creates more pronounced electromagnetic interference (EMI) issues. The rapid dv/dt and di/dt transitions, while beneficial for reducing switching losses, generate significant high-frequency noise that complicates circuit design and compliance with electromagnetic compatibility standards. This necessitates sophisticated gate drive designs and careful power loop layout considerations.

Another significant hurdle is the complex interaction between SiC device characteristics and resonant circuit components in soft-switching topologies. The non-linear output capacitance of SiC MOSFETs and their temperature-dependent behavior can disrupt the precise timing required for optimal zero-voltage switching (ZVS) or zero-current switching (ZCS) operation, particularly across varying load conditions.

Reliability concerns also persist in the industry. The repeated stress from resonant current and voltage oscillations in soft-switching circuits can potentially impact long-term device performance. Limited field data exists on the aging mechanisms of SiC devices under soft-switching conditions, creating uncertainty for applications requiring decades of operational life.

Geographically, SiC soft-switching technology development shows distinct patterns. North America and Europe lead in fundamental research and patent generation, with institutions like CPES at Virginia Tech and FREEDM Systems Center pioneering advanced topologies. Meanwhile, East Asian manufacturers, particularly in Japan and China, are rapidly scaling production capabilities and focusing on cost reduction strategies to enable broader commercial adoption.

The economic barrier remains substantial, with soft-switching SiC systems typically commanding a 20-40% premium over hard-switched alternatives. This cost differential stems from additional passive components, more sophisticated controllers, and increased design complexity. However, this gap is gradually narrowing as design tools mature and component costs decrease with volume production.

Current Soft-Switching Solutions for SiC MOSFETs

01 Zero Voltage Switching (ZVS) techniques for SiC MOSFETs

Zero Voltage Switching (ZVS) is a soft-switching technique that allows SiC MOSFETs to turn on when the voltage across the device is zero or near-zero, significantly reducing switching losses. This technique typically employs resonant circuits or auxiliary switches to create zero-voltage conditions before the main switch turns on. ZVS is particularly effective for SiC MOSFETs operating at high frequencies, as it minimizes the overlap between voltage and current during switching transitions, thereby reducing power dissipation and improving overall efficiency.- Zero Voltage Switching (ZVS) Techniques for SiC MOSFETs: Zero Voltage Switching techniques are implemented to reduce switching losses in SiC MOSFETs by ensuring that the voltage across the device is zero before switching occurs. These techniques typically involve resonant circuits that create conditions where the MOSFET turns on when the voltage across it reaches zero, eliminating turn-on losses. ZVS is particularly effective for SiC MOSFETs operating at high frequencies, as it significantly reduces the energy dissipated during switching transitions.

- Resonant Soft-Switching Converters for SiC Applications: Resonant soft-switching converters utilize LC resonant circuits to create zero-voltage or zero-current switching conditions for SiC MOSFETs. These converters include LLC resonant converters, series resonant converters, and parallel resonant topologies specifically designed to leverage the high-speed switching capabilities of SiC devices while minimizing losses. The resonant tank components are carefully selected to ensure optimal switching conditions across varying load ranges, enabling higher efficiency and reduced thermal stress on the semiconductor devices.

- Active Gate Driving Methods for Soft-Switching: Advanced gate driving techniques are employed to optimize the switching behavior of SiC MOSFETs and reduce losses. These methods include variable gate resistance, multi-level gate voltage control, and timing-optimized gate signals that adapt to operating conditions. By precisely controlling the gate voltage profile during switching transitions, these techniques manage the trade-off between switching speed and losses, while also mitigating electromagnetic interference. Some implementations use closed-loop control systems that monitor switching parameters in real-time to adjust gate driving signals accordingly.

- Auxiliary Circuit Designs for Soft-Switching SiC MOSFETs: Auxiliary switching circuits are implemented alongside main SiC MOSFETs to create soft-switching conditions. These circuits typically include additional switches, inductors, and capacitors that temporarily divert current from the main switches during commutation. The auxiliary components create alternative current paths that allow the main SiC MOSFETs to switch under zero-voltage or zero-current conditions. Various topologies such as auxiliary resonant commutated pole converters and quasi-resonant snubber circuits are used to achieve soft-switching while minimizing the additional components and complexity.

