How Ethyl Acetate Adapts to Modern Manufacturing Needs?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Evolution

Ethyl acetate has undergone a significant evolution in its manufacturing processes and applications over the years, adapting to the changing needs of modern industry. Initially produced through traditional esterification methods, the synthesis of ethyl acetate has seen remarkable advancements to meet the increasing demand and stringent quality requirements of various sectors.

In the early stages of its industrial production, ethyl acetate was primarily manufactured using batch processes, which were characterized by long reaction times and limited output. However, as the demand for this versatile solvent grew, particularly in the coatings, adhesives, and pharmaceutical industries, there was a pressing need for more efficient production methods.

The introduction of continuous flow reactors marked a significant milestone in ethyl acetate manufacturing. This technology allowed for increased production capacity, improved product consistency, and reduced energy consumption. Continuous processes also facilitated better control over reaction parameters, leading to higher yields and purer end products.

Another notable advancement in ethyl acetate production has been the development of heterogeneous catalysts. These catalysts have largely replaced traditional homogeneous catalysts, offering benefits such as easier separation from the reaction mixture, longer catalyst lifetimes, and the potential for catalyst recycling. This shift has not only improved process efficiency but also aligned with the growing emphasis on sustainable manufacturing practices.

Recent years have seen a focus on green chemistry principles in ethyl acetate production. Researchers and manufacturers have explored bio-based feedstocks as alternatives to petrochemical-derived raw materials. This approach not only addresses sustainability concerns but also opens up new avenues for product differentiation in an increasingly environmentally conscious market.

The evolution of ethyl acetate manufacturing has also been influenced by advancements in process intensification techniques. Microreactor technology, for instance, has shown promise in enhancing reaction efficiency and reducing the environmental footprint of production processes. These miniaturized reaction systems offer benefits such as improved heat and mass transfer, leading to faster reactions and potentially higher yields.

In response to modern manufacturing needs, there has been a growing emphasis on developing flexible production systems for ethyl acetate. These adaptable setups allow manufacturers to quickly adjust production volumes and product specifications to meet fluctuating market demands, a crucial capability in today's fast-paced industrial landscape.

In the early stages of its industrial production, ethyl acetate was primarily manufactured using batch processes, which were characterized by long reaction times and limited output. However, as the demand for this versatile solvent grew, particularly in the coatings, adhesives, and pharmaceutical industries, there was a pressing need for more efficient production methods.

The introduction of continuous flow reactors marked a significant milestone in ethyl acetate manufacturing. This technology allowed for increased production capacity, improved product consistency, and reduced energy consumption. Continuous processes also facilitated better control over reaction parameters, leading to higher yields and purer end products.

Another notable advancement in ethyl acetate production has been the development of heterogeneous catalysts. These catalysts have largely replaced traditional homogeneous catalysts, offering benefits such as easier separation from the reaction mixture, longer catalyst lifetimes, and the potential for catalyst recycling. This shift has not only improved process efficiency but also aligned with the growing emphasis on sustainable manufacturing practices.

Recent years have seen a focus on green chemistry principles in ethyl acetate production. Researchers and manufacturers have explored bio-based feedstocks as alternatives to petrochemical-derived raw materials. This approach not only addresses sustainability concerns but also opens up new avenues for product differentiation in an increasingly environmentally conscious market.

The evolution of ethyl acetate manufacturing has also been influenced by advancements in process intensification techniques. Microreactor technology, for instance, has shown promise in enhancing reaction efficiency and reducing the environmental footprint of production processes. These miniaturized reaction systems offer benefits such as improved heat and mass transfer, leading to faster reactions and potentially higher yields.

In response to modern manufacturing needs, there has been a growing emphasis on developing flexible production systems for ethyl acetate. These adaptable setups allow manufacturers to quickly adjust production volumes and product specifications to meet fluctuating market demands, a crucial capability in today's fast-paced industrial landscape.

Market Demand Analysis

The global market for ethyl acetate has been experiencing steady growth, driven by its versatile applications across various industries. In the modern manufacturing landscape, ethyl acetate has become an indispensable component, particularly in sectors such as paints and coatings, adhesives, pharmaceuticals, and food packaging.

The paint and coating industry remains the largest consumer of ethyl acetate, accounting for a significant portion of the market demand. This is primarily due to ethyl acetate's excellent solvency properties and low toxicity, making it an ideal choice for environmentally conscious manufacturers. The increasing focus on sustainable and eco-friendly products has further boosted the demand for ethyl acetate as a replacement for more harmful solvents.

