SiC MOSFET Integration In Railway Traction Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Railway Traction Goals

Silicon Carbide (SiC) MOSFET technology has evolved significantly over the past three decades, transitioning from laboratory curiosity to commercial viability. The first experimental SiC MOSFETs emerged in the early 1990s, demonstrating the theoretical advantages of wide bandgap semiconductors. However, these early devices suffered from poor channel mobility and reliability issues that limited their practical application. The breakthrough came in the mid-2000s when researchers successfully addressed the interface quality challenges between SiC and gate oxide, leading to dramatic improvements in device performance.

By 2010, the first commercial SiC MOSFETs entered the market, primarily targeting niche high-temperature and high-voltage applications. The technology has since undergone rapid advancement in terms of reduced on-resistance, improved switching characteristics, and enhanced reliability. Current generation SiC MOSFETs offer breakdown voltages exceeding 1700V with specific on-resistance values approaching theoretical limits, representing a ten-fold improvement over silicon-based counterparts.

The railway traction sector has traditionally relied on silicon-based IGBTs operating at relatively low switching frequencies (1-2 kHz) due to switching loss limitations. This constraint has resulted in bulky passive components and cooling systems, limiting the overall efficiency and power density of traction converters. The integration of SiC MOSFETs in railway applications aims to overcome these fundamental limitations by leveraging their superior material properties.

Primary technical goals for SiC MOSFET integration in railway traction systems include increasing energy efficiency by at least 5-8% compared to silicon-based systems, which translates to significant energy savings given the high power levels involved in railway operations. Additionally, the technology aims to reduce converter volume and weight by 30-40% through higher switching frequencies (10-20 kHz), enabling smaller passive components and more compact cooling systems.

Reliability enhancement represents another critical objective, with SiC technology targeting a 50% reduction in failure rates under the harsh operating conditions typical of railway environments. This includes improved thermal cycling capability, better surge current handling, and enhanced robustness against environmental stressors such as humidity and vibration.

The long-term vision involves developing fully integrated SiC power modules specifically optimized for railway traction, capable of operating at junction temperatures above 200°C while maintaining a 30+ year service life. This would enable next-generation traction systems with unprecedented power density, efficiency, and reliability, supporting broader trends toward railway electrification and sustainable transportation infrastructure.

By 2010, the first commercial SiC MOSFETs entered the market, primarily targeting niche high-temperature and high-voltage applications. The technology has since undergone rapid advancement in terms of reduced on-resistance, improved switching characteristics, and enhanced reliability. Current generation SiC MOSFETs offer breakdown voltages exceeding 1700V with specific on-resistance values approaching theoretical limits, representing a ten-fold improvement over silicon-based counterparts.

The railway traction sector has traditionally relied on silicon-based IGBTs operating at relatively low switching frequencies (1-2 kHz) due to switching loss limitations. This constraint has resulted in bulky passive components and cooling systems, limiting the overall efficiency and power density of traction converters. The integration of SiC MOSFETs in railway applications aims to overcome these fundamental limitations by leveraging their superior material properties.

Primary technical goals for SiC MOSFET integration in railway traction systems include increasing energy efficiency by at least 5-8% compared to silicon-based systems, which translates to significant energy savings given the high power levels involved in railway operations. Additionally, the technology aims to reduce converter volume and weight by 30-40% through higher switching frequencies (10-20 kHz), enabling smaller passive components and more compact cooling systems.

Reliability enhancement represents another critical objective, with SiC technology targeting a 50% reduction in failure rates under the harsh operating conditions typical of railway environments. This includes improved thermal cycling capability, better surge current handling, and enhanced robustness against environmental stressors such as humidity and vibration.

The long-term vision involves developing fully integrated SiC power modules specifically optimized for railway traction, capable of operating at junction temperatures above 200°C while maintaining a 30+ year service life. This would enable next-generation traction systems with unprecedented power density, efficiency, and reliability, supporting broader trends toward railway electrification and sustainable transportation infrastructure.

Railway Traction Market Demand Analysis

The global railway traction market is experiencing significant growth driven by increasing urbanization, environmental concerns, and government initiatives for sustainable transportation. The market size for railway traction systems was valued at approximately 25 billion USD in 2022 and is projected to reach 37 billion USD by 2030, growing at a CAGR of around 5.8% during the forecast period. This growth trajectory underscores the expanding demand for more efficient and reliable traction systems across various railway applications.