- Hybrid Soft-Switching Strategies for SiC-based Power Converters: Hybrid soft-switching approaches combine multiple techniques to optimize the performance of SiC MOSFET-based converters across different operating conditions. These strategies may integrate passive snubber circuits with active switching control methods, or combine resonant techniques with synchronous rectification. Some implementations use adaptive control algorithms that select the most appropriate soft-switching technique based on load conditions, input voltage, and temperature. These hybrid approaches aim to maximize efficiency across the entire operating range while maintaining reliability and minimizing component count.

02 Zero Current Switching (ZCS) implementations for SiC devices

Zero Current Switching (ZCS) techniques enable SiC MOSFETs to turn off when the current through the device is zero, eliminating turn-off losses. These implementations typically use resonant tanks or auxiliary circuits to shape the current waveform and create zero-current conditions at switching instances. ZCS is particularly beneficial for reducing the stress on SiC MOSFETs during high-current applications, extending device lifetime and improving thermal performance while minimizing switching losses.Expand Specific Solutions03 Resonant converter topologies for SiC MOSFET applications

Resonant converter topologies leverage LC resonant tanks to achieve soft-switching conditions for SiC MOSFETs. These include LLC, CLLC, and series resonant converters specifically optimized for SiC devices. By operating at or near resonant frequency, these topologies naturally create zero-voltage or zero-current switching conditions, significantly reducing switching losses while allowing SiC MOSFETs to operate at higher frequencies. The resonant operation also reduces electromagnetic interference (EMI) and improves power density in converter designs.Expand Specific Solutions04 Active auxiliary circuits for soft-switching SiC MOSFETs

Active auxiliary circuits employ additional semiconductor switches and passive components to create soft-switching conditions for the main SiC MOSFETs. These circuits actively control the voltage and current trajectories during switching transitions, enabling zero-voltage or zero-current switching. Techniques include active clamps, auxiliary resonant commutated pole converters, and transition assistance circuits specifically designed for SiC MOSFET characteristics. These approaches can be adaptively controlled to maintain soft-switching across varying load conditions, maximizing efficiency benefits.Expand Specific Solutions05 Gate drive optimization for SiC MOSFET soft-switching

Advanced gate drive techniques can significantly enhance soft-switching performance of SiC MOSFETs. These include variable gate resistance, multi-level gate voltage control, and precise timing control tailored to SiC MOSFET characteristics. By optimizing gate voltage profiles and switching trajectories, these techniques reduce switching losses even in partial soft-switching conditions. Intelligent gate drivers can adapt to changing operating conditions, ensuring optimal switching performance while protecting the SiC MOSFET from voltage overshoots and ringing that commonly occur during high-speed switching transitions.Expand Specific Solutions

Key Industry Players in SiC MOSFET Development

The soft-switching techniques for SiC MOSFET applications market is currently in a growth phase, with increasing adoption across power electronics sectors. The global market size is expanding rapidly, driven by demand for higher efficiency power conversion in electric vehicles, renewable energy, and industrial applications. Technical maturity varies among key players, with companies like Wolfspeed, Infineon Technologies, and ON Semiconductor leading commercial development with advanced SiC MOSFET portfolios. Chinese institutions including University of Electronic Science & Technology of China, Zhejiang University, and Huawei are making significant research contributions. Academic-industrial collaborations between universities and companies like Fuji Electric, Mitsubishi Electric, and State Grid are accelerating innovation in soft-switching topologies that reduce switching losses and improve thermal performance in SiC-based power systems.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed proprietary soft-switching techniques for their SiC MOSFET product line that focus on minimizing switching losses in high-power applications. Their approach combines resonant switching circuits with advanced gate drive technology specifically optimized for the switching characteristics of SiC devices. Mitsubishi's solutions incorporate dual-active bridge (DAB) and series resonant converter (SRC) topologies that enable high-efficiency power conversion at elevated switching frequencies. Their technology includes specialized gate driver designs with precise timing control that maintains optimal switching trajectories even under varying load and temperature conditions. Mitsubishi has demonstrated these technologies in industrial motor drives and renewable energy applications, achieving power density improvements of up to 40% compared to conventional hard-switching designs. Their soft-switching implementations also feature advanced thermal management solutions that address the unique heat dissipation challenges associated with high-frequency SiC operation.