In the adhesives sector, ethyl acetate has gained traction as a key ingredient in the production of flexible packaging adhesives. The growing e-commerce industry and the subsequent rise in packaging requirements have contributed to the increased demand for ethyl acetate in this segment. Additionally, the pharmaceutical industry utilizes ethyl acetate in the production of various drugs and as a solvent in the extraction of active pharmaceutical ingredients.

The food and beverage industry has also emerged as a significant consumer of ethyl acetate, particularly in the production of artificial flavors and essences. As consumer preferences shift towards natural and organic products, the demand for ethyl acetate in this sector is expected to witness substantial growth.

Geographically, Asia-Pacific dominates the ethyl acetate market, with China and India being the major consumers. The rapid industrialization and urbanization in these countries have led to increased demand across various end-use industries. North America and Europe follow closely, driven by stringent environmental regulations promoting the use of eco-friendly solvents.

The market demand for ethyl acetate is influenced by several factors, including the growth of end-use industries, technological advancements in manufacturing processes, and regulatory policies. The shift towards bio-based ethyl acetate, derived from renewable resources, is gaining momentum as manufacturers strive to reduce their carbon footprint and meet sustainability goals.

Despite the positive outlook, the ethyl acetate market faces challenges such as price volatility of raw materials and competition from alternative solvents. However, ongoing research and development efforts aimed at improving production efficiency and exploring new applications are expected to create lucrative opportunities for market growth in the coming years.

The paint and coating industry remains the largest consumer of ethyl acetate, accounting for a significant portion of the market demand. This is primarily due to ethyl acetate's excellent solvency properties and low toxicity, making it an ideal choice for environmentally conscious manufacturers. The increasing focus on sustainable and eco-friendly products has further boosted the demand for ethyl acetate as a replacement for more harmful solvents.

In the adhesives sector, ethyl acetate has gained traction as a key ingredient in the production of flexible packaging adhesives. The growing e-commerce industry and the subsequent rise in packaging requirements have contributed to the increased demand for ethyl acetate in this segment. Additionally, the pharmaceutical industry utilizes ethyl acetate in the production of various drugs and as a solvent in the extraction of active pharmaceutical ingredients.

The food and beverage industry has also emerged as a significant consumer of ethyl acetate, particularly in the production of artificial flavors and essences. As consumer preferences shift towards natural and organic products, the demand for ethyl acetate in this sector is expected to witness substantial growth.

Geographically, Asia-Pacific dominates the ethyl acetate market, with China and India being the major consumers. The rapid industrialization and urbanization in these countries have led to increased demand across various end-use industries. North America and Europe follow closely, driven by stringent environmental regulations promoting the use of eco-friendly solvents.

The market demand for ethyl acetate is influenced by several factors, including the growth of end-use industries, technological advancements in manufacturing processes, and regulatory policies. The shift towards bio-based ethyl acetate, derived from renewable resources, is gaining momentum as manufacturers strive to reduce their carbon footprint and meet sustainability goals.

Despite the positive outlook, the ethyl acetate market faces challenges such as price volatility of raw materials and competition from alternative solvents. However, ongoing research and development efforts aimed at improving production efficiency and exploring new applications are expected to create lucrative opportunities for market growth in the coming years.

Technical Challenges

The adaptation of ethyl acetate to modern manufacturing needs faces several technical challenges that require innovative solutions. One of the primary obstacles is the optimization of production processes to meet increasing demand while maintaining cost-effectiveness. Traditional batch production methods often struggle to achieve the necessary throughput and efficiency required by contemporary industries.

Continuous flow chemistry presents a promising alternative, but its implementation for ethyl acetate production introduces complexities in process control and scalability. Achieving precise temperature regulation and maintaining optimal reaction conditions throughout the continuous flow system pose significant engineering challenges. Additionally, the development of catalysts that can withstand the rigors of continuous operation without rapid degradation remains an area of active research.

Environmental concerns also drive the need for greener production methods. The conventional synthesis of ethyl acetate often relies on petrochemical feedstocks and energy-intensive processes. Developing bio-based routes for ethyl acetate production, such as utilizing ethanol derived from renewable sources, faces hurdles in terms of yield, purity, and economic viability when compared to traditional methods.