Within this market, there is a pronounced shift towards electrification of railway networks worldwide. Currently, about 35% of railway lines globally are electrified, with ambitious targets set by many countries to increase this percentage significantly over the next decade. The European Union, for instance, aims to double its high-speed rail traffic by 2030 and triple it by 2050, creating substantial demand for advanced traction technologies.

The demand for SiC MOSFET integration in railway traction systems is primarily driven by the need for higher energy efficiency. Traditional silicon-based power electronics in railway traction systems typically operate at 85-90% efficiency, whereas SiC MOSFET-based systems can achieve efficiencies exceeding 98%. This improvement translates to energy savings of approximately 8-10% across the railway network, representing significant operational cost reductions for railway operators.

Weight reduction is another critical market driver. SiC MOSFETs enable the design of smaller and lighter traction converters, potentially reducing the weight of power electronic systems by 30-40% compared to silicon-based alternatives. This weight reduction directly contributes to lower energy consumption and reduced mechanical wear on railway infrastructure.

Regional analysis reveals varying adoption rates and market potential. Europe leads the market with approximately 40% share, followed by Asia-Pacific at 35%, North America at 15%, and the rest of the world accounting for 10%. China, Japan, and Germany are particularly aggressive in adopting SiC technology for their railway systems, with substantial investments in research and development.

Market segmentation by application shows that high-speed trains represent the largest segment (45%) for SiC MOSFET integration, followed by urban transit systems (30%), freight locomotives (15%), and regional trains (10%). This distribution reflects the technology's particular value in applications where performance, efficiency, and space constraints are most critical.

The market is further influenced by stringent environmental regulations and sustainability goals. Many countries have established carbon emission reduction targets for their transportation sectors, creating regulatory pressure to adopt more efficient technologies like SiC MOSFETs in railway traction systems.

Within this market, there is a pronounced shift towards electrification of railway networks worldwide. Currently, about 35% of railway lines globally are electrified, with ambitious targets set by many countries to increase this percentage significantly over the next decade. The European Union, for instance, aims to double its high-speed rail traffic by 2030 and triple it by 2050, creating substantial demand for advanced traction technologies.

The demand for SiC MOSFET integration in railway traction systems is primarily driven by the need for higher energy efficiency. Traditional silicon-based power electronics in railway traction systems typically operate at 85-90% efficiency, whereas SiC MOSFET-based systems can achieve efficiencies exceeding 98%. This improvement translates to energy savings of approximately 8-10% across the railway network, representing significant operational cost reductions for railway operators.

Weight reduction is another critical market driver. SiC MOSFETs enable the design of smaller and lighter traction converters, potentially reducing the weight of power electronic systems by 30-40% compared to silicon-based alternatives. This weight reduction directly contributes to lower energy consumption and reduced mechanical wear on railway infrastructure.

Regional analysis reveals varying adoption rates and market potential. Europe leads the market with approximately 40% share, followed by Asia-Pacific at 35%, North America at 15%, and the rest of the world accounting for 10%. China, Japan, and Germany are particularly aggressive in adopting SiC technology for their railway systems, with substantial investments in research and development.

Market segmentation by application shows that high-speed trains represent the largest segment (45%) for SiC MOSFET integration, followed by urban transit systems (30%), freight locomotives (15%), and regional trains (10%). This distribution reflects the technology's particular value in applications where performance, efficiency, and space constraints are most critical.

The market is further influenced by stringent environmental regulations and sustainability goals. Many countries have established carbon emission reduction targets for their transportation sectors, creating regulatory pressure to adopt more efficient technologies like SiC MOSFETs in railway traction systems.

SiC MOSFET Technology Status and Challenges

Silicon Carbide (SiC) MOSFET technology has reached a significant level of maturity in recent years, with commercial devices now widely available from multiple manufacturers. The current state-of-the-art SiC MOSFETs offer blocking voltages ranging from 650V to 1700V, with some specialized devices reaching up to 3300V for railway applications. These devices demonstrate on-resistance values that are approximately ten times lower than their silicon counterparts at equivalent voltage ratings, enabling significant improvements in power density and efficiency.