Strengths: Extensive experience in high-power industrial applications; integrated power module solutions with optimized thermal performance; proven reliability in demanding environments. Weaknesses: Solutions often optimized for higher power applications with less focus on compact consumer electronics; relatively complex implementation requiring specialized engineering expertise; higher system cost compared to traditional silicon solutions.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed advanced soft-switching techniques specifically optimized for their SiC MOSFET product lines. Their approach focuses on Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS) methodologies that leverage the unique characteristics of SiC devices. Their proprietary gate driver designs incorporate adaptive dead-time control algorithms that dynamically adjust switching parameters based on load conditions and temperature variations. Wolfspeed's soft-switching solutions include resonant circuit topologies such as LLC converters and phase-shifted full-bridge configurations that have been optimized to minimize switching losses while maintaining high efficiency across wide operating ranges. Their technology enables switching frequencies exceeding 500kHz while maintaining efficiency above 98% in many applications, significantly higher than conventional silicon-based solutions. Wolfspeed has also developed specialized packaging techniques that minimize parasitic inductances, which is critical for high-frequency soft-switching applications.

Strengths: Industry-leading SiC substrate and device technology with vertical integration from wafer to module; extensive expertise in high-frequency applications; comprehensive design support ecosystem. Weaknesses: Higher cost compared to silicon alternatives; requires more sophisticated control algorithms; thermal management challenges at extreme power densities.

Critical Patents and Technical Literature Analysis

Silicon carbide field-effect transistors

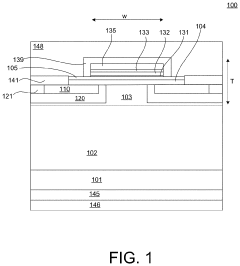

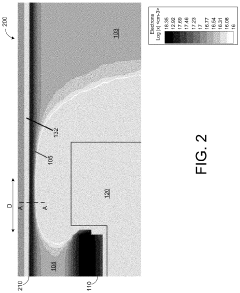

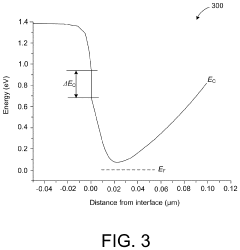

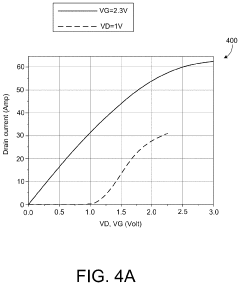

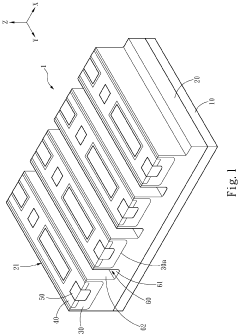

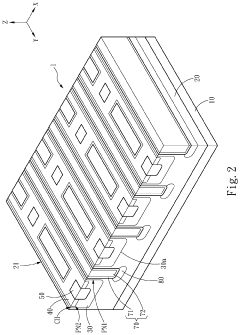

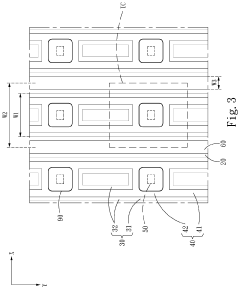

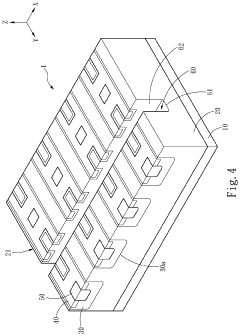

PatentActiveUS20220013661A1

Innovation

- A silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) design incorporating a substrate, drift region, spreading layer, body region, and source region with a gate structure that includes a gate oxide layer, aluminum nitride, and p-type gallium nitride layers, achieving low on-state specific resistance and high threshold voltage.

Silicon carbide semiconductor device

PatentPendingUS20240234569A9

Innovation

- A silicon carbide semiconductor device with a hybrid gate structure featuring a trench gate configuration that reduces JFET resistance and parasitic gate-to-drain capacitance, enhancing switching performance by increasing channel width density and optimizing the layout of doped regions and trenches.

Thermal Management Strategies for SiC MOSFET Applications

Thermal management is a critical aspect of SiC MOSFET applications, particularly when implementing soft-switching techniques. While soft-switching reduces switching losses, the thermal challenges remain significant due to the high power density and fast switching capabilities of SiC devices. Effective thermal management strategies must address both the steady-state and transient thermal behaviors unique to SiC MOSFETs operating under soft-switching conditions.