Purification and separation technologies represent another critical area for improvement. Current distillation techniques used to isolate ethyl acetate from reaction mixtures are energy-intensive and can lead to significant product loss. Advanced separation methods, such as membrane technologies or novel adsorbents, show promise but require further development to achieve industrial-scale applicability and cost-effectiveness.

The volatility of ethyl acetate presents challenges in handling, storage, and transportation. Developing safer, more efficient containment systems and implementing advanced vapor recovery technologies are essential for minimizing losses and ensuring worker safety. Moreover, the flammability of ethyl acetate necessitates the development of improved fire suppression systems and safety protocols tailored to modern manufacturing facilities.

Quality control and consistency in large-scale production remain ongoing challenges. Variations in feedstock quality and reaction conditions can lead to inconsistencies in the final product. Implementing real-time monitoring systems and developing robust process analytical technologies (PAT) are crucial for maintaining product quality while adapting to the high-throughput demands of modern manufacturing.

Lastly, the integration of ethyl acetate production into broader chemical manufacturing ecosystems presents logistical and technical challenges. Optimizing supply chains, developing flexible production capabilities to respond to market fluctuations, and ensuring compatibility with downstream processes all require innovative approaches and technologies. As industries increasingly move towards circular economy models, finding ways to recycle or upcycle ethyl acetate waste streams becomes an important area for technological development.

Continuous flow chemistry presents a promising alternative, but its implementation for ethyl acetate production introduces complexities in process control and scalability. Achieving precise temperature regulation and maintaining optimal reaction conditions throughout the continuous flow system pose significant engineering challenges. Additionally, the development of catalysts that can withstand the rigors of continuous operation without rapid degradation remains an area of active research.

Environmental concerns also drive the need for greener production methods. The conventional synthesis of ethyl acetate often relies on petrochemical feedstocks and energy-intensive processes. Developing bio-based routes for ethyl acetate production, such as utilizing ethanol derived from renewable sources, faces hurdles in terms of yield, purity, and economic viability when compared to traditional methods.

Purification and separation technologies represent another critical area for improvement. Current distillation techniques used to isolate ethyl acetate from reaction mixtures are energy-intensive and can lead to significant product loss. Advanced separation methods, such as membrane technologies or novel adsorbents, show promise but require further development to achieve industrial-scale applicability and cost-effectiveness.

The volatility of ethyl acetate presents challenges in handling, storage, and transportation. Developing safer, more efficient containment systems and implementing advanced vapor recovery technologies are essential for minimizing losses and ensuring worker safety. Moreover, the flammability of ethyl acetate necessitates the development of improved fire suppression systems and safety protocols tailored to modern manufacturing facilities.

Quality control and consistency in large-scale production remain ongoing challenges. Variations in feedstock quality and reaction conditions can lead to inconsistencies in the final product. Implementing real-time monitoring systems and developing robust process analytical technologies (PAT) are crucial for maintaining product quality while adapting to the high-throughput demands of modern manufacturing.

Lastly, the integration of ethyl acetate production into broader chemical manufacturing ecosystems presents logistical and technical challenges. Optimizing supply chains, developing flexible production capabilities to respond to market fluctuations, and ensuring compatibility with downstream processes all require innovative approaches and technologies. As industries increasingly move towards circular economy models, finding ways to recycle or upcycle ethyl acetate waste streams becomes an important area for technological development.

Current Manufacturing

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate, which is an important industrial solvent and chemical intermediate.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts or reactants to improve yield and purity. Some processes focus on continuous production methods or the recovery of ethyl acetate from waste streams.

- Applications of ethyl acetate in industrial processes: Ethyl acetate is utilized in various industrial applications, including as a solvent in chemical processes, in the production of coatings and adhesives, and in the pharmaceutical industry. Its use in extraction processes, particularly in the food and beverage industry, is also noted.

- Ethyl acetate in polymer and material science: The use of ethyl acetate in polymer synthesis, material modifications, and as a component in composite materials is described. This includes its role in creating specific material properties, such as improved adhesion or controlled release characteristics.

- Environmental and safety considerations for ethyl acetate: Processes and systems for the safe handling, storage, and disposal of ethyl acetate are outlined. This includes methods for reducing environmental impact, recovering ethyl acetate from waste streams, and ensuring workplace safety when using the compound.