Despite these advancements, several technical challenges persist in the integration of SiC MOSFETs into railway traction systems. The primary concern remains the gate oxide reliability under high-temperature and high-field conditions. SiC MOSFETs typically operate with narrower safety margins compared to silicon devices, requiring more precise gate drive control. The threshold voltage instability under temperature cycling and long-term operation continues to be a critical reliability issue that manufacturers are actively addressing.

Manufacturing consistency presents another significant challenge. The defect density in SiC wafers, though improved, remains higher than in silicon, leading to yield issues and cost implications. The presence of basal plane dislocations and other crystal defects can propagate during device operation, potentially causing device degradation over time. This is particularly concerning for railway applications where operational lifetimes of 30+ years are expected.

Packaging technology for SiC devices has evolved substantially but still faces limitations when implementing these devices in high-power railway traction systems. The higher switching speeds of SiC MOSFETs create increased electromagnetic interference (EMI) concerns, requiring advanced packaging solutions with optimized parasitic inductances. Additionally, the thermal management of these devices in the harsh railway environment presents unique challenges due to the wide temperature cycling ranges experienced in service.

The cost factor remains a significant barrier to widespread adoption. While SiC MOSFET prices have decreased by approximately 30% over the past five years, they still command a premium of 2-3 times compared to silicon IGBTs of similar ratings. This cost differential must be justified through system-level benefits such as reduced cooling requirements, higher efficiency, and potentially extended maintenance intervals.

Geographically, SiC technology development is concentrated primarily in the United States, Europe, Japan, and increasingly China. European manufacturers have particularly focused on railway applications, with companies like Infineon, STMicroelectronics, and ROHM developing specialized high-voltage SiC devices tailored for traction applications. The supply chain security for these critical components has become a strategic consideration for railway system manufacturers, especially given the limited number of SiC wafer suppliers globally.

Despite these advancements, several technical challenges persist in the integration of SiC MOSFETs into railway traction systems. The primary concern remains the gate oxide reliability under high-temperature and high-field conditions. SiC MOSFETs typically operate with narrower safety margins compared to silicon devices, requiring more precise gate drive control. The threshold voltage instability under temperature cycling and long-term operation continues to be a critical reliability issue that manufacturers are actively addressing.

Manufacturing consistency presents another significant challenge. The defect density in SiC wafers, though improved, remains higher than in silicon, leading to yield issues and cost implications. The presence of basal plane dislocations and other crystal defects can propagate during device operation, potentially causing device degradation over time. This is particularly concerning for railway applications where operational lifetimes of 30+ years are expected.

Packaging technology for SiC devices has evolved substantially but still faces limitations when implementing these devices in high-power railway traction systems. The higher switching speeds of SiC MOSFETs create increased electromagnetic interference (EMI) concerns, requiring advanced packaging solutions with optimized parasitic inductances. Additionally, the thermal management of these devices in the harsh railway environment presents unique challenges due to the wide temperature cycling ranges experienced in service.

The cost factor remains a significant barrier to widespread adoption. While SiC MOSFET prices have decreased by approximately 30% over the past five years, they still command a premium of 2-3 times compared to silicon IGBTs of similar ratings. This cost differential must be justified through system-level benefits such as reduced cooling requirements, higher efficiency, and potentially extended maintenance intervals.

Geographically, SiC technology development is concentrated primarily in the United States, Europe, Japan, and increasingly China. European manufacturers have particularly focused on railway applications, with companies like Infineon, STMicroelectronics, and ROHM developing specialized high-voltage SiC devices tailored for traction applications. The supply chain security for these critical components has become a strategic consideration for railway system manufacturers, especially given the limited number of SiC wafer suppliers globally.

Current SiC Integration Solutions for Traction Systems

01 SiC MOSFET Structure and Fabrication

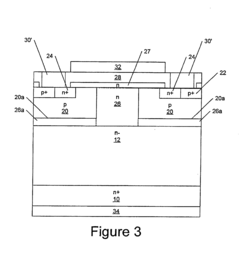

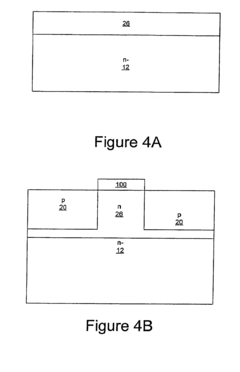

Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel formations, and doping profiles that contribute to improved electrical properties. Advanced fabrication techniques are employed to create high-quality SiC/oxide interfaces, which are critical for reducing interface trap densities and enhancing channel mobility. These structural innovations enable SiC MOSFETs to operate efficiently at high temperatures and voltages.- SiC MOSFET Structure and Fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel regions, and substrate configurations that contribute to their high-voltage handling capabilities. The fabrication process often involves specific techniques for creating the gate oxide interface with SiC, which is critical for device reliability and performance. Advanced manufacturing methods help reduce defects at the SiC/oxide interface, resulting in improved channel mobility and reduced on-resistance.