The primary thermal management approaches for SiC MOSFETs include advanced packaging technologies that minimize thermal resistance. Direct bonded copper (DBC) substrates and silver sintering die-attach methods have demonstrated superior thermal performance compared to traditional packaging, reducing junction-to-case thermal resistance by up to 30%. These improvements are particularly beneficial in soft-switching applications where thermal cycling can still be significant despite reduced switching losses.

Active cooling solutions represent another critical thermal management strategy. Liquid cooling systems have shown exceptional effectiveness for high-power SiC applications, capable of dissipating heat fluxes exceeding 500 W/cm². When combined with soft-switching techniques, these cooling systems can be optimized for the specific thermal profiles generated, focusing on steady-state thermal management rather than transient peaks that are minimized through soft-switching.

Thermal interface materials (TIMs) play a crucial role in the thermal management chain. Novel composite TIMs incorporating graphene or boron nitride nanostructures have demonstrated thermal conductivities above 10 W/m·K, significantly outperforming conventional materials. The selection of appropriate TIMs becomes particularly important in soft-switching applications where thermal gradients may be less severe but more consistent over time.

Temperature monitoring and dynamic thermal management systems represent the intelligence layer of thermal solutions. Advanced temperature sensors with response times under 1 millisecond can detect thermal events before they become problematic. When integrated with control systems that adjust switching parameters, these systems can optimize the balance between switching losses and conduction losses in real-time, maintaining optimal thermal conditions.

Computational fluid dynamics (CFD) and electrothermal co-simulation tools have become essential for designing thermal management systems for SiC MOSFET applications. These tools allow engineers to predict hotspots and thermal transients under various soft-switching conditions, enabling optimization of both electrical and thermal performance simultaneously. Recent advances in these simulation tools have reduced the gap between predicted and measured temperatures to less than 5%.

The integration of these thermal management strategies with soft-switching techniques creates a synergistic approach that maximizes the benefits of SiC technology. By addressing the unique thermal challenges of SiC MOSFETs, these strategies enable higher power densities, greater reliability, and extended device lifetimes in demanding applications such as electric vehicle powertrains, renewable energy systems, and industrial power conversion.

The primary thermal management approaches for SiC MOSFETs include advanced packaging technologies that minimize thermal resistance. Direct bonded copper (DBC) substrates and silver sintering die-attach methods have demonstrated superior thermal performance compared to traditional packaging, reducing junction-to-case thermal resistance by up to 30%. These improvements are particularly beneficial in soft-switching applications where thermal cycling can still be significant despite reduced switching losses.

Active cooling solutions represent another critical thermal management strategy. Liquid cooling systems have shown exceptional effectiveness for high-power SiC applications, capable of dissipating heat fluxes exceeding 500 W/cm². When combined with soft-switching techniques, these cooling systems can be optimized for the specific thermal profiles generated, focusing on steady-state thermal management rather than transient peaks that are minimized through soft-switching.

Thermal interface materials (TIMs) play a crucial role in the thermal management chain. Novel composite TIMs incorporating graphene or boron nitride nanostructures have demonstrated thermal conductivities above 10 W/m·K, significantly outperforming conventional materials. The selection of appropriate TIMs becomes particularly important in soft-switching applications where thermal gradients may be less severe but more consistent over time.

Temperature monitoring and dynamic thermal management systems represent the intelligence layer of thermal solutions. Advanced temperature sensors with response times under 1 millisecond can detect thermal events before they become problematic. When integrated with control systems that adjust switching parameters, these systems can optimize the balance between switching losses and conduction losses in real-time, maintaining optimal thermal conditions.

Computational fluid dynamics (CFD) and electrothermal co-simulation tools have become essential for designing thermal management systems for SiC MOSFET applications. These tools allow engineers to predict hotspots and thermal transients under various soft-switching conditions, enabling optimization of both electrical and thermal performance simultaneously. Recent advances in these simulation tools have reduced the gap between predicted and measured temperatures to less than 5%.