- Novel synthesis routes and derivatives of ethyl acetate: Research into new methods for synthesizing ethyl acetate or creating novel derivatives is presented. This includes the exploration of alternative feedstocks, catalytic processes, and the development of ethyl acetate-based compounds with enhanced properties for specific applications.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes and applications, such as in the production of other chemicals, as a solvent in pharmaceutical manufacturing, and in the synthesis of polymers and resins. Its versatility and relatively low toxicity make it a valuable compound in many industrial sectors.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed as a solvent in extraction and separation processes for various compounds, including natural products, pharmaceuticals, and other organic substances. Its properties make it suitable for liquid-liquid extraction and other separation techniques.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling and storage practices to minimize risks associated with its flammability and volatility.Expand Specific Solutions05 Novel applications and formulations of ethyl acetate

Innovative uses and formulations of ethyl acetate are being explored, including its application in advanced materials, coatings, and specialty chemicals. These developments aim to expand the utility of ethyl acetate beyond its traditional roles as a solvent and chemical intermediate.Expand Specific Solutions

Industry Leaders

The ethyl acetate market is in a mature stage, with a global market size estimated to be over $3 billion. The industry is characterized by established players and increasing demand from various end-use sectors, particularly in manufacturing and industrial applications. Technological advancements are focused on improving production efficiency and sustainability. Key players like Celanese, Eastman Chemical, and SABIC are driving innovation in process technologies and product formulations. Chinese companies such as China Petroleum & Chemical Corp. and Jiangsu Baichuan High-Tech New Materials are also making significant strides in production capacity and market share. The competitive landscape is further shaped by collaborations between industry and academic institutions, as seen with partnerships involving universities like Nanjing Normal University and Hebei University of Science & Technology.

Celanese International Corp.

Technical Solution: Celanese has developed an advanced continuous production process for ethyl acetate, utilizing reactive distillation technology. This method combines esterification and distillation in a single column, improving efficiency and product purity. The process employs a heterogeneous catalyst, which enhances reaction rates and selectivity[1]. Celanese's approach also incorporates heat integration systems, reducing energy consumption by up to 30% compared to conventional batch processes[2]. Additionally, they have implemented real-time monitoring and control systems, allowing for precise adjustments to reaction conditions and ensuring consistent product quality[3].

Strengths: High efficiency, improved product purity, reduced energy consumption, and consistent quality. Weaknesses: Higher initial capital investment and potential complexity in process control.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a large-scale, integrated ethyl acetate production process that leverages its existing petrochemical infrastructure. Their approach utilizes acetic acid produced from coal-based syngas, coupled with ethanol from their ethylene oxide production units[7]. Sinopec's process incorporates a novel fixed-bed reactor design with improved mass transfer characteristics, increasing conversion rates by up to 15%[8]. They have also implemented advanced process control systems using artificial intelligence algorithms, optimizing reaction conditions in real-time and reducing energy consumption. Additionally, Sinopec has developed a zero-liquid discharge system for their ethyl acetate plants, significantly reducing water usage and environmental impact[9].

Strengths: Large-scale production capability, vertical integration, and improved resource efficiency. Weaknesses: Reliance on coal-based feedstocks and potential environmental concerns.

Key Innovations

Process for production of ethyl acetate

PatentWO2025072073A1

Innovation

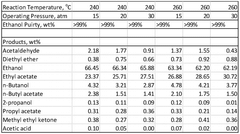

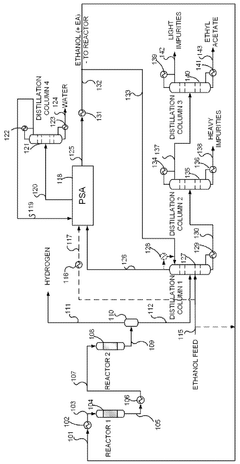

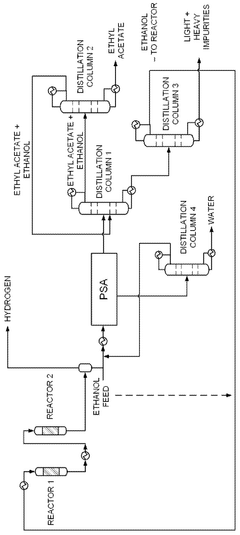

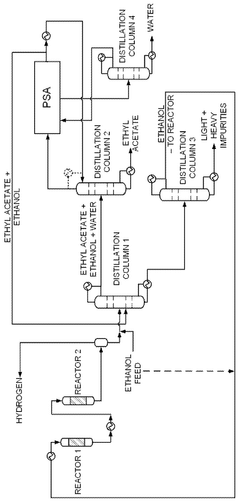

- A novel process that converts ethanol to ethyl acetate through dehydrogenation, followed by selective hydrogenation of byproducts to facilitate easier separation, and utilizes pressure swing adsorption to minimize water content and protect the catalyst.