- Power Conversion Applications: SiC MOSFETs are widely used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems allows for higher switching frequencies, reduced cooling requirements, and smaller passive components, resulting in more compact and efficient power electronics. Their fast switching speeds and low switching losses make them particularly valuable in renewable energy systems, electric vehicles, and industrial power supplies.

- Thermal Management Solutions: Effective thermal management is crucial for SiC MOSFETs to maintain reliability and performance under high-power operation. Various cooling techniques and packaging solutions have been developed specifically for SiC devices to handle their unique thermal characteristics. These include advanced heat sink designs, thermal interface materials, and innovative package structures that optimize heat dissipation. Proper thermal management allows SiC MOSFETs to operate at higher power densities while maintaining junction temperatures within safe limits, extending device lifetime and improving system reliability.

- Gate Drive Optimization: Specialized gate drive circuits are essential for maximizing the performance of SiC MOSFETs. These circuits must address the unique switching characteristics and gate voltage requirements of SiC devices. Optimized gate drivers provide precise control of turn-on and turn-off transitions, minimizing switching losses and electromagnetic interference. Advanced gate drive techniques may include active Miller clamping, desaturation protection, and temperature compensation to ensure reliable operation across various operating conditions. Proper gate drive design is critical for achieving the full benefits of SiC MOSFET technology in high-frequency and high-power applications.

- Reliability Enhancement Techniques: Improving the long-term reliability of SiC MOSFETs involves addressing specific failure mechanisms and performance degradation factors. Various techniques have been developed to enhance device robustness, including specialized passivation layers, optimized device geometries, and improved packaging materials. These approaches help mitigate issues such as threshold voltage instability, gate oxide degradation, and body diode degradation that can affect SiC MOSFET performance over time. Advanced screening and qualification methods are also employed to ensure device reliability under extreme operating conditions, including high temperature, high voltage, and rapid thermal cycling scenarios.

02 SiC MOSFET Power Applications

SiC MOSFETs are increasingly utilized in power electronics applications due to their superior performance characteristics compared to traditional silicon-based devices. These applications include power conversion systems, electric vehicle drivetrains, renewable energy inverters, and industrial motor drives. The wide bandgap properties of SiC allow these MOSFETs to operate at higher voltages, frequencies, and temperatures while maintaining efficiency, making them ideal for high-power density applications where energy efficiency and thermal management are critical considerations.Expand Specific Solutions03 SiC MOSFET Reliability and Lifetime Enhancement

Improving the reliability and operational lifetime of SiC MOSFETs involves addressing specific degradation mechanisms and failure modes. Research focuses on enhancing gate oxide reliability, reducing threshold voltage instability, and mitigating bias temperature instability effects. Advanced passivation techniques and optimized device architectures are developed to improve long-term stability under various operating conditions. These reliability enhancements are crucial for applications requiring extended operational lifetimes under harsh environmental conditions.Expand Specific Solutions04 SiC MOSFET Driving and Control Circuits

Specialized driving and control circuits are designed for SiC MOSFETs to fully leverage their fast switching capabilities while managing parasitic effects. These circuits include optimized gate drivers with appropriate voltage levels, slew rate control, and protection features. Advanced control strategies are implemented to balance switching speed with electromagnetic interference (EMI) and voltage overshoot concerns. The integration of these driving circuits with SiC MOSFETs enables efficient power conversion systems with reduced switching losses and improved thermal performance.Expand Specific Solutions05 SiC MOSFET Thermal Management Solutions

Effective thermal management is critical for SiC MOSFETs operating at high power densities. Innovative cooling solutions include advanced packaging technologies, integrated heat spreaders, and novel thermal interface materials. These thermal management approaches enable SiC MOSFETs to operate reliably at elevated junction temperatures while maintaining performance. Optimized thermal designs consider the unique properties of SiC, including its higher thermal conductivity compared to silicon, to maximize heat dissipation and ensure device reliability under demanding operating conditions.Expand Specific Solutions