The integration of these thermal management strategies with soft-switching techniques creates a synergistic approach that maximizes the benefits of SiC technology. By addressing the unique thermal challenges of SiC MOSFETs, these strategies enable higher power densities, greater reliability, and extended device lifetimes in demanding applications such as electric vehicle powertrains, renewable energy systems, and industrial power conversion.

Reliability and Lifetime Assessment of SiC Power Devices

The reliability and lifetime assessment of SiC power devices represents a critical aspect when implementing soft-switching techniques in SiC MOSFET applications. Silicon Carbide devices, while offering superior performance characteristics compared to traditional silicon counterparts, present unique reliability challenges that must be thoroughly evaluated to ensure long-term operational stability.

SiC MOSFETs exhibit different degradation mechanisms compared to silicon devices, particularly under soft-switching conditions. The primary reliability concerns include threshold voltage instability, body diode degradation, and gate oxide integrity. Under soft-switching operations, these devices experience reduced switching losses but may face increased stress on the gate oxide due to high dv/dt and di/dt rates, potentially accelerating aging mechanisms.

Accelerated lifetime testing methodologies have been developed specifically for SiC power devices operating under soft-switching conditions. These tests typically involve thermal cycling, power cycling, and high-temperature gate bias stress tests that simulate years of operation within compressed timeframes. Recent studies indicate that SiC MOSFETs can maintain performance parameters within acceptable ranges for 15-20 years when properly implemented with soft-switching techniques, significantly outperforming silicon alternatives.

The failure modes in soft-switched SiC applications differ from hard-switched implementations. While hard-switching primarily causes failures through thermal cycling and bond wire fatigue, soft-switching applications show predominant failure mechanisms related to gate oxide degradation and threshold voltage drift. Statistical analysis of field data suggests that properly designed soft-switching circuits can extend SiC MOSFET lifetime by 30-40% compared to hard-switching implementations.

Condition monitoring techniques have evolved to provide real-time assessment of SiC device health in soft-switching applications. Parameters such as on-state resistance, switching energy, and thermal impedance serve as effective indicators of device degradation. Advanced monitoring systems now incorporate machine learning algorithms to predict remaining useful life based on operational data patterns.

Manufacturers have responded to reliability concerns by developing specialized SiC MOSFETs optimized for soft-switching applications, featuring enhanced gate oxide quality, improved packaging technologies, and refined die attach materials. These advancements have contributed to a steady improvement in the projected lifetime of soft-switched SiC power systems, with the latest generation devices demonstrating mean time between failures exceeding 100,000 hours under typical operating conditions.

SiC MOSFETs exhibit different degradation mechanisms compared to silicon devices, particularly under soft-switching conditions. The primary reliability concerns include threshold voltage instability, body diode degradation, and gate oxide integrity. Under soft-switching operations, these devices experience reduced switching losses but may face increased stress on the gate oxide due to high dv/dt and di/dt rates, potentially accelerating aging mechanisms.

Accelerated lifetime testing methodologies have been developed specifically for SiC power devices operating under soft-switching conditions. These tests typically involve thermal cycling, power cycling, and high-temperature gate bias stress tests that simulate years of operation within compressed timeframes. Recent studies indicate that SiC MOSFETs can maintain performance parameters within acceptable ranges for 15-20 years when properly implemented with soft-switching techniques, significantly outperforming silicon alternatives.

The failure modes in soft-switched SiC applications differ from hard-switched implementations. While hard-switching primarily causes failures through thermal cycling and bond wire fatigue, soft-switching applications show predominant failure mechanisms related to gate oxide degradation and threshold voltage drift. Statistical analysis of field data suggests that properly designed soft-switching circuits can extend SiC MOSFET lifetime by 30-40% compared to hard-switching implementations.

Condition monitoring techniques have evolved to provide real-time assessment of SiC device health in soft-switching applications. Parameters such as on-state resistance, switching energy, and thermal impedance serve as effective indicators of device degradation. Advanced monitoring systems now incorporate machine learning algorithms to predict remaining useful life based on operational data patterns.

Manufacturers have responded to reliability concerns by developing specialized SiC MOSFETs optimized for soft-switching applications, featuring enhanced gate oxide quality, improved packaging technologies, and refined die attach materials. These advancements have contributed to a steady improvement in the projected lifetime of soft-switched SiC power systems, with the latest generation devices demonstrating mean time between failures exceeding 100,000 hours under typical operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!