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

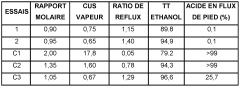

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

Sustainability Aspects

Ethyl acetate's adaptation to modern manufacturing needs is increasingly focused on sustainability aspects, reflecting the growing emphasis on environmentally responsible practices in industrial processes. The production and use of ethyl acetate have undergone significant transformations to align with sustainable manufacturing principles.

One of the key sustainability improvements in ethyl acetate production is the shift towards bio-based feedstocks. Traditional methods rely on petrochemical sources, but modern approaches utilize renewable resources such as ethanol derived from agricultural waste or other biomass sources. This transition reduces dependency on fossil fuels and decreases the overall carbon footprint of ethyl acetate production.

Energy efficiency in manufacturing processes has also been a focal point for sustainability enhancements. Advanced distillation techniques and heat integration systems have been implemented to minimize energy consumption during ethyl acetate synthesis. These improvements not only reduce environmental impact but also contribute to cost savings in production.

Water conservation efforts have been integrated into ethyl acetate manufacturing. Closed-loop water recycling systems and advanced wastewater treatment technologies have been adopted to minimize water usage and reduce the discharge of potentially harmful effluents. This approach aligns with the principles of circular economy and responsible resource management.

The development of greener reaction pathways has further enhanced the sustainability profile of ethyl acetate production. Catalytic processes that operate under milder conditions and require less energy input have been introduced. These methods often result in higher yields and fewer by-products, contributing to both environmental and economic sustainability.

End-of-life considerations for ethyl acetate have also been addressed in modern manufacturing. Improved recycling and recovery methods have been developed to capture and reuse ethyl acetate from various industrial processes. This not only reduces waste but also decreases the demand for new production, creating a more circular and sustainable supply chain.

Safety aspects of ethyl acetate handling and storage have been enhanced to meet modern sustainability standards. Advanced containment systems and vapor recovery units have been implemented to prevent emissions and protect worker health. These measures contribute to the overall sustainability of ethyl acetate use in manufacturing environments.

The packaging and transportation of ethyl acetate have also undergone sustainability-focused improvements. Lightweight, recyclable containers and optimized logistics strategies have been adopted to reduce the environmental impact associated with product distribution. These changes contribute to lowering the overall carbon footprint of ethyl acetate throughout its lifecycle.

One of the key sustainability improvements in ethyl acetate production is the shift towards bio-based feedstocks. Traditional methods rely on petrochemical sources, but modern approaches utilize renewable resources such as ethanol derived from agricultural waste or other biomass sources. This transition reduces dependency on fossil fuels and decreases the overall carbon footprint of ethyl acetate production.

Energy efficiency in manufacturing processes has also been a focal point for sustainability enhancements. Advanced distillation techniques and heat integration systems have been implemented to minimize energy consumption during ethyl acetate synthesis. These improvements not only reduce environmental impact but also contribute to cost savings in production.

Water conservation efforts have been integrated into ethyl acetate manufacturing. Closed-loop water recycling systems and advanced wastewater treatment technologies have been adopted to minimize water usage and reduce the discharge of potentially harmful effluents. This approach aligns with the principles of circular economy and responsible resource management.

The development of greener reaction pathways has further enhanced the sustainability profile of ethyl acetate production. Catalytic processes that operate under milder conditions and require less energy input have been introduced. These methods often result in higher yields and fewer by-products, contributing to both environmental and economic sustainability.

End-of-life considerations for ethyl acetate have also been addressed in modern manufacturing. Improved recycling and recovery methods have been developed to capture and reuse ethyl acetate from various industrial processes. This not only reduces waste but also decreases the demand for new production, creating a more circular and sustainable supply chain.

Safety aspects of ethyl acetate handling and storage have been enhanced to meet modern sustainability standards. Advanced containment systems and vapor recovery units have been implemented to prevent emissions and protect worker health. These measures contribute to the overall sustainability of ethyl acetate use in manufacturing environments.