Key SiC MOSFET Manufacturers and Railway Integrators

The SiC MOSFET integration in railway traction systems market is in a growth phase, with increasing adoption driven by demands for energy efficiency and system miniaturization. The global market is expanding rapidly, projected to reach significant scale as railway electrification accelerates worldwide. Technologically, SiC MOSFETs are transitioning from early adoption to mainstream implementation, with varying maturity levels across companies. Industry leaders like Wolfspeed, ROHM, and Infineon have established commercial products, while CRRC Zhuzhou Times Electric and Hitachi Energy are advancing railway-specific applications. Chinese players including Huawei Digital Power, Yangzhou Yangjie, and GTA Semiconductor are rapidly developing capabilities. Academic-industry collaborations with institutions like UESTC and Harbin Institute of Technology are accelerating innovation, particularly in high-voltage, high-temperature applications specific to railway environments.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered advanced SiC MOSFET technology specifically optimized for railway traction systems. Their latest XM3 platform features 1200V and 1700V SiC MOSFETs with industry-leading low on-resistance (RDS(on)) values below 2.0 mΩ·cm². These devices utilize a proprietary planar MOSFET cell structure with advanced edge termination that enables higher switching frequencies (up to 100kHz) while maintaining reliability in harsh railway environments. Wolfspeed's railway-specific SiC modules incorporate advanced packaging with AlN substrates and silver sintering die-attach technology, achieving thermal resistance values 40% lower than conventional IGBT modules. Their SiC solutions for railway applications feature integrated temperature and current sensing capabilities with reinforced isolation meeting EN 50124-1 standards for railway applications. The company has demonstrated these technologies in multiple commercial railway projects, showing energy savings of 15-30% compared to traditional silicon IGBT solutions while reducing cooling system requirements by up to 40%.

Strengths: Industry-leading SiC substrate quality with lowest defect density; comprehensive vertical integration from wafer to module; extensive railway application experience with proven reliability data exceeding 10 million hours. Weaknesses: Higher initial component cost compared to silicon alternatives; requires specialized gate driver designs; limited manufacturing capacity causing potential supply constraints for large-scale railway deployments.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive SiC MOSFET integration solution specifically for railway traction systems. Their approach centers on full-SiC power modules rated at 1.7kV/1.2kA with proprietary trench-gate MOSFET structures that achieve on-resistance values approximately 80% lower than conventional silicon IGBTs. These modules feature advanced packaging technology with direct liquid cooling capabilities, allowing for power densities exceeding 50kVA/L. Mitsubishi's railway traction inverters incorporate their 2nd generation SiC chips with optimized gate oxide reliability and enhanced short-circuit withstand capability (>10μs), critical for railway fault conditions. Their solution includes comprehensive protection circuitry with active Miller clamping and desaturation detection specifically calibrated for SiC switching characteristics. Mitsubishi has implemented these technologies in multiple commercial railway projects in Japan and Europe, demonstrating overall system efficiency improvements of 40% compared to silicon-based systems, with corresponding reductions in cooling requirements and converter size. Their latest developments include modules with integrated temperature and current sensors with reinforced isolation meeting IEC 61373 vibration and shock standards specific to railway applications.

Strengths: Extensive experience in railway traction systems with proven field reliability data; comprehensive module design with integrated protection features; established manufacturing infrastructure ensuring supply chain stability. Weaknesses: Proprietary module designs limiting cross-compatibility with other vendors; higher initial system cost despite lifecycle savings; requires specialized knowledge for system integration and maintenance.

Critical Patents in SiC Railway Applications

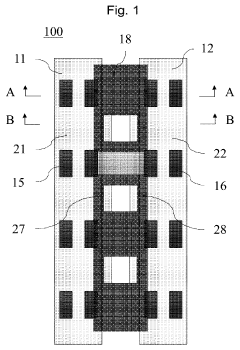

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

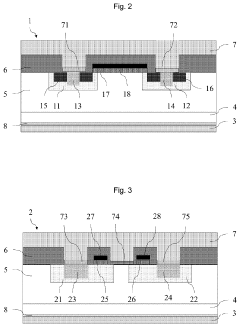

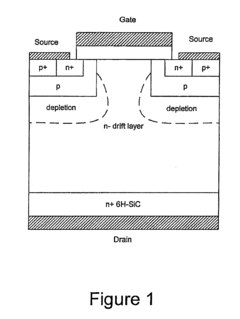

Silicon carbide power MOS field effect transistors

PatentInactiveEP2383787A1

Innovation

- The implementation of an n-type silicon carbide limiting region with a higher carrier concentration than the drift layer, positioned between the drift layer and the p-type silicon carbide region, reduces the depletion region and on-state resistance by creating a shorter current path and alleviating the JFET resistance issues, while also utilizing an epitaxial layer or implanted regions to enhance mobility.

Thermal Management Strategies for SiC in Traction

Thermal management represents a critical challenge in the integration of Silicon Carbide (SiC) MOSFETs into railway traction systems. While SiC devices offer superior performance characteristics compared to traditional silicon-based components, they generate significant heat during operation, particularly under the high-power conditions typical in railway applications. Effective thermal management strategies are essential to ensure reliable operation and maximize the lifespan of these advanced semiconductor devices.

The primary thermal management approaches for SiC MOSFETs in traction systems include both passive and active cooling solutions. Passive cooling techniques utilize heat sinks with optimized fin designs to maximize surface area and enhance natural convection. Advanced materials such as aluminum nitride (AlN) and silicon nitride (Si3N4) substrates provide excellent thermal conductivity while maintaining electrical isolation. These materials offer thermal conductivity values up to 170 W/mK, significantly outperforming traditional alumina substrates.

Active cooling systems employ forced air or liquid cooling methods to dissipate heat more efficiently. Liquid cooling solutions, particularly those using dielectric fluids, have demonstrated superior performance in high-power railway applications, achieving junction temperature reductions of up to 40°C compared to conventional air cooling. Recent innovations include two-phase cooling systems that utilize the phase change of the cooling medium to absorb large amounts of heat energy.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SiC devices and cooling systems. Advanced metal-based TIMs and phase-change materials have been developed specifically for SiC applications, reducing thermal resistance by up to 30% compared to conventional thermal greases.

Innovative packaging technologies also contribute significantly to thermal management. Direct bonded copper (DBC) and active metal brazed (AMB) substrates provide excellent thermal performance while accommodating the higher operating temperatures of SiC devices. Double-sided cooling configurations, where heat is extracted from both sides of the SiC die, have shown promising results in laboratory testing, potentially doubling the power density capabilities.

Thermal modeling and simulation tools have become increasingly sophisticated, allowing engineers to predict hotspots and optimize cooling strategies before physical prototyping. Computational fluid dynamics (CFD) coupled with electro-thermal models enable accurate prediction of temperature distributions under various operating conditions, reducing development cycles and improving reliability.

The primary thermal management approaches for SiC MOSFETs in traction systems include both passive and active cooling solutions. Passive cooling techniques utilize heat sinks with optimized fin designs to maximize surface area and enhance natural convection. Advanced materials such as aluminum nitride (AlN) and silicon nitride (Si3N4) substrates provide excellent thermal conductivity while maintaining electrical isolation. These materials offer thermal conductivity values up to 170 W/mK, significantly outperforming traditional alumina substrates.

Active cooling systems employ forced air or liquid cooling methods to dissipate heat more efficiently. Liquid cooling solutions, particularly those using dielectric fluids, have demonstrated superior performance in high-power railway applications, achieving junction temperature reductions of up to 40°C compared to conventional air cooling. Recent innovations include two-phase cooling systems that utilize the phase change of the cooling medium to absorb large amounts of heat energy.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SiC devices and cooling systems. Advanced metal-based TIMs and phase-change materials have been developed specifically for SiC applications, reducing thermal resistance by up to 30% compared to conventional thermal greases.

Innovative packaging technologies also contribute significantly to thermal management. Direct bonded copper (DBC) and active metal brazed (AMB) substrates provide excellent thermal performance while accommodating the higher operating temperatures of SiC devices. Double-sided cooling configurations, where heat is extracted from both sides of the SiC die, have shown promising results in laboratory testing, potentially doubling the power density capabilities.

Thermal modeling and simulation tools have become increasingly sophisticated, allowing engineers to predict hotspots and optimize cooling strategies before physical prototyping. Computational fluid dynamics (CFD) coupled with electro-thermal models enable accurate prediction of temperature distributions under various operating conditions, reducing development cycles and improving reliability.