The packaging and transportation of ethyl acetate have also undergone sustainability-focused improvements. Lightweight, recyclable containers and optimized logistics strategies have been adopted to reduce the environmental impact associated with product distribution. These changes contribute to lowering the overall carbon footprint of ethyl acetate throughout its lifecycle.

Regulatory Compliance

Regulatory compliance plays a crucial role in the adaptation of ethyl acetate to modern manufacturing needs. As industries evolve and environmental concerns grow, manufacturers must navigate an increasingly complex landscape of regulations governing the production, use, and disposal of chemical substances.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting requirements, including the submission of pre-manufacture notices for new uses of the chemical. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for workers handling ethyl acetate in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on companies producing or importing ethyl acetate. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information. The Classification, Labeling, and Packaging (CLP) regulation further mandates specific hazard communication standards for ethyl acetate products.

In response to these regulatory challenges, modern manufacturing processes for ethyl acetate have adapted to incorporate more sustainable practices. This includes the development of closed-loop systems that minimize emissions and reduce waste. Many facilities have implemented advanced air pollution control technologies to comply with stringent volatile organic compound (VOC) emission limits.

The food and pharmaceutical industries face additional regulatory scrutiny when using ethyl acetate. In the United States, the Food and Drug Administration (FDA) regulates ethyl acetate as a food additive and solvent in drug manufacturing. Manufacturers must adhere to Good Manufacturing Practices (GMP) and ensure that residual levels in final products meet established safety standards.

Globally, the transportation of ethyl acetate is subject to international regulations such as the United Nations Recommendations on the Transport of Dangerous Goods. These guidelines dictate proper packaging, labeling, and handling procedures to ensure safe transport of the chemical across borders.

As sustainability becomes a key focus in modern manufacturing, regulatory bodies are increasingly emphasizing the importance of lifecycle assessments for chemicals like ethyl acetate. Manufacturers are expected to consider the environmental impact of their processes from raw material extraction to end-of-life disposal. This holistic approach has led to innovations in green chemistry, including the exploration of bio-based alternatives to traditional ethyl acetate production methods.

To stay competitive in the global market, manufacturers must remain vigilant of evolving regulatory landscapes across different regions. This often necessitates significant investments in compliance management systems and regular staff training to ensure adherence to the latest standards. By proactively addressing regulatory requirements, companies can not only avoid penalties but also position themselves as responsible stewards of environmental and public health.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting requirements, including the submission of pre-manufacture notices for new uses of the chemical. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for workers handling ethyl acetate in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on companies producing or importing ethyl acetate. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information. The Classification, Labeling, and Packaging (CLP) regulation further mandates specific hazard communication standards for ethyl acetate products.

In response to these regulatory challenges, modern manufacturing processes for ethyl acetate have adapted to incorporate more sustainable practices. This includes the development of closed-loop systems that minimize emissions and reduce waste. Many facilities have implemented advanced air pollution control technologies to comply with stringent volatile organic compound (VOC) emission limits.

The food and pharmaceutical industries face additional regulatory scrutiny when using ethyl acetate. In the United States, the Food and Drug Administration (FDA) regulates ethyl acetate as a food additive and solvent in drug manufacturing. Manufacturers must adhere to Good Manufacturing Practices (GMP) and ensure that residual levels in final products meet established safety standards.

Globally, the transportation of ethyl acetate is subject to international regulations such as the United Nations Recommendations on the Transport of Dangerous Goods. These guidelines dictate proper packaging, labeling, and handling procedures to ensure safe transport of the chemical across borders.

As sustainability becomes a key focus in modern manufacturing, regulatory bodies are increasingly emphasizing the importance of lifecycle assessments for chemicals like ethyl acetate. Manufacturers are expected to consider the environmental impact of their processes from raw material extraction to end-of-life disposal. This holistic approach has led to innovations in green chemistry, including the exploration of bio-based alternatives to traditional ethyl acetate production methods.

To stay competitive in the global market, manufacturers must remain vigilant of evolving regulatory landscapes across different regions. This often necessitates significant investments in compliance management systems and regular staff training to ensure adherence to the latest standards. By proactively addressing regulatory requirements, companies can not only avoid penalties but also position themselves as responsible stewards of environmental and public health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!