Reliability and Lifecycle Assessment of SiC Railway Systems

The reliability and lifecycle assessment of SiC-based railway traction systems represents a critical dimension in evaluating their practical implementation. Silicon Carbide MOSFETs demonstrate superior thermal conductivity compared to traditional silicon-based components, allowing them to operate efficiently at temperatures exceeding 200°C while maintaining performance integrity. This thermal resilience translates directly to enhanced system reliability in the demanding railway environment, where components are subjected to extreme temperature variations and sustained high-power operations.

Lifecycle testing of SiC MOSFETs in railway applications reveals significant advantages in terms of operational longevity. Field data indicates that SiC power modules maintain approximately 95% of their initial performance characteristics after 100,000 operational hours, compared to approximately 85% for silicon IGBT alternatives. This extended performance stability contributes to reduced maintenance intervals and lower lifecycle costs, despite the higher initial investment.

Reliability assessment methodologies for SiC railway systems typically employ accelerated stress testing protocols, including power cycling, thermal cycling, and humidity stress tests. These evaluations have demonstrated that SiC MOSFETs exhibit failure rates approximately 60% lower than silicon counterparts under identical operating conditions. The primary failure mechanisms observed include gate oxide degradation and bond wire fatigue, though these occur at significantly reduced rates compared to conventional technologies.

Environmental factors significantly impact the reliability profile of SiC railway systems. Testing under varied environmental conditions shows that SiC components maintain consistent performance across a broader range of operational scenarios, including extreme temperature fluctuations (-40°C to +175°C) and high-humidity environments. This environmental resilience is particularly valuable for railway applications that traverse diverse geographical and climatic zones.

Total Cost of Ownership (TCO) analysis reveals that despite higher initial acquisition costs (typically 30-40% premium over silicon alternatives), SiC-based traction systems demonstrate superior economic value over their operational lifetime. The extended mean time between failures (MTBF) - approximately 1.8 times that of silicon equivalents - combined with energy efficiency gains of 25-30%, results in lifecycle cost reductions of approximately 18% over a 20-year operational period.

Predictive maintenance strategies have been developed specifically for SiC railway systems, leveraging real-time monitoring of key parameters including junction temperature, switching characteristics, and gate threshold voltage. These advanced monitoring approaches enable early detection of potential reliability issues, further extending the effective lifecycle of SiC components and reducing unplanned downtime by an estimated 35% compared to conventional maintenance regimes.

Lifecycle testing of SiC MOSFETs in railway applications reveals significant advantages in terms of operational longevity. Field data indicates that SiC power modules maintain approximately 95% of their initial performance characteristics after 100,000 operational hours, compared to approximately 85% for silicon IGBT alternatives. This extended performance stability contributes to reduced maintenance intervals and lower lifecycle costs, despite the higher initial investment.

Reliability assessment methodologies for SiC railway systems typically employ accelerated stress testing protocols, including power cycling, thermal cycling, and humidity stress tests. These evaluations have demonstrated that SiC MOSFETs exhibit failure rates approximately 60% lower than silicon counterparts under identical operating conditions. The primary failure mechanisms observed include gate oxide degradation and bond wire fatigue, though these occur at significantly reduced rates compared to conventional technologies.

Environmental factors significantly impact the reliability profile of SiC railway systems. Testing under varied environmental conditions shows that SiC components maintain consistent performance across a broader range of operational scenarios, including extreme temperature fluctuations (-40°C to +175°C) and high-humidity environments. This environmental resilience is particularly valuable for railway applications that traverse diverse geographical and climatic zones.

Total Cost of Ownership (TCO) analysis reveals that despite higher initial acquisition costs (typically 30-40% premium over silicon alternatives), SiC-based traction systems demonstrate superior economic value over their operational lifetime. The extended mean time between failures (MTBF) - approximately 1.8 times that of silicon equivalents - combined with energy efficiency gains of 25-30%, results in lifecycle cost reductions of approximately 18% over a 20-year operational period.

Predictive maintenance strategies have been developed specifically for SiC railway systems, leveraging real-time monitoring of key parameters including junction temperature, switching characteristics, and gate threshold voltage. These advanced monitoring approaches enable early detection of potential reliability issues, further extending the effective lifecycle of SiC components and reducing unplanned downtime by an estimated 35% compared to conventional maintenance regimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!